Conveyor-type automatic oil mist coating machine

An automatic spraying and conveying technology, applied in the direction of coating, spraying device, device for coating liquid on the surface, etc., can solve the problem of easily polluted production sites and handling machinery, large-scale production of large operating space, and increased oil consumption and other issues to achieve the effect of meeting the requirements of low-carbon economy, not polluting the working environment, and low fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

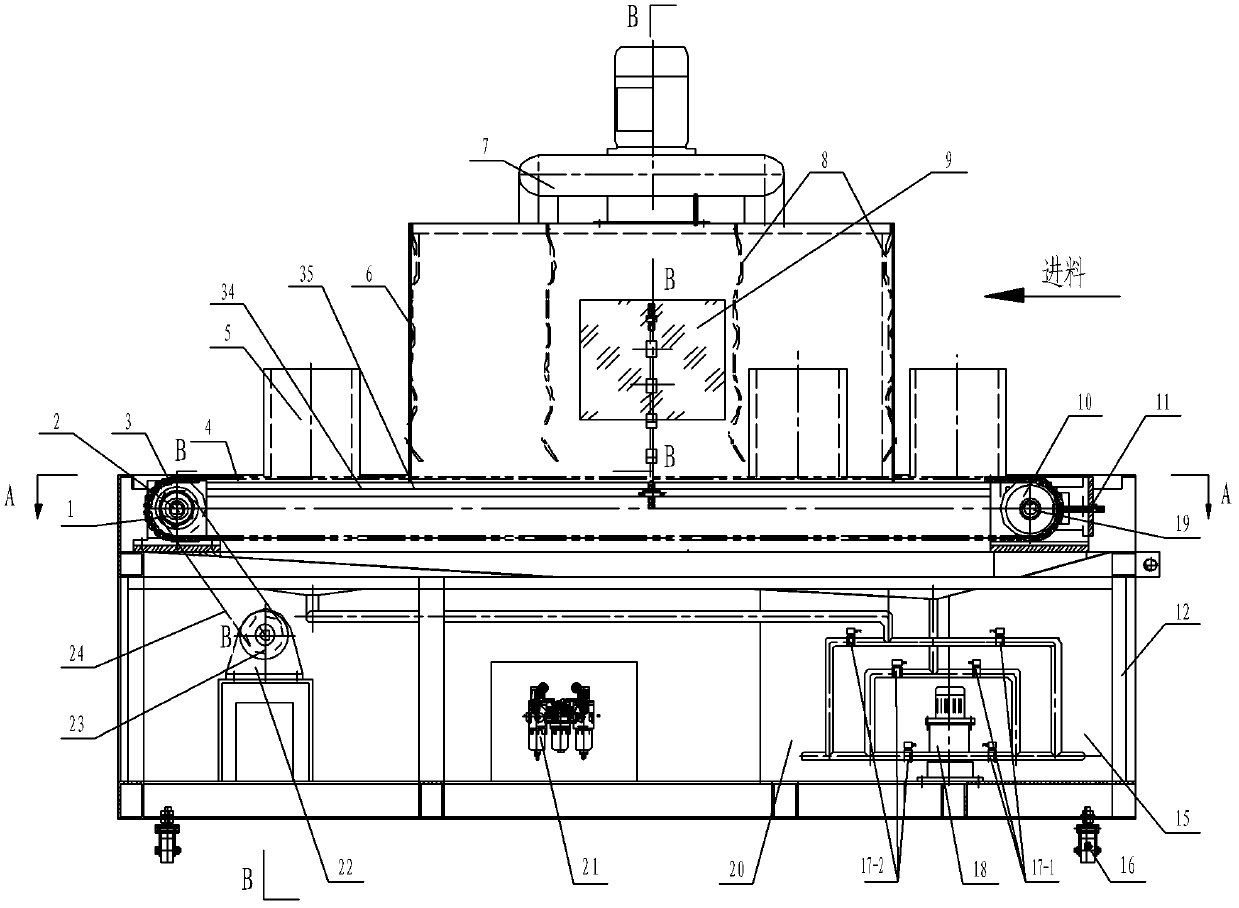

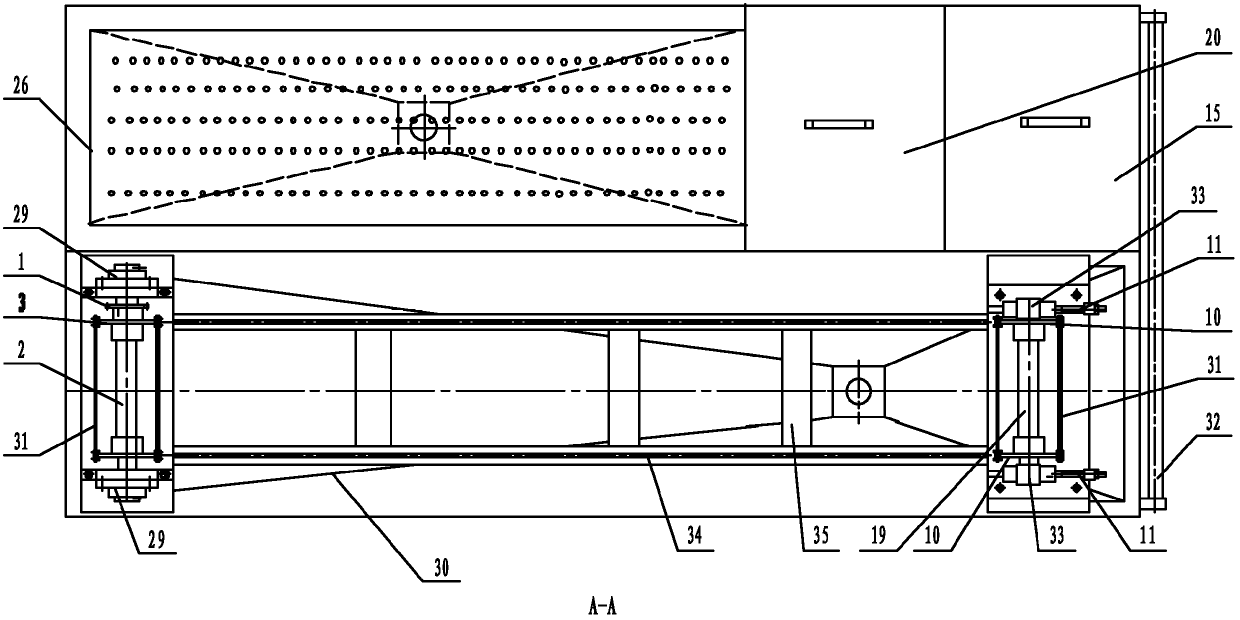

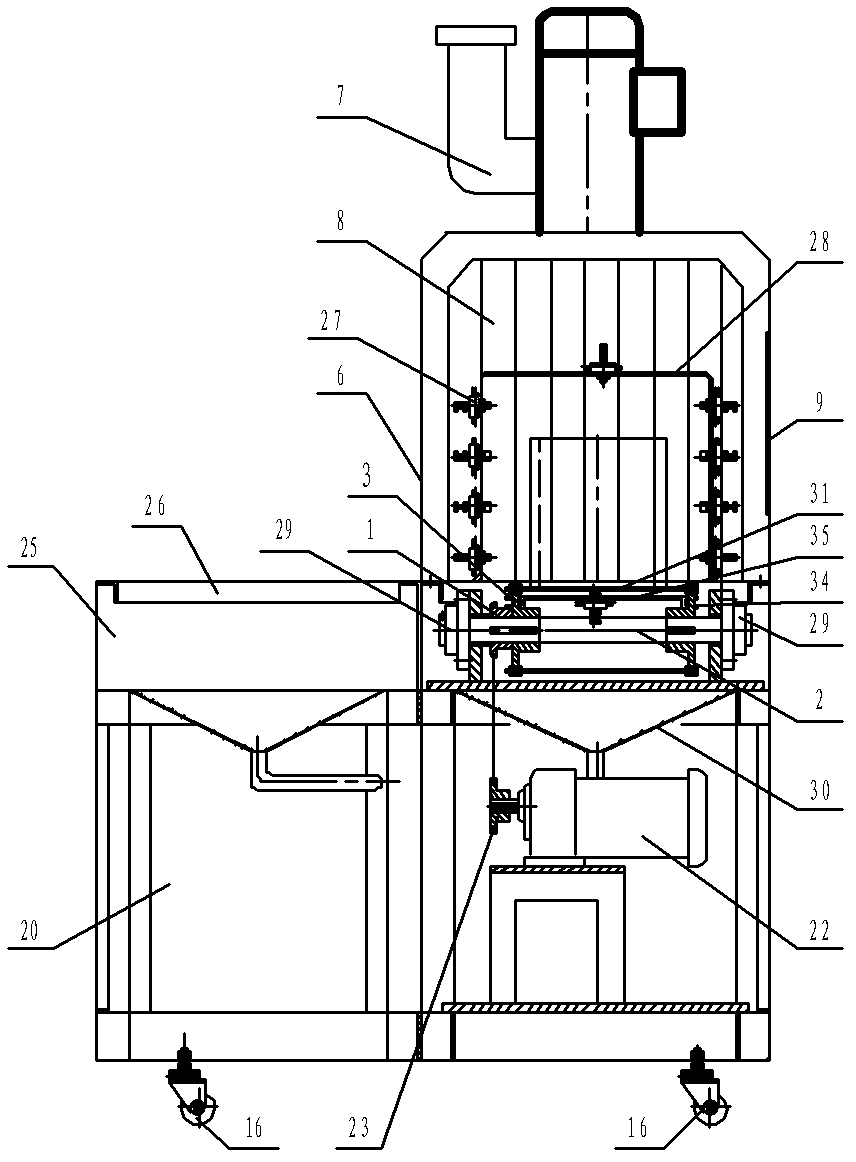

[0021] like Figure 1-3 As shown, the machine includes electrical control system, air source supply device, frame 12, air source treatment part 21, oil mist collector 7, atomizing oil nozzle 27, oil pump 18, oil tank, solenoid valve, chain transmission device and chain Conveyor device; chain transmission device comprises sprocket reducer 22, driving sprocket 23, driven sprocket 1, chain 24, sprocket shaft 2, bearing seat 29 which are arranged on frame 12; driving sprocket 23 is arranged on sprocket On the power output shaft of the speed reducer 22, the driven sprocket 1 is arranged on the power transmission shaft including the sprocket shaft 2 and the bearing seat 29, and the chain 24 is arranged on the driving sprocket 23 and the driven sprocket 1; the chain conveying device includes A pair of conveying sprockets 3, a pair of driven conveying sprockets 10 and a pair of conveying chains 4 arranged on the frame, a pair of conveying sprockets 3 and driven sprockets 1 are arrange...

Embodiment 2

[0028]In this embodiment, one fuel tank in the above-mentioned first embodiment is divided into two independent fuel tanks, and the rest of the structure is the same as that of the first embodiment; Oil, use different types of oil according to different workpieces; in order to make the oil of the same specification recycled to the oil tank of the same specification after use, a three-way pipe is provided on the oil inlet of the oil pump 18, and the set three-way pipe is connected with the oil tank. A solenoid valve 1 17-1 is provided on the pipeline connected with the first 15, and a solenoid valve 17-2 is provided on the pipeline connected with the oil tank 2 20; the oil collection tank 1 25, the oil collection tank 2 30 and the oil mist collector 7 The oil discharge pipes are all provided with three-way pipes, and each of the three-way pipes is respectively provided with a solenoid valve one 17-1 on the pipeline communicated with the fuel tank one 15, and is respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com