A vanadium battery splicing conductive plastic bipolar plate

A conductive plastic and bipolar plate technology, applied in the field of vanadium batteries, can solve the problems of increasing the amount of conductive bipolar plates, reducing the energy efficiency of the stack, increasing material costs, etc., to reduce the internal leakage current of the battery, accelerate the crystallization speed, and reduce the cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A vanadium battery splicing conductive plastic bipolar plate, the preparation process is as follows:

[0025] The components of the conductive plate 1: polypropylene PP 20%, carbon black 50%, graphite 10%, EVA 20%.

[0026] The composition of the non-conductive plate 2: polypropylene PP 60%, silicon dioxide 30%, EVA 10%.

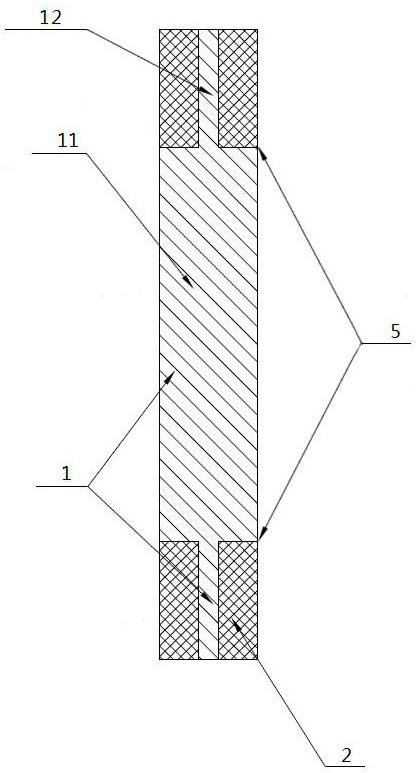

[0027] Preparation of conductive plate 1 and non-conductive plate 2: Weigh the above raw materials and mix them uniformly at high speed in a high-speed mixer, and prepare conductive plate 1 and non-conductive plate 2 on a sheet extrusion molding machine. The square plate structure 11 of the conductive plate 1 has a thickness of 1 mm, the protruding strip structure 12 has a thickness of 0.3 mm, and the non-conductive plate 2 has a thickness of 0.35 mm.

[0028] Preparation of spliced bipolar plates: Place a non-conductive plate 2 on the upper and lower surfaces of the protruding strip structure 12 of the conductive plate 1, put them into a hot-melt ...

Embodiment 2

[0030] A vanadium battery splicing conductive plastic bipolar plate, the preparation process is as follows:

[0031] Components of conductive plate 1: polyethylene PE 25%, carbon black 48%, conductive graphite 10%, carbon nanotube 2%, POE 10%, EVA 5%.

[0032] The composition of the non-conductive plate 2: polyethylene PE 75%, titanium dioxide 20%, POE 5%.

[0033] Preparation of conductive plate 1 and non-conductive plate 2: Weigh the above raw materials and mix them uniformly at high speed in a high-speed mixer, and prepare conductive plate 1 and non-conductive plate 2 on a sheet extrusion molding machine. The thickness of the square plate structure 11 of the conductive plate 1 is 2 mm, the thickness of the protruding strip structure 12 is 0.3 mm, and the thickness of the non-conductive plate 2 is 0.85 mm.

[0034] Preparation of spliced bipolar plates: place a non-conductive plate 2 on the upper and lower surfaces of the protruding strip structure 12 of the conductive pl...

Embodiment 3

[0036] A vanadium battery splicing conductive plastic bipolar plate, the preparation process is as follows:

[0037] The components of the conductive plate 1: polypropylene PP 15%, carbon black 50%, conductive graphite 28%, graphene 2%, SBS 5%.

[0038] The composition of the non-conductive plate 2: polypropylene PP 60%, silicon dioxide 20%, silicate 10%, SBS 10%.

[0039] Preparation of conductive plate 1 and non-conductive plate 2: Weigh the above raw materials and mix them uniformly at high speed in a high-speed mixer, and prepare conductive plate 1 and non-conductive plate 2 on a sheet extrusion molding machine. The thickness of the square plate structure 11 of the conductive plate 1 is 3 mm, the thickness of the protruding strip structure 12 is 1 mm, and the thickness of the non-conductive plate 2 is 1 mm.

[0040] Preparation of spliced bipolar plates: Place a non-conductive plate 2 on the upper and lower surfaces of the protruding strip structure 12 of the conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com