A split type air filling seat

A gas filling port and split-type technology, applied in the field of auto parts, can solve the problems of small assembly space for installing or replacing gas valves, bottlenecks in production line processing, low efficiency, etc., and achieve the effect of reducing assembly difficulties and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

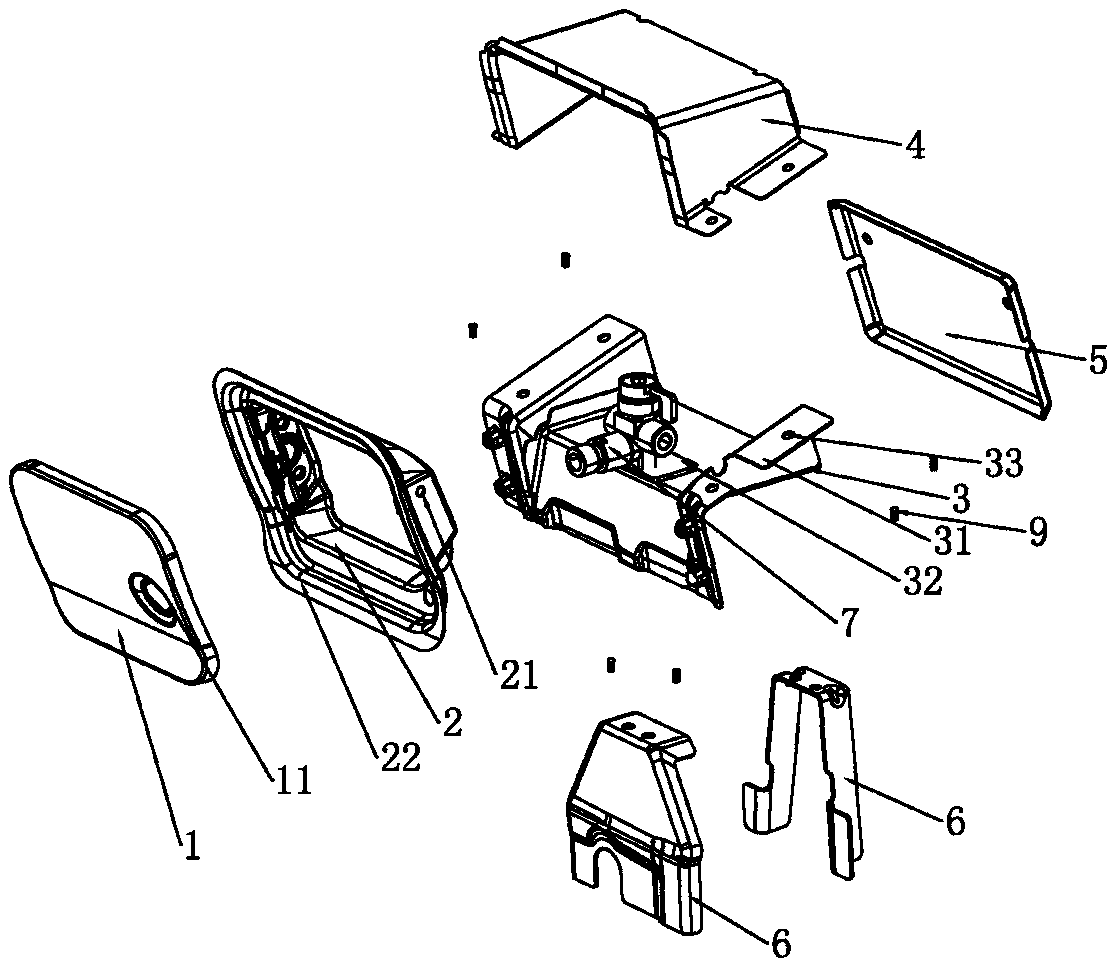

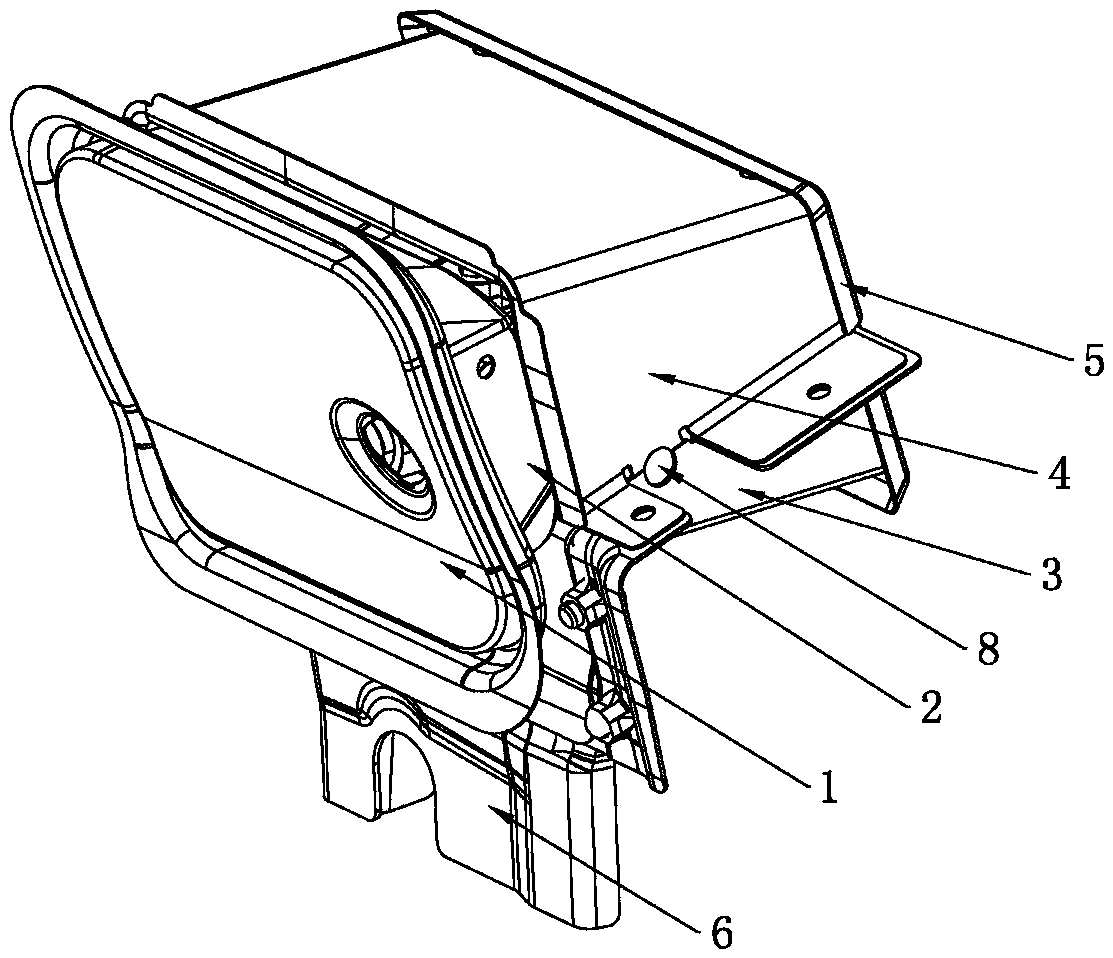

[0017] like figure 1 and 2 As shown in the figure, a split-type air filling port seat is installed on the lower part of the vehicle body, including a front cover 1, a connecting seat 2, a filling valve seat 3, an upper cover 4 and a rear cover 5. The sealing seat body of the cavity, the air filling valve 7 is installed in the cavity, and there is a high pressure pipe port 8 on the side of the seat body for the high pressure pipe (not shown) to pass through.

[0018] The front cover 1 is sealed at the front end of the connecting base 2, and a gas filling port 11 which can be opened for the air filling gun to penetrate deep into the front cover 1 is opened.

[0019] The connecting seat 2 is installed on the side wall outer plate of the automobile. The front end of the connecting seat 2 is provided with a radially convex connecting edge 22, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com