Heat dissipating system

A heat dissipation system and heat exchanger technology, applied in air cooling, engine components, machines/engines, etc., can solve problems such as poor heat dissipation effect and low fan blowing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

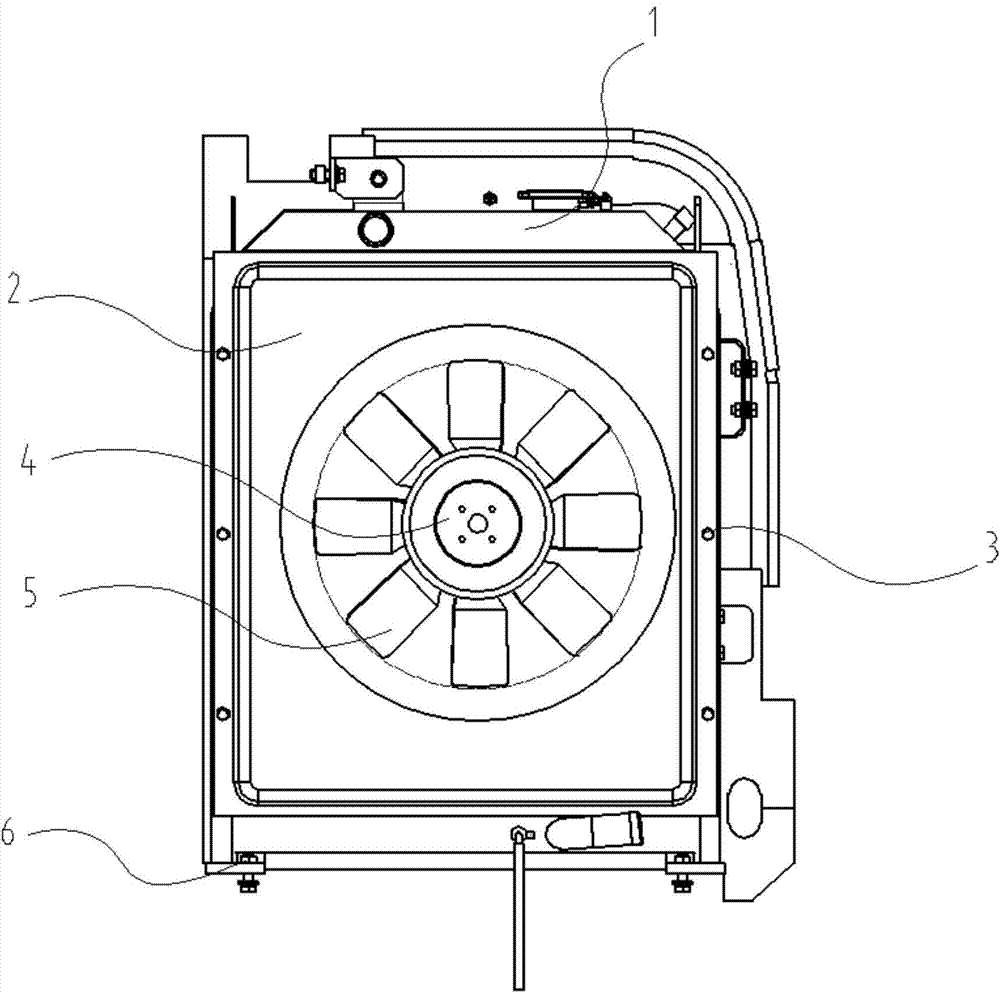

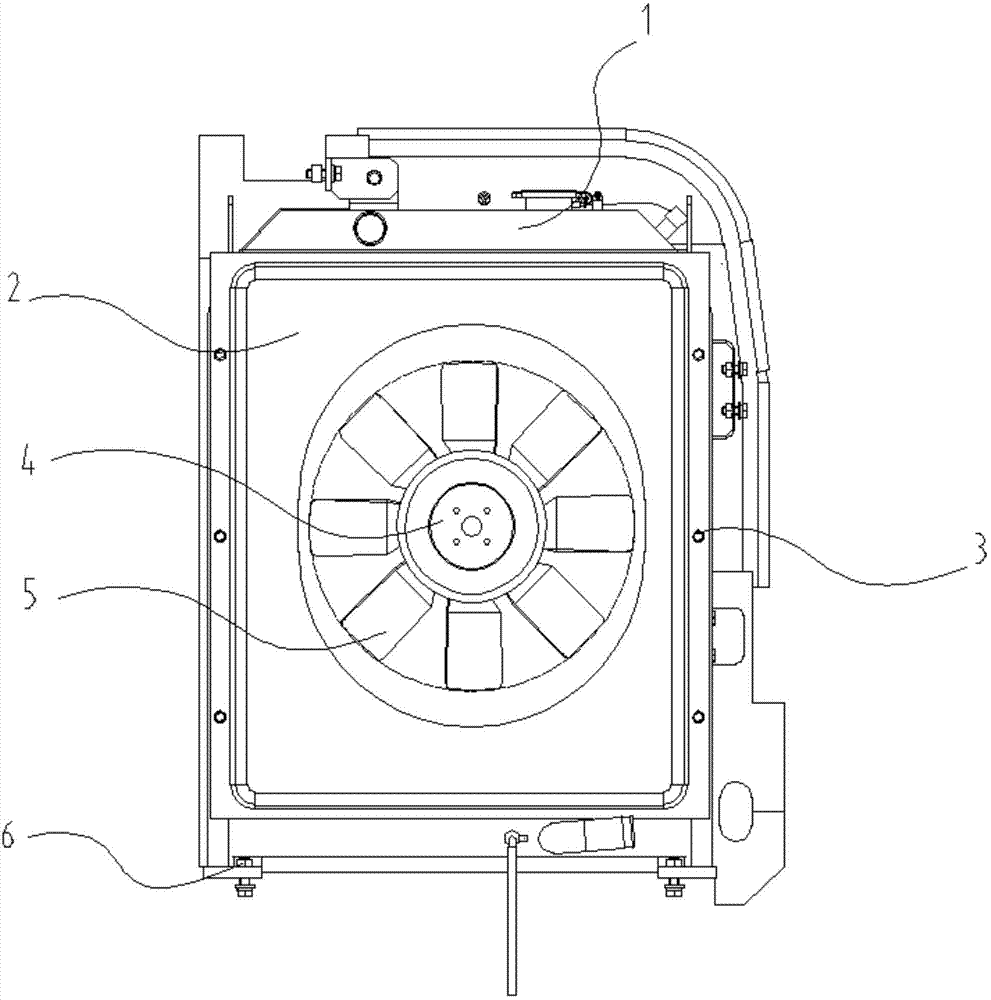

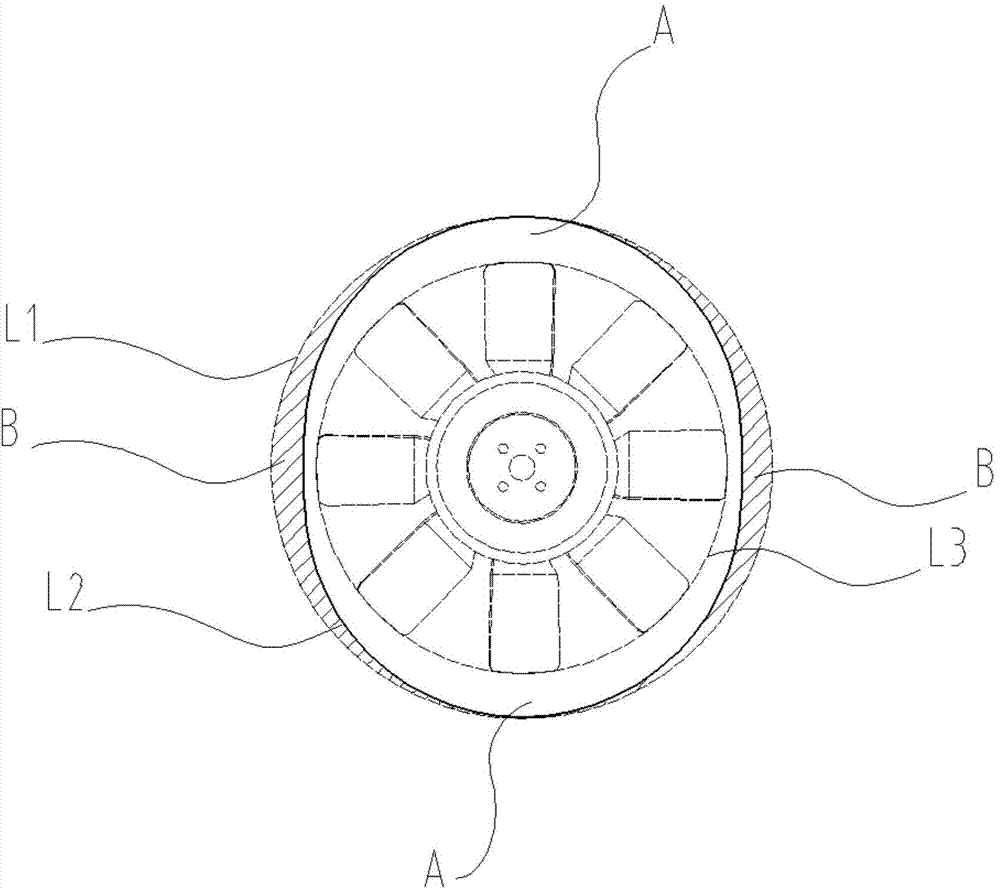

[0020] Such as figure 2 image 3 As shown, in this embodiment, the heat exchanger 1 is fixedly installed on the vehicle frame through the mounting bolts 6 , and the wind guide cover 2 is fixed on the heat exchanger 1 through the fixing bolts 3 to form an air duct. The fan 5 is directly connected to the engine through the fan spacer 4, and the fan is located in the inner hole of the air guide cover and is driven by the engine to drive the air flow to generate wind, which flows through the heat exchanger to achieve cooling effect. In this embodiment, the center of the fan is coaxial with the center of the inner hole of the air guide cover, and the fan rotates its fan blade tip under static conditions to form a circular trajectory line L3, and the opening inner hole of the air guide cover corresponding to the fan is set as an oblong hole, The long diameter direction of the oblong hole is the vertical direction, the radial distance from a point on the circular locus line to the ...

Embodiment 2

[0023] Compared with Example 1, the difference lies in the shapes of the left and right sides of the inner hole of the air guide cover, such as Figure 4 As shown, in this embodiment, in the contour line of the inner hole of the air guide cover, there are two arcs on the left and right sides, and the radius of curvature of the arcs gradually decreases as the arc extends to the upper and lower ends and is finally equal to the upper and lower circles The radius of the arc. L2 is the contour line of the inner hole of the windshield in this embodiment, and the contour line is left-right asymmetrical, wherein the radial distance from the inner hole contour line on the left side to the static trajectory line of the fan blade tip is greater than that on the right side from the inner hole contour line to The radial distance of the static trajectory line of the fan blade tip, L4 is the contour line of the inner hole of the air guide cover in Embodiment 1, and the closed area surrounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com