A wine bottle depalletizing device

A wine bottle and depalletizing technology, which is applied in the direction of object destacking, object stacking, transportation and packaging, can solve problems such as bottle damage and dangerous efficiency, improve safety, ensure accuracy, and shorten recycling. Use the effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

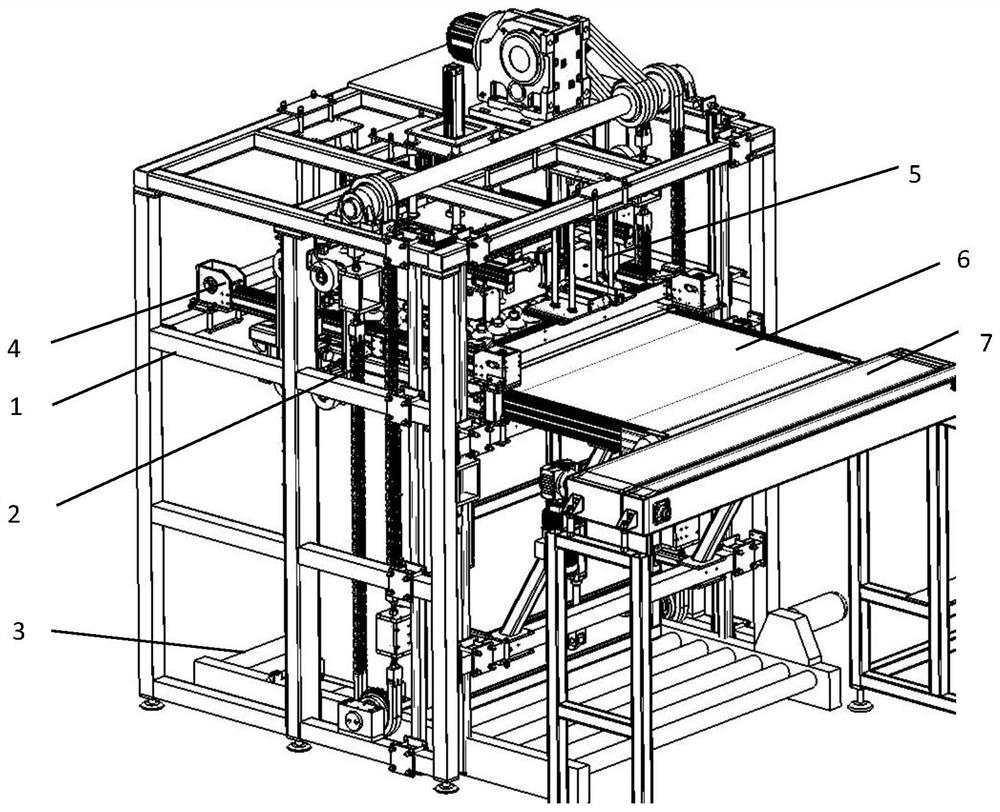

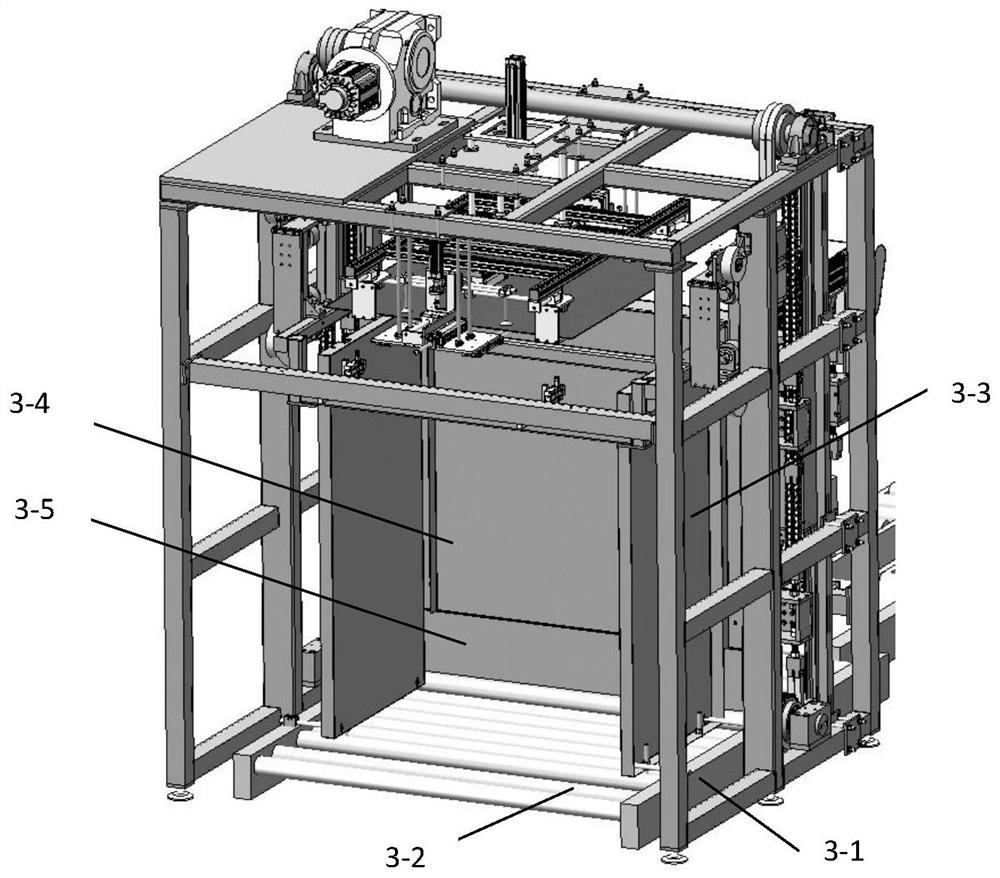

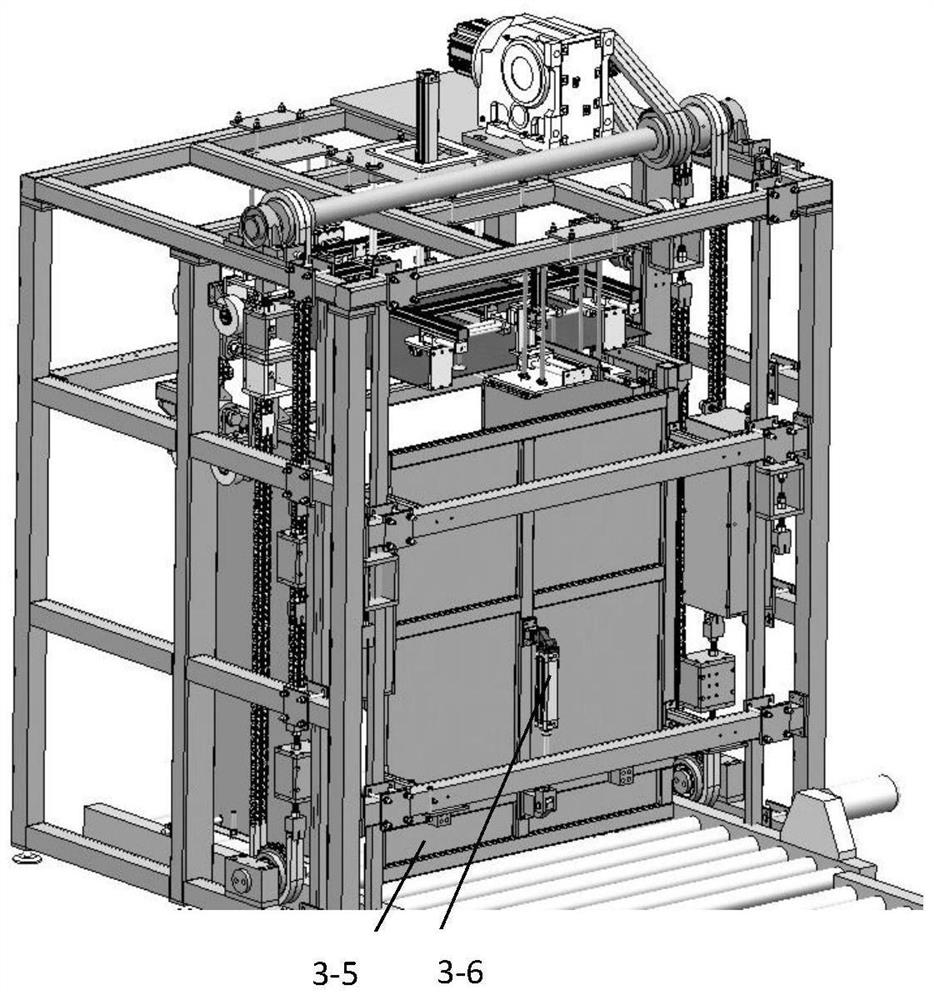

[0028] Such as figure 1 As shown, a wine bottle depalletizing device includes a main frame 1, a pallet lifting mechanism 2, a pallet incoming conveying line 3, a first pushing mechanism 4, a clapboard grabbing and placing mechanism 5, a transition conveying line 6 and a first single row Conveying line 7, the tray incoming material conveying line 3 is arranged on the lower inner side of the main frame 1, multi-layer wine bottles are arranged on the tray, each layer of wine bottles is separated by a partition, and the tray lifting mechanism 2 is arranged on the main frame 1 on both sides, the tray lifting mechanism 2 is used to drive the tray and the multi-layer wine bottles on it to rise, the first pushing mechanism 4 is arranged on the upper part of the main frame 1, and the transition conveying line 6 is arranged on the outer side of the upper part of the main frame 1 and is located at the first push On one side of the mechanism 4, the first pushing mechanism 4 is used to pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com