Efficient energy-saving centrifugal blower

An energy-saving, centrifugal technology, used in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve problems such as high failure rate, reduced useful power of blowers, complex impeller structure, etc., to achieve stable gas flow rate and pressure. , The use of safe and reliable, improve the effect of blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

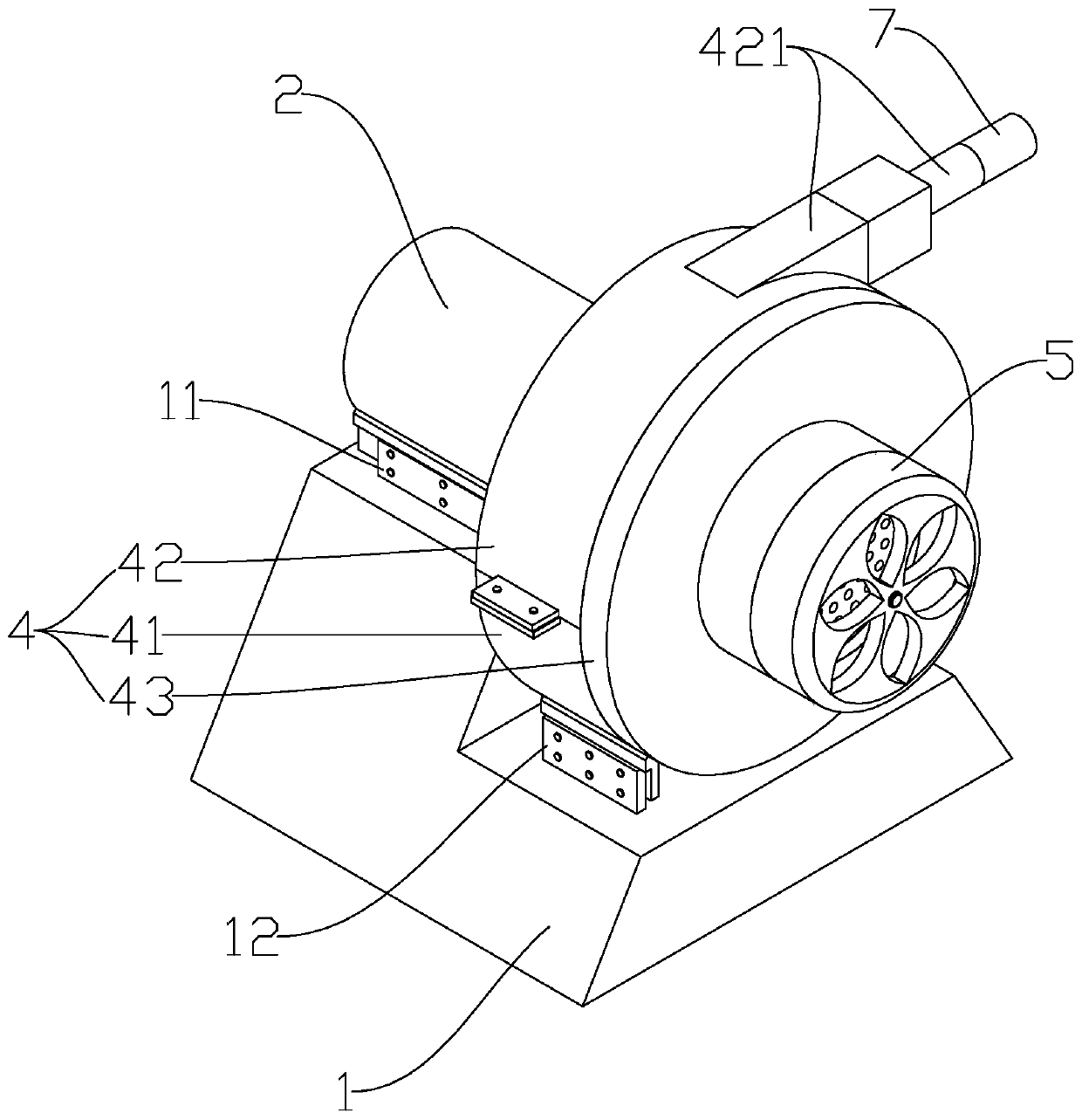

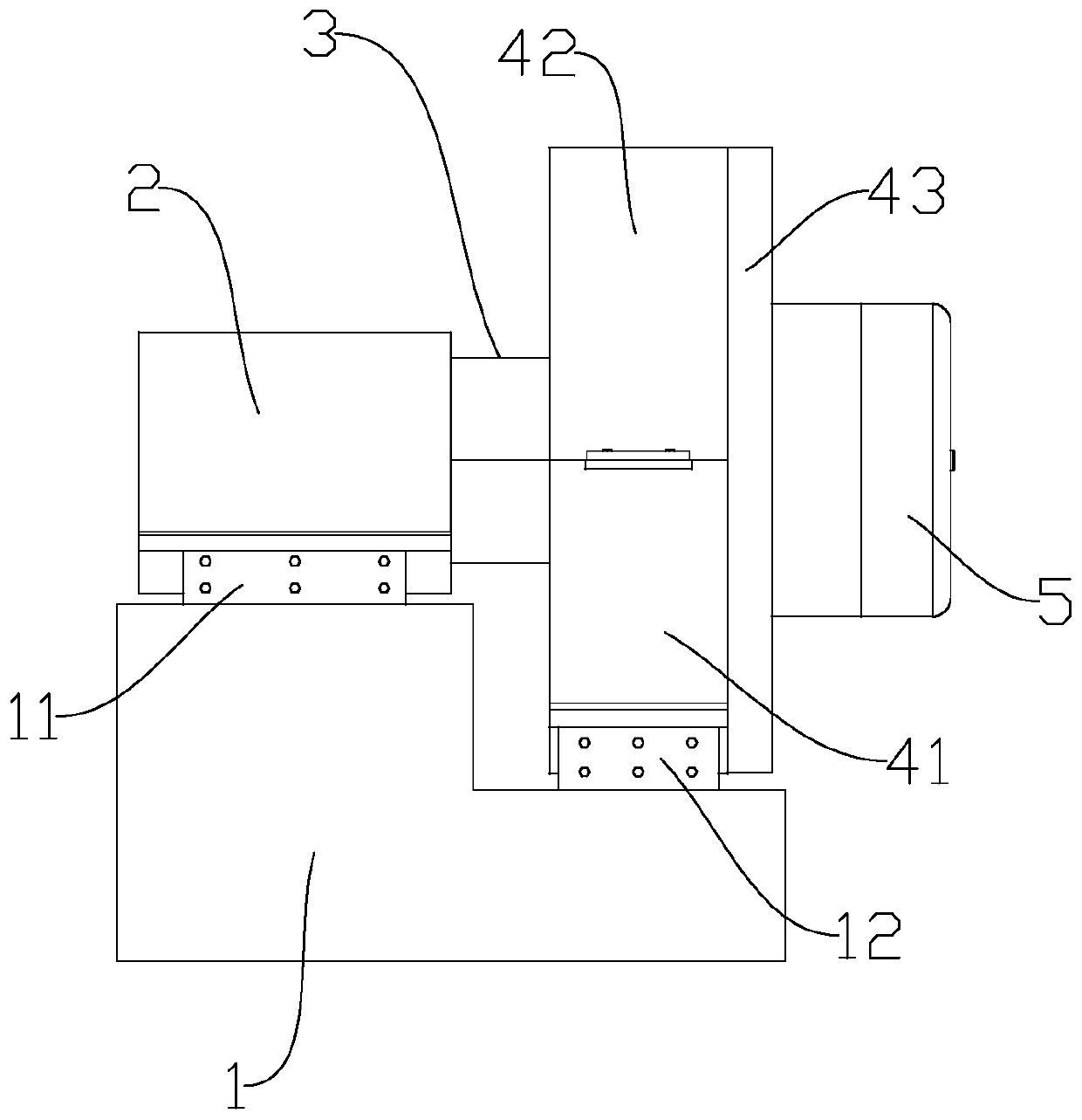

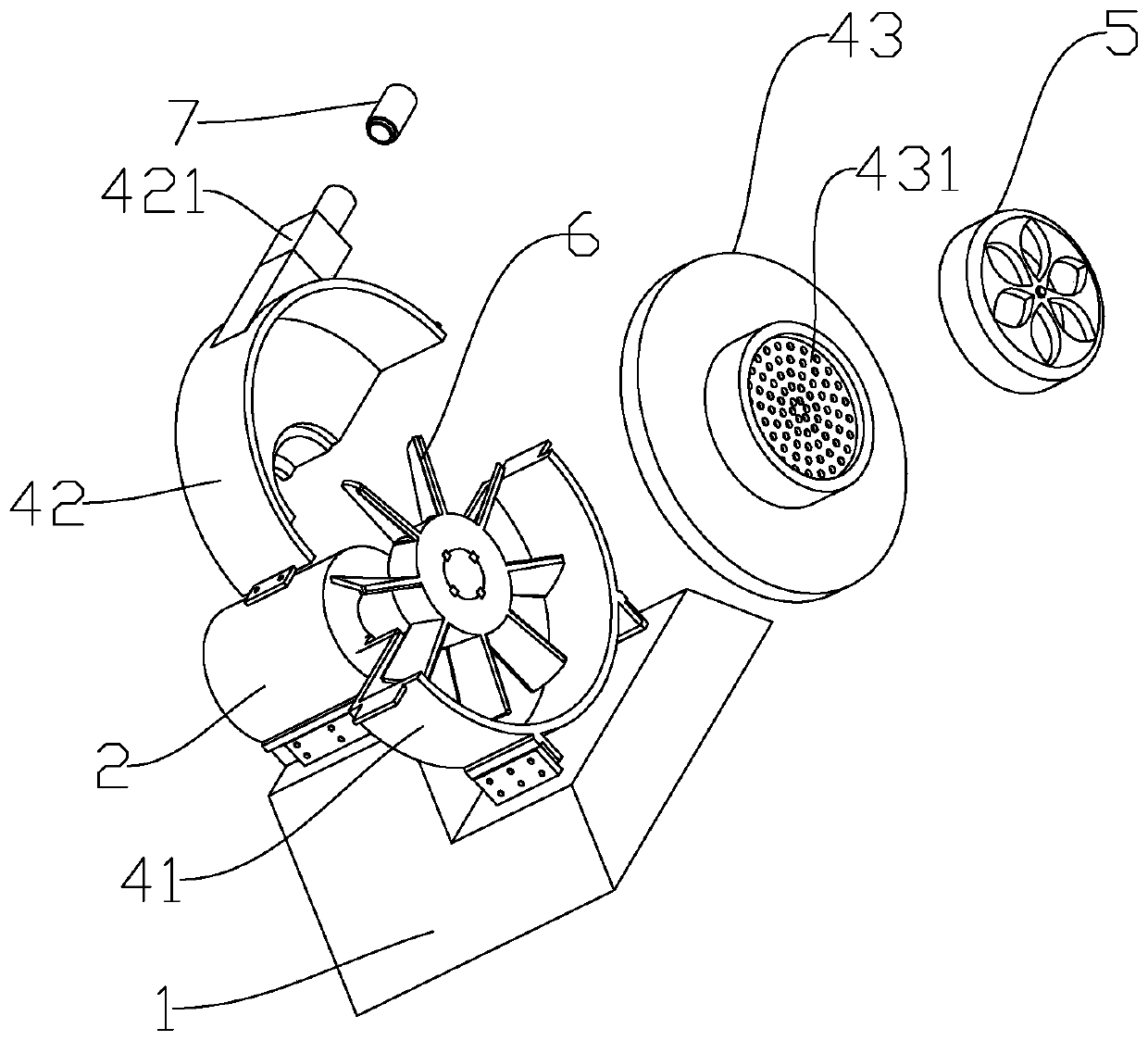

[0041] Such as Figures 1 to 5 As shown, a high-efficiency and energy-saving centrifugal blower includes a base 1, on which a motor 2 is arranged; connected; the casing 4 includes a lower casing 41, an upper casing 42 and a side cover 43; after the lower casing 41 is connected with the upper casing 42, the side cover 43 is detachably and fixedly connected to the lower casing On the side of the casing 41 and the upper casing 42 away from the side of the motor 2, the sealing sleeve 3 is detachably and fixedly connected to the side of the lower casing 41 and the upper casing 42 close to the side of the motor 2 Above; the impeller 6 includes a blade 61, the blade 61 is a curved surface, and its radius of curvature is 60-80; the blade 61 is also provided with a wind gathering frill 611 near the side cover 43; The distance between the wind frill 611 and the blade 61 is 8-15 mm, and the distance gradually decreases along the direction close to the center of the blade 61; the upper c...

Embodiment 2

[0043] Such as Figures 1 to 5 As shown, a high-efficiency energy-saving centrifugal blower, including

[0044] A machine base 1, the said machine base 1 is provided with a motor 2;

[0045] The output end of the motor 2 passes through the sealing sleeve 3 and is connected with the impeller 6 in the casing 4;

[0046] The casing 4 includes a lower casing 41, an upper casing 42 and a side cover 43; the lower casing 41 is connected to the upper casing 42 (welding, or other detachable fixed connection methods, such as screw connections; necessary At present, rubber gaskets are arranged on the contact surface of the lower casing 41 and the upper casing 42 to improve the sealing performance, and the same or similar methods can be used for other joints in the same way) After the sealing performance is improved, the side cover 43 is detachable and fixed Connected to the side of the lower casing 41 and the upper casing 42 away from the motor 2, the sealing sleeve 3 is detachably and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com