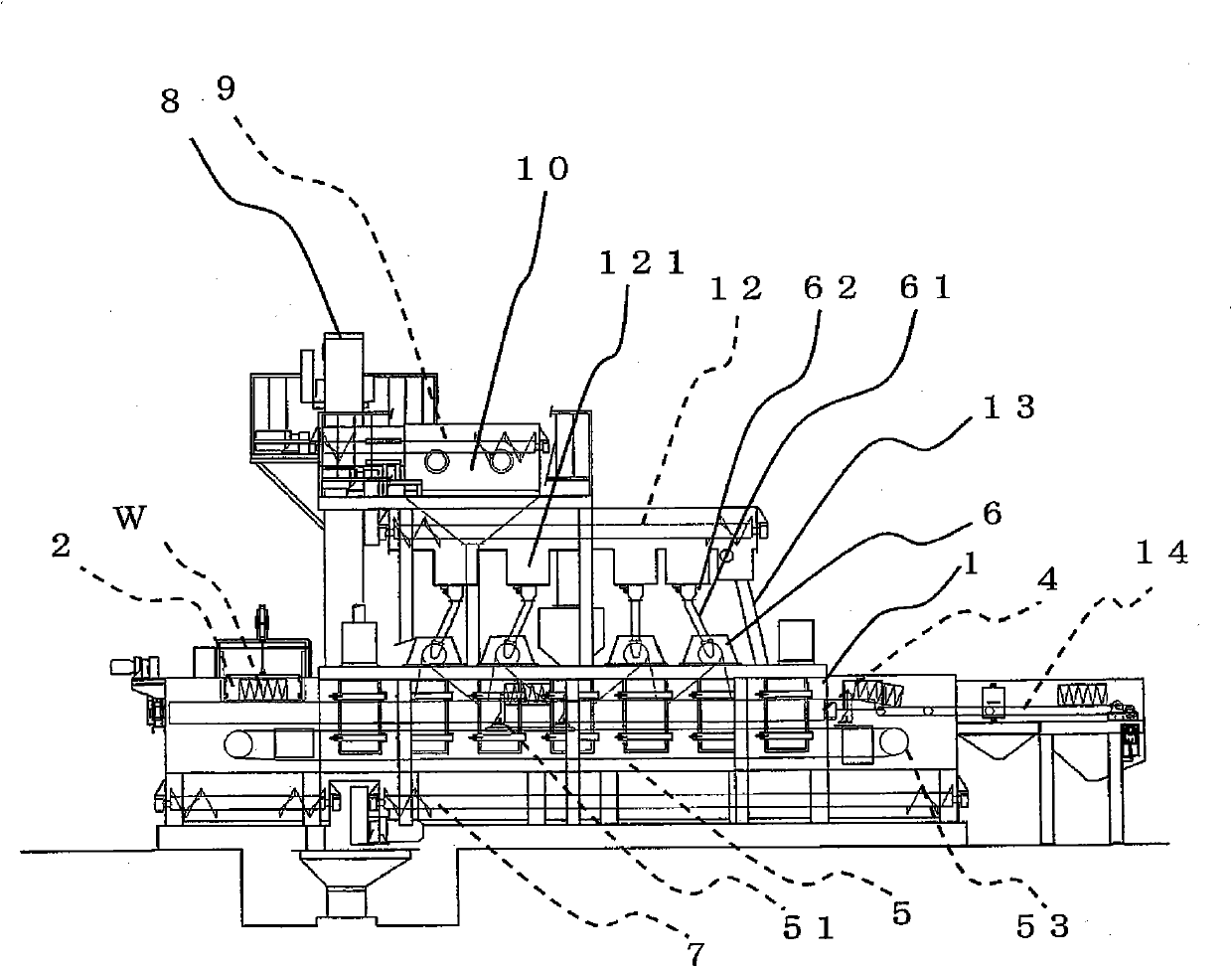

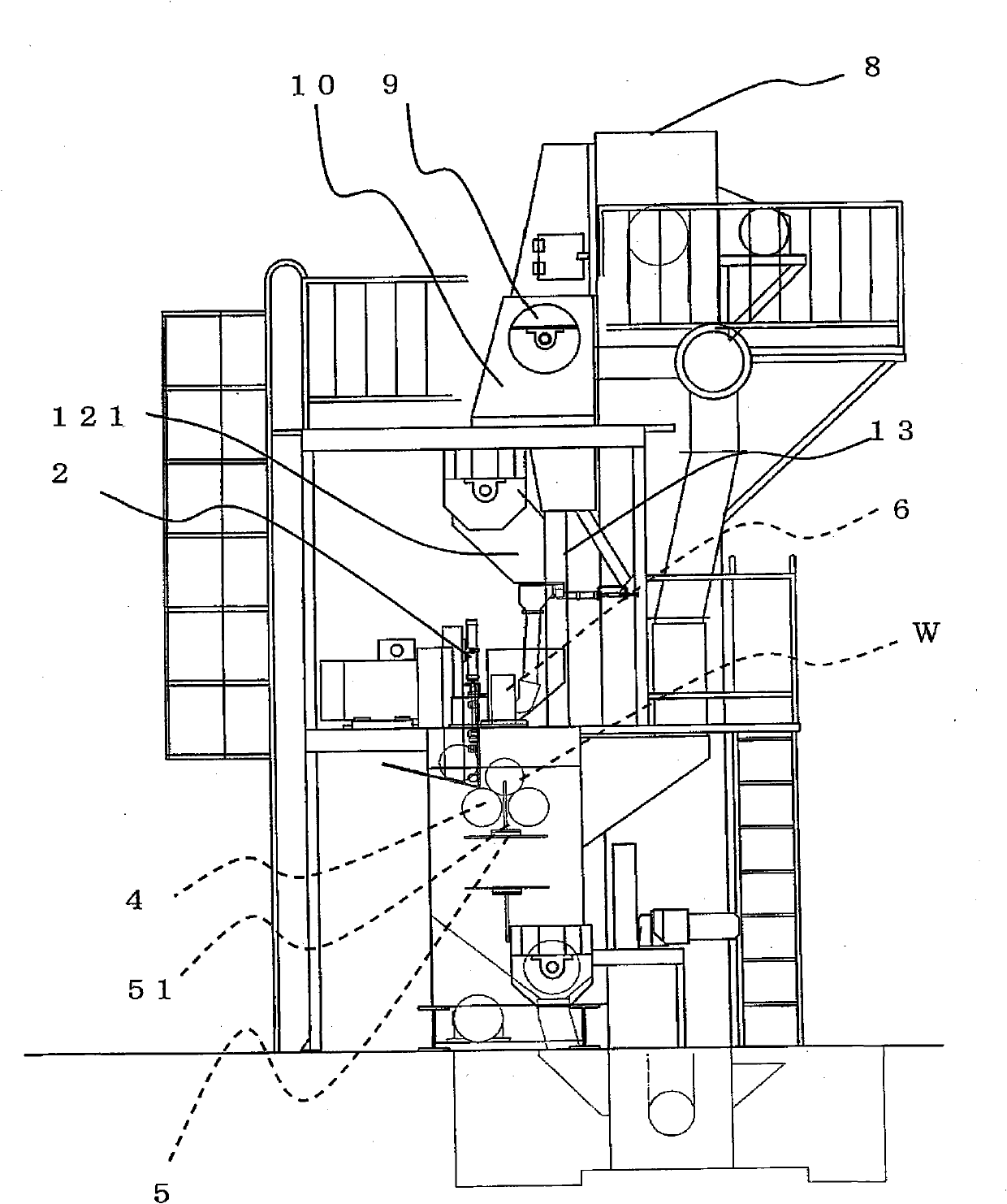

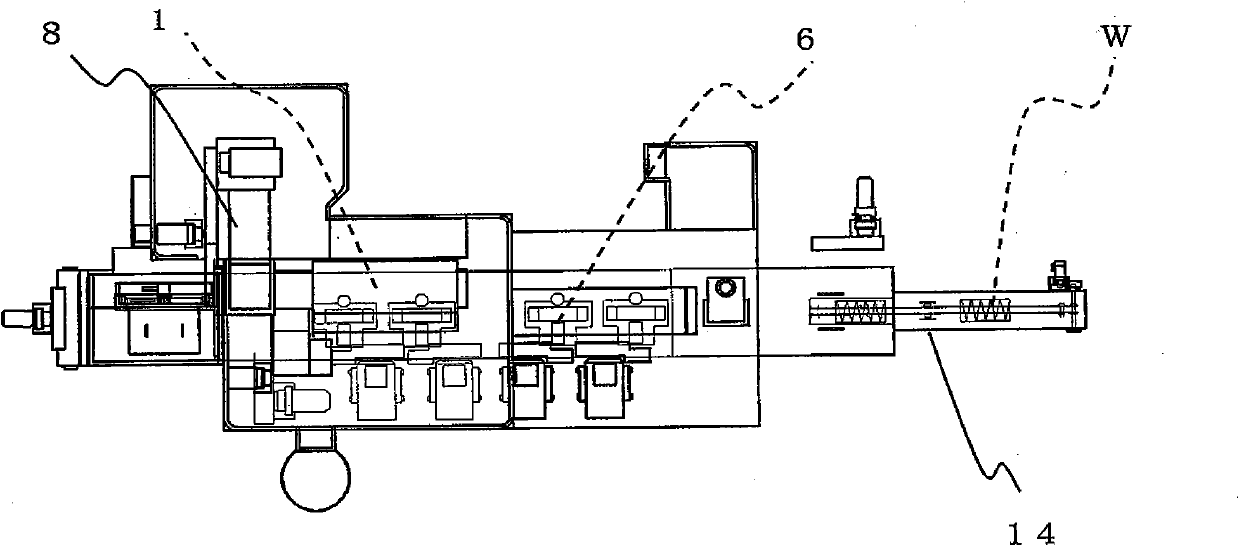

Continuous conveyor type peen vulcanizing device and method

A technology of shot peening and chain conveyors, which is applied in the direction of abrasive jetting machine tools, metal processing equipment, manufacturing tools, etc., and can solve problems such as inability to fix the conveying posture, increase in equipment cost, and falling off of long rollers and conveyor belts for rotation , to achieve the effect of stable shot peening treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Four centrifugal projection devices 6 are used as projection materials 1.2mm spherical steel wire cut shot, with a projection speed of 70m / s, each projecting 200kg / min. The conveying speed of the chain conveyor 5 was set to 3 m / min, and the conveying speed was set to 7.5 m / min using a conveyor belt for the carry-out conveyor 14 .

[0062] As a result, it was possible to obtain a shot peening effect equivalent to an average of 0.6 mm in the case of using the arc height value indicating the treatment intensity when the A steel strip was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com