Patents

Literature

38results about How to "Reduce assembly difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

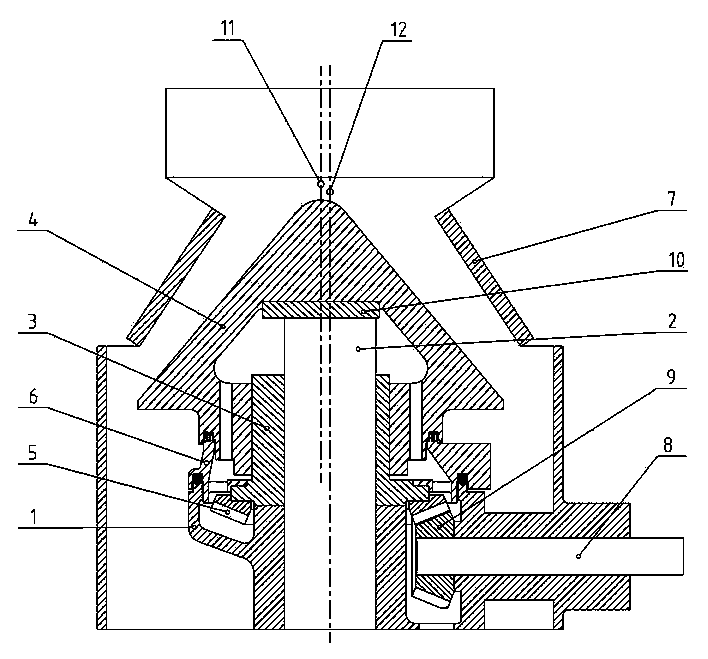

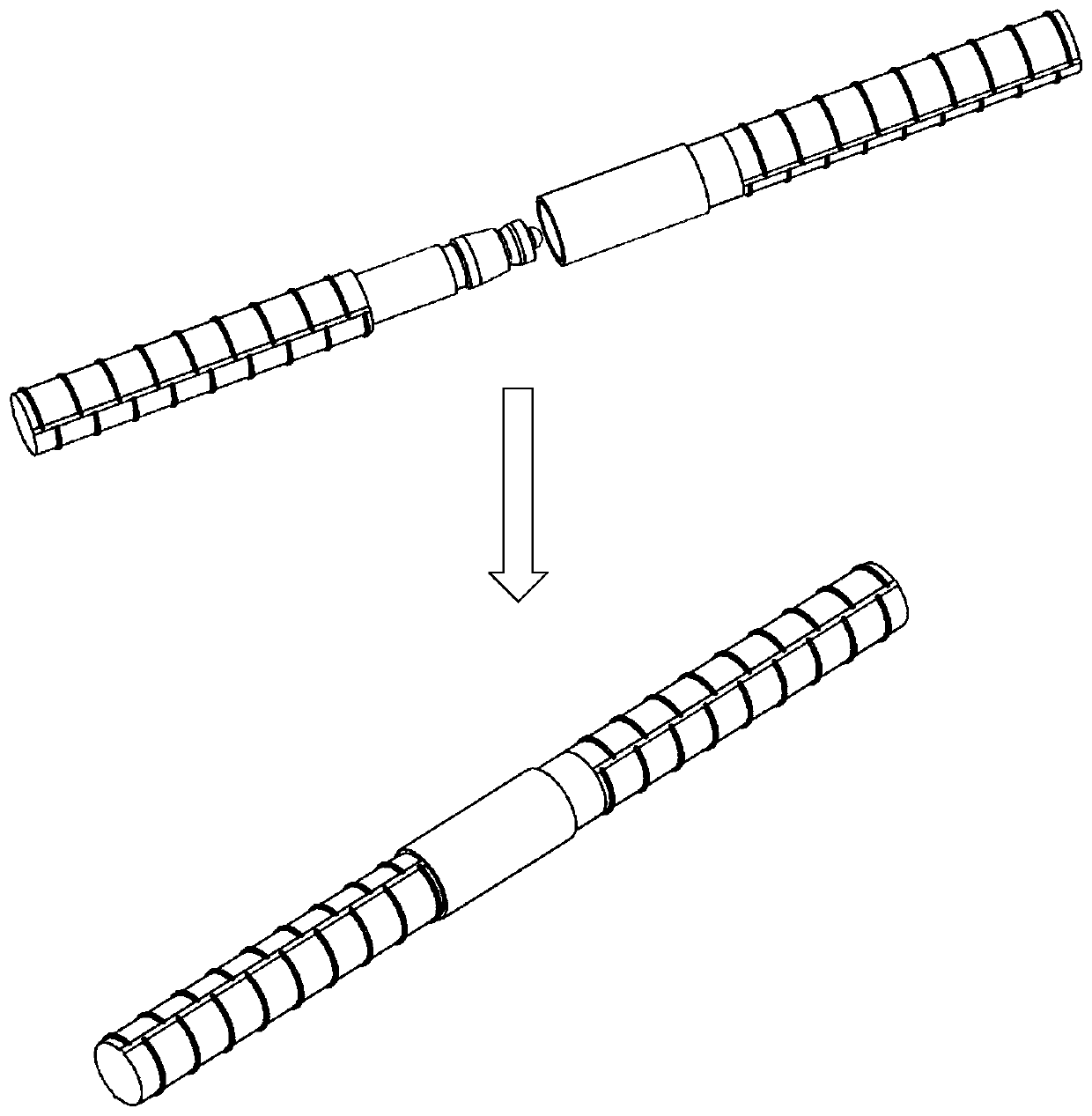

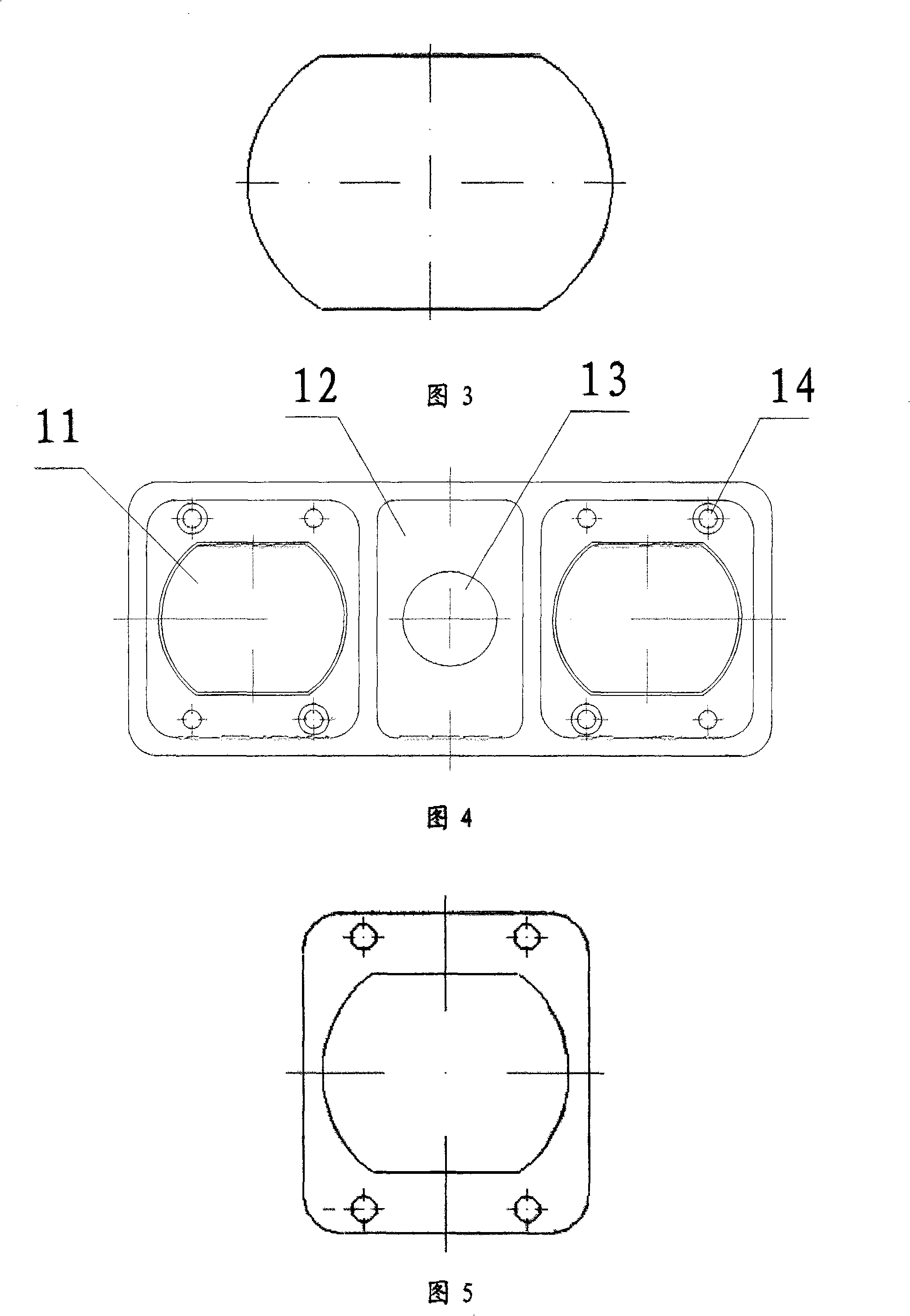

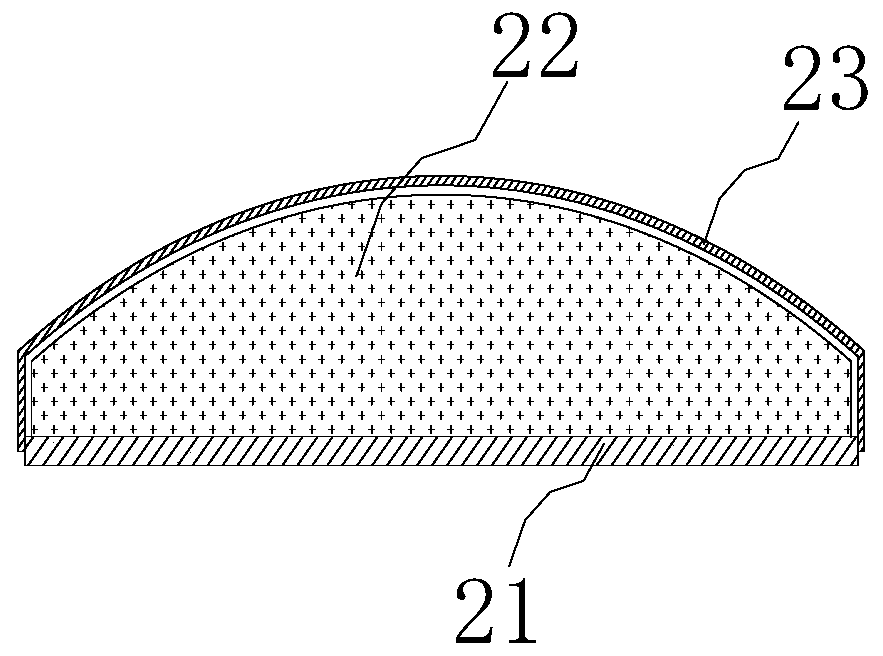

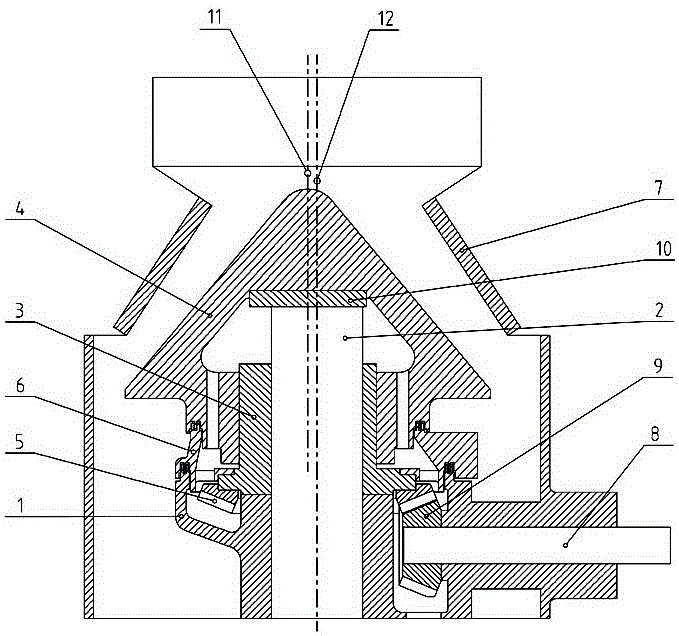

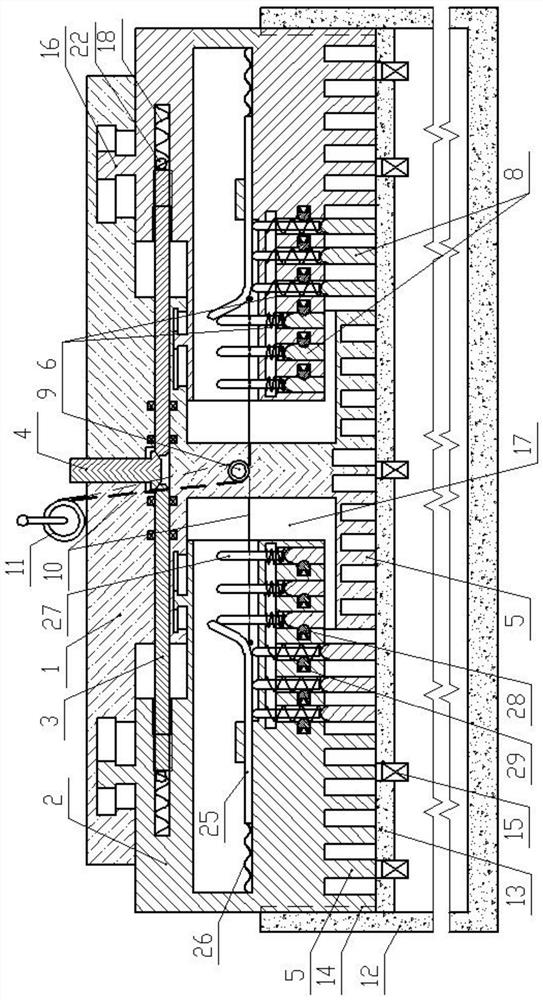

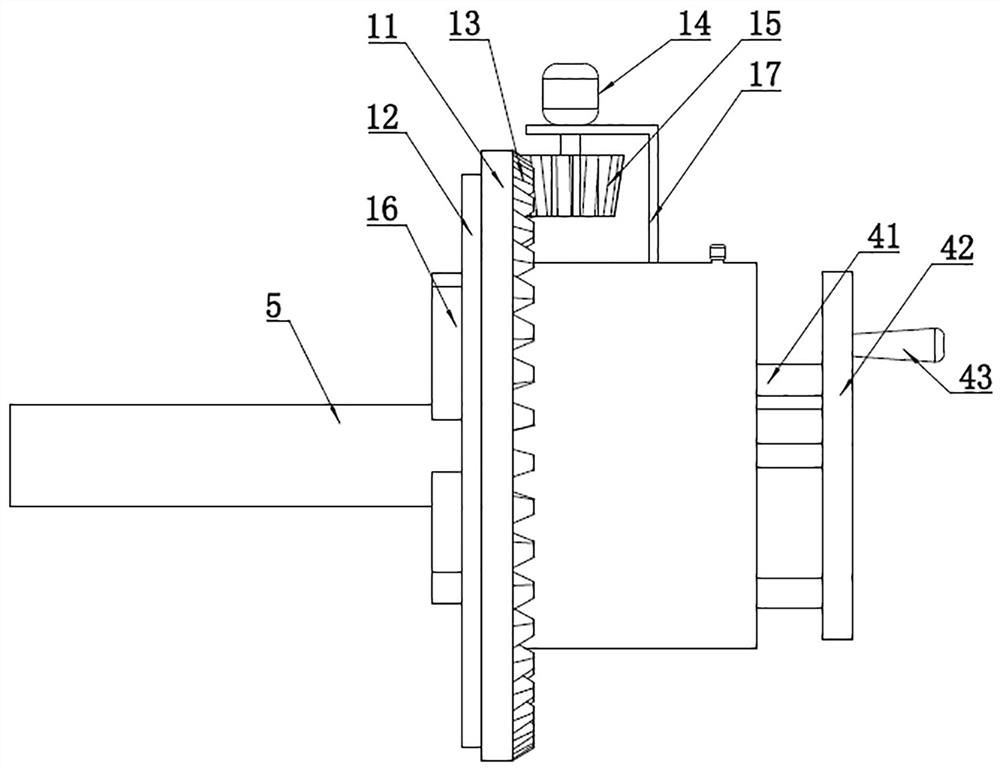

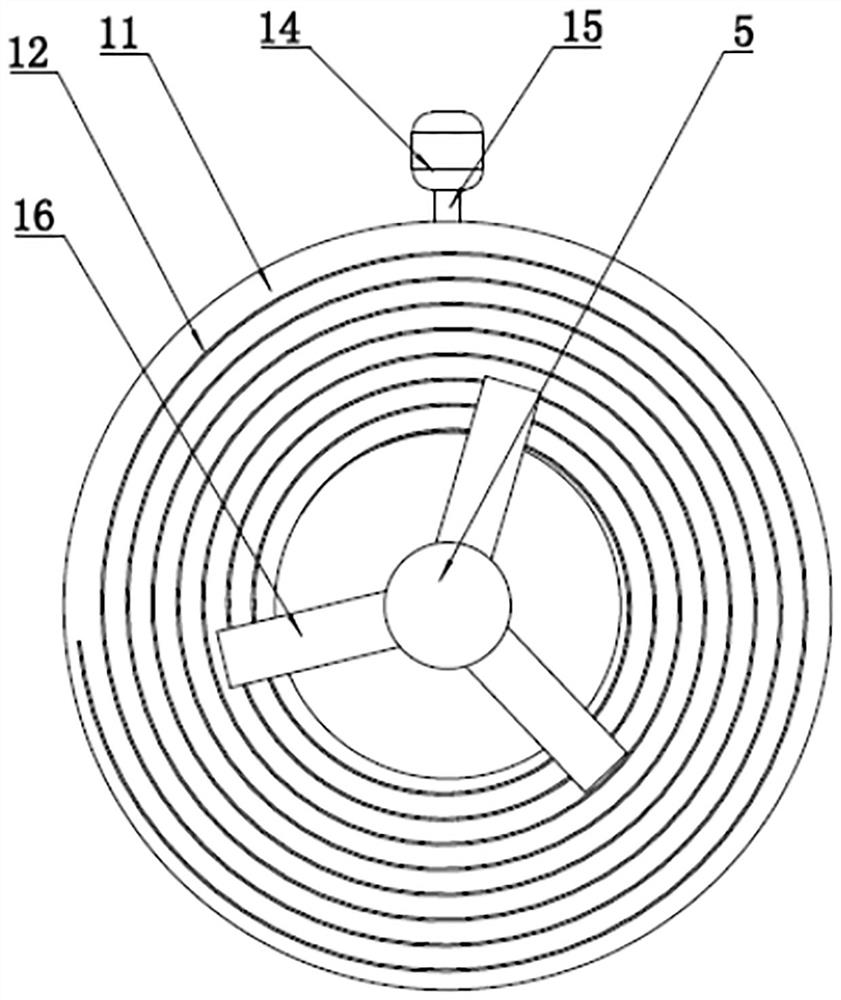

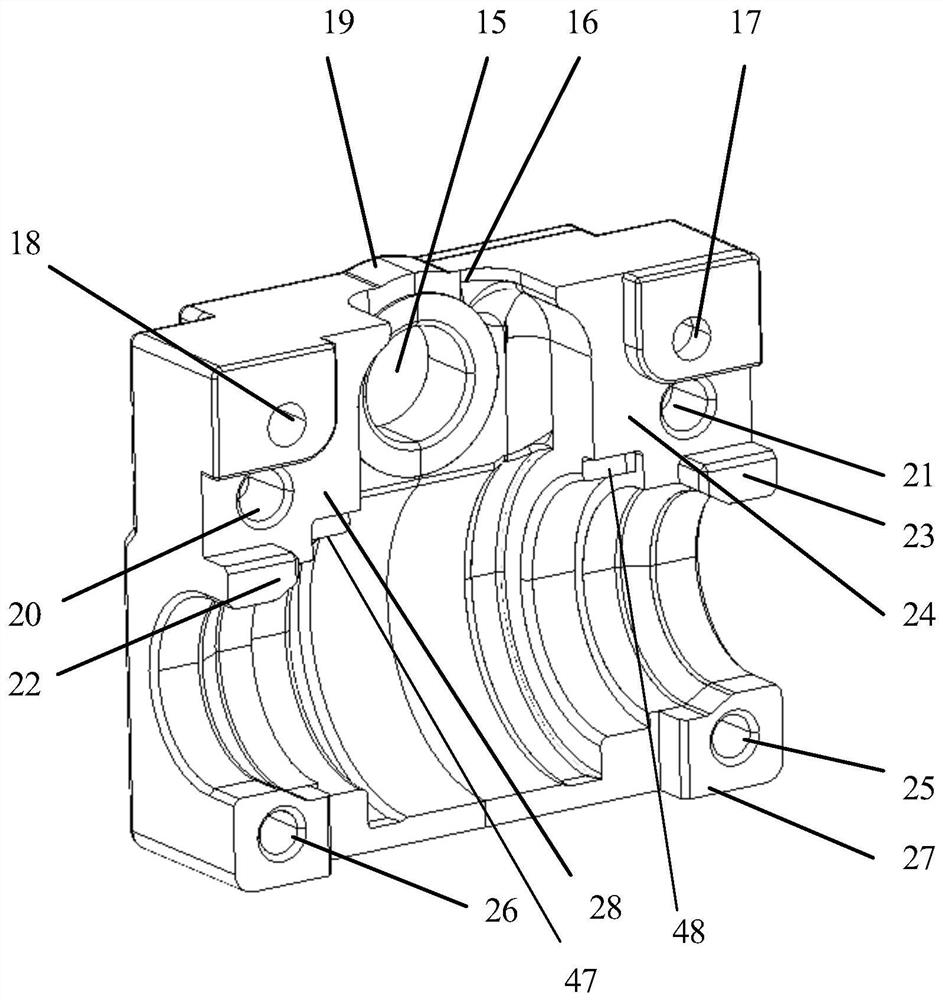

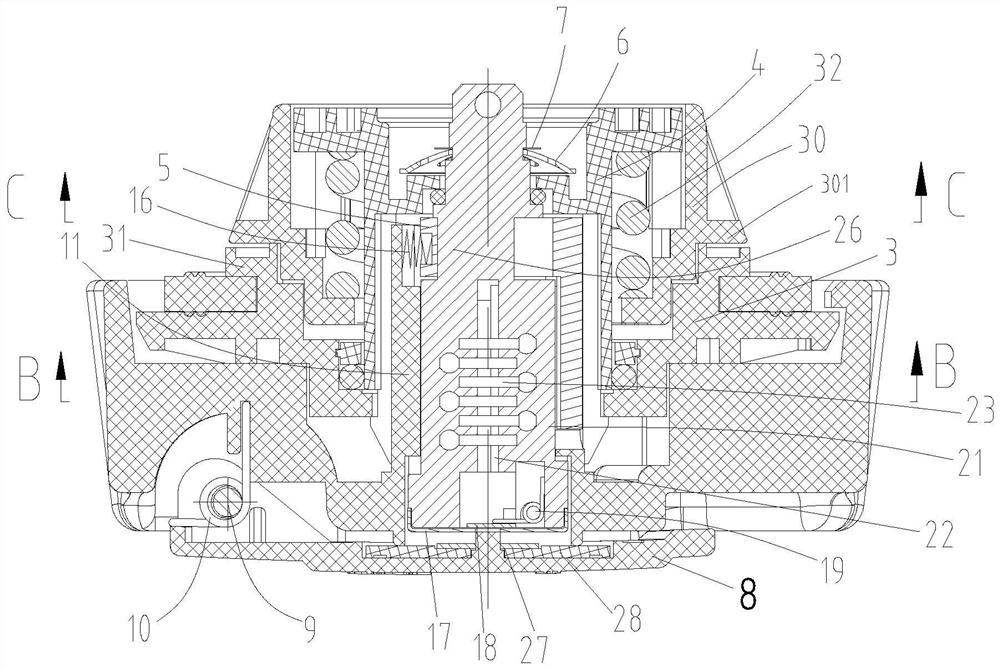

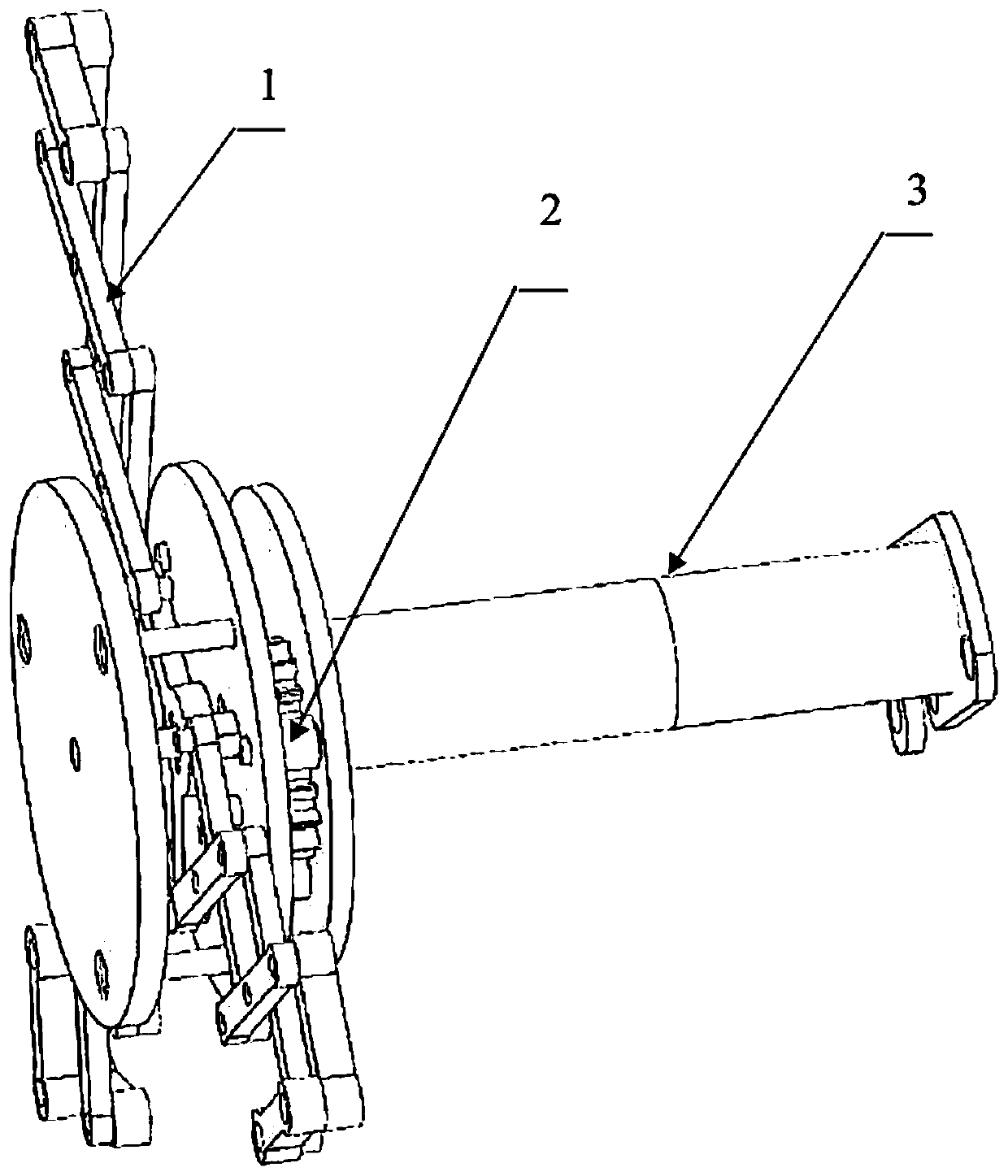

Parallel-axis cone crusher

ActiveCN103691509AGuaranteed parallelismReduce assembly difficultiesGrain treatmentsEngineeringCrusher

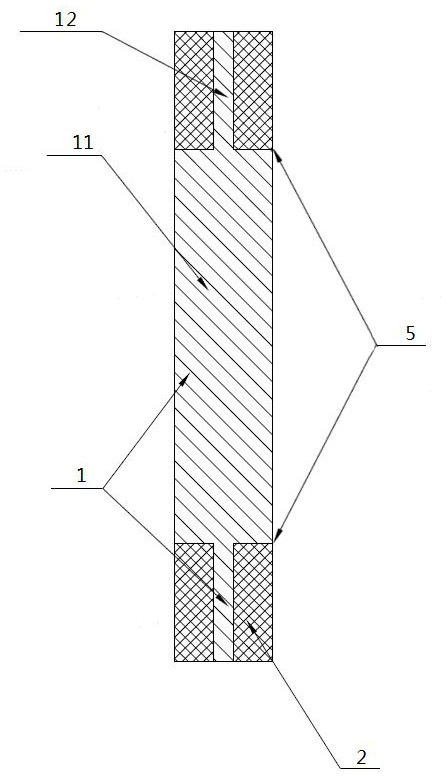

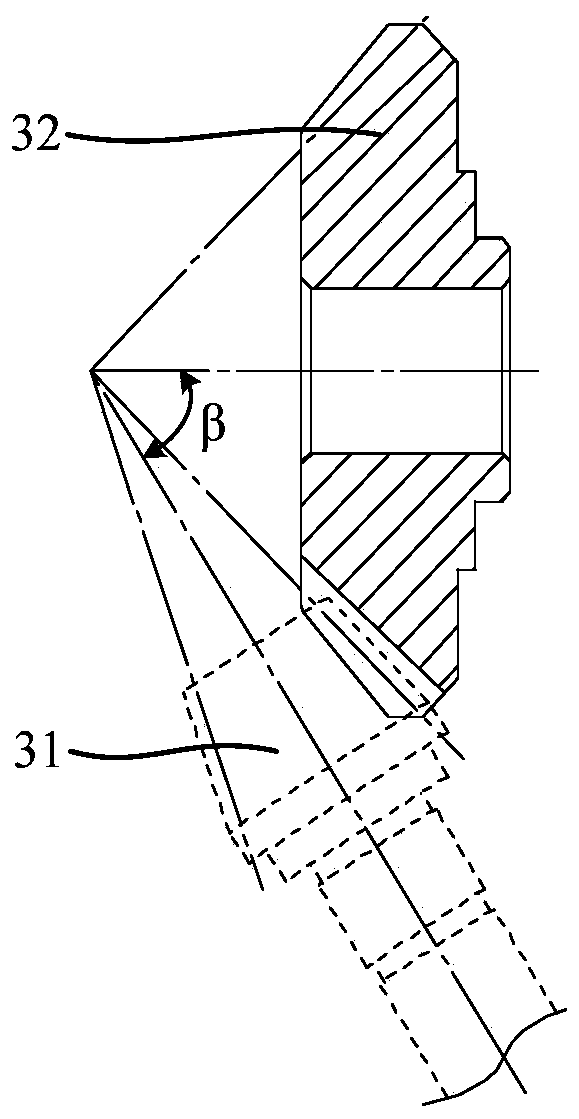

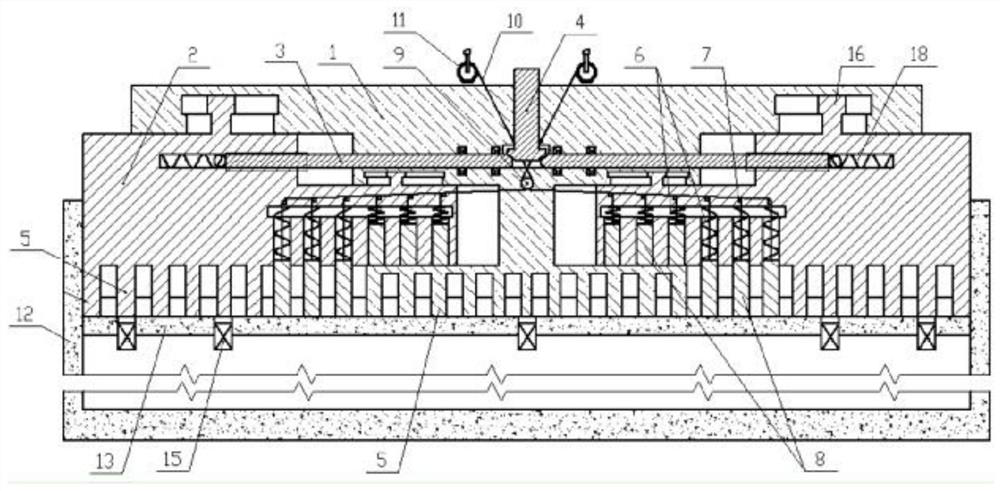

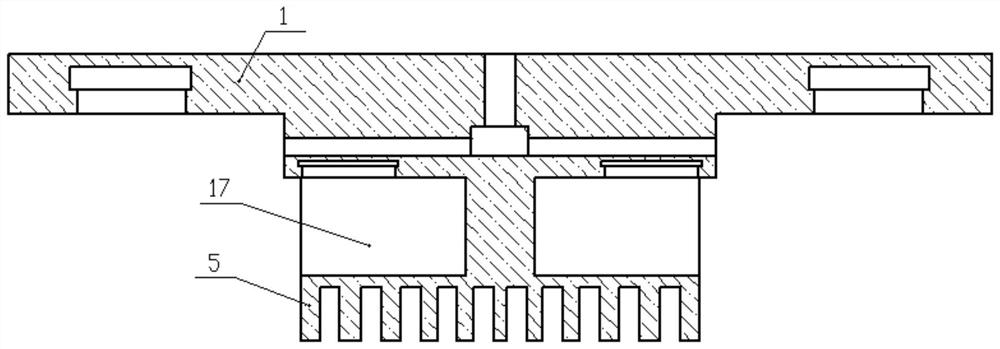

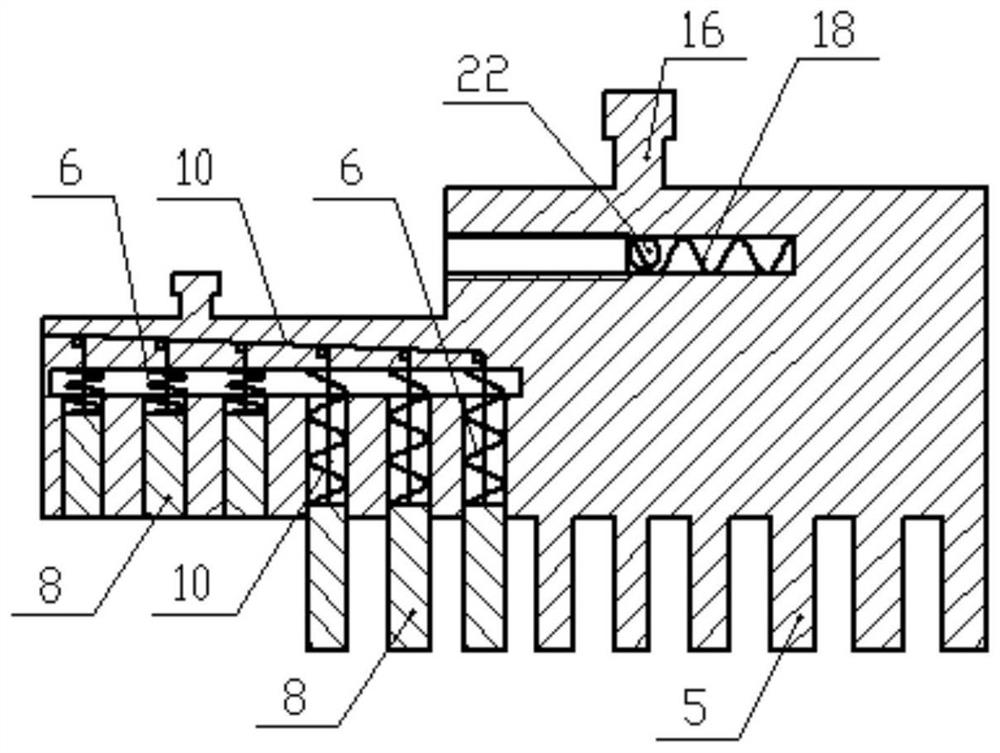

The invention discloses a parallel-axis cone crusher. The parallel-axis cone crusher comprises a rack, a main shaft, an eccentric sleeve, a movable cone and a fixed cone, wherein the excircle and the inner hole of the eccentric sleeve are in parallel eccentric structures; the inner hole of the eccentric sleeve and the excircle of the main shaft form a cylindrical friction pair; the lower end of the cylindrical friction pair and the rack form a planar friction pair; the inner hole of the movable cone and the excircle of the eccentric sleeve form the cylindrical friction pair; a planar bearing is arranged at the top end inside the movable cone; the planar bearing and the upper plane of the main shaft form the planar friction pair. The parallel-axis cone crusher disclosed by the invention has the advantages that the excircle and the inner hole of the eccentric sleeve are designed into parallel eccentric structures, and the movable cone and the top of the main shaft are connected by the planar bearing, so that a parallel relationship between a movement axis of the movable cone and the axis of the rack is ensured, and difficulty of machining internal and external angles of the eccentric parts and assembling the components is reduced; and meanwhile, a problem that the conventional cone crusher cannot normally work due to inclined angle changes caused by abrasion with a shaft sleeve in a using process is also avoided.

Owner:HENAN LIMING HEAVY IND SCI & TECH

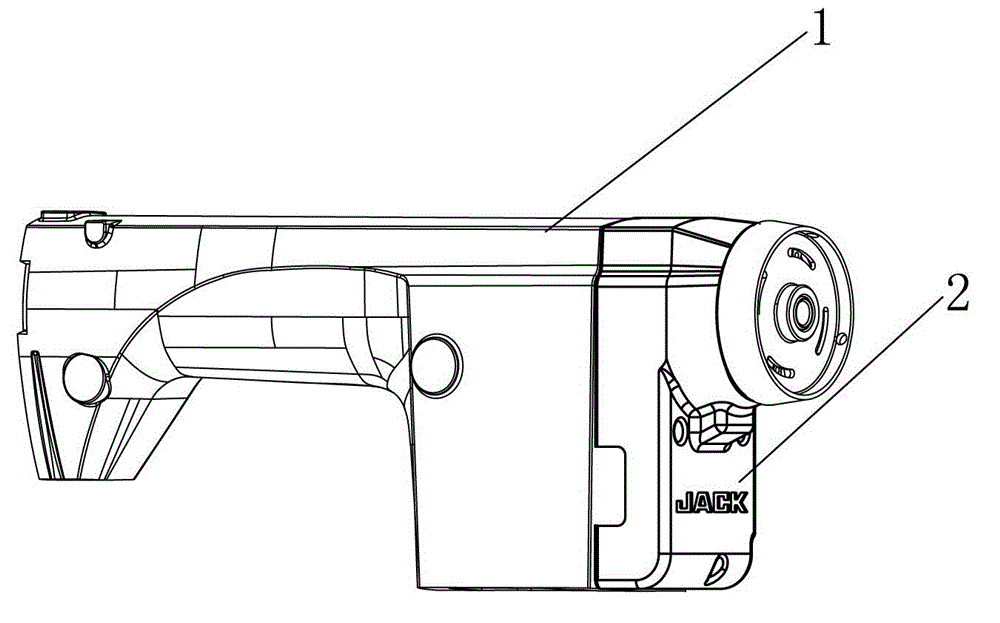

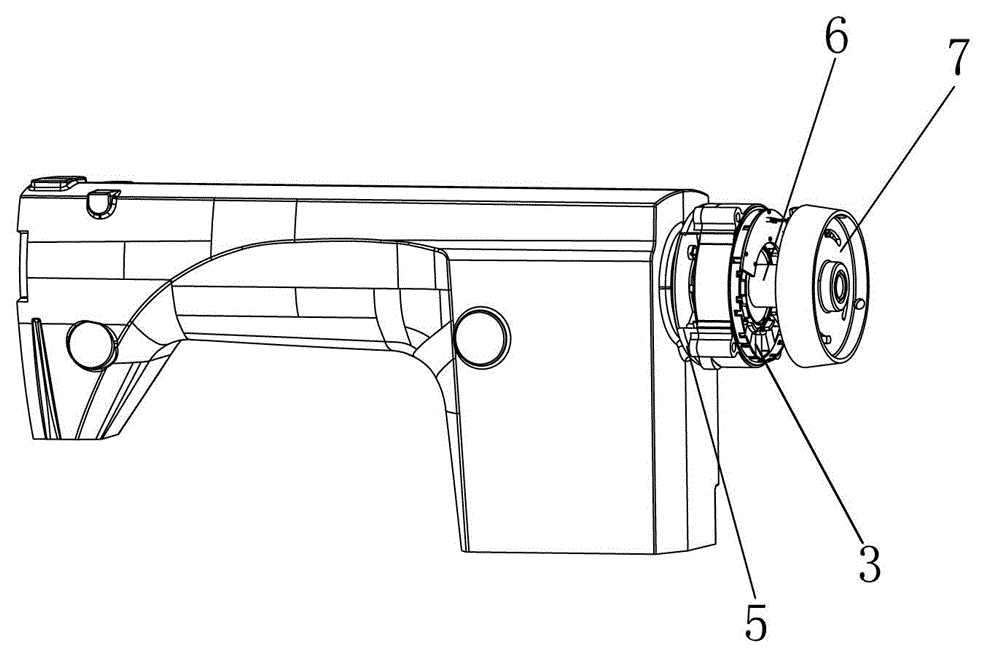

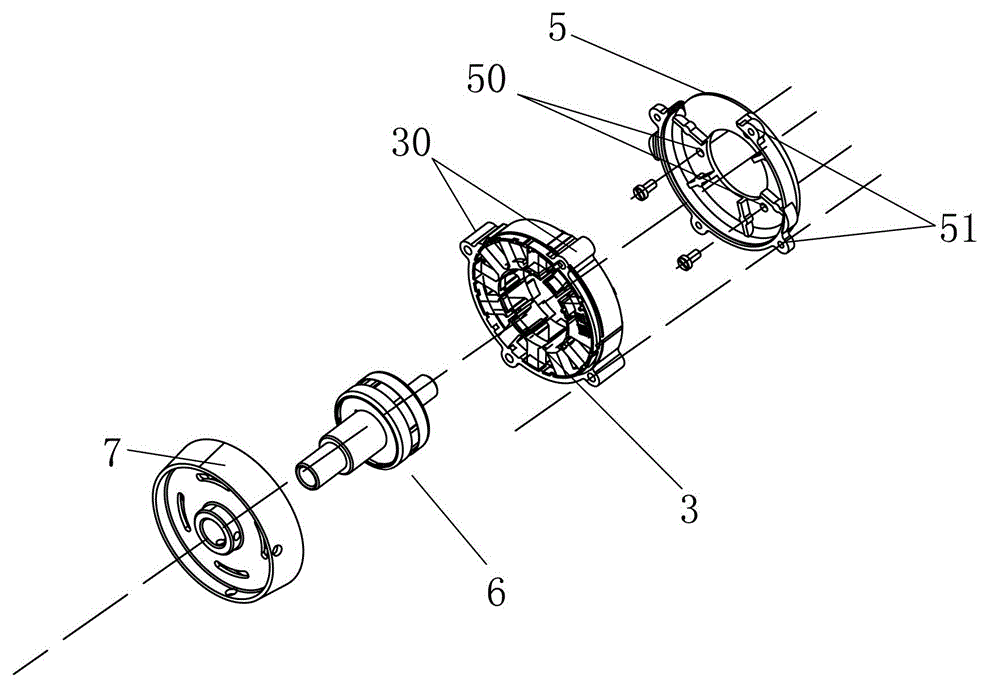

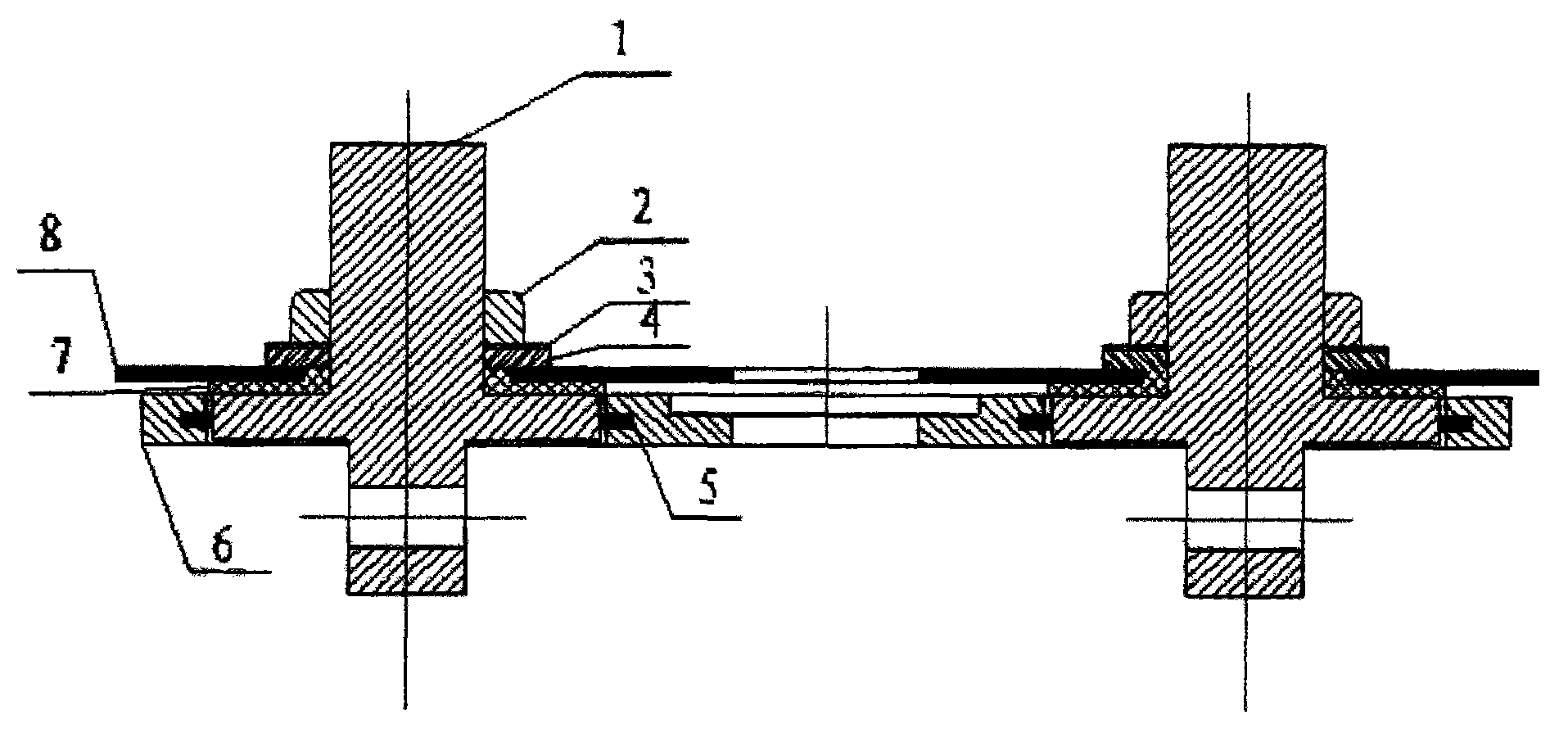

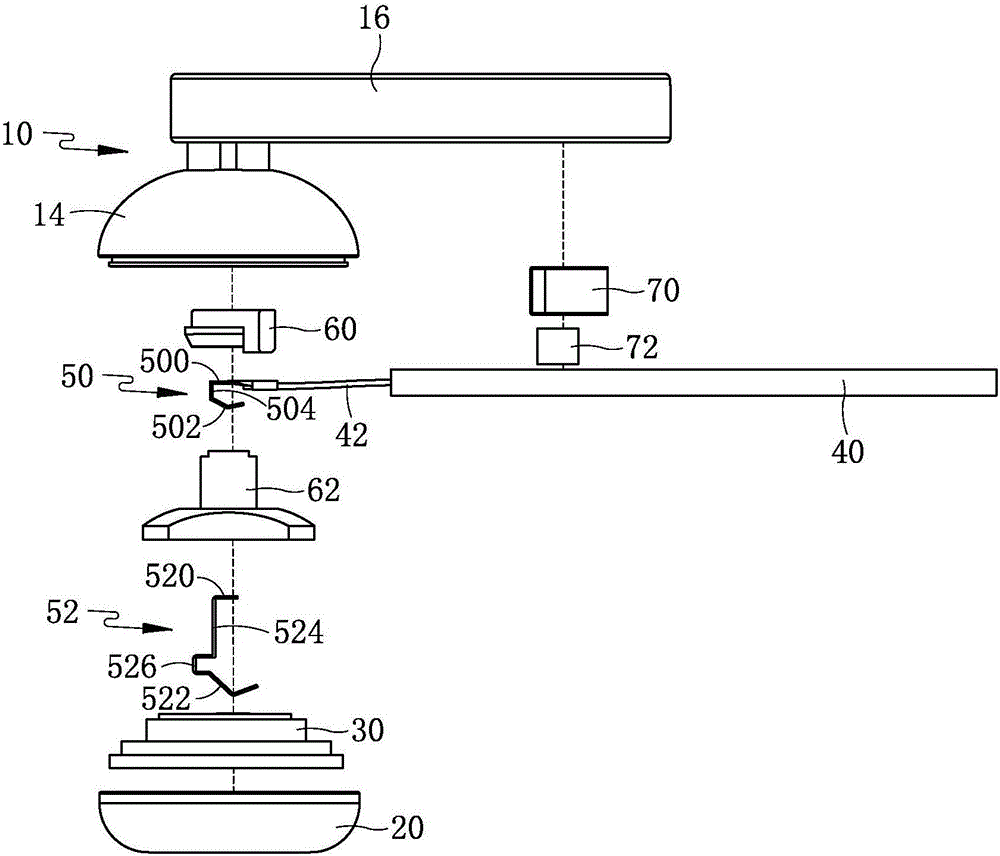

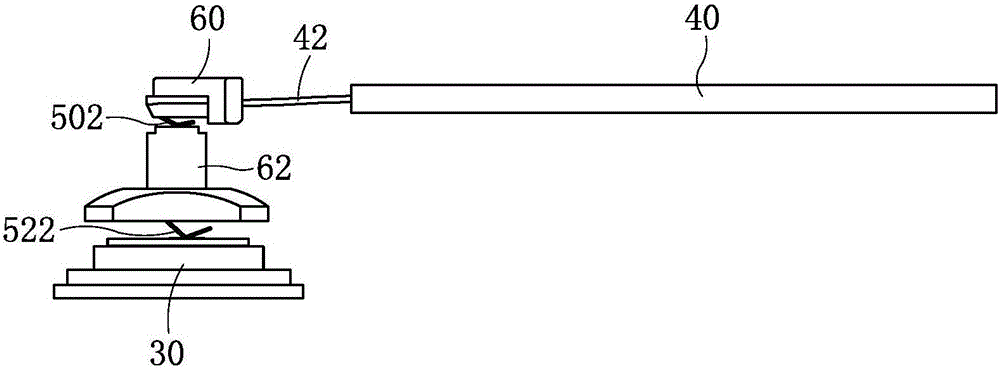

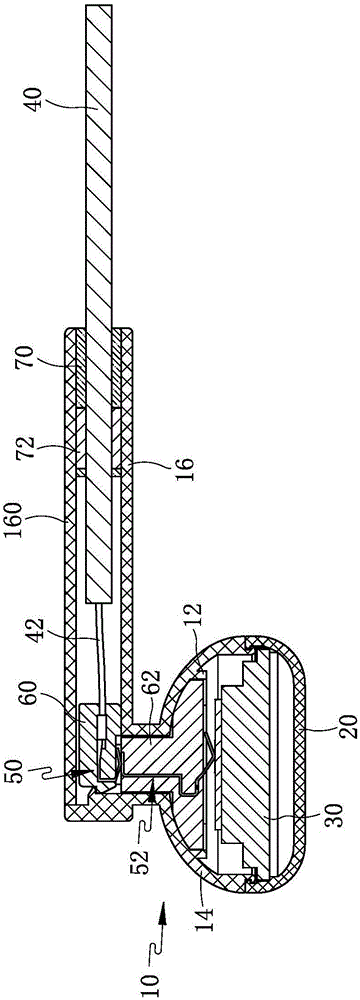

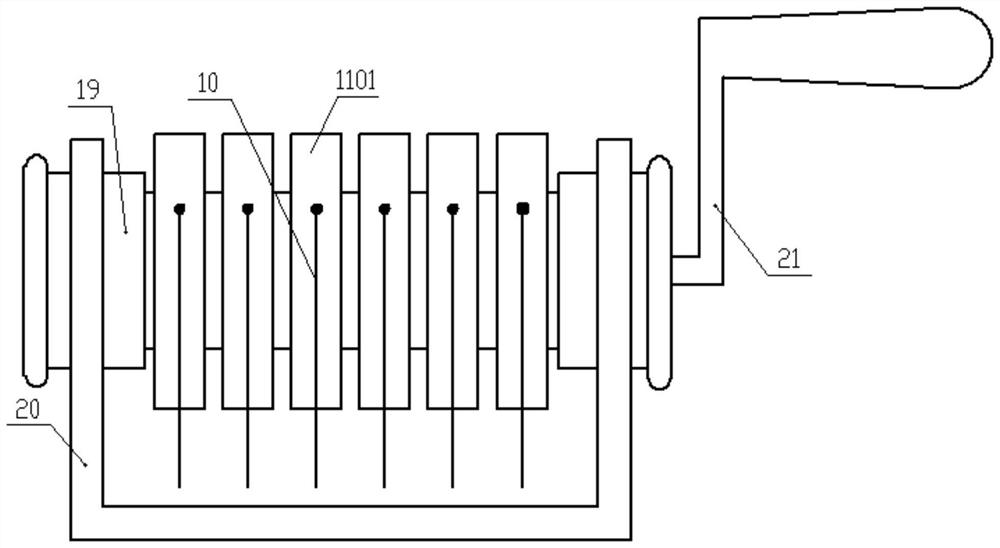

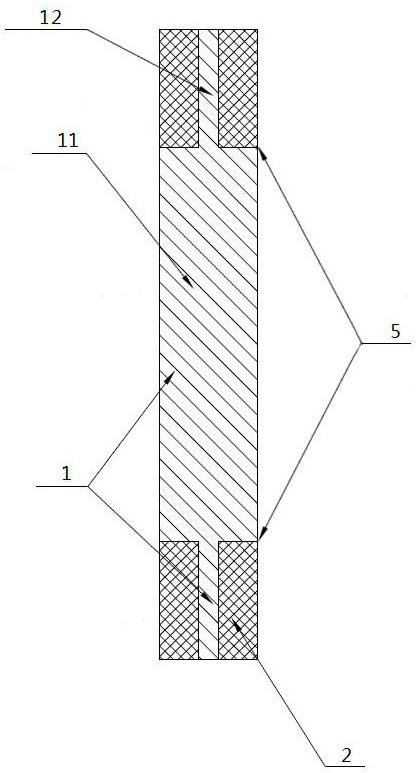

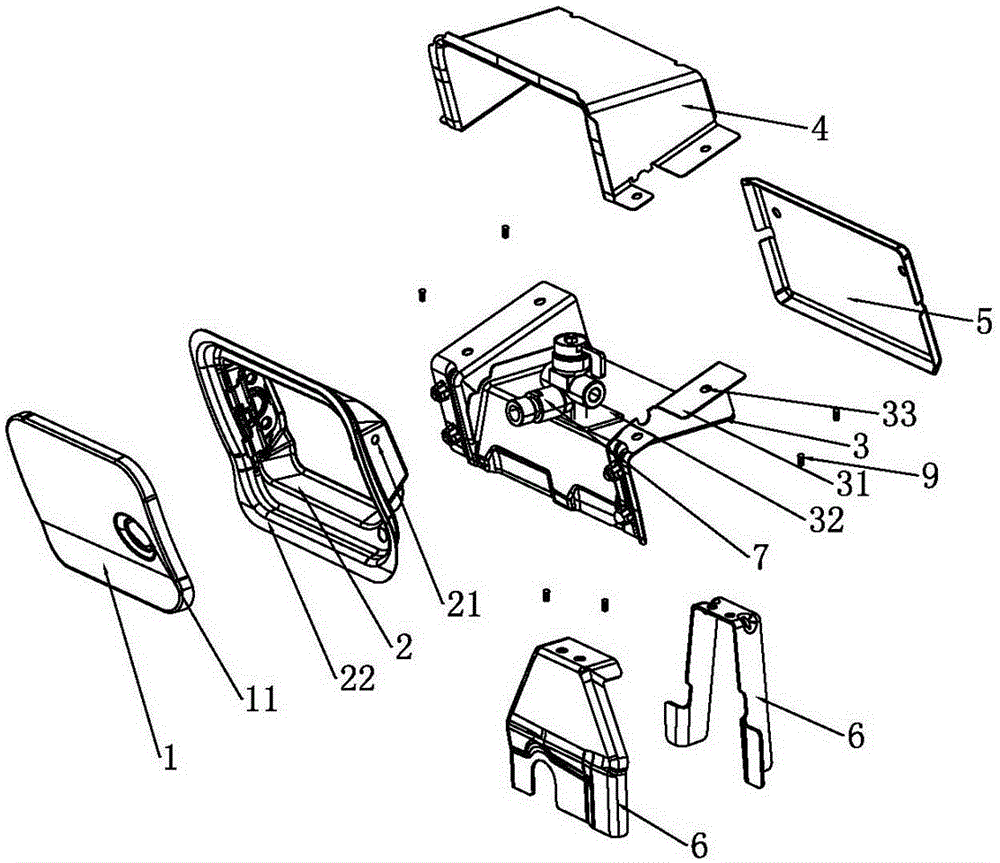

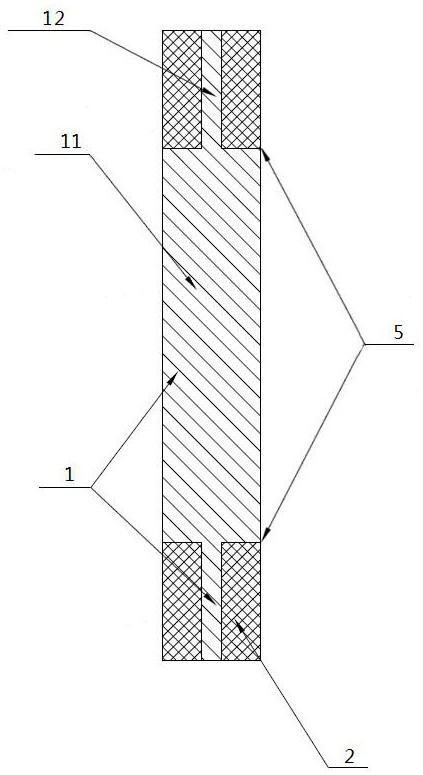

Direct drive structure of sewing machine

InactiveCN102720013AOutstanding and Beneficial Technical EffectsReduce assembly difficultiesSewing-machine control devicesMechanical energy handlingStatorEngineering

The invention provides a direct drive structure of a sewing machine and belongs to the technical field of sewing machines. The invention solves the problems that the existing direct-drive sewing machine is not ideal enough in the aspects of mounting, operating and maintenance, and the like. The direct drive of the sewing machine comprises a machine head of the sewing machine, wherein a motor locating plate is fixedly arranged on one end surface of the machine head of the sewing machine; a motor stator is fixedly arranged on the motor locating plate through a through hole arranged in the outer ring of the motor stator; a motor rotor is arranged in the motor stator; one end of the rotor is connected with a main shaft of the sewing machine, and the other end of the rotor is fixedly connected with a hand wheel of the sewing machine; the motor stator and the motor locating plate are all arranged in a machine head enclosure; and the hand wheel of the sewing machine extends out of an opening of the machine head enclosure. The direct drive structure of the sewing machine has the advantages of ingenious concept on structure, good heat dissipation effect, wide application range and the like.

Owner:JACK SEWING MASCH CO LTD

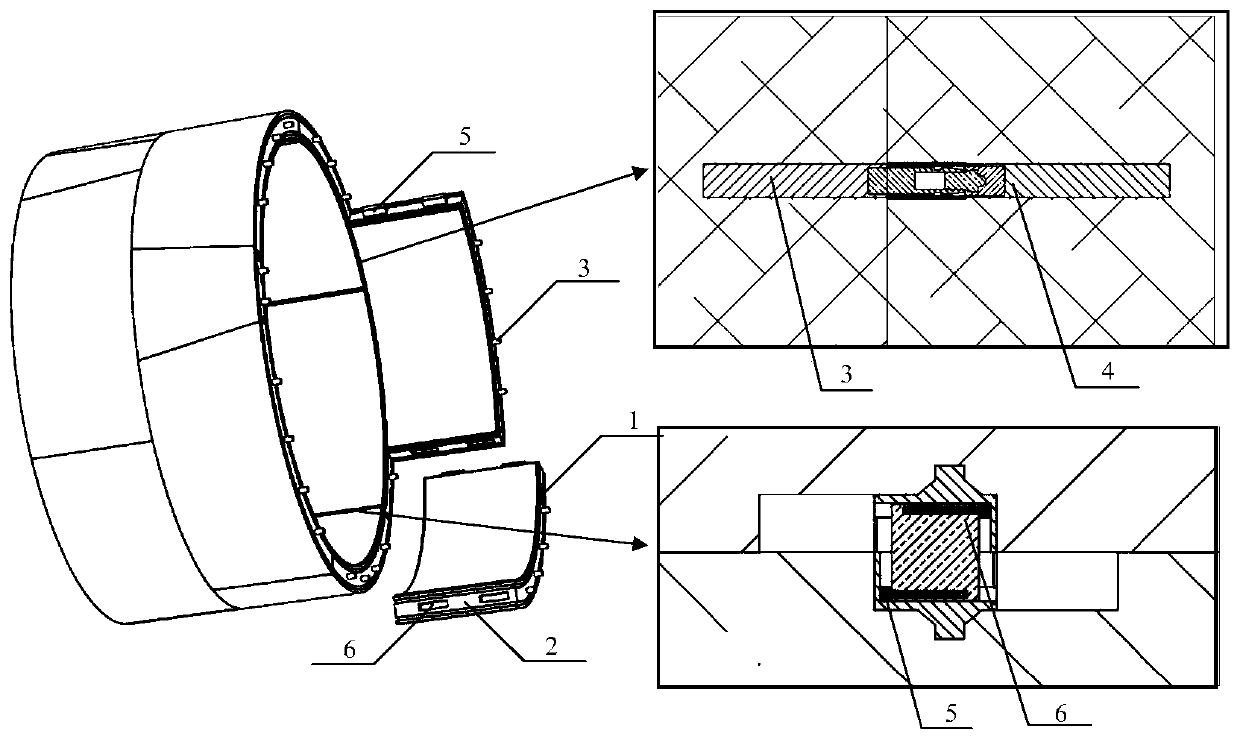

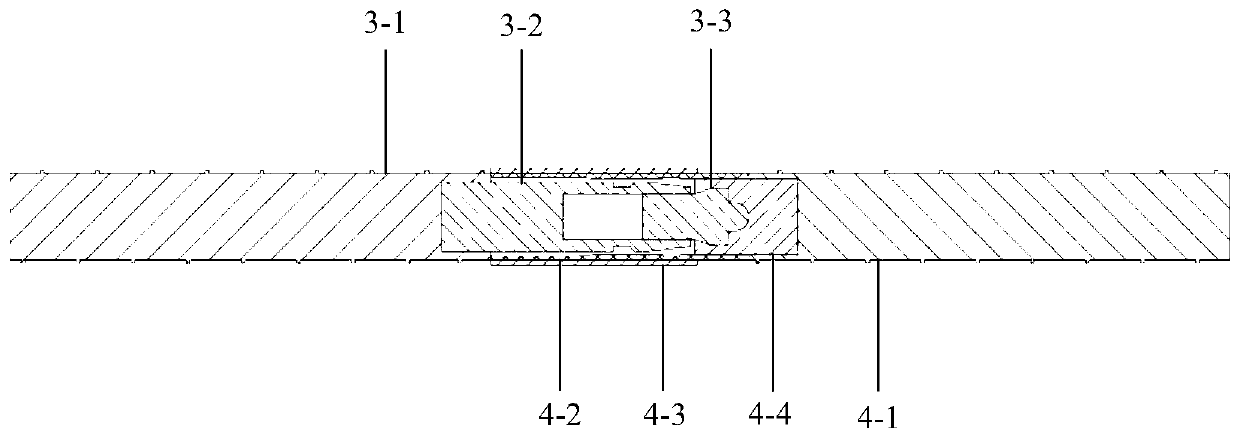

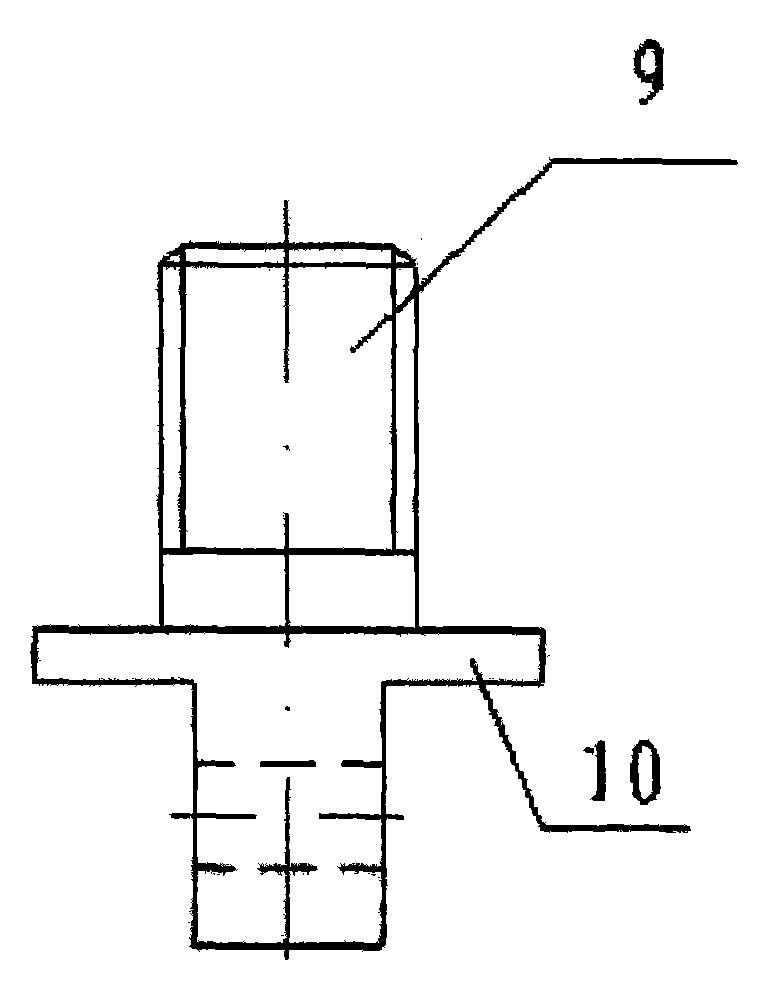

Segment structure with horizontal pin type mortise and tenon and push-and-press fastening type joint connecting assemblies

ActiveCN110761806AAchieve precision assemblyEasy constructionUnderground chambersTunnel liningMortise and tenonStructural engineering

The invention belongs to the technical field of shield tunnel lining structure correlation, and discloses a segment structure with horizontal pin type mortise and tenon and push-and-press fastening type joint connecting assemblies. The segment structure comprises shield segments and the horizontal pin type mortise and tenon connection assembly which are connected, and each assembly comprises a mortise and tenon joint connecting piece and a push-and-press joint connecting piece. Each shield segment is in an arc shape. The mortise and tenon joint connecting pieces are connected with two oppositerectangular ends and the push-and-press joint connecting pieces are connected with two opposite arc-shaped ends so as to realize axial and circumferential connection of the adjacent shield segments.Each mortise and tenon joint connecting piece comprises a male clamping joint and a female clamping joint, wherein a T-shaped second containing cavity is formed in each female clamping joint; and eachmale clamping joint comprises a first C-shaped piece and a connecting body connected to the first C-shaped piece, and each connecting body is accommodated in the corresponding second containing cavity. During mounting, the connecting bodies are clamped into the second containing cavities through sliding, so that the male clamping joints and the female clamping joints form mortise and tenon connection. The segment structure is easy to construct, and cost and manpower and material resources are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +2

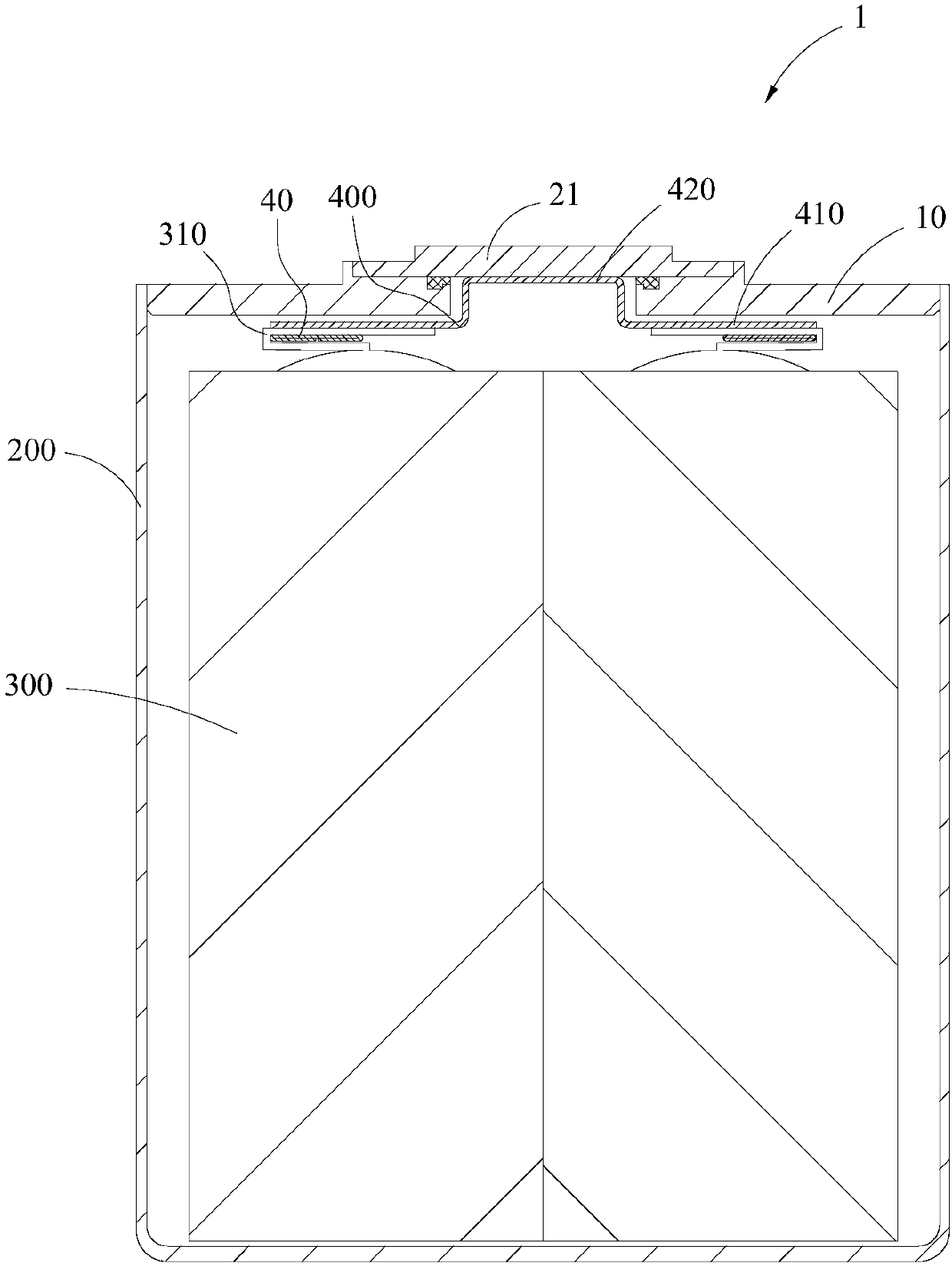

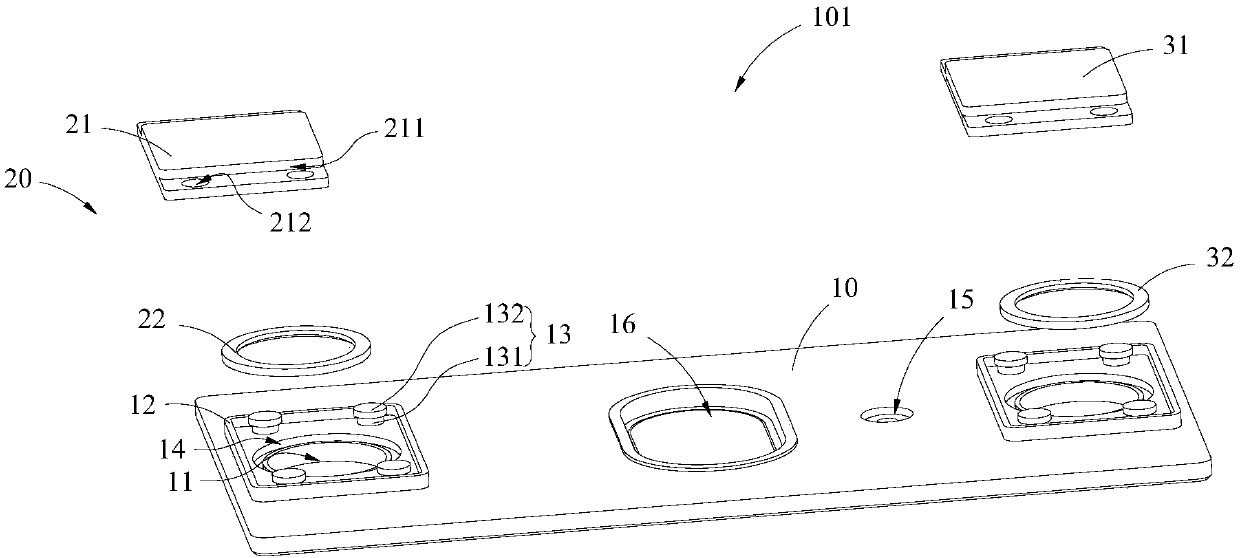

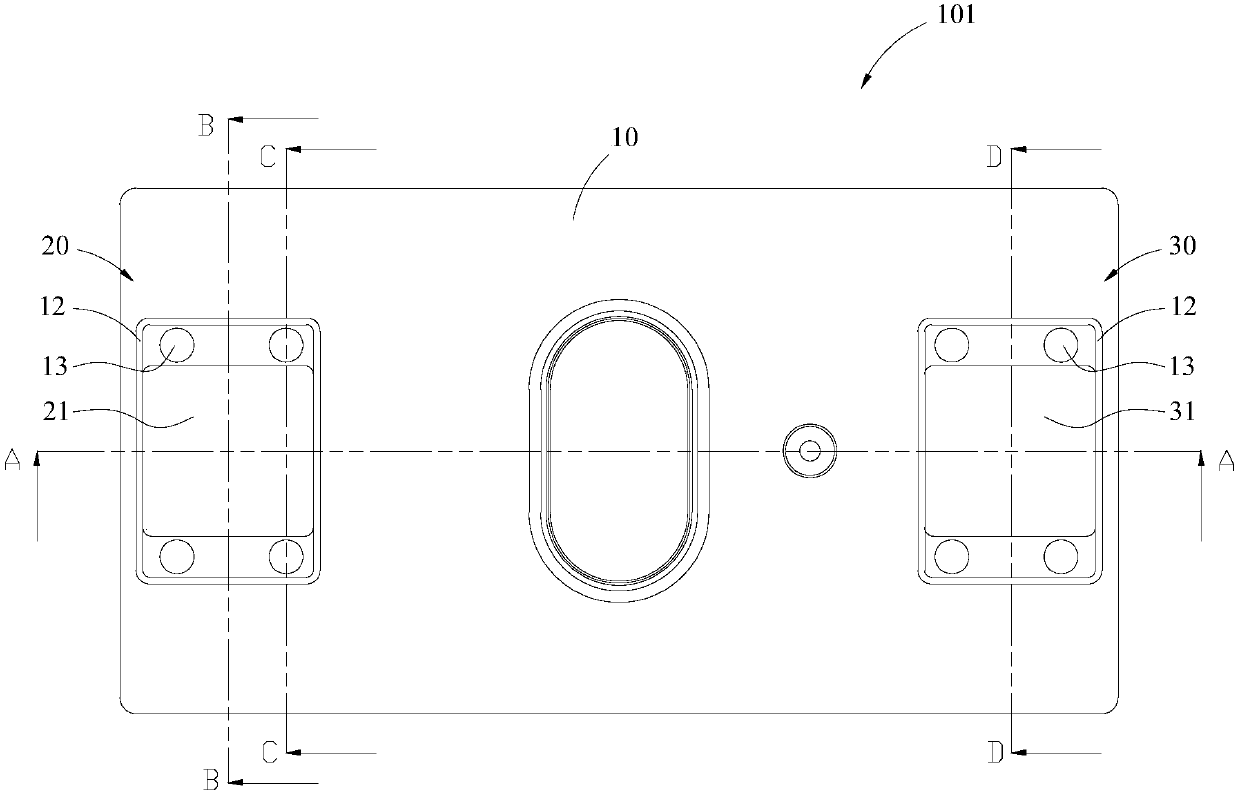

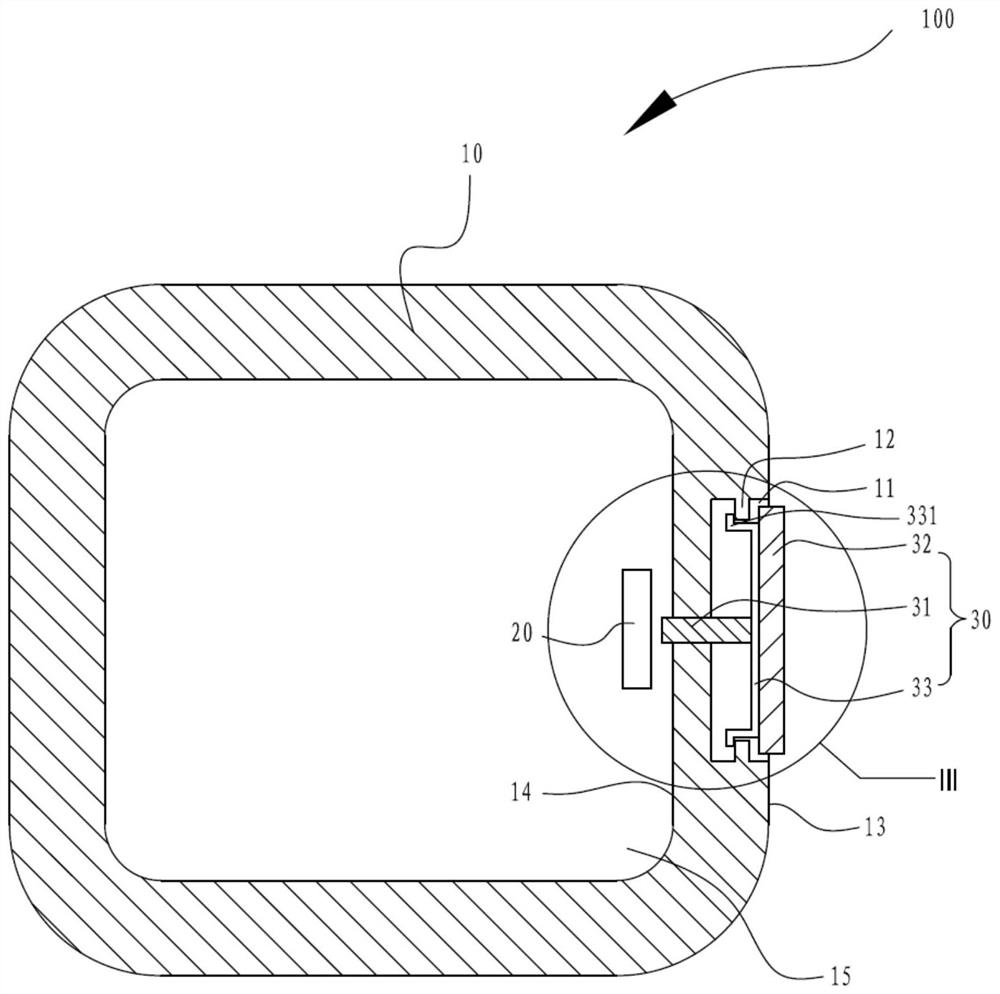

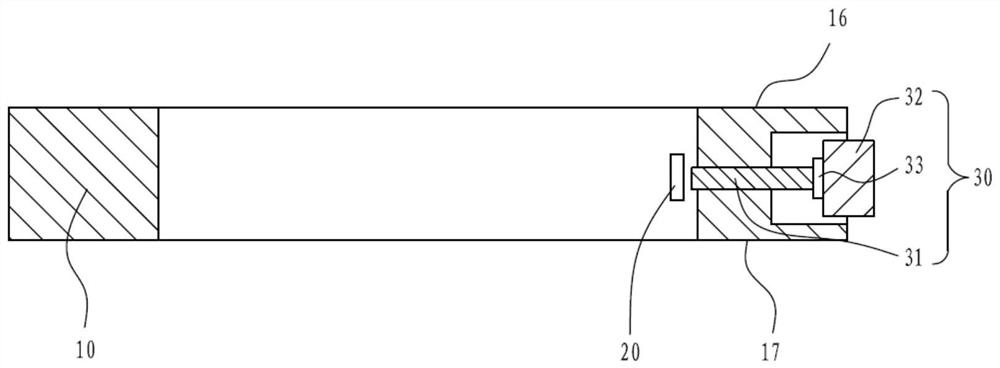

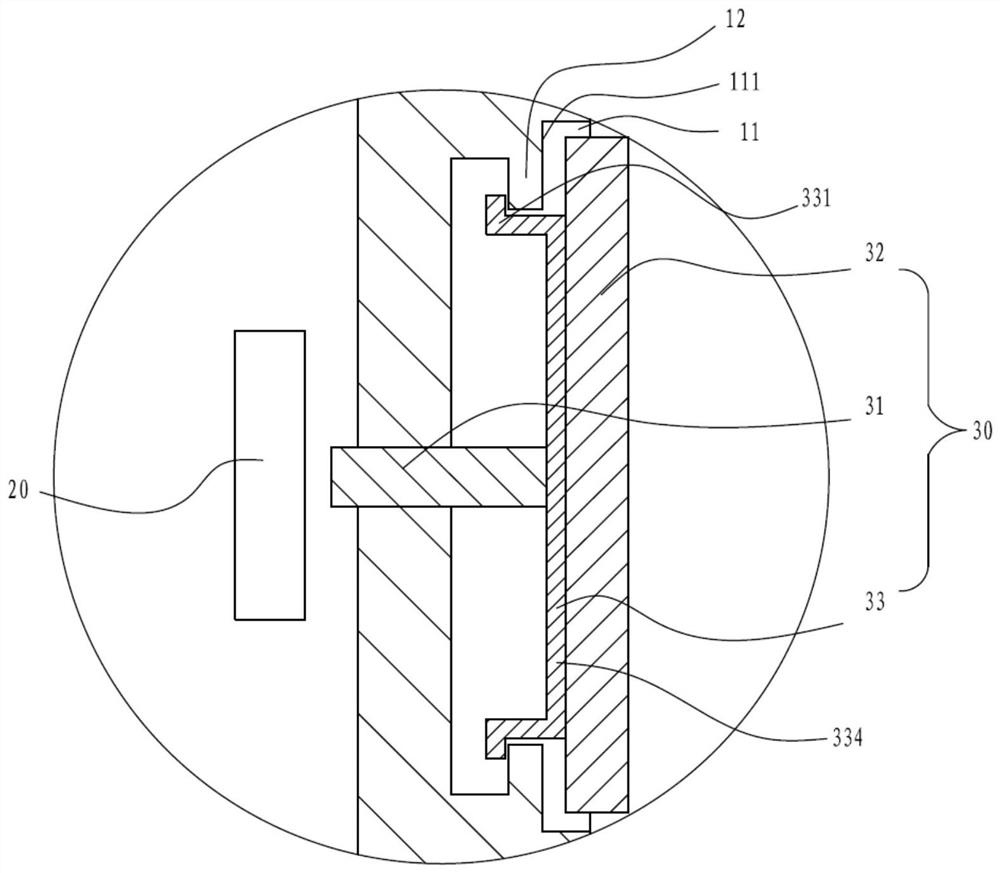

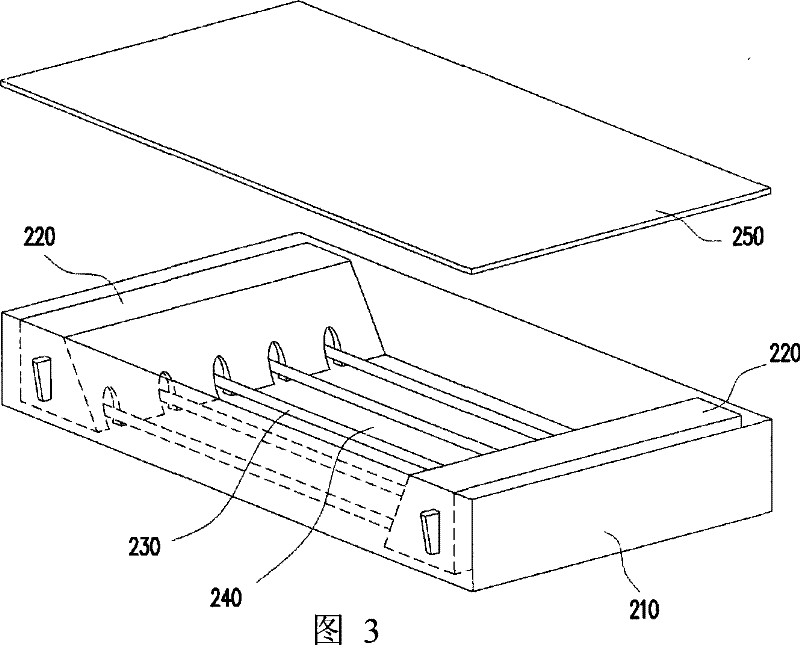

Top cover assembly of secondary battery and secondary battery

ActiveCN109585717AIncrease energy densityGuaranteed reliabilityCell lids/coversElectric connector introductionElectrical batteryElectrical and Electronics engineering

The invention provides a top cover assembly of a secondary battery and the secondary battery. The top cover assembly of the secondary battery comprises a top cover plate, a first electrode terminal, aconnection piece and a sealing piece, wherein the material of the top cover plate is insulation plastic, an electrode leading-out hole is formed in the top cover plate, the first electrode terminal comprises a terminal plate, the terminal plate is arranged at one side of the top cover plate and covers the electrode leading-out hole, a peripheral surface of the terminal plate protrudes out of an inner wall surface of the electrode leading-out hole, the connection piece is connected with the top cover plate and the first electrode terminal, the first electrode terminal is fixedly arranged at the top cover plate by the connection piece, and the sealing piece encircles the electrode leading-out hole and is arranged between the top cover plate and the terminal plate so as to seal the electrodeleading-out hole. By the top cover assembly, the sealing effect of a secondary battery shell is ensured, the occupancy of the internal space of the battery shell is reduced, thus, the energy densityof the secondary battery can be improved, and the application reliability of the secondary battery is ensured.

Owner:CONTEMPORARY AMPEREX TECH CO

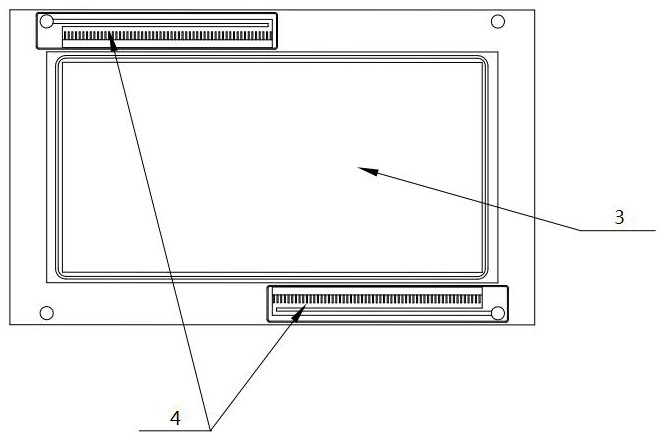

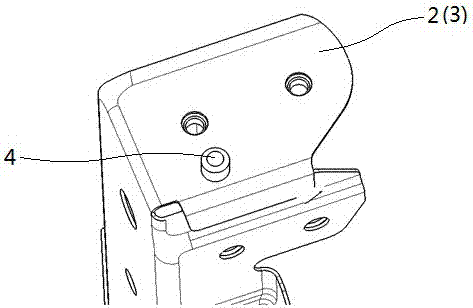

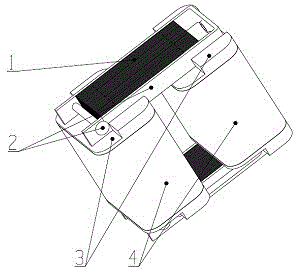

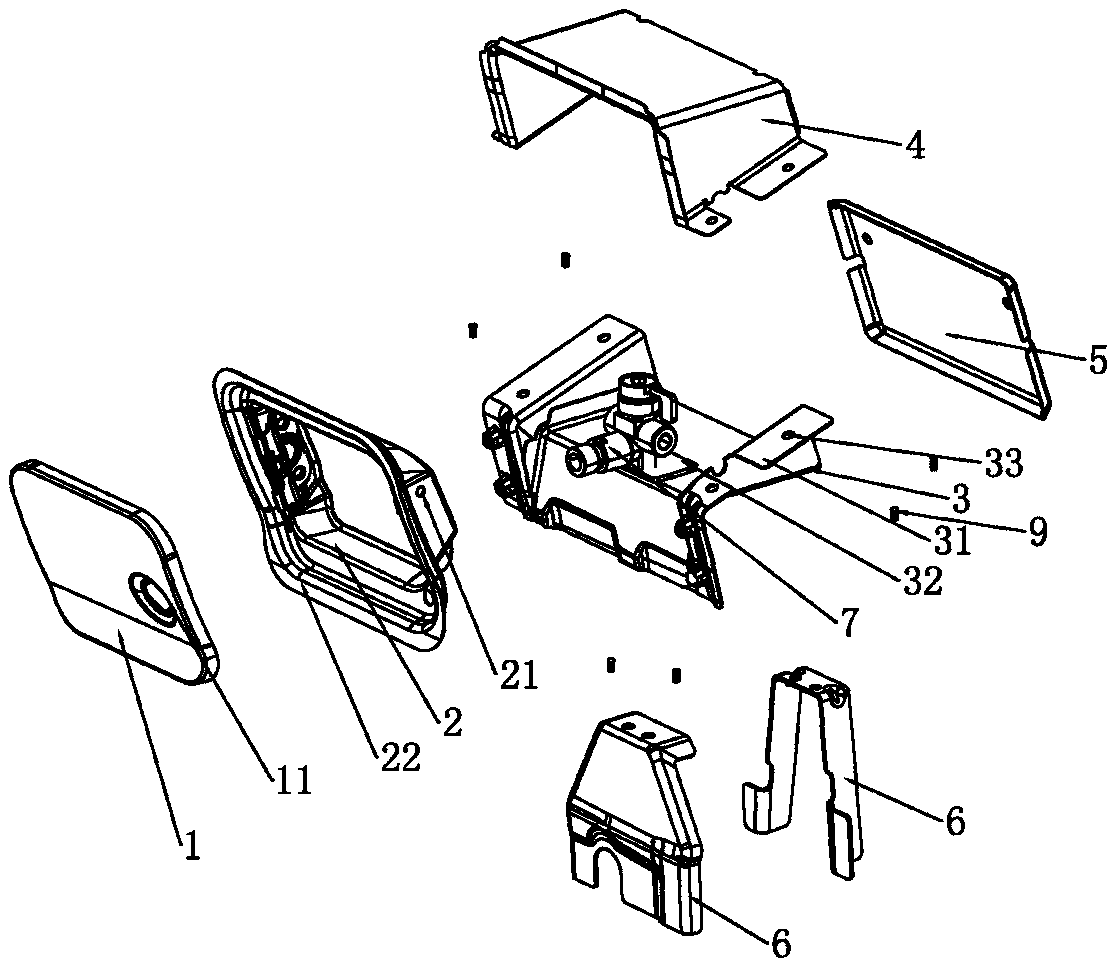

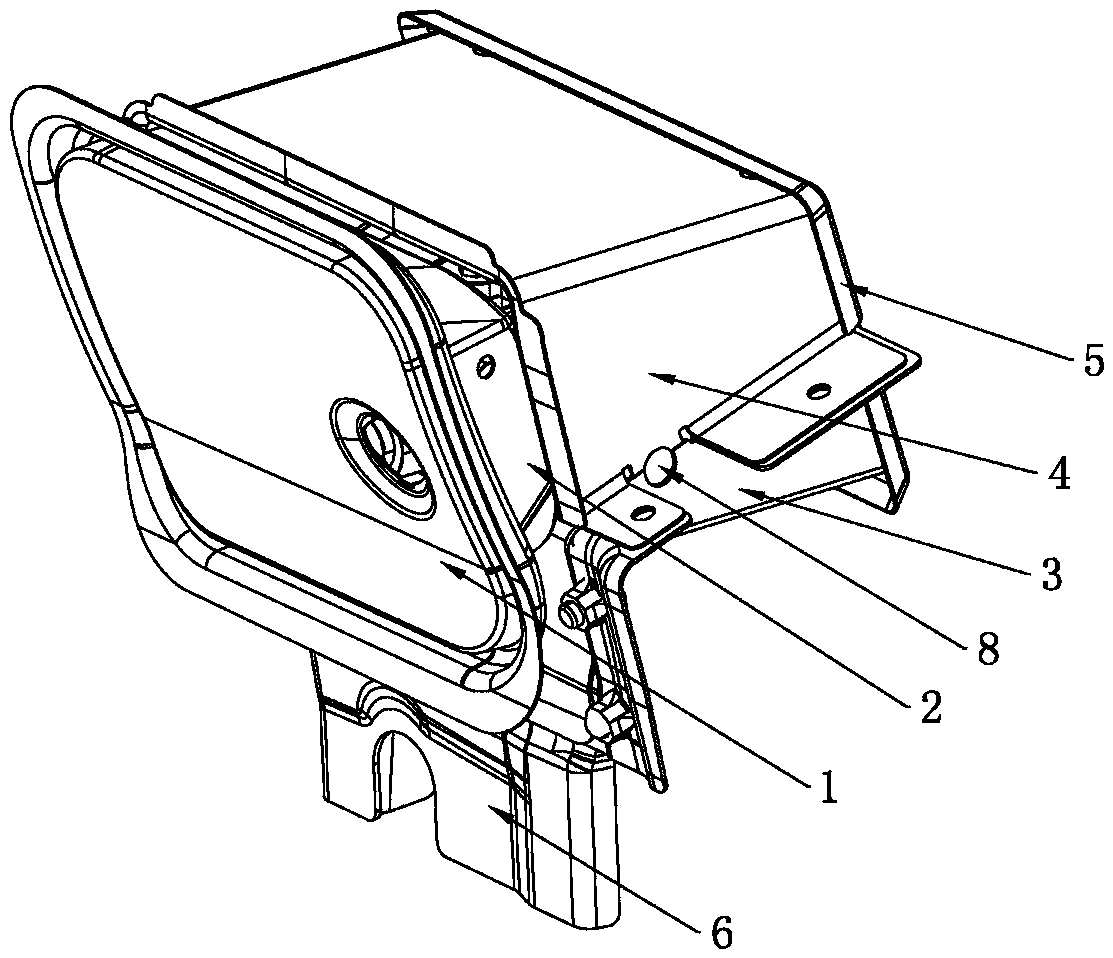

Electronic device

PendingCN113496836AEnsure stabilityImprove stabilityCasings/cabinets/drawers detailsElectric switchesKey pressingFlip-flop

The invention discloses an electronic device which comprises a frame, a signal trigger device fixed on the inner side of the frame and a key installed on the frame in a penetrating mode, the frame is provided with a key hole right opposite to the signal trigger device, and the inner side wall of the key hole is provided with a stop protrusion. The key comprises a key column, a key cap and a clamping plate, wherein the key column penetrates through the frame and is adjacent to the signal trigger device, the key cap is connected with the key column and is matched with the key hole, the clamping plate is buckled to the side, facing the signal trigger device, of the key cap, and the clamping plate is provided with a clamping hook matched with the stopping protrusion in a limiting mode. According to the key structure, the clamping hooks of the clamping plate realize safe limiting and separation prevention of the key cap, and the stability of the clamping plate and the key cap is ensured, so that the stability of the key structure is improved, and the assembly difficulty is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Square lithium ion battery pole anti-rotation structure and manufacturing method thereof

ActiveCN101546814BMeet the requirements of anti-rotation strengthReduce assembly difficultiesSmall-sized cells cases/jacketsCell lids/coversElectrical batterySelf locking

Owner:CHERY AUTOMOBILE CO LTD

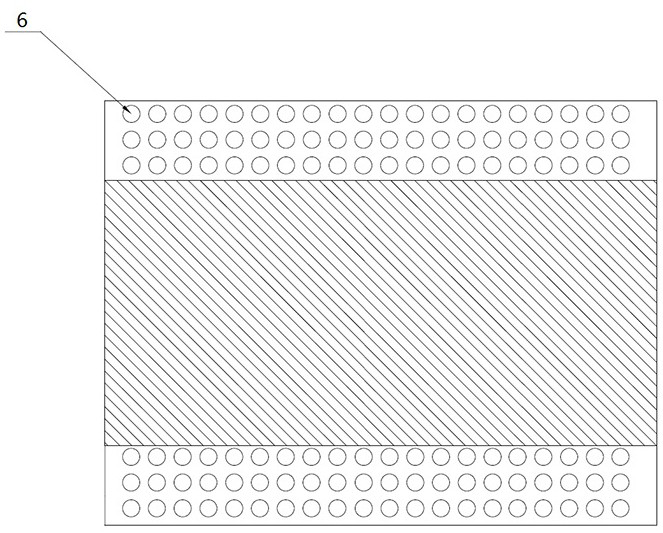

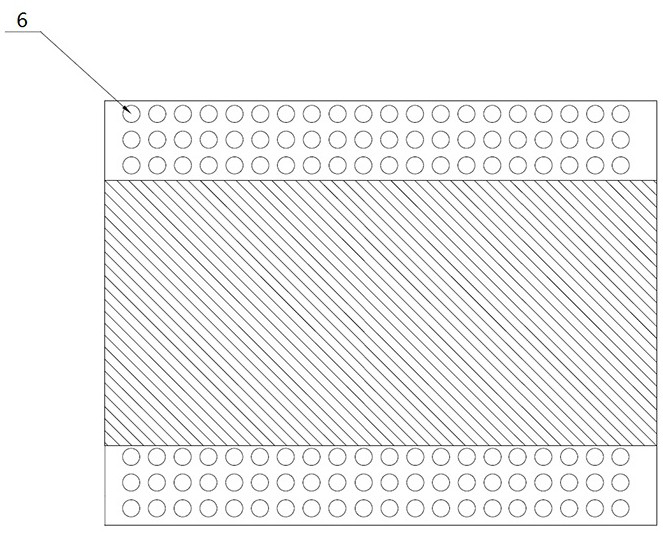

Electrode frame for all-vanadium flow battery

PendingCN108550885AEvenly distributedReduce leakage currentRegenerative fuel cellsIon-exchange membranesEngineering

The invention mainly discloses an electrode frame for all-vanadium flow battery. The technical scheme is as follows: an electrode cavity is arranged in the middle of an electrode frame main body, a positive liquid inlet, a positive liquid outlet, a negative liquid inlet and a negative liquid outlet are respectively arranged at four corners of the electrode frame; the positive liquid inlet is orderly connected with a positive liquid inlet main runner, a positive liquid inlet first sub-runner and a positive liquid inlet interlayer runner; the positive liquid outlet is orderly connected with a positive liquid outlet main runner, a positive liquid outlet first sub-runner and a positive liquid outlet interlayer runner; an ion exchange membrane is arranged at the reverse side of the electrode frame main body; sealing grooves are arranged at the positive liquid inlet, the positive liquid outlet, the electrode cavity and the edges around the ion exchange membrane, sealing strips are arranged at the sealing grooves, and the edges around the ion exchange membrane are fixed through the sealing strips. Through the electrode frame disclosed by the invention, the distribution uniformity of the electrolyte can be improved, the battery reaction efficiency is improved, and the split sealing design reduces the leakage current and the electric pile thickness, the assembling procedure is reduced,the assembling difficulty is lowered, and the electric pile cost is lowered.

Owner:杭州德海艾科能源科技有限公司

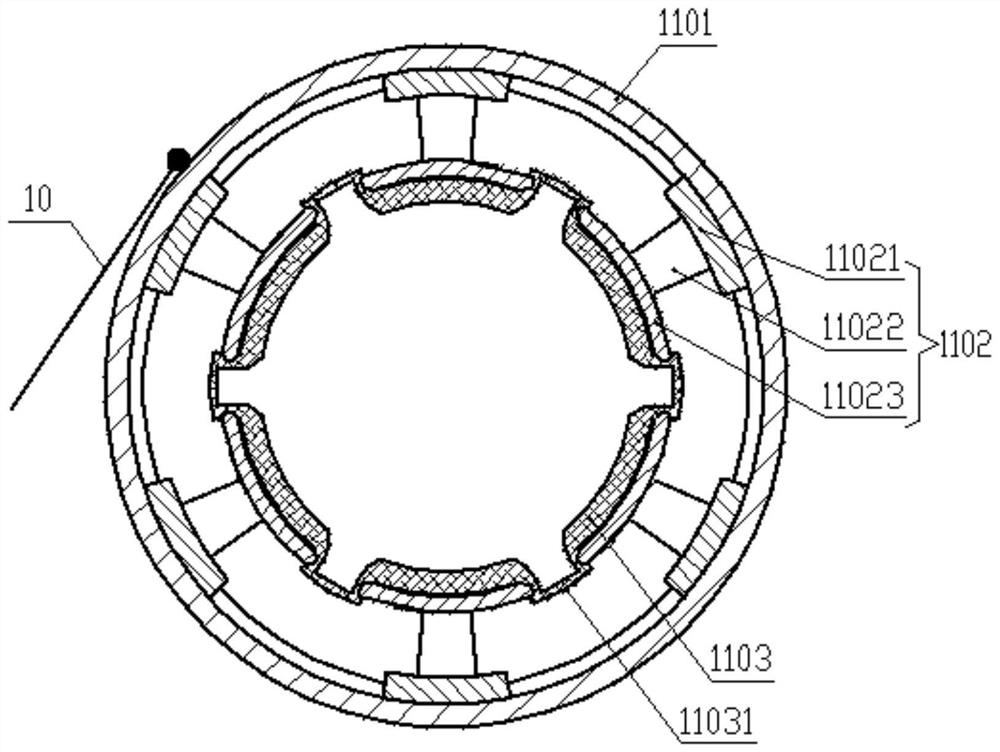

Permanent magnetism aerogenerator and rotor thereof

InactiveCN109842227AConducive to lower positioningReduce positioningMagnetic circuit rotating partsWind energy generationMagnetic polesEngineering

The invention discloses a permanent magnetism aerogenerator and a rotor thereof. A magnet yoke of a rotor includes grooves distributed along the circumferential direction, and the sidewall of each groove includes protruded ribs; the shape of the bottom side of a magnetic pole module matches that of the groove, and one part of the magnetic pole module is embedded into the groove; and a fixation part for compressing the magnetic pole module is arranged on the protruded ribs. The grooves are used to bear the magnetic pole module, the rotor and stator assembling difficulty and the installing and positioning difficulty of the magnetic pole assembly are reduced greatly, the fixation part is used to further fix the magnetic pole module, and the rotor processing difficulty and cost are reduced greatly.

Owner:ZHEJIANG UNIV +1

Vanadium battery spliced conductive plastic bipolar plate

ActiveCN111816886AReduce leakage currentImprove efficiencyCell electrodesRegenerative fuel cellsElectrolytic agentElectrochemical response

The invention relates to a vanadium battery spliced conductive plastic bipolar plate, which comprises a conductive plate and a non-conductive plate, wherein the conductive plate covers an electrochemical reaction area and makes contact with electrolyte in the electrochemical reaction area; the non-conductive plate covers an electrolyte flow channel area and makes contact with electrolyte in an electrolyte flow channel area; the conductive plate is a polymer resin material plate added with a conductive agent, the non-conductive plate is a polymer resin material plate added with a non-conductivematerial, and polymer resin in the conductive plate and polymer resin in the non-conductive plate are the same polymer resin; and the conductive plate and the non-conductive plate are welded throughhot pressing. The polymer resin material plate added with the conductive agent and the polymer resin material plate added with the non-conductive material are spliced to form the spliced bipolar plate, so that the cost is low, the internal leakage current of the battery can be reduced, and the battery efficiency is improved.

Owner:杭州德海艾科能源科技有限公司

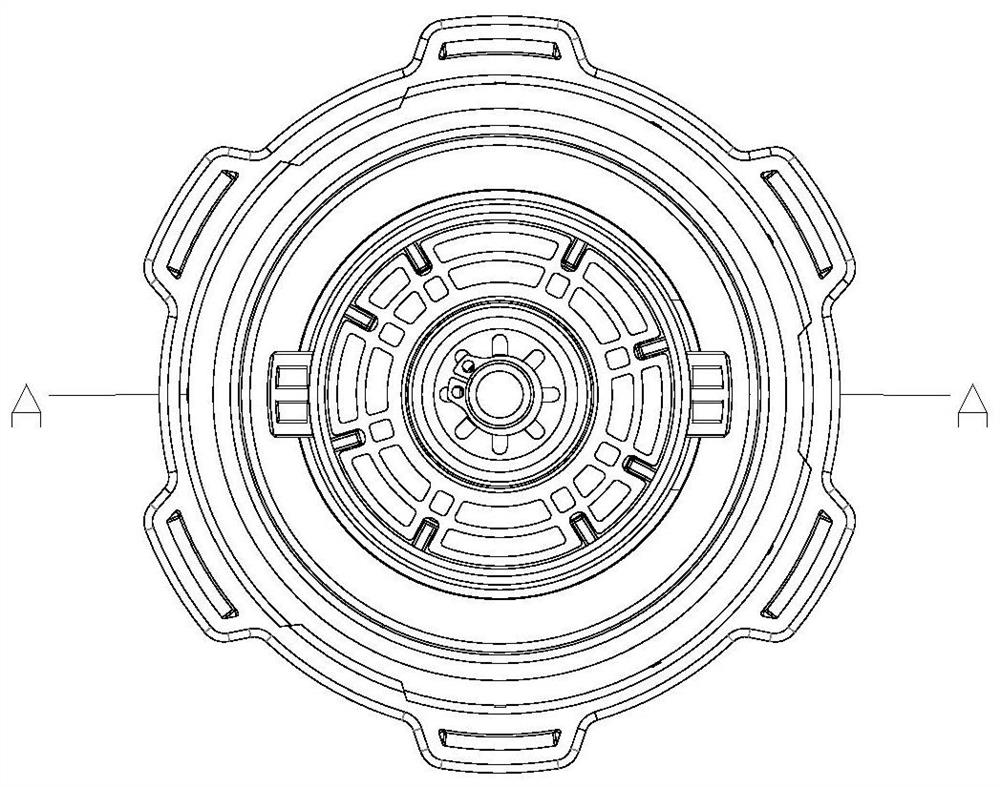

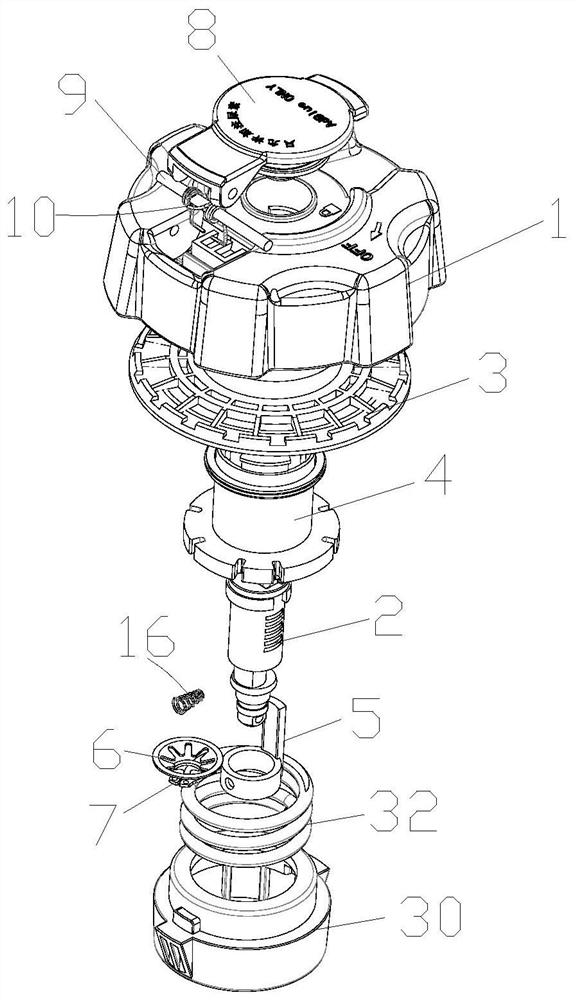

Parallel Shaft Cone Crusher

ActiveCN103691509BGuaranteed parallelismReduce assembly difficultiesGrain treatmentsEngineeringCrusher

The invention discloses a parallel-axis cone crusher. The parallel-axis cone crusher comprises a rack, a main shaft, an eccentric sleeve, a movable cone and a fixed cone, wherein the excircle and the inner hole of the eccentric sleeve are in parallel eccentric structures; the inner hole of the eccentric sleeve and the excircle of the main shaft form a cylindrical friction pair; the lower end of the cylindrical friction pair and the rack form a planar friction pair; the inner hole of the movable cone and the excircle of the eccentric sleeve form the cylindrical friction pair; a planar bearing is arranged at the top end inside the movable cone; the planar bearing and the upper plane of the main shaft form the planar friction pair. The parallel-axis cone crusher disclosed by the invention has the advantages that the excircle and the inner hole of the eccentric sleeve are designed into parallel eccentric structures, and the movable cone and the top of the main shaft are connected by the planar bearing, so that a parallel relationship between a movement axis of the movable cone and the axis of the rack is ensured, and difficulty of machining internal and external angles of the eccentric parts and assembling the components is reduced; and meanwhile, a problem that the conventional cone crusher cannot normally work due to inclined angle changes caused by abrasion with a shaft sleeve in a using process is also avoided.

Owner:HENAN LIMING HEAVY IND SCI & TECH

Earphone

ActiveCN105120408AReliable electrical connectionIncrease contactElectrical transducersEngineeringHeadphones

The invention discloses an earphone, relating to the technical field of electroacoustic products. The earphone comprises an earphone shell and a loudspeaker cover combined together; a loudspeaker unit is contained in a space formed by the earphone shell and the loudspeaker cover in an encircling manner; the earphone further comprises an earphone line for being electrically connected to the loudspeaker unit and audio-frequency equipment; the earphone line and the loudspeaker unit are electrically connected through an elastic sheet component; the elastic sheet component comprises an elastic sheet and a fixing part for fixing the elastic sheet in the earphone shell; the elastic sheet and the fixing part are combined into a whole; one end of the elastic sheet and the earphone line are electrically connected fixedly; and the other end of the elastic sheet and the loudspeaker are electrically connected in a contact manner. According to the invention, the technical problems of low circuit conduction reliability, low assembly efficiency and the like of the earphone in the prior art can be solved; automatic modular assembly of the earphone disclosed by the invention can be realized; and the earphone disclosed by the invention is high in production efficiency, low in production cost, high in working stability and long in service life simultaneously.

Owner:GOERTEK INC

Spliced graphite bipolar plate of vanadium battery

ActiveCN111933963ASimple processReduce assembly difficultiesCell electrodesRegenerative fuel cellsElectrochemical responseHigh polymer

The invention relates to a spliced graphite bipolar plate of a vanadium battery. The bipolar plate comprises a conductive plate and a non-conductive plate, and the conductive plate covers an electrochemical reaction area and an electrolyte in contact with the electrochemical reaction area. The non-conductive plate covers the electrolyte flow channel area and is in contact with the electrolyte in the electrolyte flow channel area, the conductive plate is a conductive graphite plate, the non-conductive plate is a non-conductive high polymer material plate, and the conductive plate and the non-conductive plate are welded through hot pressing. The non-conductive plate is prepared by adding a non-conductive material into a polymer resin material. The conductive graphite plate and the non-conductive polymer material plate are spliced to form the spliced bipolar plate, so that the cost is low, the internal leakage current of the battery can be reduced, and the battery efficiency is improved.

Owner:杭州德海艾科能源科技有限公司

Mounting structure of water tank upper cross beam of automobile

InactiveCN107953768AAvoid the risk of slipping teethPrecise positioningSuperstructure subunitsPropulsion coolingEngineeringWater tanks

The invention relates to a mounting structure of a water tank upper cross beam of an automobile. The mounting structure includes the water tank upper cross beam and is characterized in that the mounting structure further includes a left supporting plate and a right supporting plate, and the water tank upper cross beam, the left supporting plate and the right supporting plate are positioned througha positioning mechanism correspondingly and are detachably connected together to form an upper cross beam mounting assembly; the upper cross beam mounting assembly is connected with a white automobile body; the positioning mechanism comprises composite positioning holes formed in the water tank upper cross beam or in the left supporting plate and the right supporting plate and positioning pins arranged on the left supporting plate and the right supporting plate or the water tank upper cross beam; and the composite positioning holes are matched with the corresponding positioning pins to facilitate initial mounting positioning and repeated disassembly and assembly positioning of the water tank upper cross beam. The mounting structure is simple in structure, convenient to operate and low incost, and accurate composite positioning of the water tank upper cross beam is achieved practically and effectively.

Owner:CHERY AUTOMOBILE CO LTD

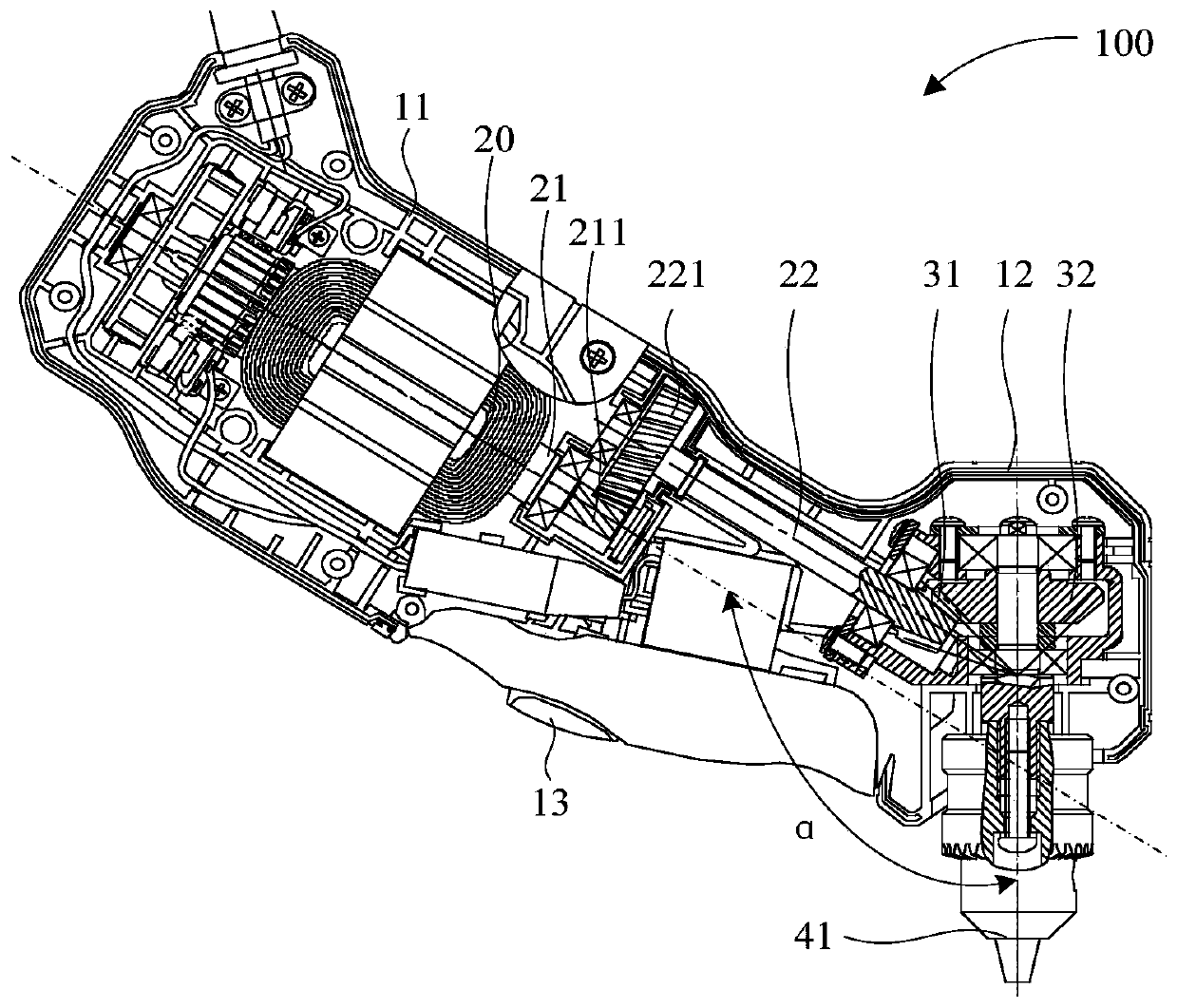

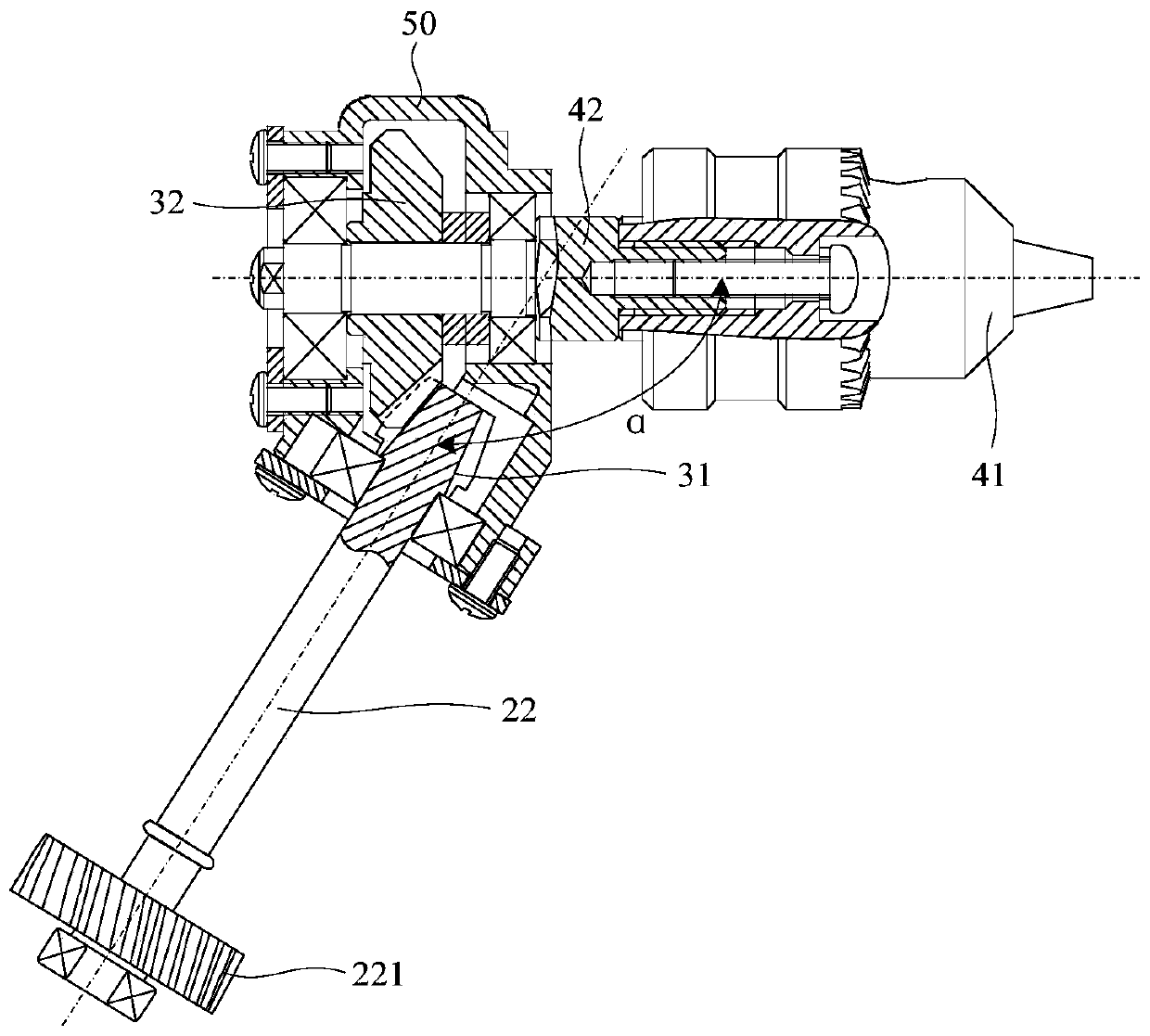

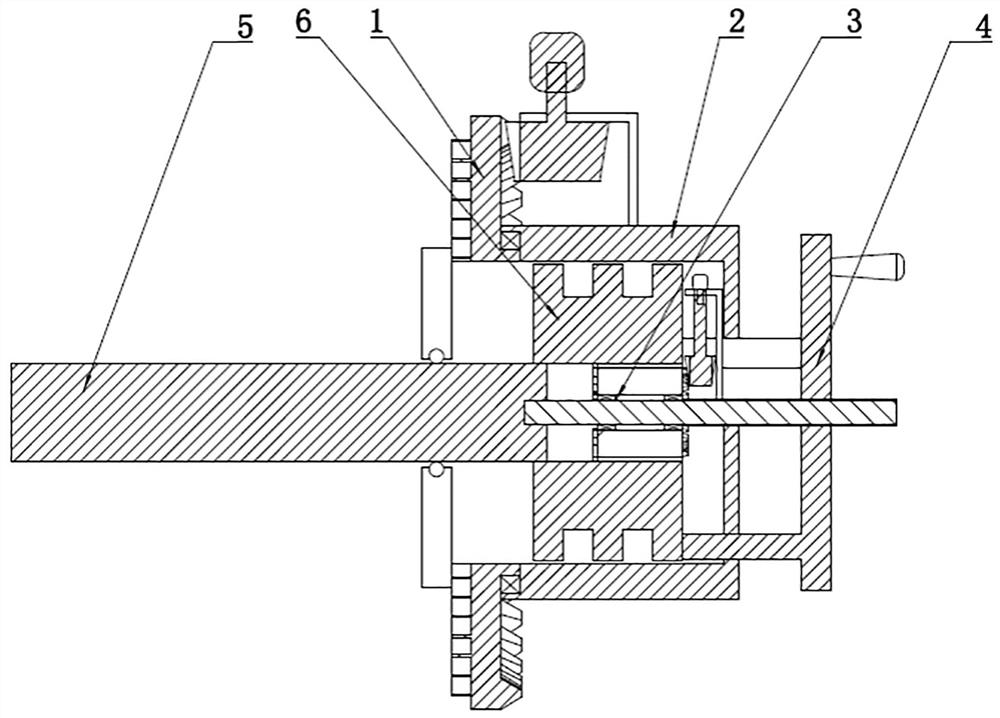

Handheld angle drill

InactiveCN110193618AImprove driving efficiencyReduce axial forceDriving apparatusPortable drilling machinesAxial forcePetroleum engineering

The invention relates to the technical field of electric drills, in particular to a handheld angle drill. The invention aims to solve the technical problems that a transmission mechanism of the handheld angle drill is complex in structure and low in transmission efficiency. For the purpose, the invention provides a handheld angle drill. The handheld angle drill comprises a housing, a driving device, a bevel gear train and a drill bit assembly; the housing comprises a grip housing part and a drill bit housing part; and the driving device is arranged in the grip housing part, the drill bit assembly is arranged at the drill bit housing part and extends out of the drill bit housing part, and the driving device drives the drill bit assembly through the bevel gear train. The driving device in the handheld angle drill drives the drill bit assembly through the bevel gear train, not only the transmission mechanism of the handheld angle drill is simplified, but also the transmission efficiency of the driving device is improved; and meanwhile, the bevel gear train can share part of the axial force of the drill bit assembly, so that the phenomenon that the axial force of the drill bit assemblydirectly acts to the driving device to damage the driving device is reduced.

Owner:ZHEJIANG KAICHUANG ELECTRICAL CO LTD

Normally open overflow drainage sluice structure for small and medium flows

InactiveCN111827212AAdjustable widthReduce assembly difficultiesBarrages/weirsWater dischargeTraction cord

The invention provides a normally open overflow drainage sluice structure for small and medium flows. A sluice valve comprises a central flashboard and two sliding flashboards installed on the two sides of the central flashboard, the bottoms of the central flashboard and the sliding flashboards are provided with a plurality of comb-shaped fixed sluice pieces arranged at intervals. the sides, facing the central flashboard, of the sliding flashboards each are provided with a strip-shaped inserting part, and the other sides of the sliding flashboards are inserted into guide grooves; the insertingparts are inserted into inserting holes in a sliding fit mode, the two sliding flashboards each extend out in the width direction of a base so that sliding sluice pieces which extend out of the inserting holes and in the inserting parts can be automatically popped up downwards; and a friction ring of a winding device is connected to the other end of a traction rope, a circle of friction groove isformed in the inner wall of the friction ring in the circumferential direction thereof, the end, with abrasive resistance, of a friction piece is located in the friction groove and is in close contact with the friction groove, and the other end of the friction piece is fixedly connected to the surface of an air bag. According to the structure, rapid installation and construction of a drainage sluice of a river channel water outlet can be realized, the water drainage amount can be adjusted, and the adaptability is strong.

Owner:陶桂芳

Normally-open overflow drainage sluice structure

The invention provides a normally-open overflow drainage sluice structure. A sluice valve of the normally-open overflow drainage sluice structure comprises a central sluice plate and two sliding sluice plates disposed on the two side of the central sluice plate. The two sliding sluice plates extend out in the width direction of a base respectively. A rod shaped like a walking stick is horizontallydisposed in each sliding sluice plate and is in horizontal sliding fit in the sliding sluice plate. A handle section of each rod inclines towards the upper side of one side of the central sluice plate and is connected with a traction rope. The two traction ropes on the two sides are each wound around a tensioning wheel to be tied onto a reset mechanism that is disposed at the upper end of the central sluice plate. A rope winding device of each reset mechanism comprises two friction rings, a plurality of friction pieces and an air bag, wherein the friction rings are connected with the corresponding traction rope, and when sluice pieces are completely pulled into installing holes where the sluice pieces are located, the friction rings and the air bag rotate relatively. The normally-open overflow drainage sluice structure can be rapidly installed and constructed at a riverway outfall to resist large water flow impact, and the normally-open overflow drainage sluice structure has flexibleand selectable working mechanism and high adaptability.

Owner:陶桂芳

Current transformer wide in measurement range

InactiveCN104576008AImprove anti-magnetic saturationImprove abilitiesTransformersTransformers/inductances magnetic coresLarge sizeSilicon

The invention relates to the technical field of current transformers, in particular to a current transformer wide in measurement range, aiming at overcoming the defects of large size and poor magnetic saturation resistance of existing current transformers. The current transformer wide in measurement range comprises an iron core and coils and is characterized in that the iron core is made of four strip-shaped oriented silicon steel sheets with two ends free of punched holes and formed by stacking the four silicon steel sheets integrally in a staggered manner, the coils are wound around coil skeletons of a fixing device, and the current transformer is subjected to integral paint dipping treatment. The current transformer wide in measurement range has the advantages that the magnetic saturation resistance of the current transformer for a reclosure molded case circuit breaker or an electronic type molded case circuit breaker is improved greatly; the four silicon steel sheets are stacked together and then assembled integrally in a staggered manner, so that assembly difficulty of the strip-shaped silicon steel sheets is lowered.

Owner:CNC ELECTRIC GRP

A split type air filling seat

ActiveCN105109560BBreak through the processing bottleneckEasy to operateSuperstructure subunitsProduction lineEngineering

The invention relates to a split-type gas filling port seat, which is assembled into a sealed seat body with a cavity by a plurality of disassembled parts, and the parts specifically include a gas filling valve seat and a cover fixedly installed on the side plate of the floor The upper cover, the rear cover, the connecting seat fixed on the outer panel of the side wall, and the front cover above the air filling valve seat; the front cover has an air filling port; the air filling valve seat and the upper cover form a The side wall of the mouth, the rear peripheral surface of the connecting seat is provided with an axially protruding flange, the flange passes through the floor side plate and is inserted into the side wall, the front cover closes the front end of the connecting seat, and the rear cover closes the side wall backend. In this structure, the gas filling port seat is designed as a structure that can be disassembled into multiple parts. When installing or replacing the gas filling valve, the upper upper cover and the rear rear cover can be removed to make the operation more convenient; the gas filling valve seat and the upper The covers are connected by longitudinal bolts, which reduces assembly difficulties and breaks through the bottleneck of production line processing to improve production efficiency.

Owner:XIAMEN GOLDEN DRAGON AUTO BODY

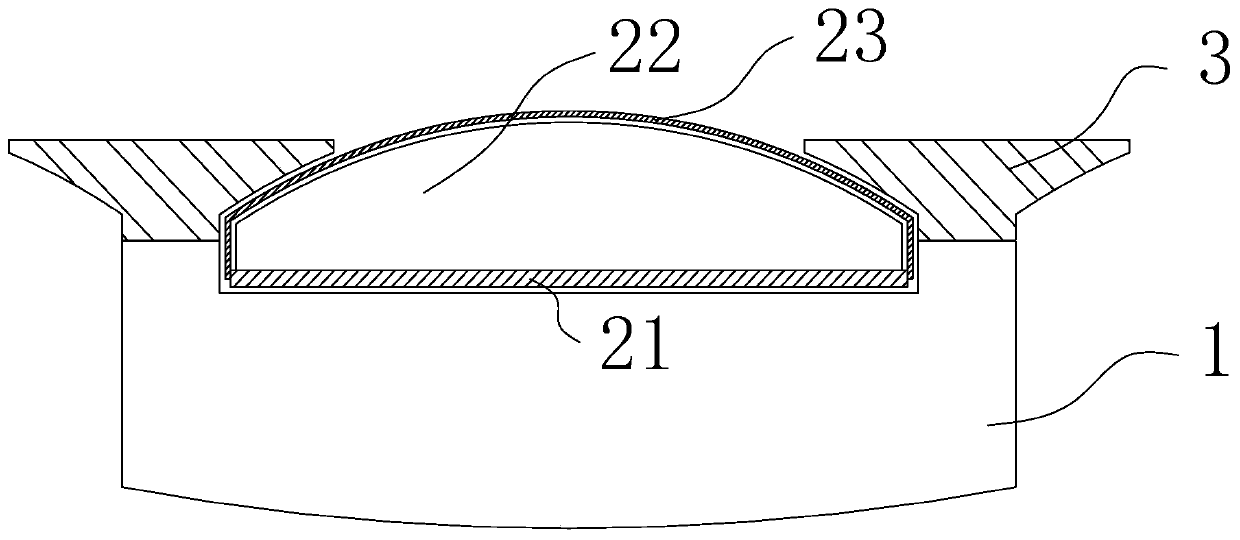

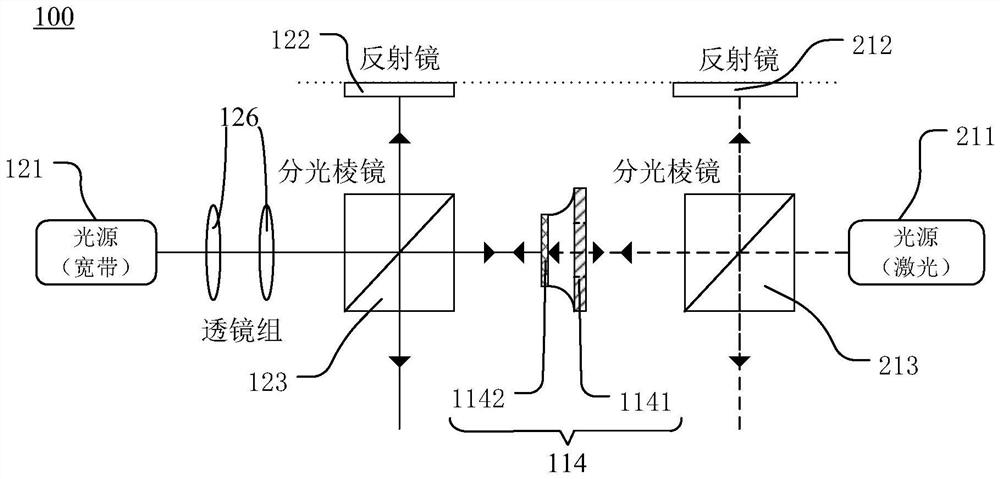

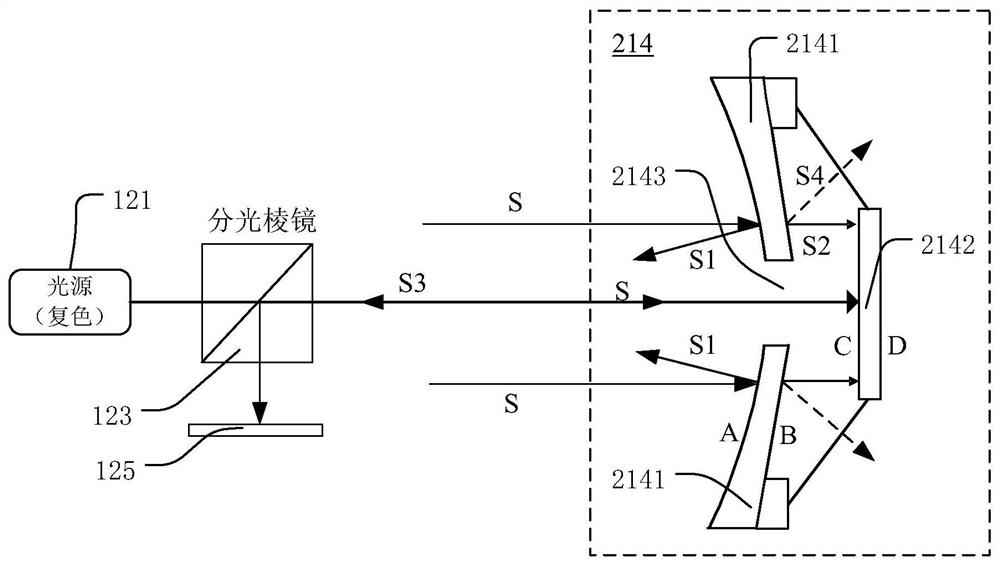

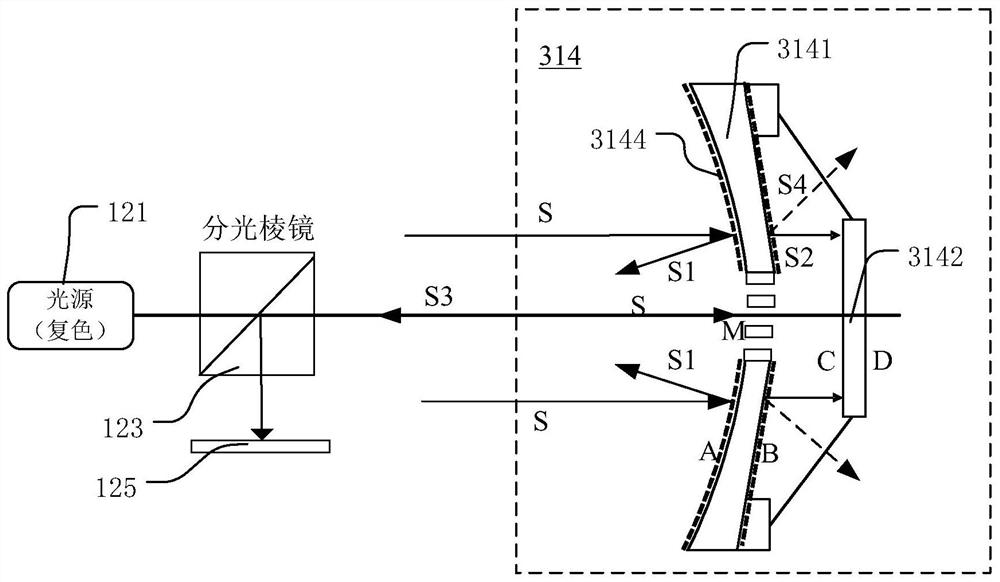

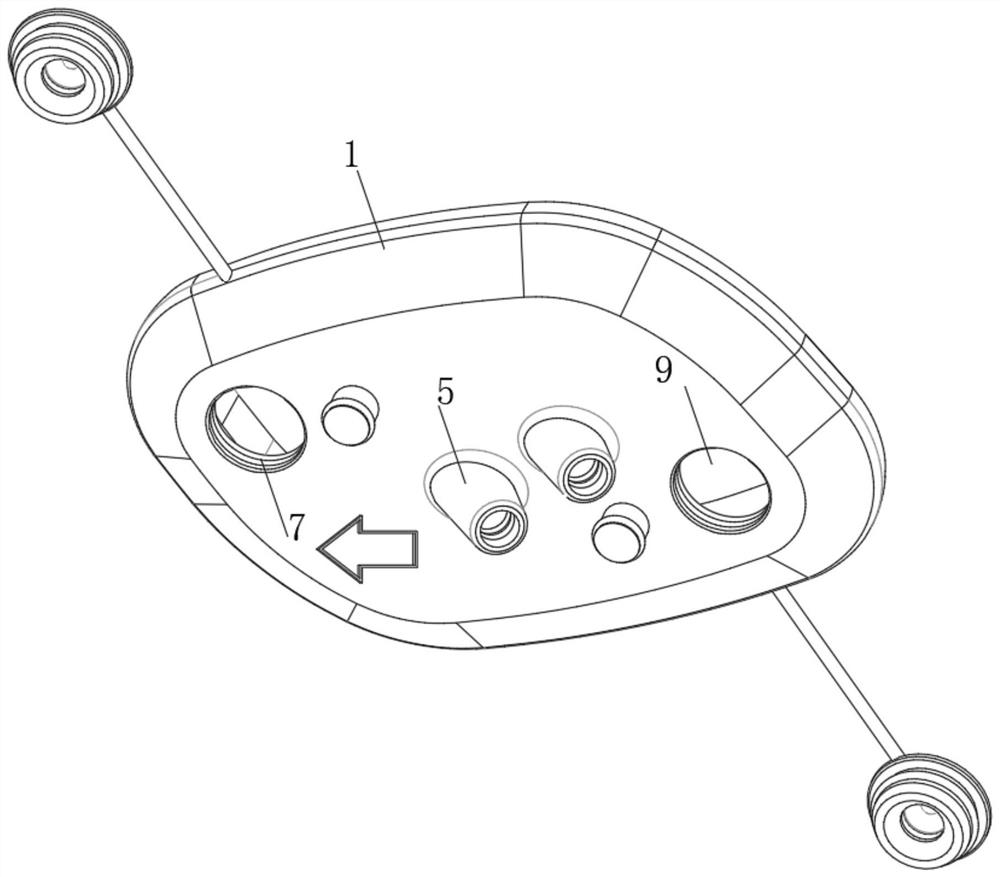

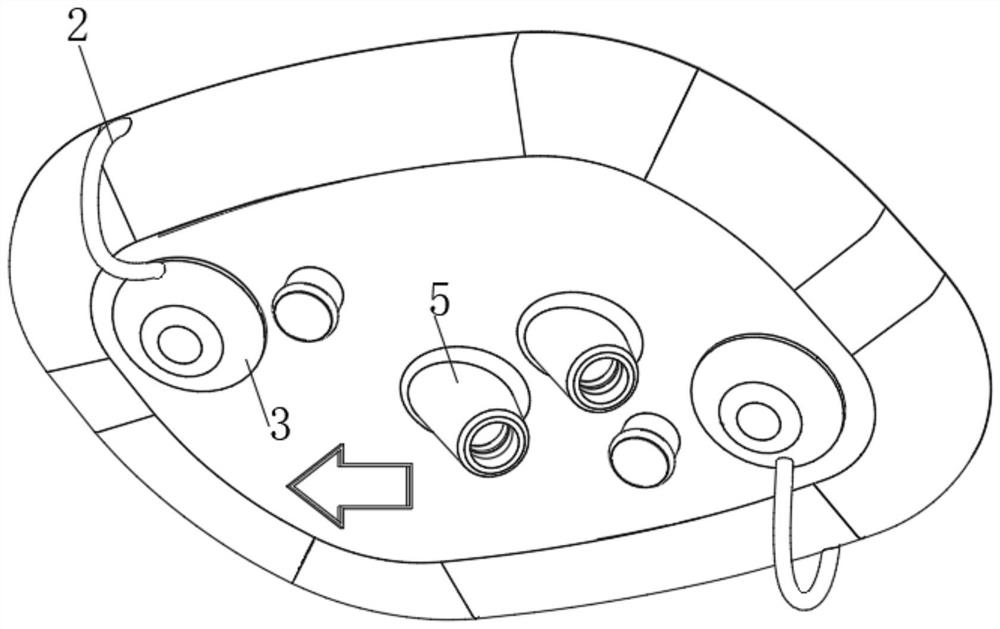

mems micromirror, Michelson interference system and optical system

ActiveCN112859325BSimple structureSmall sizeInterferometric spectrometryOptical elementsOptic systemMaterials science

Disclosed are a MEMS micromirror, a Michelson interference system and an optical system. The MEMS micromirror includes a substrate and a mirror surface structure, the mirror surface is located on one side of the substrate, and the first surface of the MEMS micromirror is connected to the first surface of the substrate. A gap is formed between them, wherein the incident light emitted by the light source is irradiated on the second surface of the substrate, the first part of the incident light is reflected by the second surface of the substrate to form the first reflected light, and the second part of the incident light passes through the second surface of the mirror structure. A surface is reflected to form the second reflected light, and the first reflected light and the second reflected light are coupled to form the first interference light. The interference system is based on the characteristics of the surface reflection of the MEMS chip and the surface reflection of its substrate. The light reflected by the immobile substrate in the MEMS micromirror is coupled with the light reflected by the moving mirror structure to form an interference light path, which meets the interference requirements of the Michelson system. Furthermore, the arrangement of the fixed mirror is reduced, the optical path assembly efficiency of the interference system is effectively improved, and the cost of the optical structure is greatly reduced.

Owner:无锡微文半导体科技有限公司

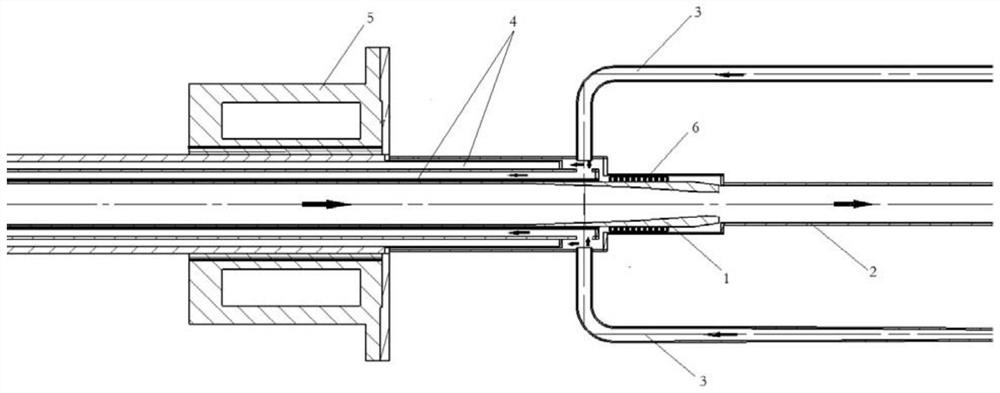

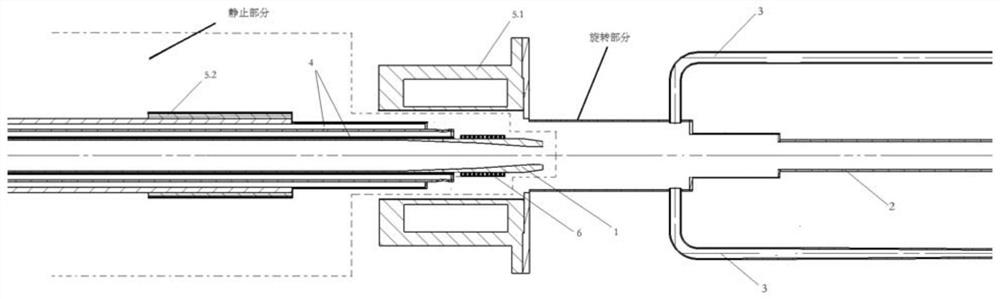

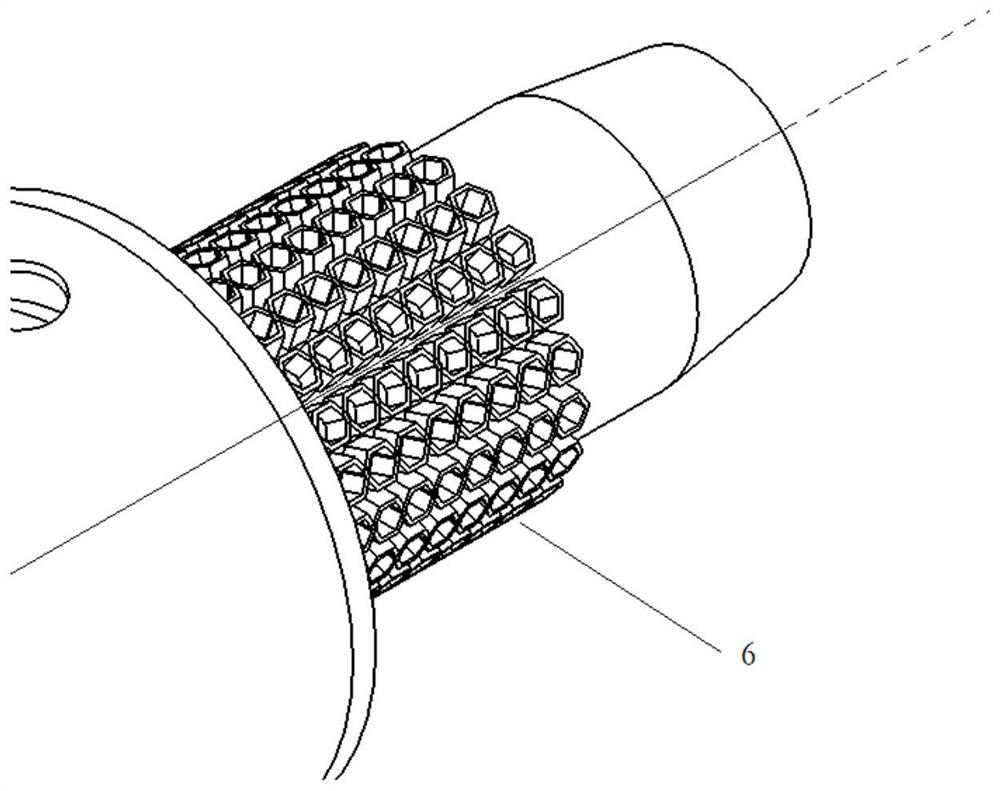

A Low-Temperature Helium Transport Sealing Structure for a Superconducting Rotary Machine

ActiveCN109340379BGuaranteed magnet coolingGuaranteed no change in magnet coolingEngine sealsDynamo-electric machinesThermodynamicsEngineering

The invention relates to a low temperature helium transmission sealing structure of superconductive rotating machinery. The structure comprises stationary air inlet pipes, a rotary air inlet pipe andan air return pipe. The stationary air inlet pipes are inserted into the rotary air inlet pipe and arranged in a spaced manner; the outlet end of each stationary air inlet pipe is a cone, the diameterof which is diminishing, along a low temperature helium feeding direction; and a honeycomb sealing structure for preventing leakage of the low temperature helium is arranged between each stationary air inlet pipe and the rotary air inlet pipe. The sealing structure adopts a primary sealing-back-step structure to reduce the pressure of the low temperature helium introduced to a leaking gap and achieves a low leakage rate at the leaking gap by a secondary honeycomb structure. The two sealing structures are easy to manufacture and process, so that the progress of engineering of the superconductive rotating machinery is accelerated effectively.

Owner:TONGJI UNIV

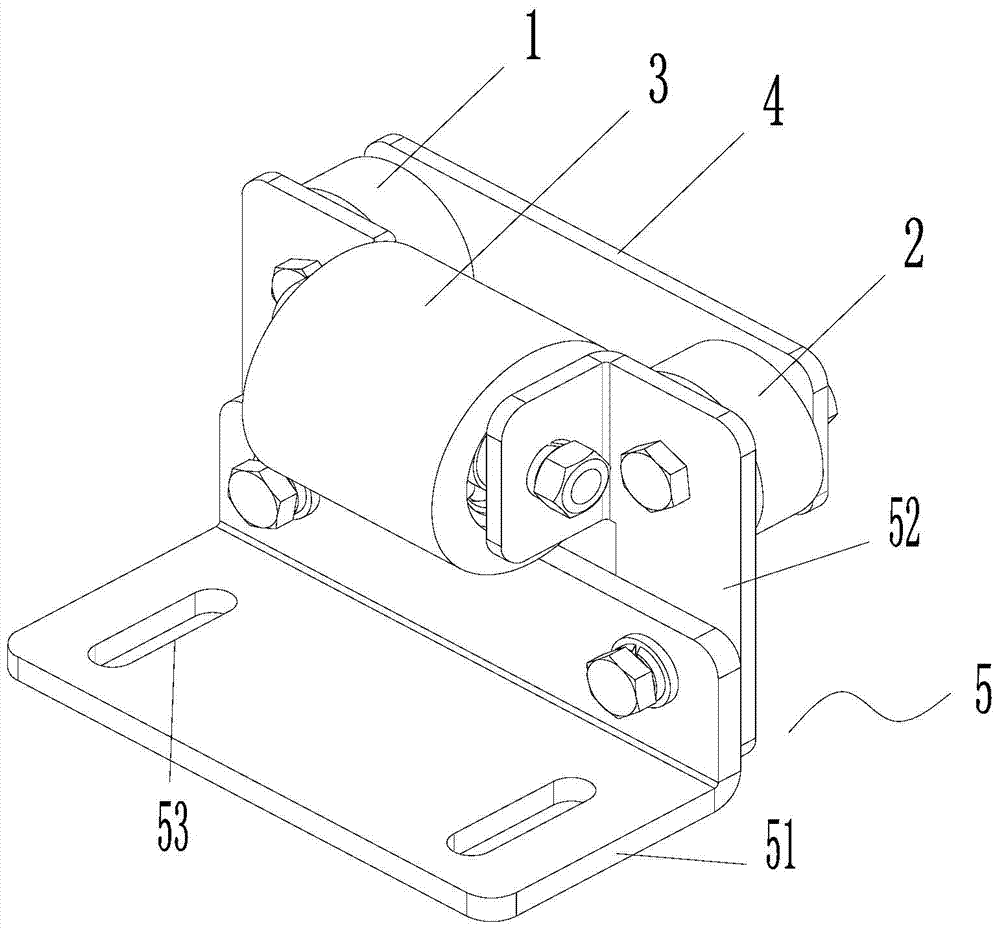

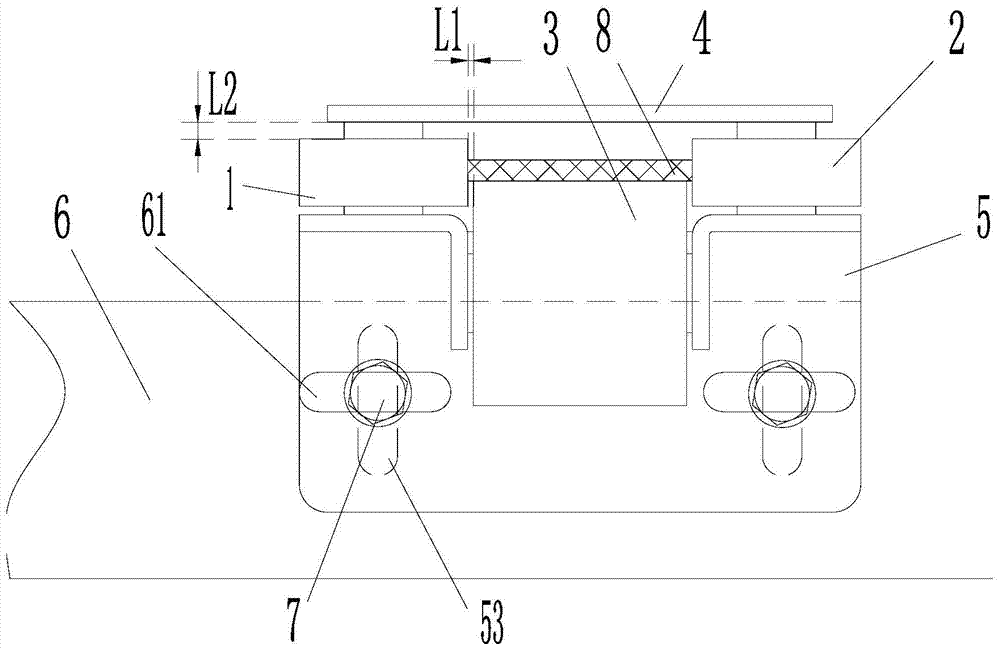

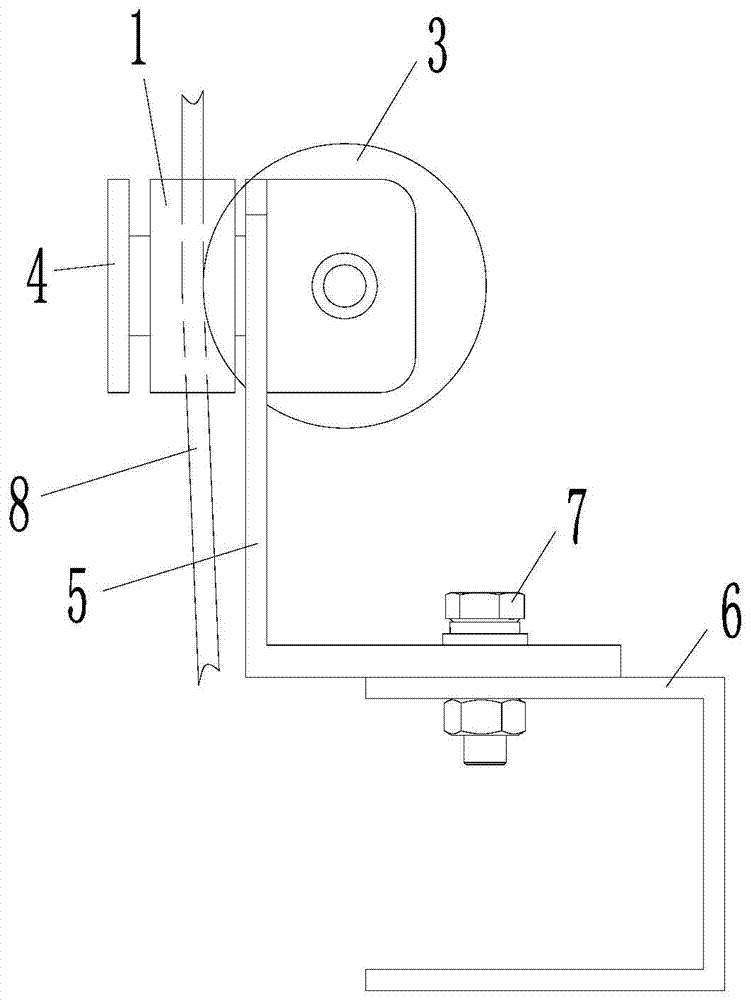

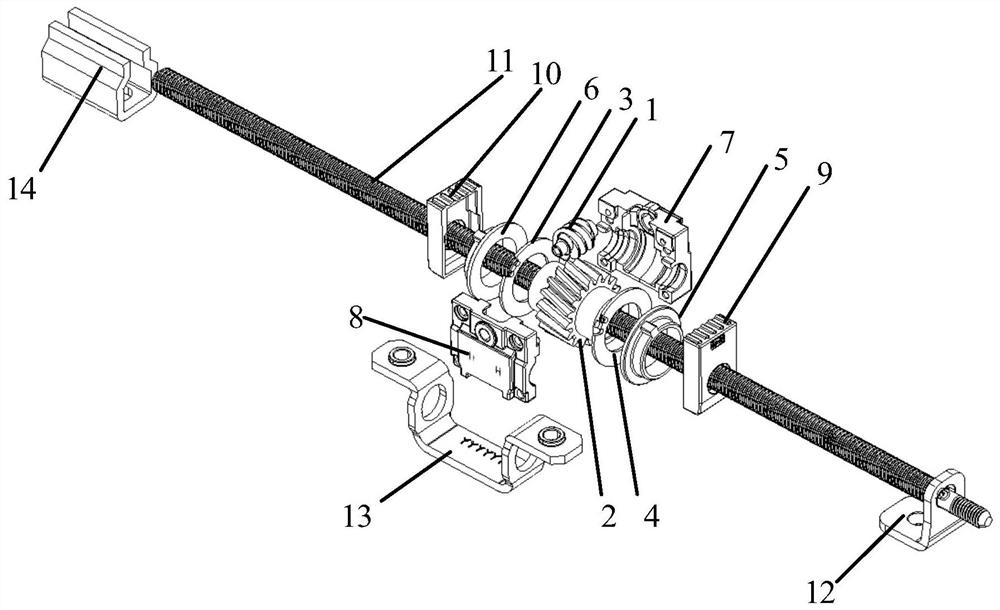

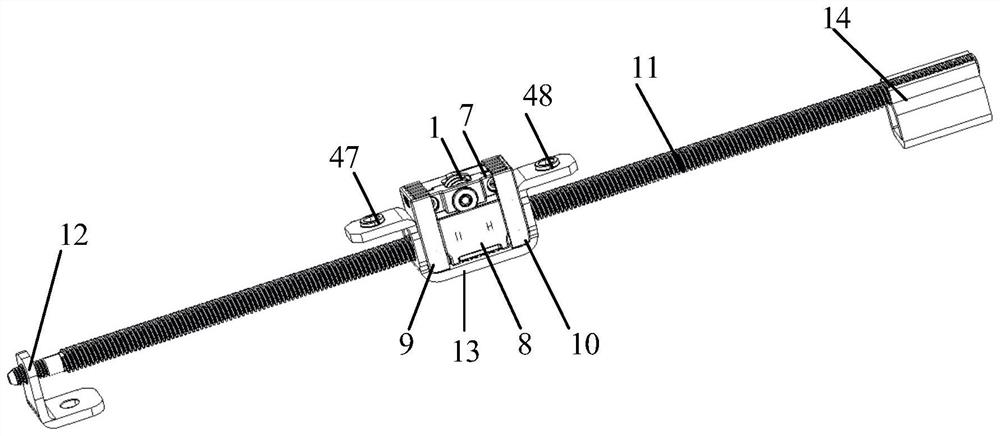

Deviation correcting device for elevator traction belt

The invention discloses a correcting device for an elevator traction belt. The device is characterized by comprising a mounting seat, a first roller, a second roller and a compressing roller; the first roller, the second roller and the compressing roller are arranged on the mounting seat; the outer round surfaces of the first roller and the second roller, at two sides of a traction belt to be corrected are limited to offset in the width direction; the positions of the outer round surfaces of the compressing roller, close to the surface of the traction belt to be corrected apply a pressure in the thickness direction. With the adoption of the correcting device for the elevator traction belt, the offset of the traction belt in running can be corrected, the verticality of the traction belt moving in and out of a belt pulley and a pulley axis is ensured, and the traction belt is prevented from being offset and damaged.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

A vanadium battery splicing conductive plastic bipolar plate

ActiveCN111816886BReduce leakage currentImprove efficiencyCell electrodesRegenerative fuel cellsElectrolytic agentElectrochemical response

Owner:杭州德海艾科能源科技有限公司

Device and method for installing collector ring of generator of wind turbine generator

PendingCN113364224AHigh precisionEasy to installManufacturing dynamo-electric machinesWind energy generationElectric generatorGenerating unit

The invention provides a collector ring mounting device for a generator of a wind generating set. The collector ring mounting device is convenient to assemble and disassemble and simple in structure. The device is characterized in that the device comprises a centering device, a sheath, a pushing and disassembling device and a handle, wherein one end of the sheath is rotationally connected to the centering device, the pushing and disassembling device is arranged on one side of the sheath, and the handle is fixedly connected to the pushing and disassembling device; the centering device is provided with a through hole; the protective sleeve is arranged on the collecting ring in a sleeving manner; the centering device and the sheath are coaxial; a supporting device is arranged at one end of the collecting ring; the supporting device penetrates through the sheath and is in sliding connection with the sheath; the supporting device is in threaded connection with the pushing and unloading device; the supporting device and the sheath are coaxial; and the centering device is sleeved on the generator shaft. By adopting the centering device, the repeated centering work of assembling, loading and then pulling out caused by difficult assembling in interference fit and inaccurate centering in the assembling process is avoided, the working time is shortened, and the working efficiency is improved.

Owner:HEBEI SUNTIEN NEW ENERGY TECH

Reinforced horizontal adjusting device and automobile electric seat comprising same

PendingCN113043923AHigh tensile strengthImprove the safety of useMovable seatsEngineeringStructural engineering

The invention discloses a reinforced horizontal adjusting device and an automobile electric seat comprising the reinforced horizontal adjusting device. The reinforced horizontal adjusting device comprises a first external box body and a second external box body which are arranged outside, the first external box body is provided with a threaded hole, a through hole is formed in the corresponding position of the second box body, and the position, where the threaded hole is located, of the first external box body is provided with a thickening part protruding outwards; and the position of the through hole of the second external box body is provided with a thinning part which is sunken inwards. Under the condition that the overall structure size is not increased, a purpose of improving the tensile strength of the first outer box body and the second outer box body is achieved, and use safety and reliability of the automobile electric seat sliding rail are improved; and heat dissipation openings are added, so the heat dissipation performance is improved. An over-positioning structure is achieved, so the tolerance compensation effect is achieved, and the probability of assembly difficulty caused by machining errors is reduced.

Owner:SEENPIN PROD ZHEJIANG

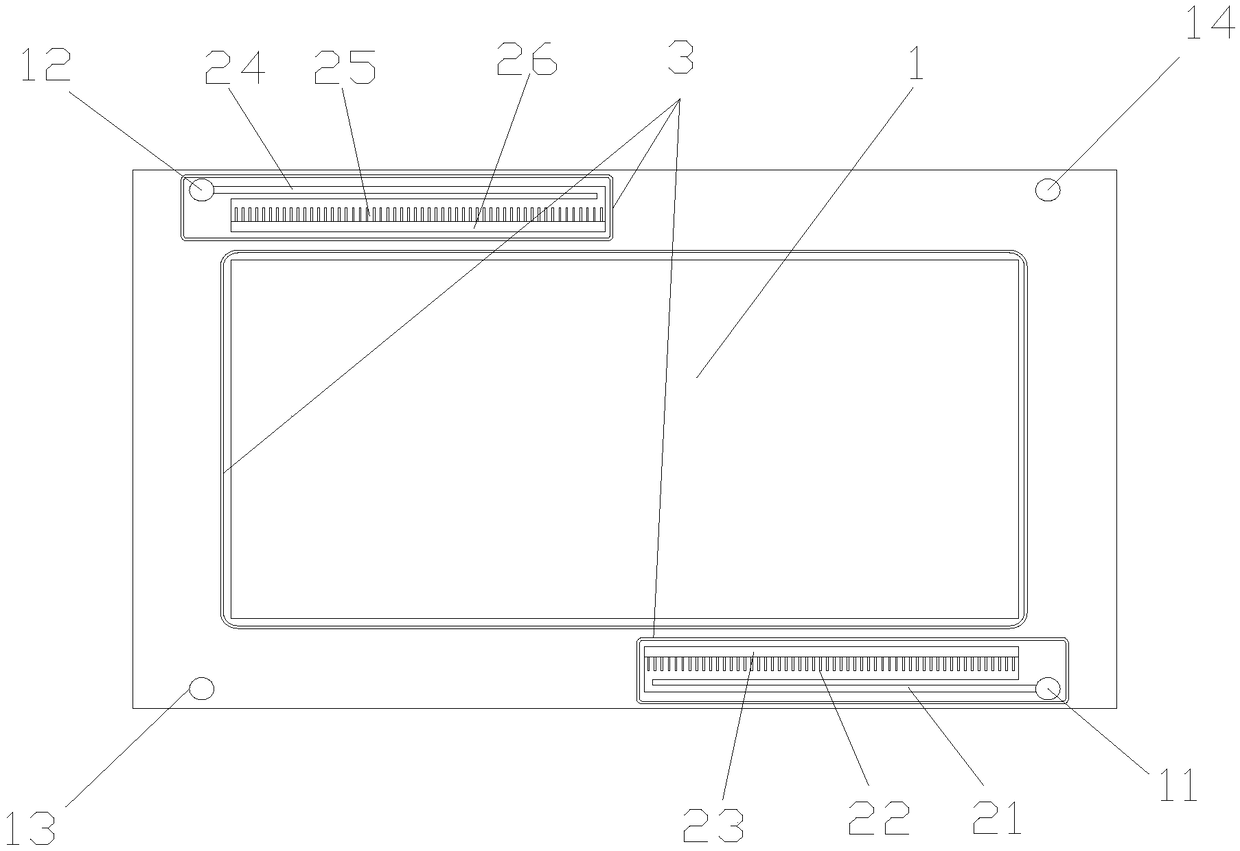

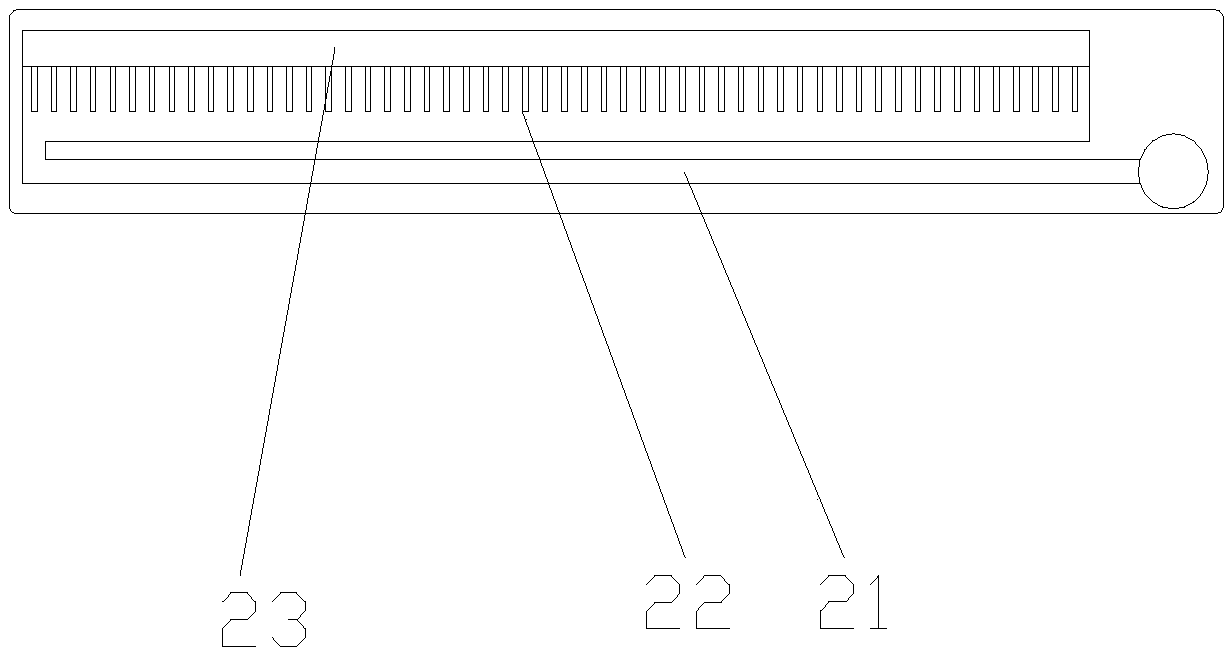

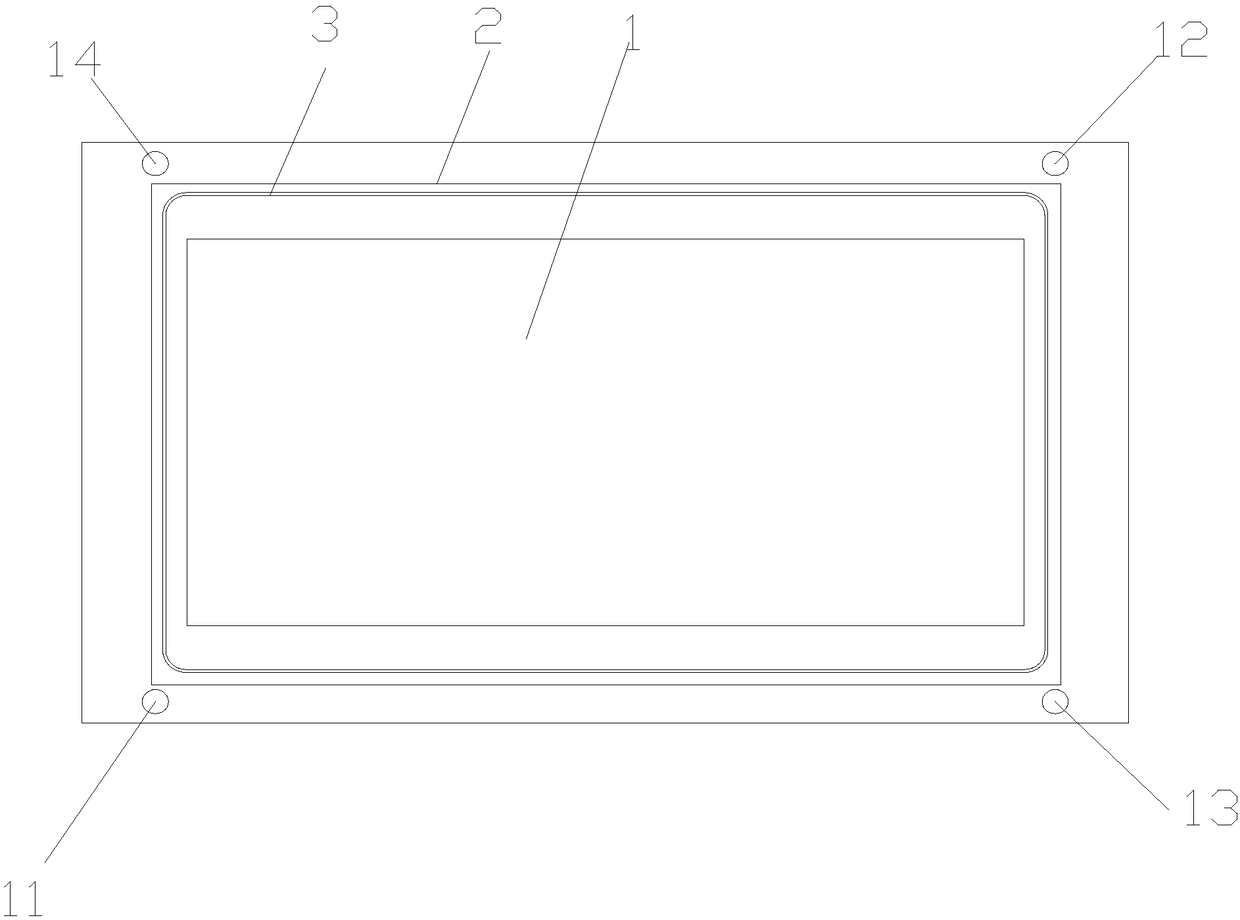

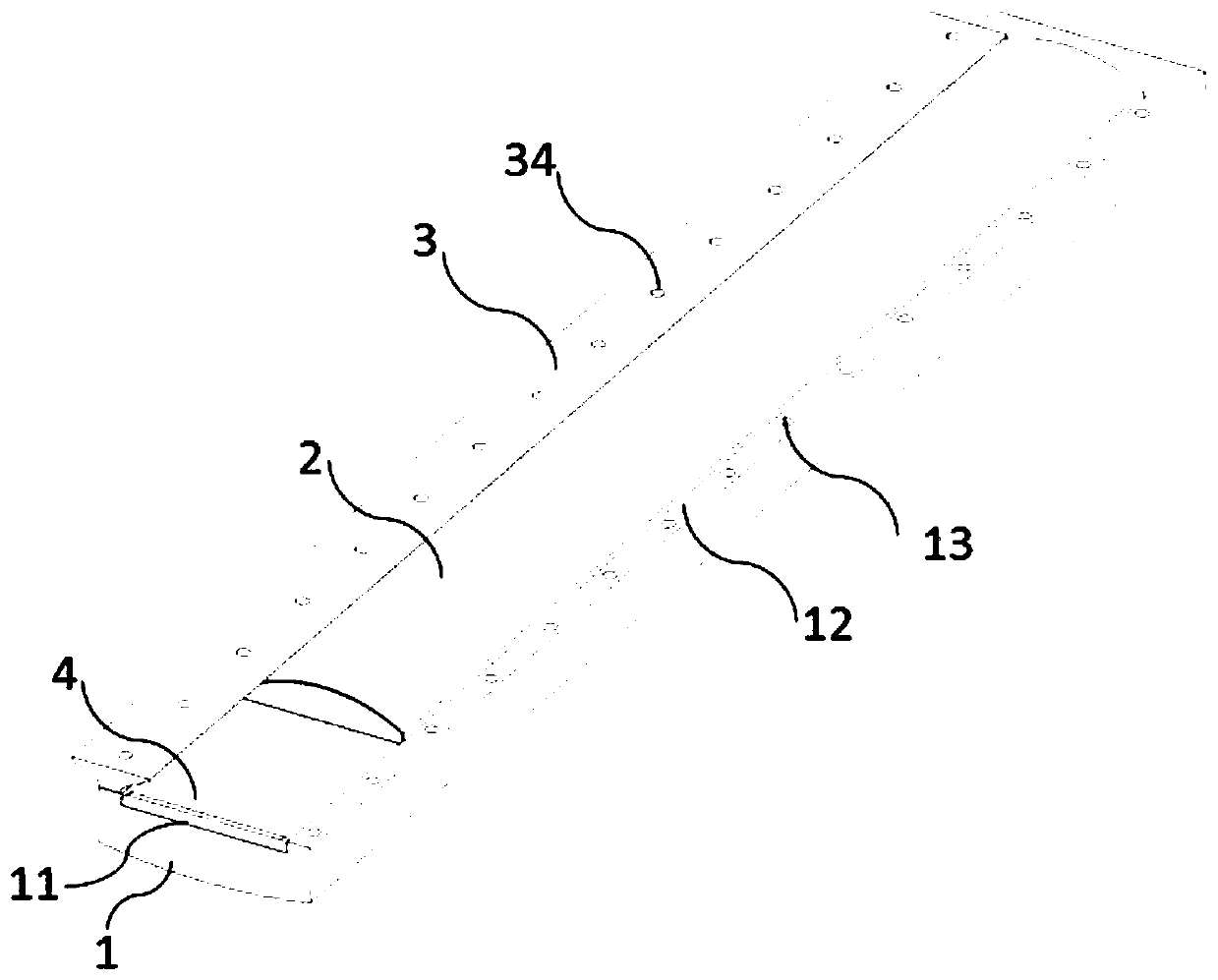

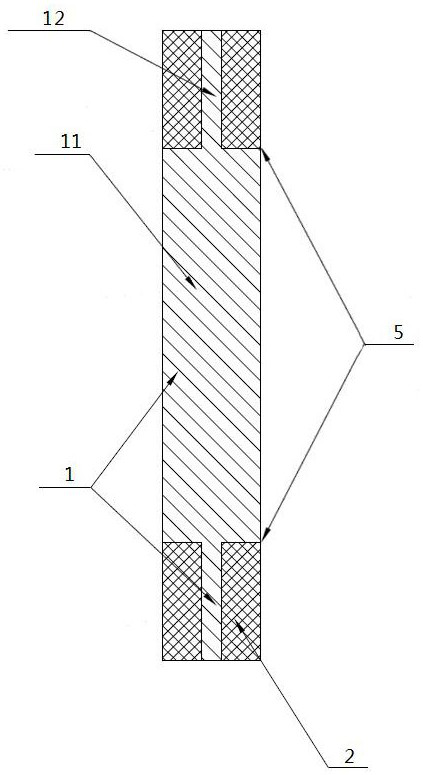

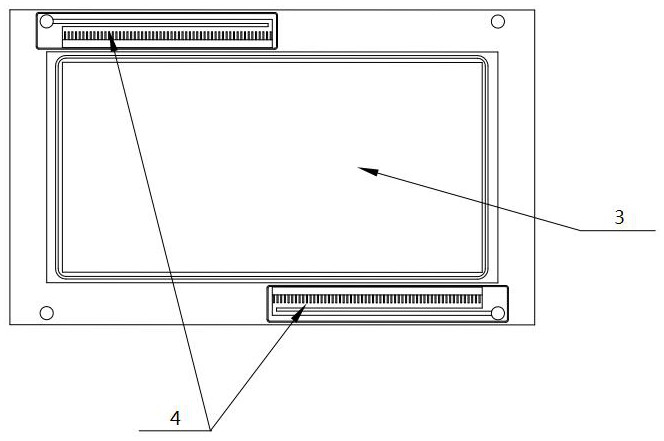

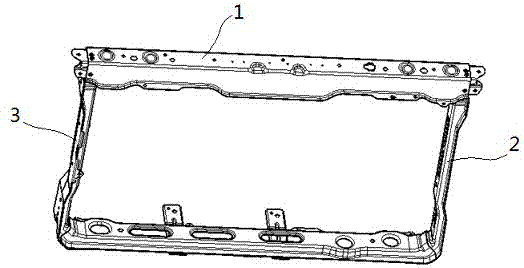

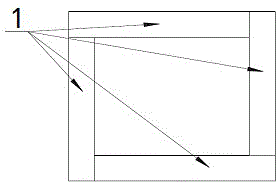

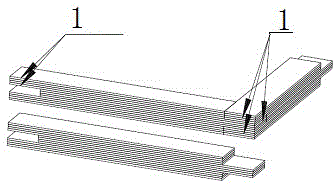

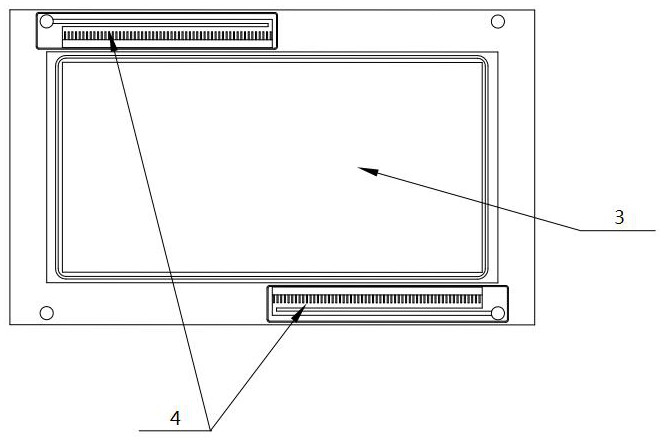

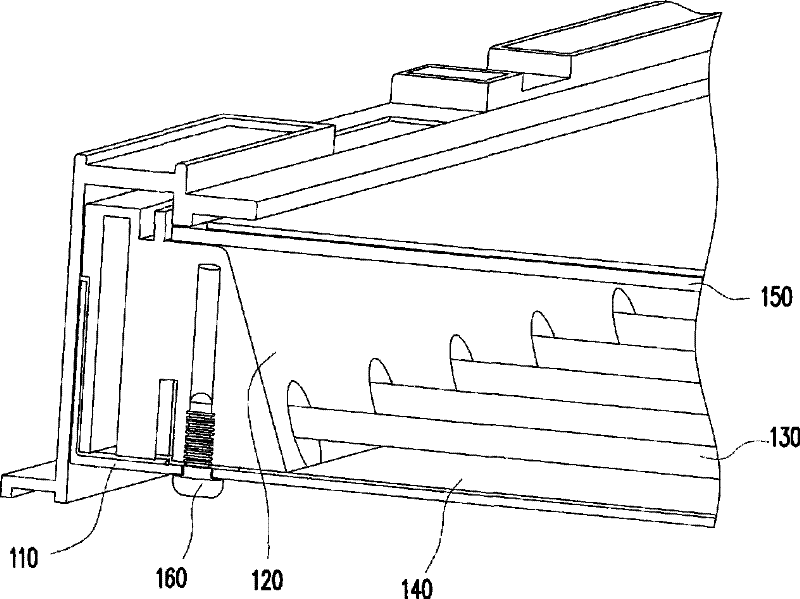

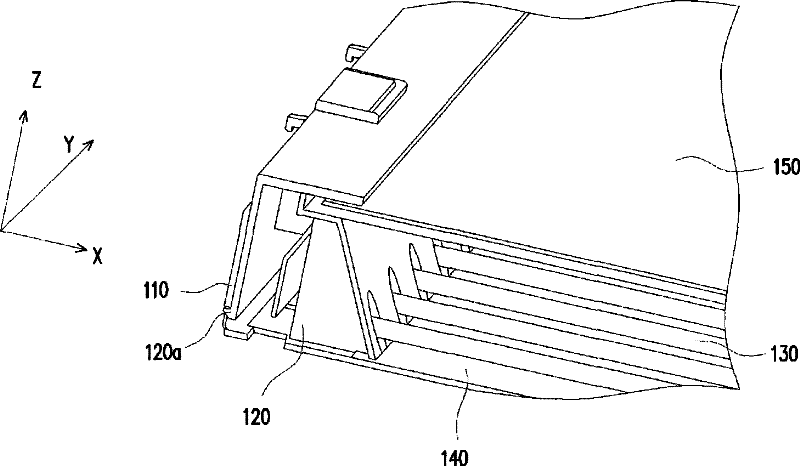

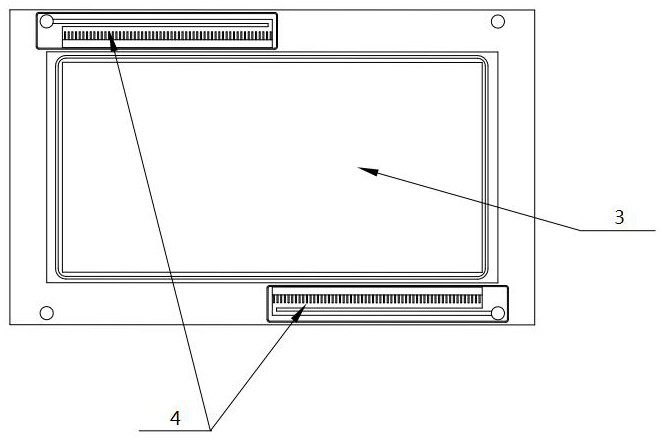

Back light module

InactiveCN101725934BReduce assembly difficultiesShorten the time required for assemblyLighting support devicesNon-linear opticsEngineeringMechanical engineering

Owner:华映视讯(吴江)有限公司 +1

Split type gas filling port seat

ActiveCN105109560ABreak through the processing bottleneckEasy to operateSuperstructure subunitsProduction lineEngineering

The invention relates to a split type gas filling port seat. A sealed seat body with a cavity is assembled by a plurality of detachable parts; the parts specifically include a gas filling valve seat, an upper cover, a back cover, a connecting seat and a front cover, wherein the gas filling valve seat is fixedly mounted on a floor sideboard; the upper cover covers above the gas filling valve seat; the connecting seat is fixed on side frame outer panel; the front cover is provided with a gas filling port; the gas filling valve seat and the upper cover form a side frame with a high pressure pipe port; axially raised flange is arranged on the back circumferential surface of the connecting seat; the flange penetrates through the floor sideboard and is inserted into the side frame; the front cover seals the front end of the connecting seat; and the back cover seals the back end of the side frame. According to the split type gas filling port seat provided by the invention, as the gas filling port seat is designed as a structure which can be detached into a plurality of parts, the upper cover on the upside and the back cover in the rear can be detached during mounting or replacing a gas filling valve so that the operation is convenient; and as the gas filling valve seat is connected with the upper cover through a longitudinal bolt, the assembling difficulty is reduced, the manufacturing bottleneck of a production line is removed and the production efficiency is increased.

Owner:XIAMEN GOLDEN DRAGON AUTO BODY

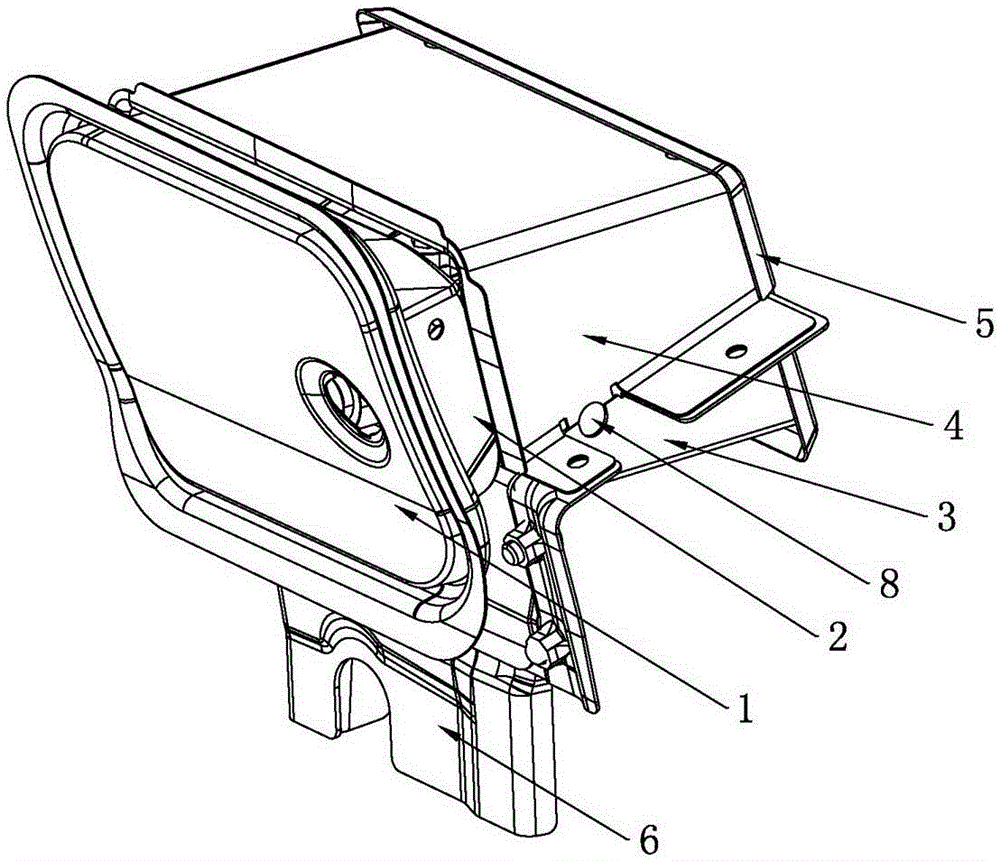

Urea cover device

PendingCN112324261AReduce assembly difficultiesInhibit sheddingExhaust apparatusBurglar prevention lockingStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of automobile parts, in particular to a urea cover device which comprises a lock body, a lock cylinder is arranged in the lock body, a rotating disc is arranged on the lower end face of the lock body, a clamping base is arranged on the rotating disc, and a spring bolt is arranged between the lock body and the clamping base. The lock cylinder is driven to rotate, linkage between the lock body and the clamping base can be achieved, a tooth opening check ring is arranged on the lock cylinder through a clamping ring, and the tooth opening check ring isin clearance fit with the lock cylinder. The urea cover device is simple in structure, can seal a filling opening of a urea tank, and can also play an anti-theft role at the same time.

Owner:江苏新华陵汽车电器有限公司

A vanadium battery splicing graphite bipolar plate

ActiveCN111933963BReduce leakage currentImprove efficiencyCell electrodesRegenerative fuel cellsElectrochemical responseElectrolytic agent

The invention relates to a spliced graphite bipolar plate for a vanadium battery, comprising a conductive plate and a non-conductive plate, the conductive plate covers the electrochemical reaction zone and contacts the electrolyte in the electrochemical reaction zone; the non-conductive plate covers the electrolyte flow channel area, contacting the electrolyte in the electrolyte flow channel area, the conductive plate is a conductive graphite plate, the non-conductive plate is a non-conductive polymer material plate, and the conductive plate and the non-conductive plate are welded by hot pressing; the non-conductive plate The conductive plate is prepared by adding non-conductive materials to polymer resin materials. The invention splices a conductive graphite plate and a non-conductive polymer material plate to form a spliced bipolar plate, has low cost, can reduce battery internal leakage current, and improves battery efficiency.

Owner:杭州德海艾科能源科技有限公司

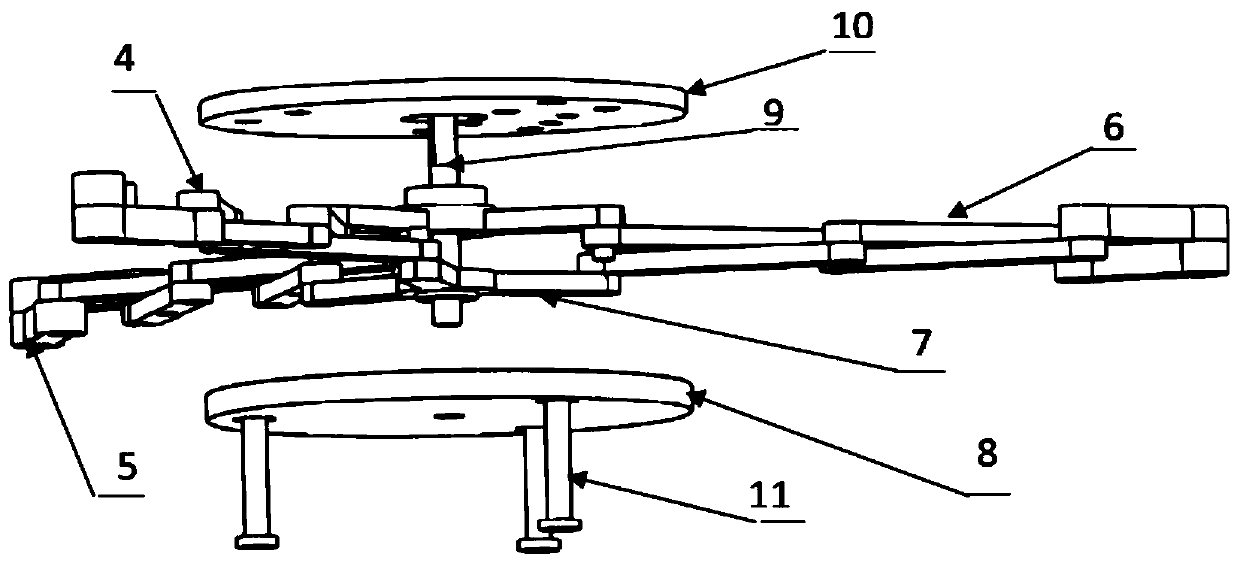

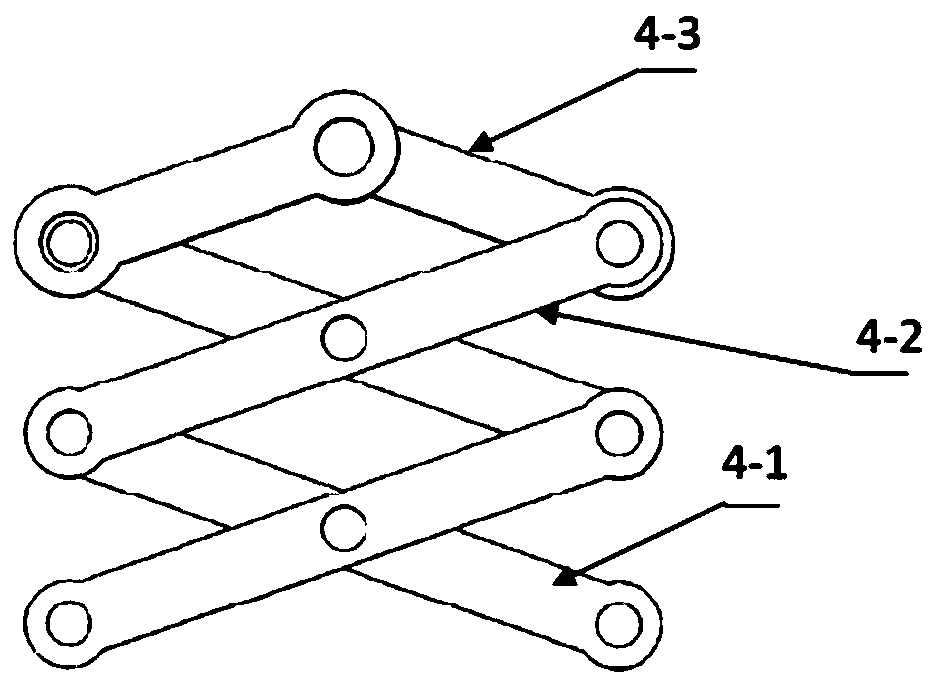

Scissor type radial dilating device for intestinal tract miniature robot

ActiveCN109846451AReduce too longReduce assembly difficultiesRectum colonoscopesRectum signoidoscopesTransmitted powerMicro robotics

The invention relates to a scissor type radial dilating device for an intestinal tract miniature robot. The scissor type radial dilating device comprises a scissor and fork type radial dilating mechanism, a coaxial backward rotating driving mechanism and a driving decelerating device, wherein the driving decelerating device is used for transmitting power to the scissor and fork type radial dilating mechanism through the coaxial backward rotating driving mechanism, so that the scissor and fork type radial dilating mechanism is driven to do dilating and contracting movement. According to the scissor type radial dilating device disclosed by the invention, the structure of the device is simplified, besides, necessary functions of all existing robots are reserved, and the operating stability ofthe mechanism is improved.

Owner:SHANGHAI JIAO TONG UNIV

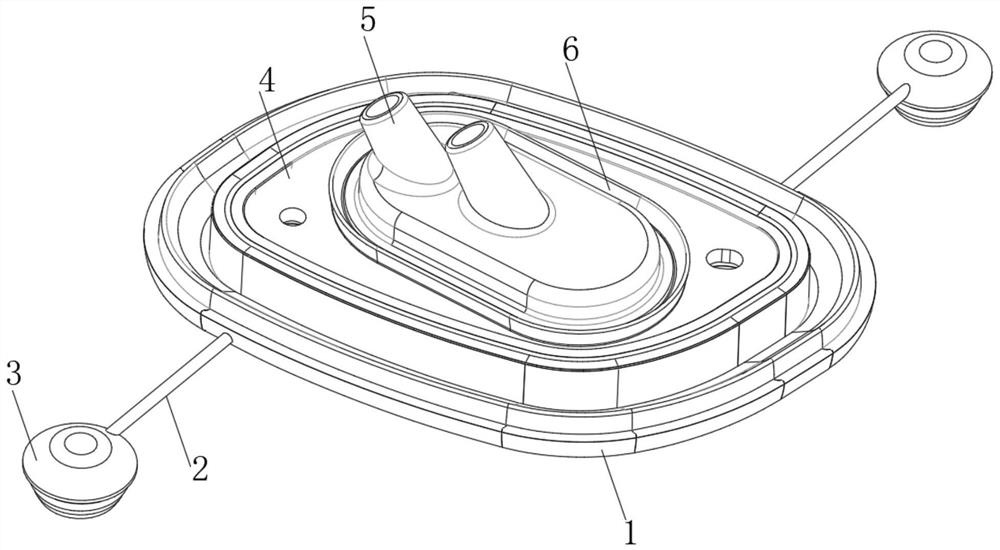

A gear shifter cable sheath used in an automobile sealing system

ActiveCN113060079BPrevent disengagementAdjust the fixed tightnessVehicle componentsStructural engineeringMechanical engineering

The invention relates to the field of cable sheaths, and specifically discloses a cable sheath for shifters in automotive sealing systems, which includes a first seat and a second seat, and the upper part of the first seat is clamped A fixed frame is installed, and the upper part of the fixed frame is clamped with a second seat body. The bottom end of the first seat body and the top end of the second seat body are connected with two direction pipes, and the first seat body and the second seat body Corresponding direction pipes are arranged through each other, and the inner walls of both sides of the direction pipes are connected with spiral strips. The assembly type of rubber and plastic parts is used, the production efficiency is increased by 60%, and the overall weight is reduced, which is conducive to light weight. It can effectively reduce assembly difficulties caused by accumulated errors, reduce the precision and difficulty of production, and improve the efficiency of subsequent installation at the same time. The position limiting mechanism can block the first fixing hole, improve the installation stability of the fixing frame, and at the same time make it difficult for impurities to enter the first fixing hole.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com