Electric fan and electric dust collector using said fan

A technology of electric fans and motors, which is applied in the fields of vacuum cleaners, engine manufacturing, machines/engines, etc., and can solve the problem that the specific area and shape of the first type of exhaust port are not described in detail relative to the relationship between the air guide components 5

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

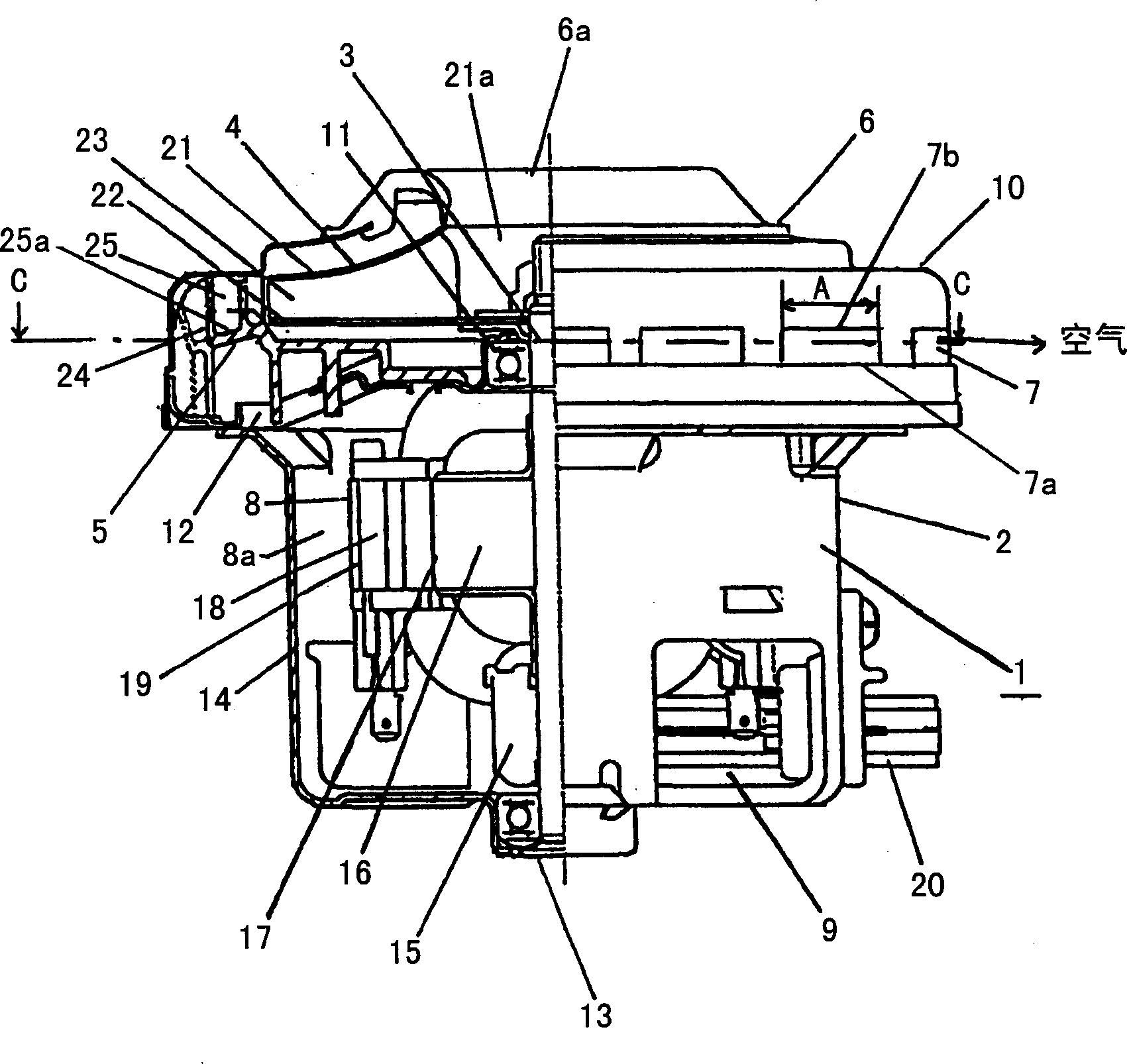

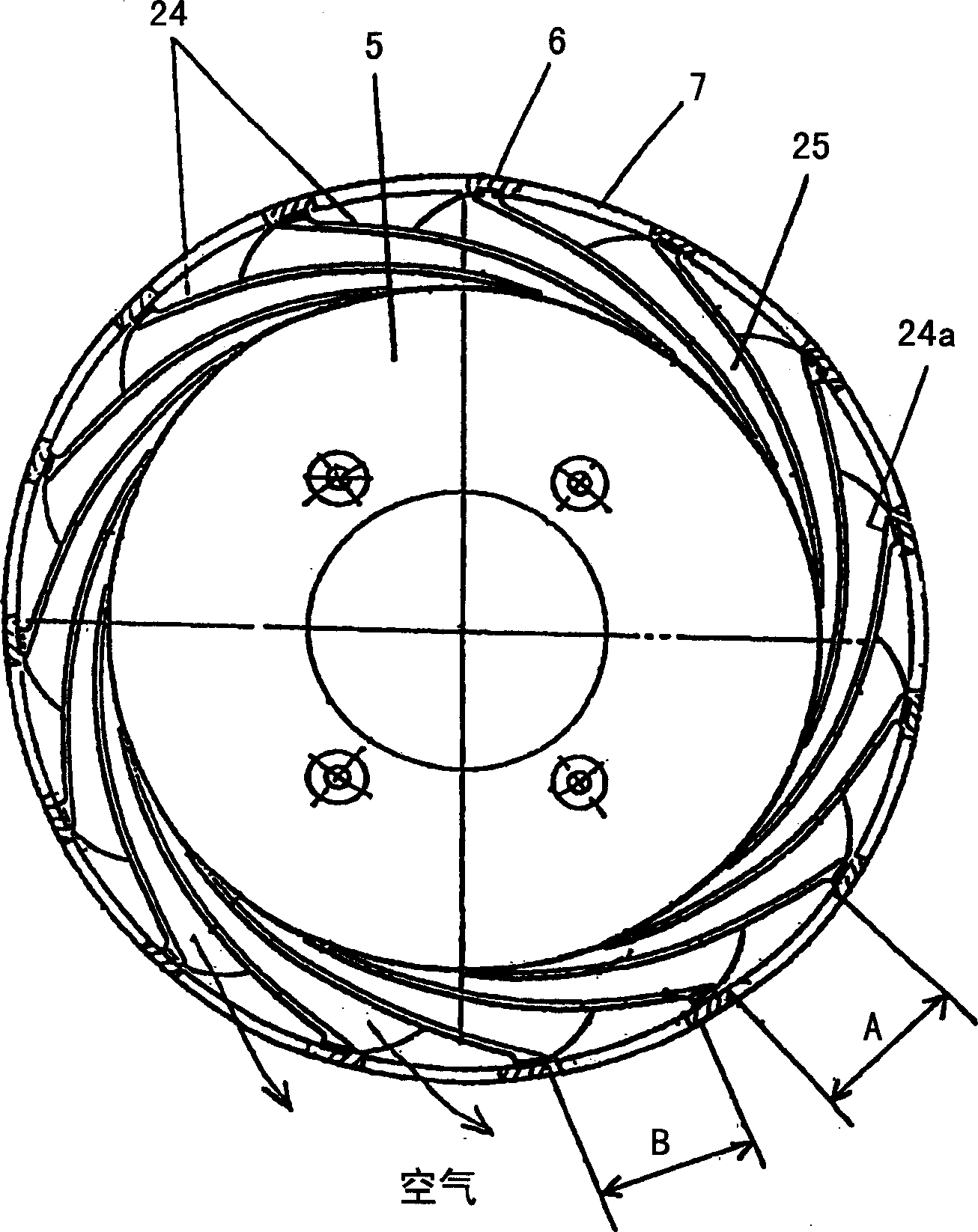

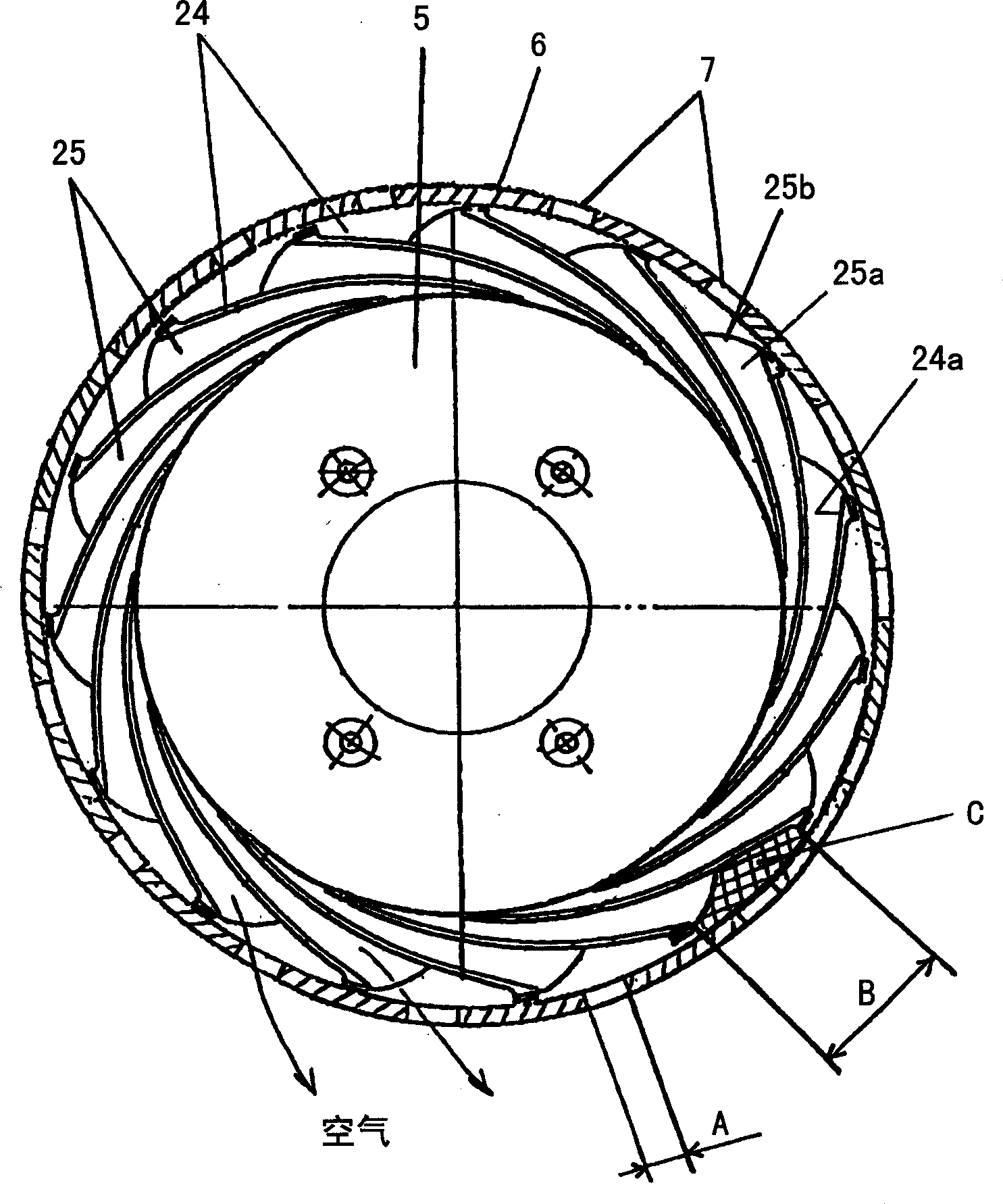

[0026] With the help of figure 1 and figure 2 The first embodiment of the present invention will be described. In the following description, the same parts as those in the conventional device are assigned the same reference symbols and their descriptions are omitted.

[0027] The electric blower 1 is composed of a motor assembly 2 and a fan assembly 10 . The casing of the motor assembly 2 is composed of a first frame 12 supporting the bearing 11 on the load side and a second frame 14 supporting the bearing 13 on the opposite side to the load, and the motor 8 is arranged inside the second frame 14 .

[0028] The motor 8 is composed of a rotor 17 and a stator 19 . The rotor 17 is formed by pressing the armature core 16 formed by laminating the commutator 15 and silicon steel sheets on the rotating shaft 3, fixing it, and then installing a coil (not shown in the figure). The stator 19 is formed by installing coils (not shown in the figure) on the excitation core 18 formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com