Automatic unstacking and conveying method and device for standard boxes

A conveying device, a standard technology, applied in the direction of unstacking of objects, conveyors, conveyor objects, etc., can solve the problem that the form of unstacking is difficult to meet the requirements, and achieve the effect of convenient unstacking, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

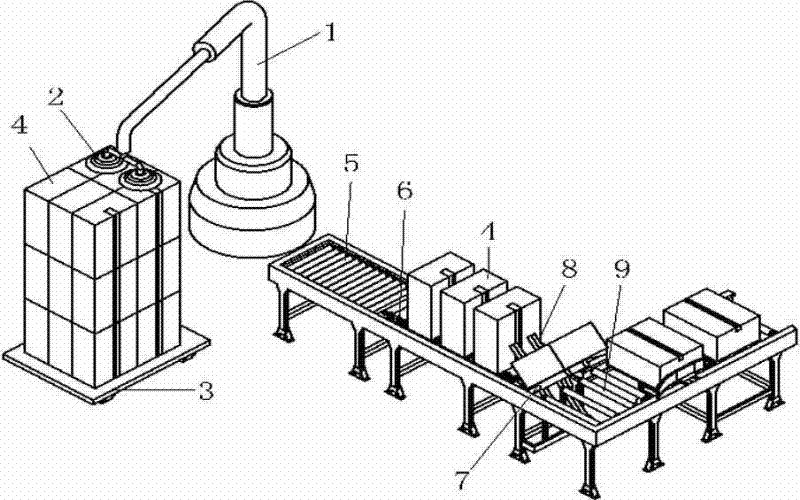

[0013] Example. figure 1 It is a structural representation of the present invention. When implementing the automatic depalletizing and conveying method of a standard box body of the present invention, it includes adopting the suction cup clamp 2 installed on the moving arm of the traditional mobile arm robot 1 to grab the palletized material in the palletized area according to the palletizing standard. The standard box 4 on the pallet 3; after the suction cup fixture 2 grasps 2 or more standard boxes 4 close together at a time, the robot 1 puts them in an upright manner on the roller conveying accumulation On the conveyor 5, the way of erecting is that for a standard box shaped as a cuboid, the plane with the smallest area is used as a conveying surface and placed upright on the accumulation conveyor; while for a standard box shaped like a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com