Blower

A blower and fan technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as increased air flow resistance, increased noise, and low blowing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

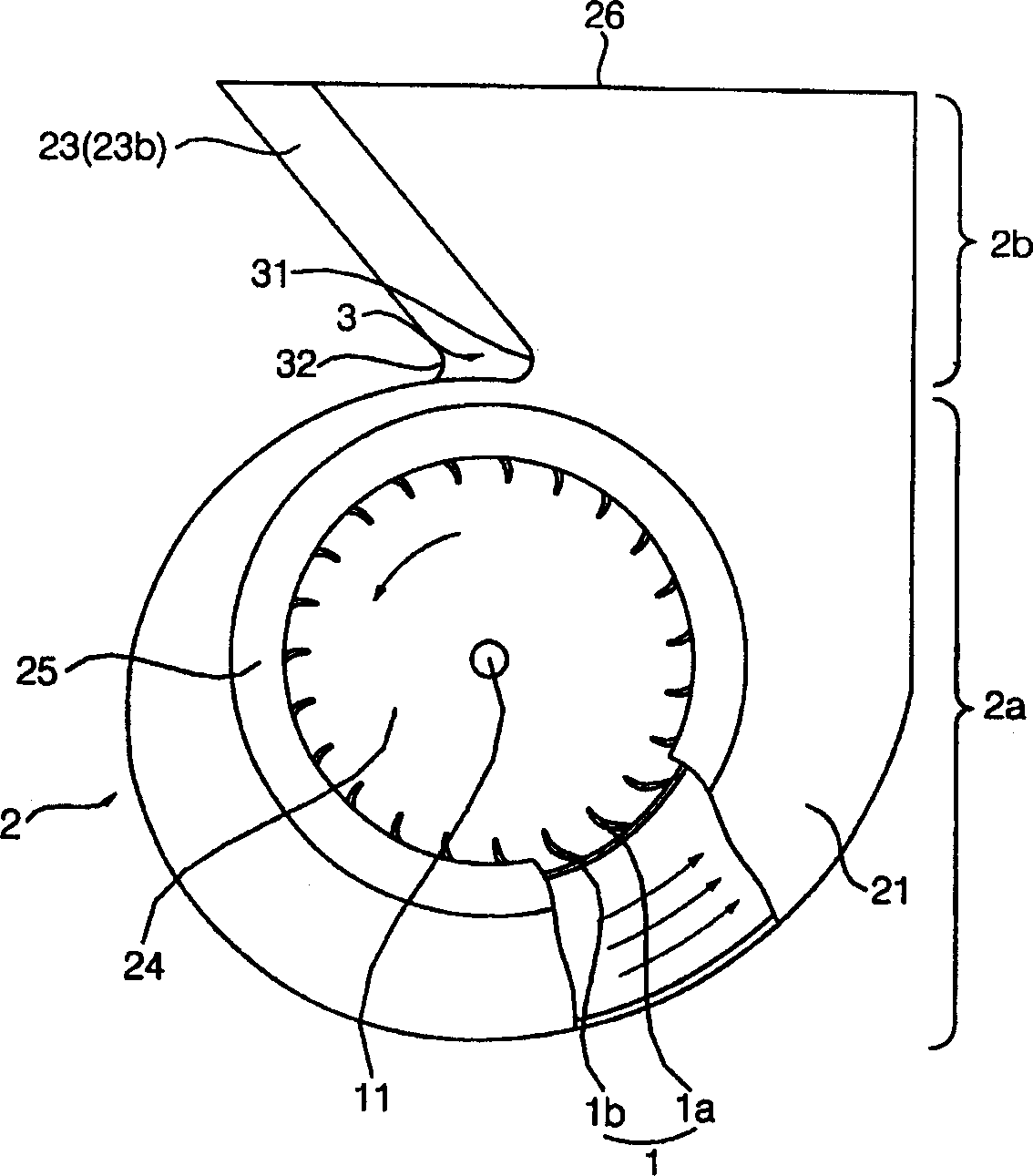

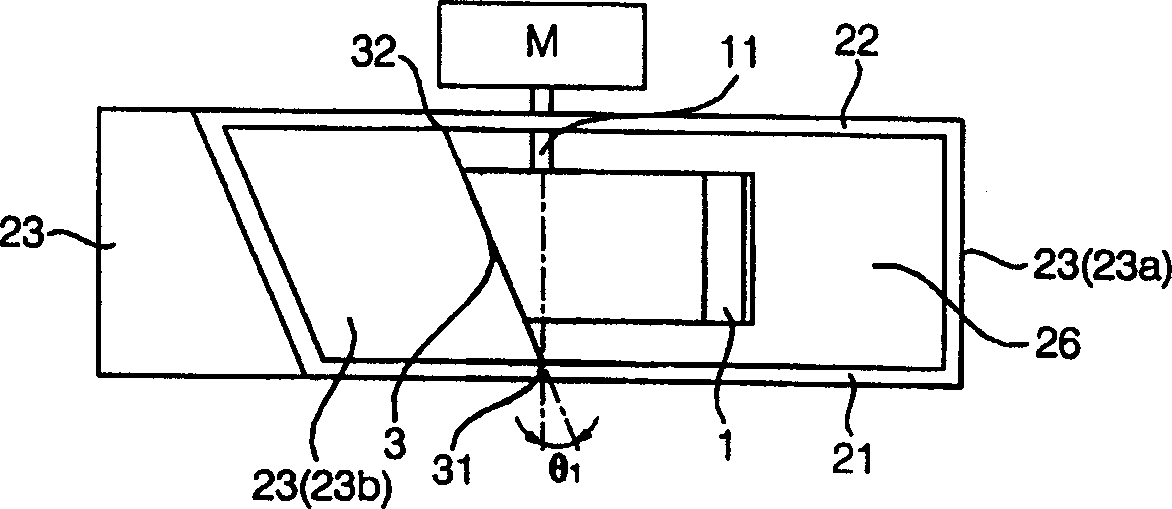

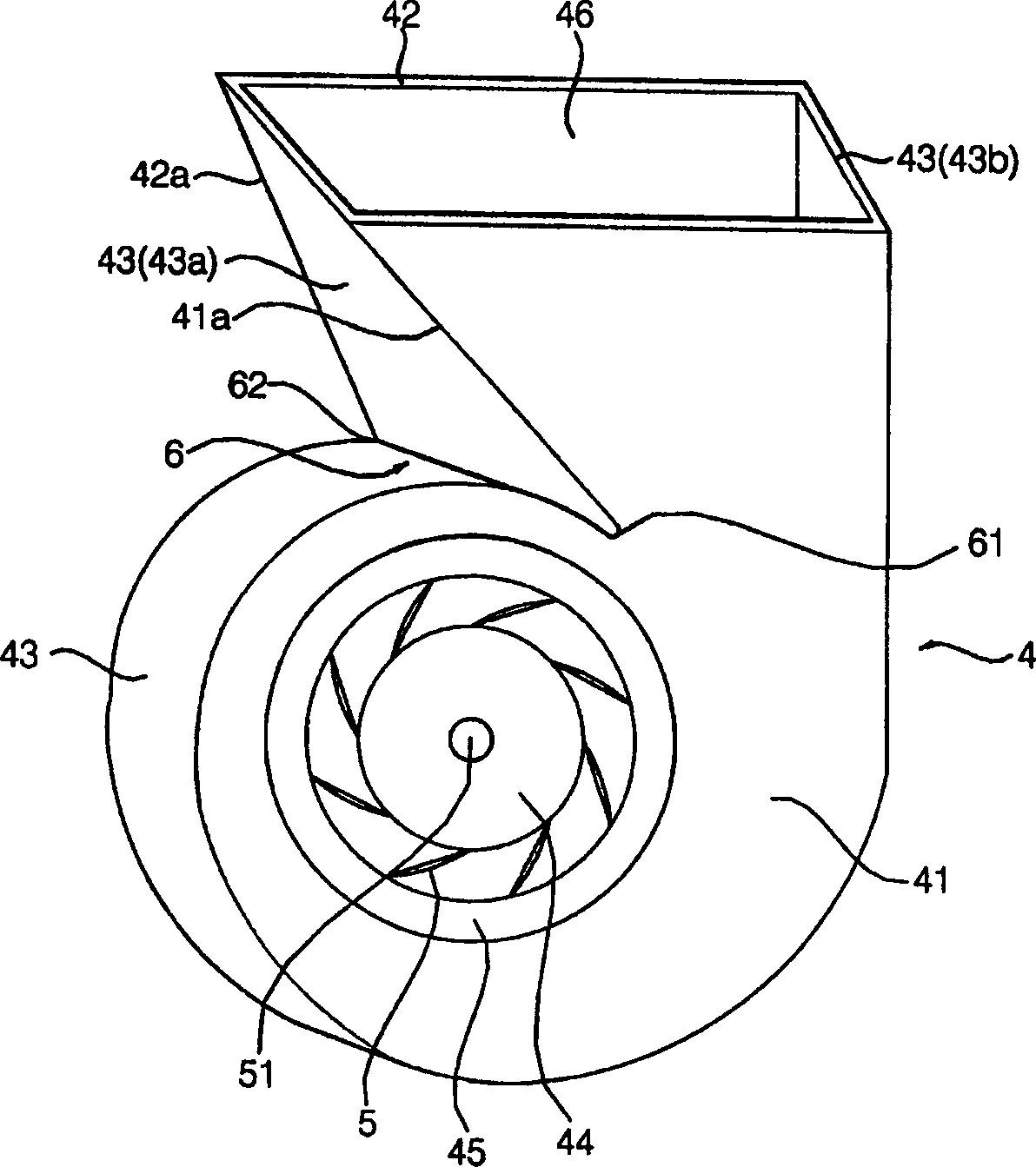

[0021] An embodiment of the blower according to the present invention will be described in detail below with reference to the accompanying drawings.

[0022] image 3 is a perspective view of a blower according to the invention, Figure 4 is a partially cut-away front view of a blower according to the invention, Figure 5 yes Figure 4 floor plan.

[0023] Such as Figures 3 to 5 As shown, the blower of the present invention is composed of a volute 4 and a turbofan 5 arranged in the volute.

[0024] Described volute 4 comprises: main body portion 4a, and it forms garden-shaped suction port 44, and forms bell mouth 45 at the outer peripheral edge of described suction port 44, and turbo fan 5 is arranged inside and guides the air sucked by described suction port 44 The direction of rotation of the turbofan 5; the funnel part 4b, which forms an exhaust port 46 at the end, extends from the main body part 4a to the exhaust port 46 side so that the discharge area gradually expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com