Electric blower

An electric blower and fan technology, which is applied to machines/engines, liquid fuel engines, mechanical equipment, etc., can solve problems such as the decrease in blowing efficiency and the inability to fully ensure the airtightness of the fan casing and the fan casing spacer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

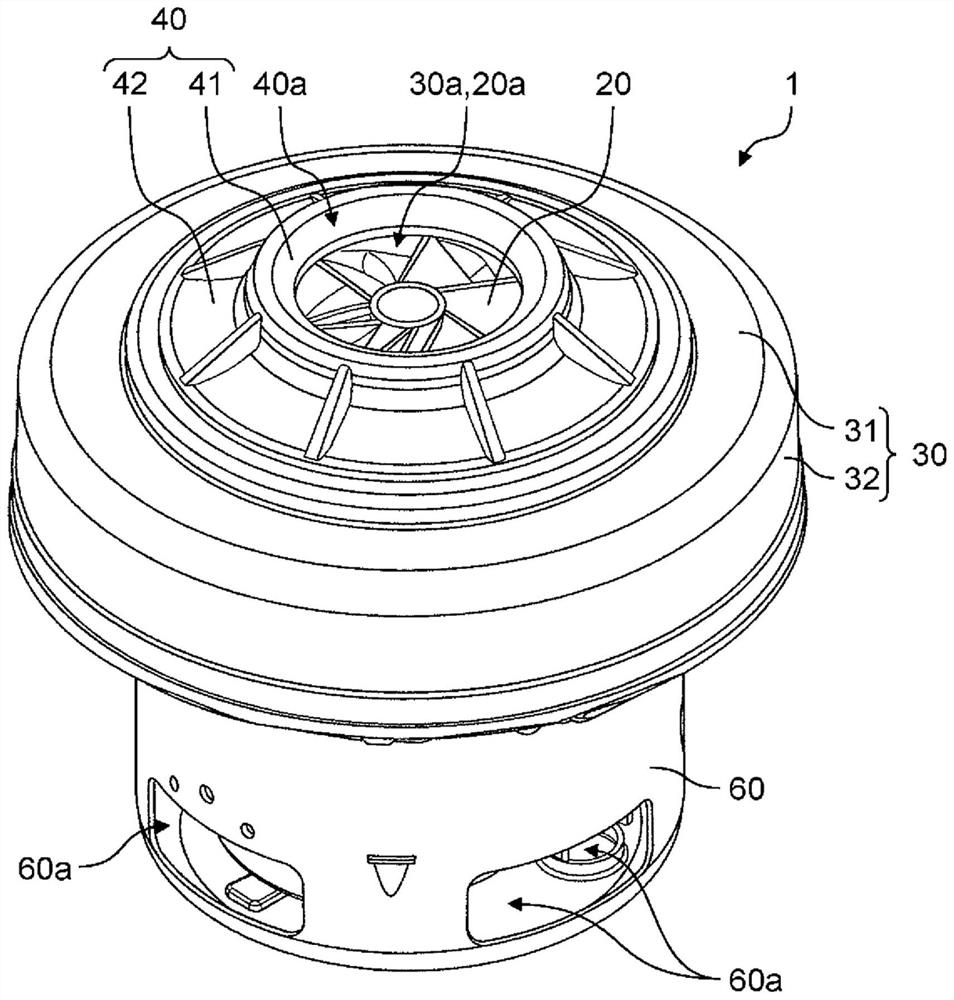

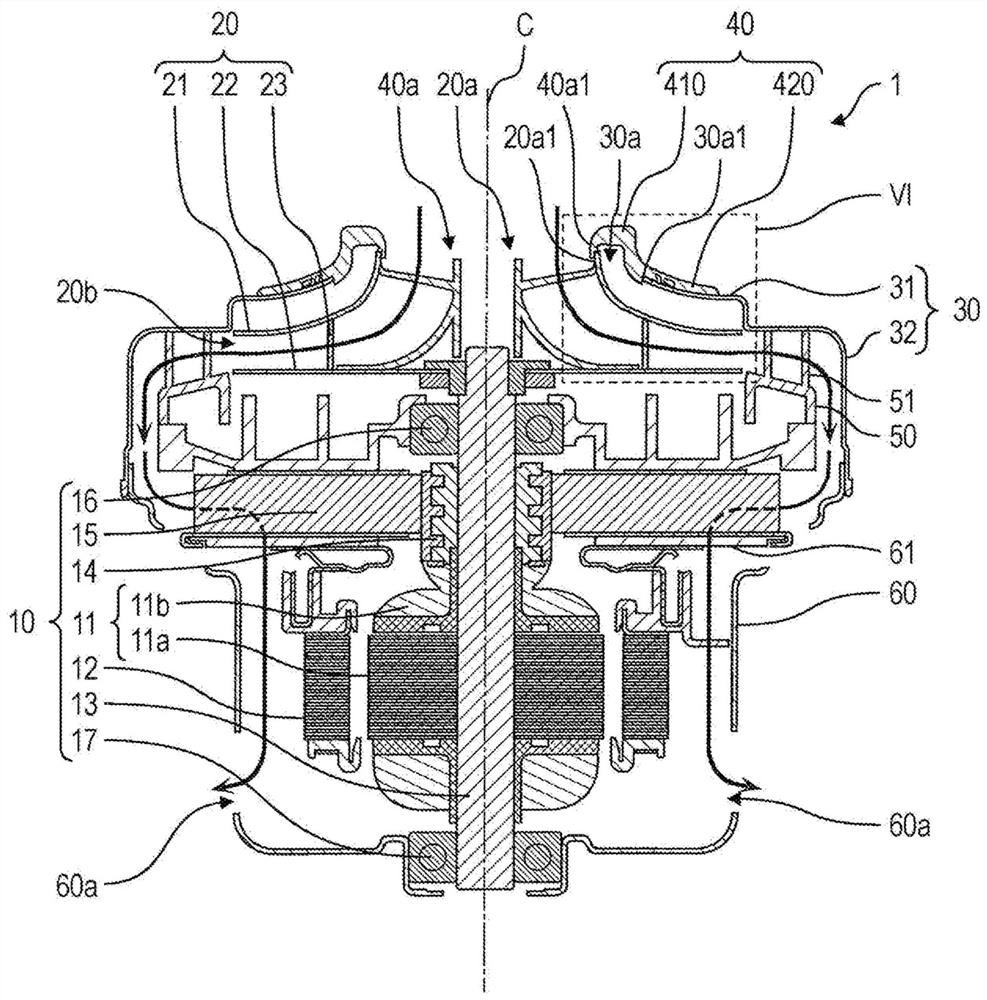

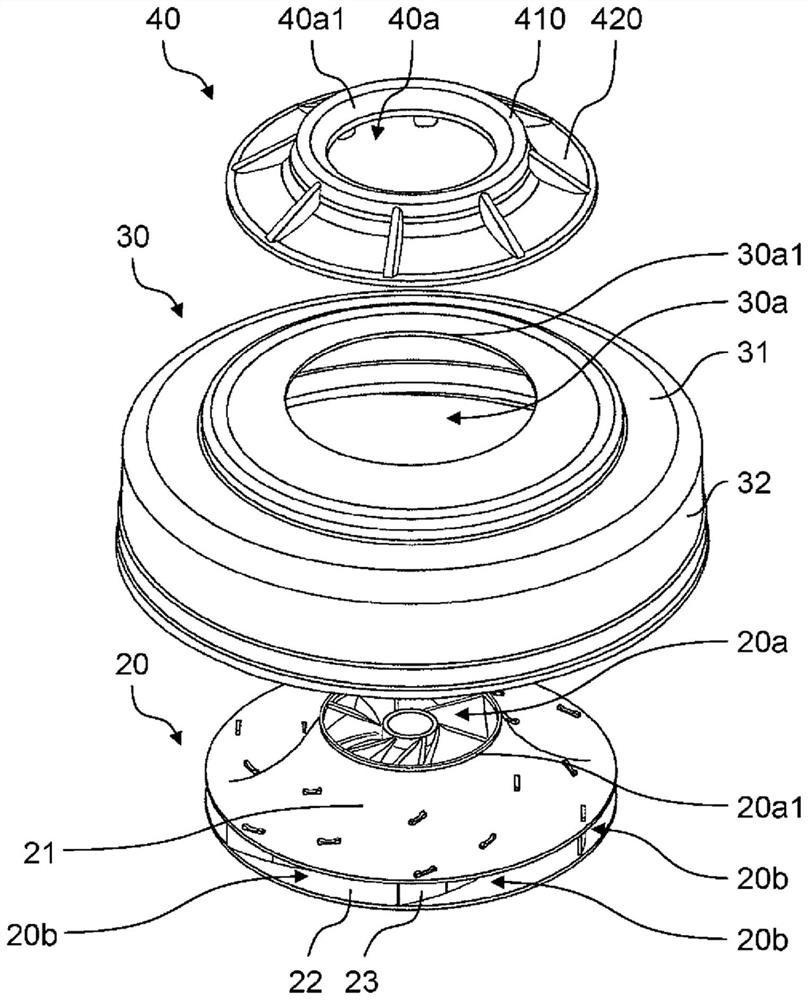

[0023] First, use figure 1 and figure 2 , and the overall structure of the electric fan 1 according to the embodiment will be described. figure 1 It is an external perspective view of the electric blower 1 of embodiment. figure 2 It is a cross-sectional view of electric blower 1 according to the embodiment. figure 2 A cross section of the electric fan 1 taken along a plane passing through the axis C of the rotating shaft 13 is shown. In addition, in figure 2 In , only the line graphs that appear in the section are shown. figure 2 The shown bold arrows indicate the flow of air sucked into the electric blower 1 .

[0024] In the description below, for convenience, the direction in which the axis C extends is referred to as the vertical direction. Specifically, in figure 2 In the direction in which the axis C extends, the output shaft side where the centrifugal fan 20 is located is set to the upper side with respect to the rotor 11, and the output shaft where the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com