Device for discharging percolate generated by aerobic fermentation of solid organic waste

An organic waste, aerobic fermentation technology, applied in the field of environmental protection, can solve the problems of reducing the blasting efficiency of the fermentation process, water storage and odor, etc., and achieve the effects of avoiding the perishability of the water body, effective discharge, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

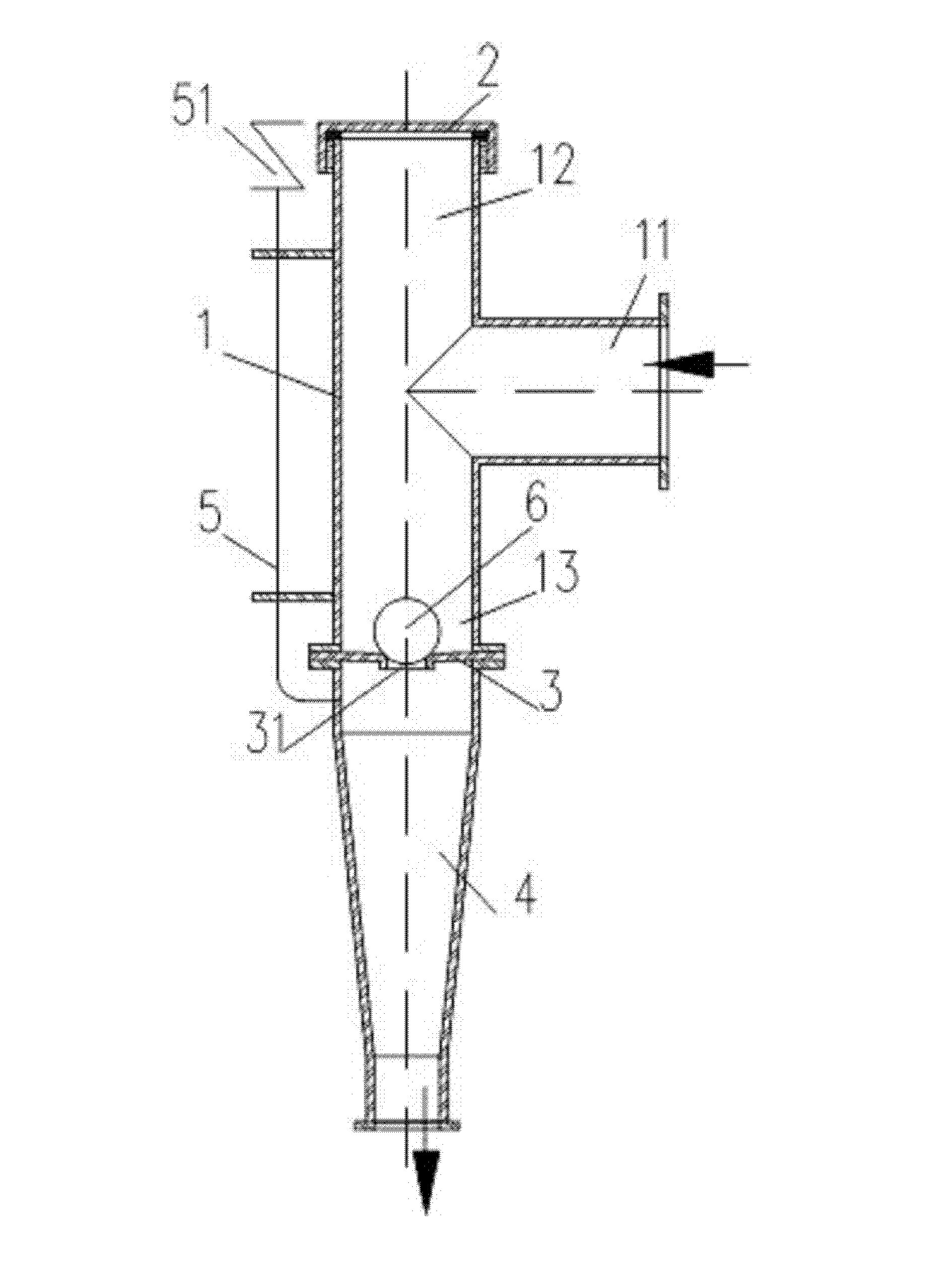

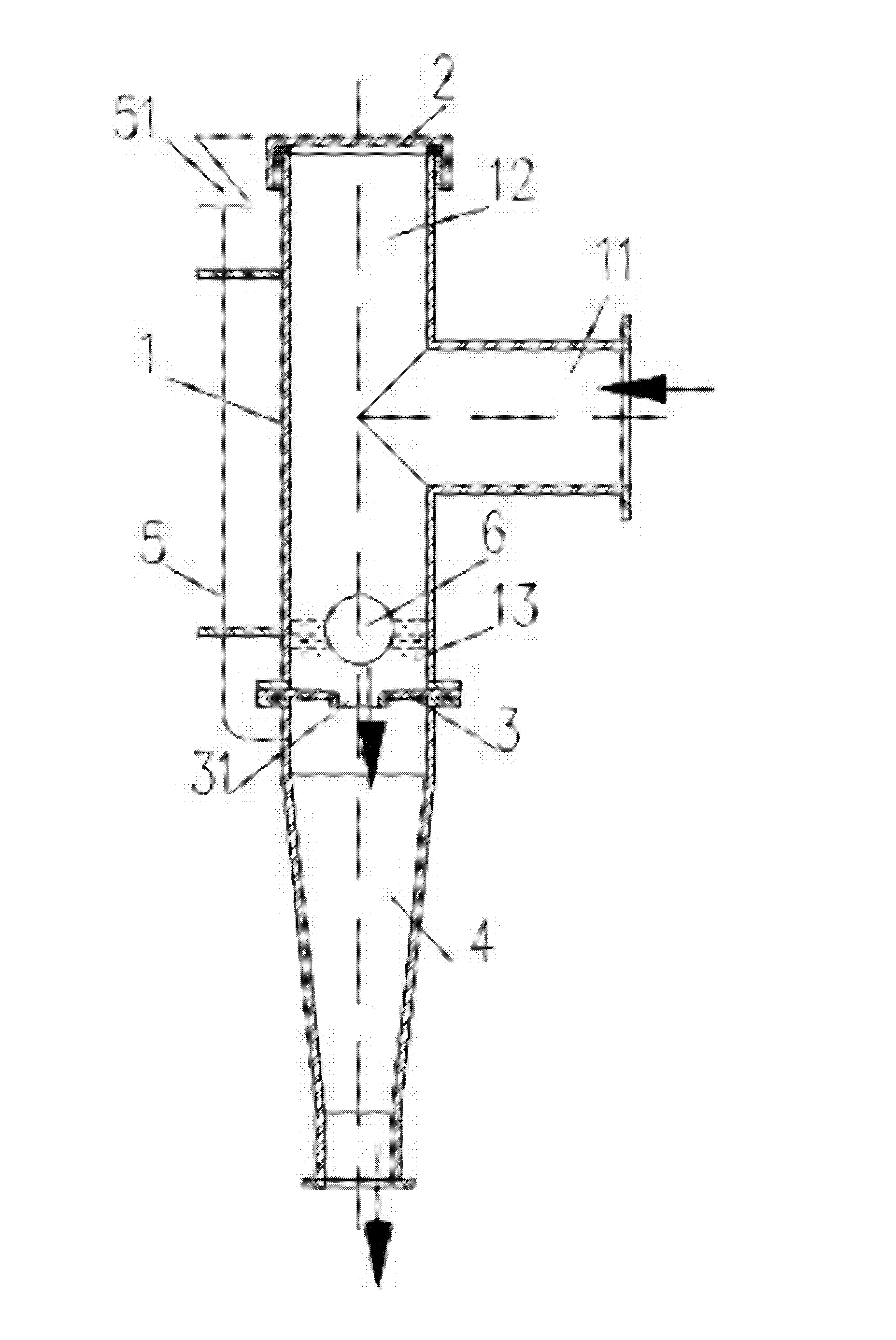

[0024] like figure 1 As shown, a specific embodiment of the leachate discharge device of aerobic fermentation of solid organic waste according to the present invention, the main body is a drainage tee 1, and the first end 11 of the drainage tee 1 is connected to the leachate discharge pipe from the pile. Drainage tee 1 can adopt PVC material or stainless steel material.

[0025] The second end 12 of the drain tee 1 is provided with a detachable flushing cap 2 . In this embodiment, the flushing cap 2 is fixedly connected to the second end 12 of the drain tee 1 through a threaded joint, and a rubber sealing ring can also be arranged therebetween.

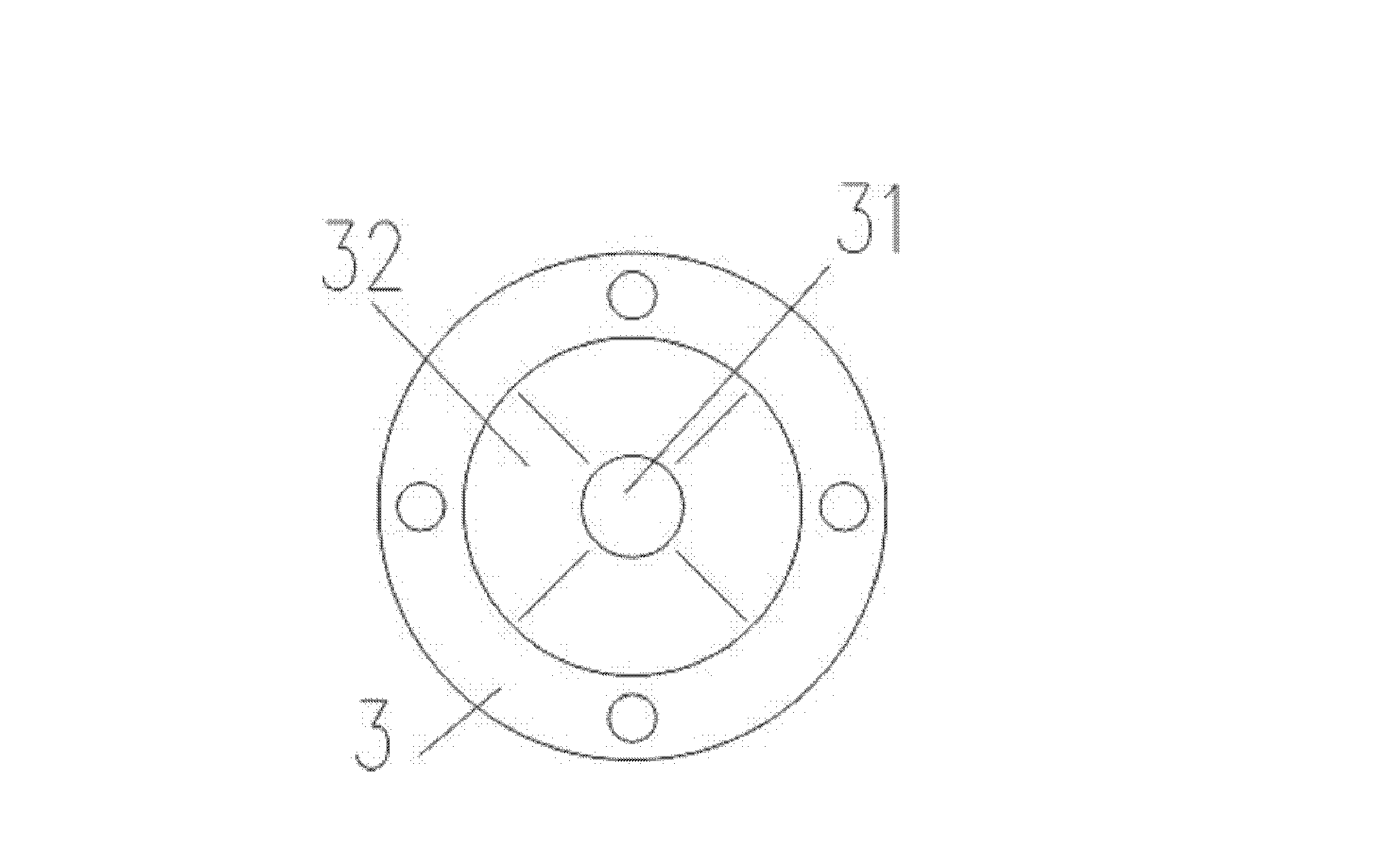

[0026] The third end 13 of the drainage tee 1 communicates with a different-diameter pipe 4 through a drainage plate 3, and the different-diameter pipe 4 is connected to the leachate main pipe. The different-diameter pipe 4 is also connected with a vent pipe 5 , and a check valve 51 is arranged on the vent pipe 5 .

[0027] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com