Exhaust volute positioning and adjusting device

A positioning adjustment and positioning device technology, applied in the direction of combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems affecting the safety, reliability and stable operation of flue gas turbines, the rotor-stator gap, the change of the seal gap, and the impact on the rotor Problems such as the load capacity of the serial bearing, to achieve the effect of ensuring work performance, improving reliability and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are to explain rather than limit the present invention.

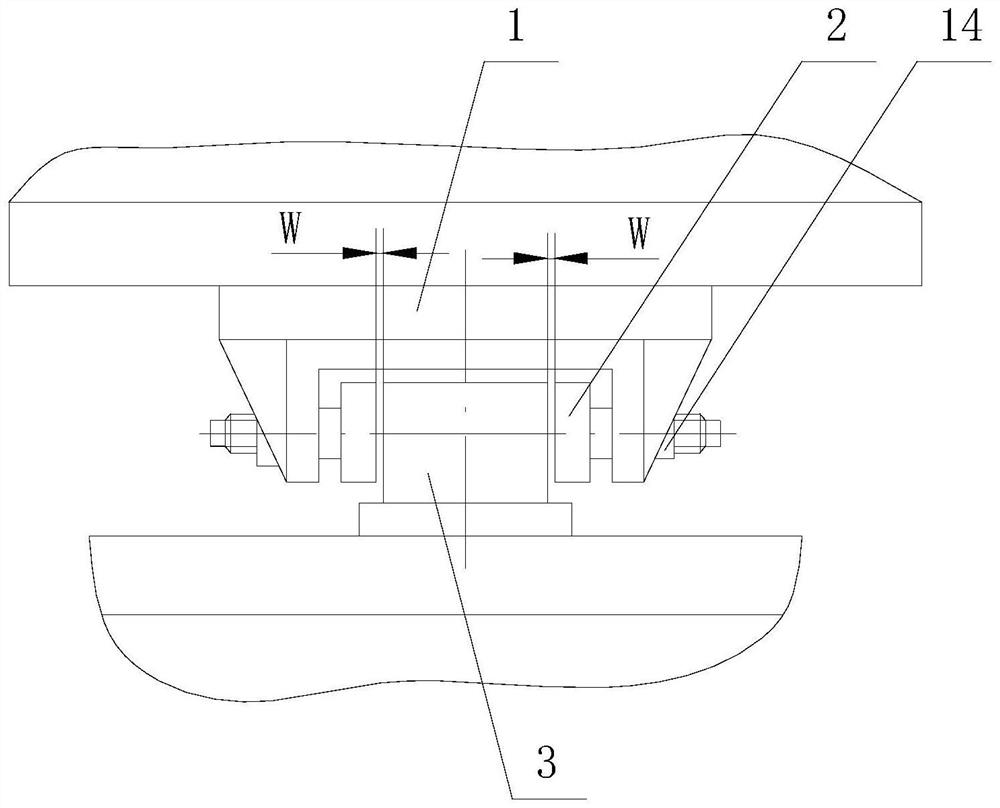

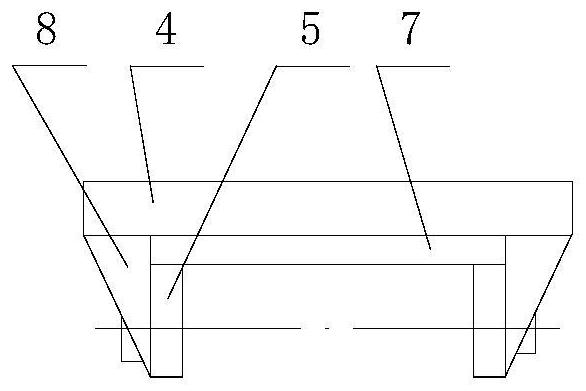

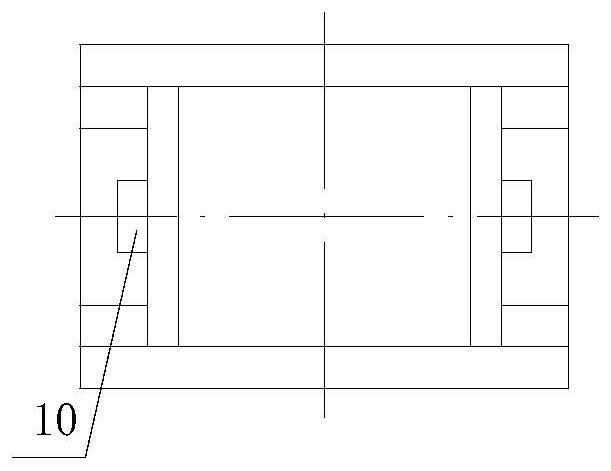

[0033] see Figure 1-10 , an exhaust volute positioning adjustment device, including a base 1 and a guide key 3 and a positioning device.

[0034] The base 1 is formed with an accommodating groove for installing the guide key 3, the base is used to be fixedly connected with the base of the flue gas turbine, and the guide key 3 is arranged in the accommodating groove and can be along the offset direction of the exhaust volute. Moving, the guide key is used to be fixedly connected with the exhaust volute, and the positioning device is arranged on the side wall of the accommodating groove to control the position of the guide key 3 in the accommodating groove.

[0035] The positioning and adjusting device for the exhaust volute of the flue gas turbine connects the base and the guide key with the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com