Permanent magnetism aerogenerator and rotor thereof

A wind turbine and rotor technology, applied in wind power generation, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of bolt fatigue damage, high processing cost, high structural strength requirements, etc., and reduce assembly Difficult, large tangential force, reduced processing difficulty and the effect of processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

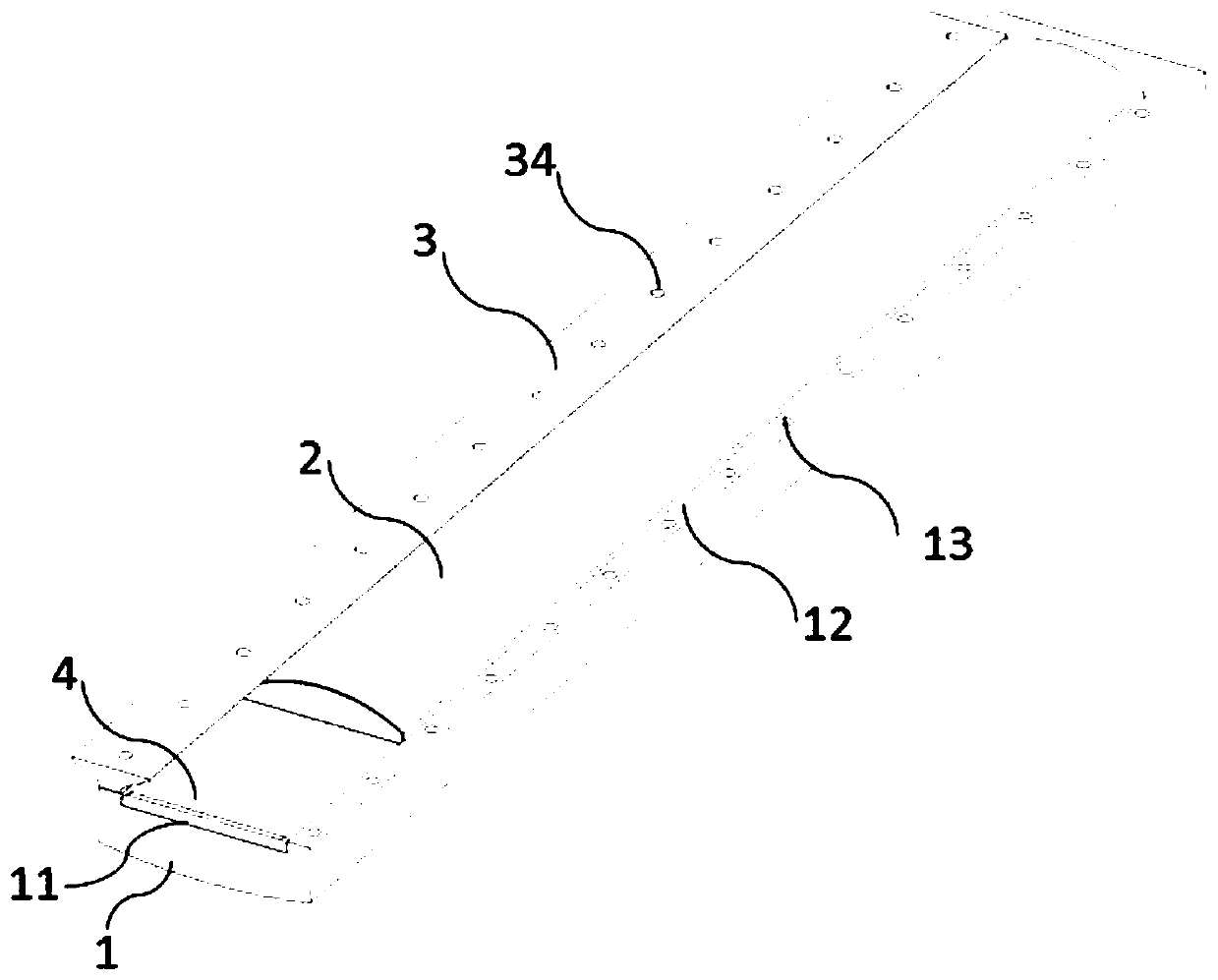

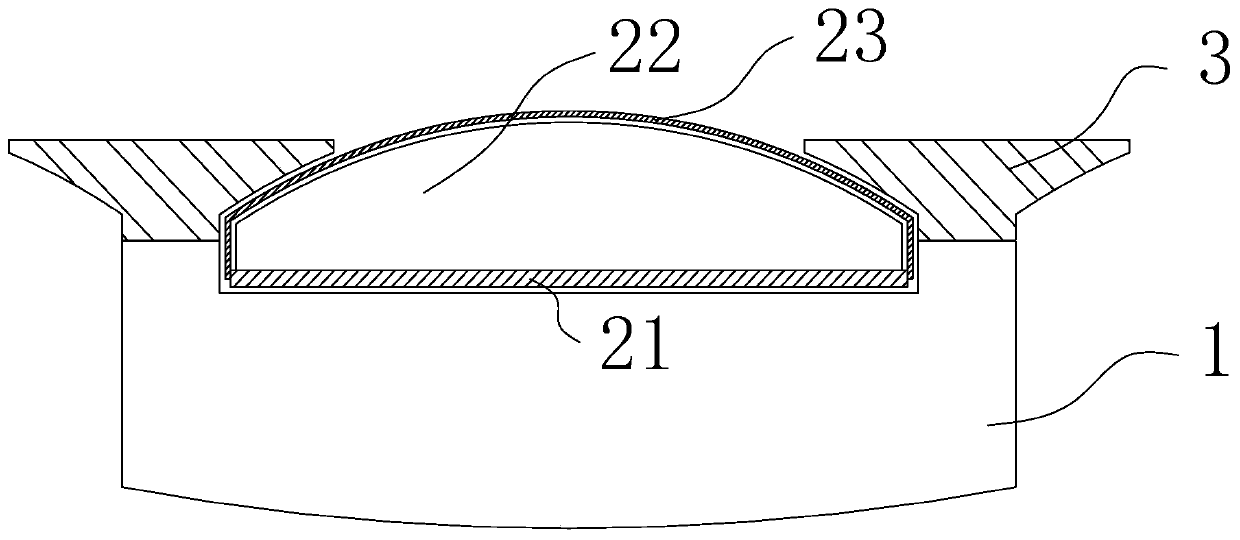

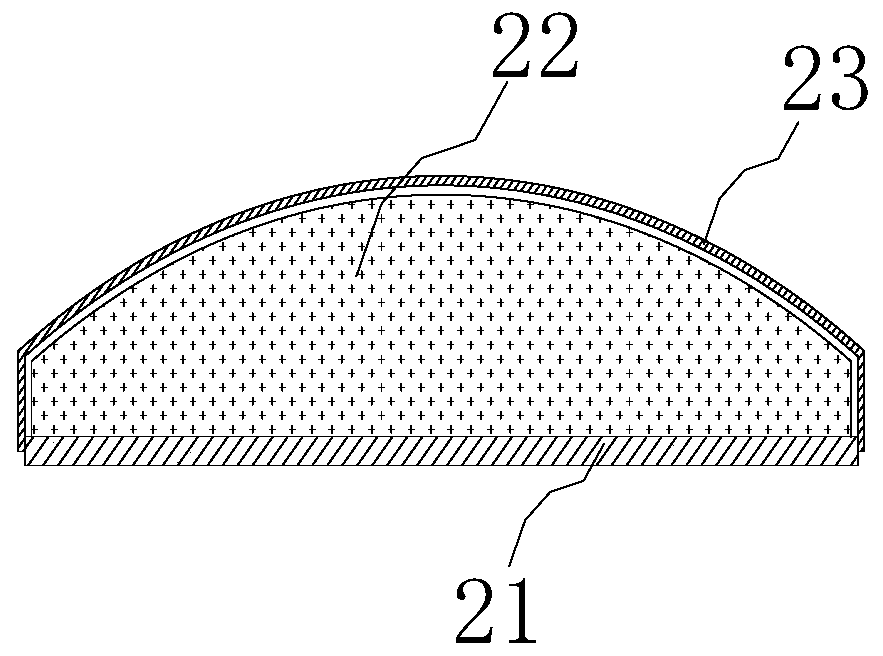

[0043] Such as figure 1 As shown, this embodiment provides a permanent magnet wind turbine rotor, which includes a rotor yoke 1 and a magnetic pole module 2. The rotor yoke 1 is provided with a plurality of circumferentially distributed grooves 11, and the grooves 11 The side wall is a protruding rib 12, and several radial threaded holes 13 are provided on the protruding rib 12; the shape of the bottom surface of the magnetic pole module 2 is adapted to the shape of the groove 11, and a part of the magnetic pole module 2 is embedded in the groove The inside of 11 is fixed with the fixing part 3, and one end of the fixing part 3 is connected with the locking part 4.

[0044] The rotor yoke 1 is a magnetically conductive material, and the radial cross-sectional shape of the groove 11 on the rotor yoke 1 is a rectangle. As an alternative, other shapes can also be used, such as a trapezoid. This shape is easy to process. The advantages. The groove 11 is formed by milling. The g...

Embodiment 2

[0050] Such as Figure 5 As shown, the basic structure of this embodiment is basically the same as that of Embodiment 1, the difference being that the fixing part 3 is a pressing block provided with a threaded hole 34 , and a plurality of pressing blocks are screwed to the protruding ribs 12 . With such a fixing part 3, the total mass of the rotor can be reduced. And a plurality of magnetic pole modules 2 are embedded in one groove 11 , which can reduce the magnetization difficulty of the packaged magnetic pole modules 2 .

Embodiment 3

[0052] Such as Figure 6 As shown, the basic structure of this embodiment is basically the same as that of Embodiment 2, the difference is that: the protruding ribs 12 are arranged at intervals in the length direction of the groove 11, and a threaded hole 13 is arranged between the two protruding ribs 12, and the pressure The block is threaded with the threaded hole 13 holes. In this way, it is beneficial to the positioning of the pressing block during installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com