Direct drive structure of sewing machine

A sewing machine, direct drive technology, applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of high error, unstable rotation of the sewing machine spindle, unsatisfactory installation, work or maintenance, etc., to reduce assembly costs Difficulty, good heat dissipation effect, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4:

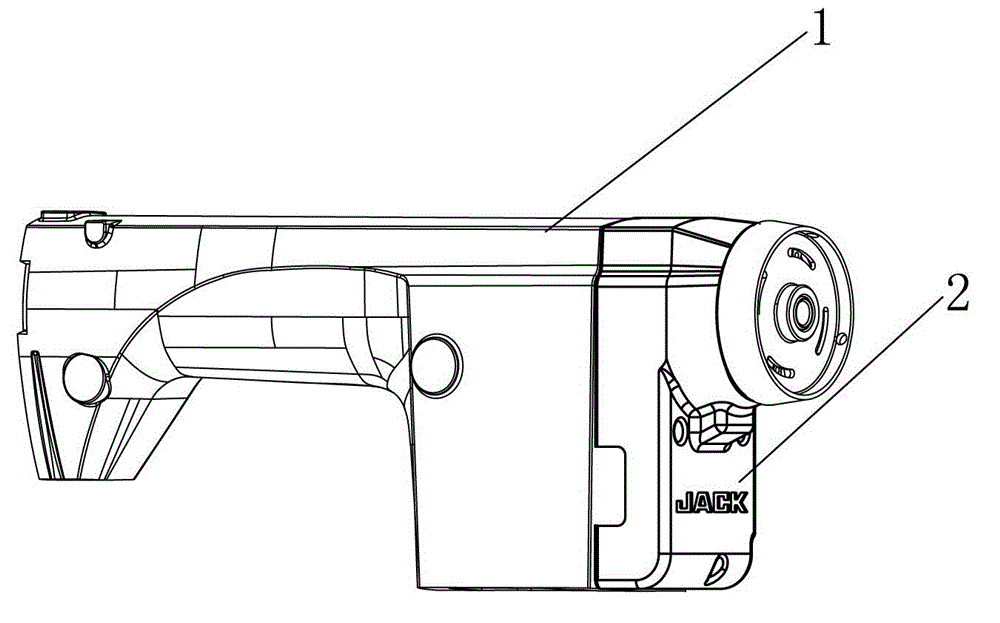

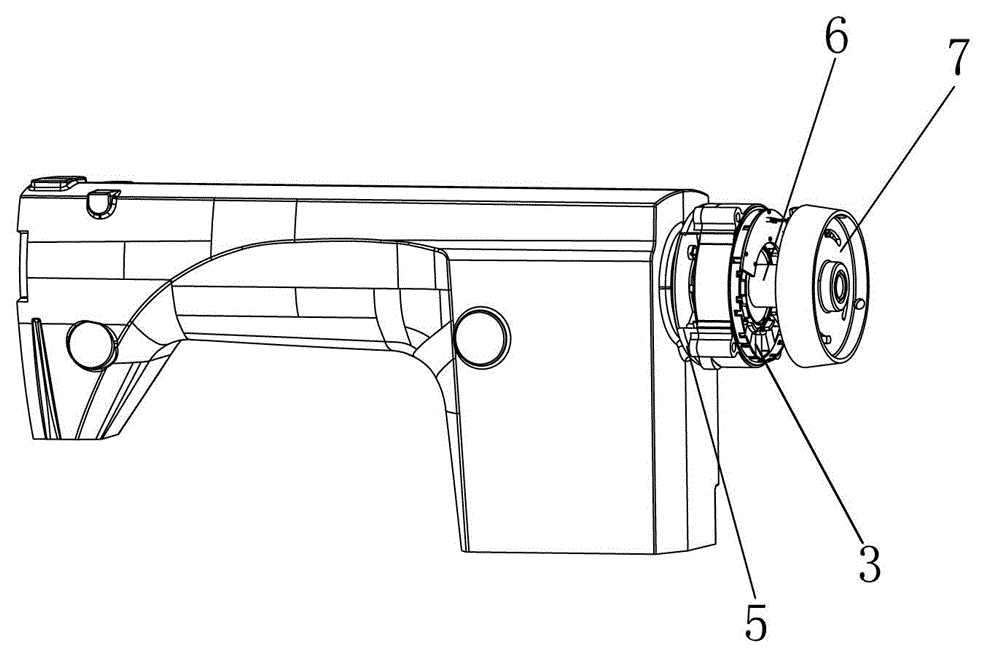

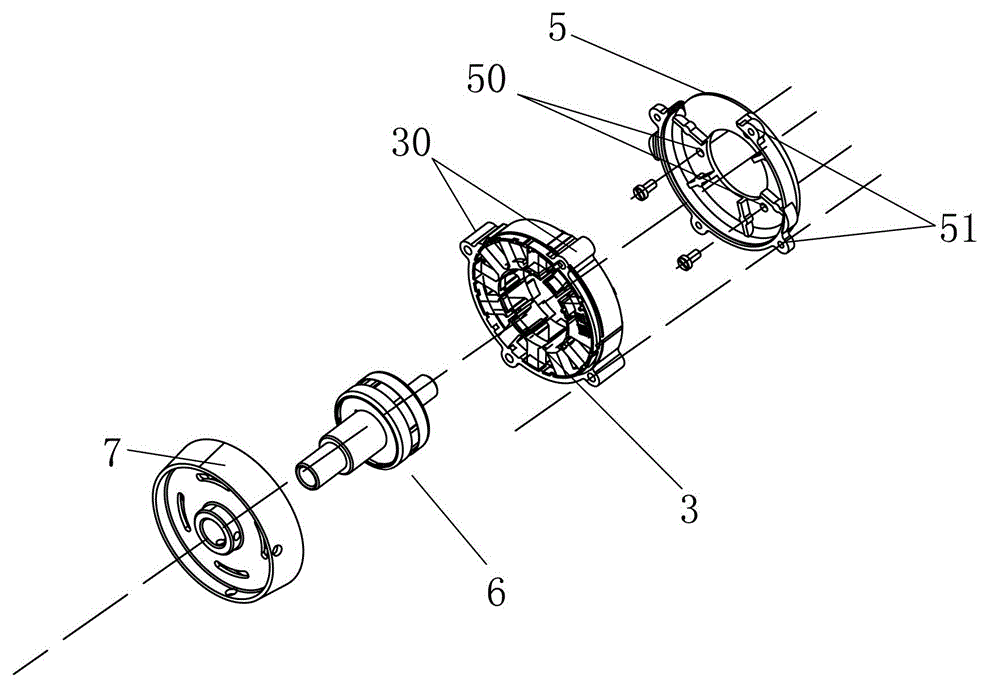

[0019] A direct drive structure of a sewing machine, comprising a sewing machine head 1, a motor positioning plate 5 is fixed on one end surface of the sewing machine head 1, and a motor stator 3 is fixed on the motor positioning plate 5 through a through hole 30 provided on its outer ring , the motor rotor 6 is located in the stator, one end of the rotor is connected with the sewing machine main shaft, and the other end is fixedly connected with the sewing machine handwheel 7, the motor stator 3 and the motor positioning plate 5 are all arranged in the nose cover 2, the sewing machine handwheel 7 stretches out of the opening of nose cover 2. In the installation process of this structure, the motor positioning plate 5 is fixed on the end face of the sewing machine head 1, the motor stator 3 is fixed to the motor positioning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com