Anti-vibration milling method for ultrathin blade of integral impeller

An integral impeller, anti-vibration technology, used in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve the problems of poor blade surface shape accuracy, rough blade surface, low processing qualification rate, etc., to reduce cutting vibration and The effect of deformation, breaking through the processing bottleneck, high shape accuracy and high surface quality accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

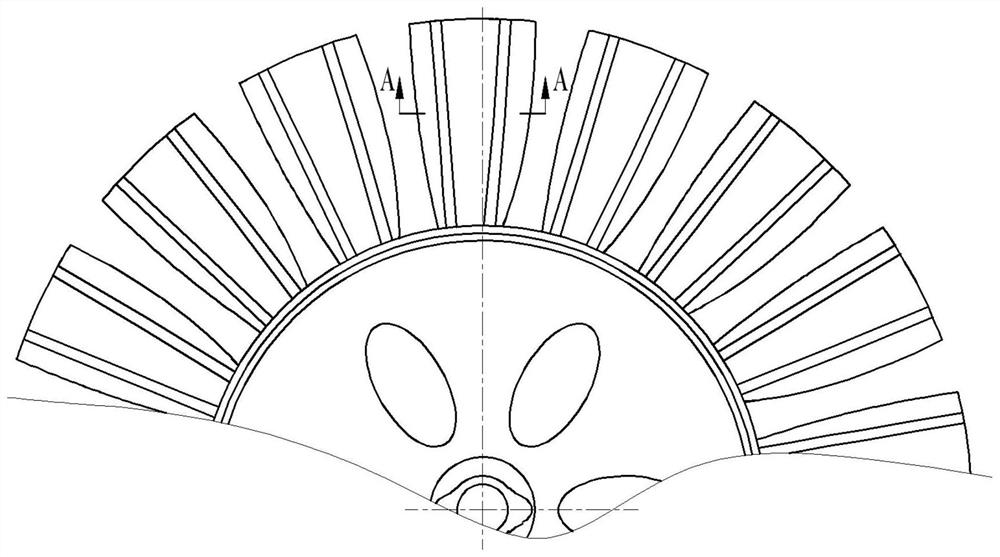

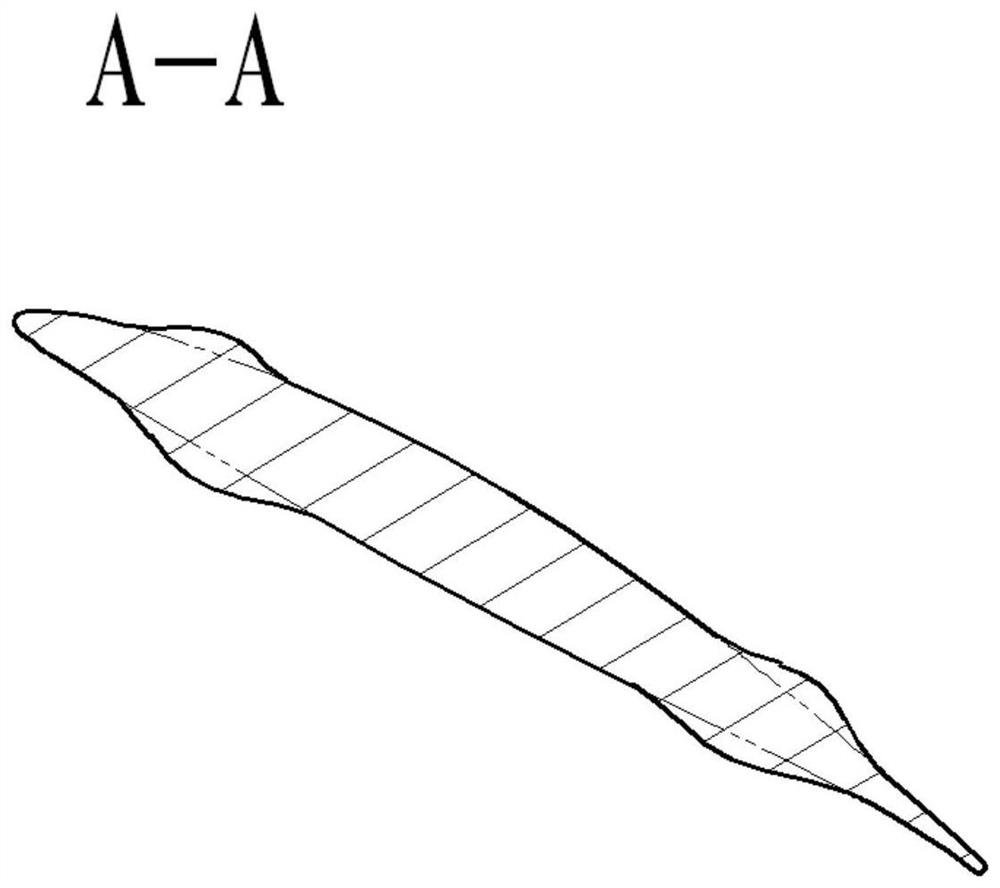

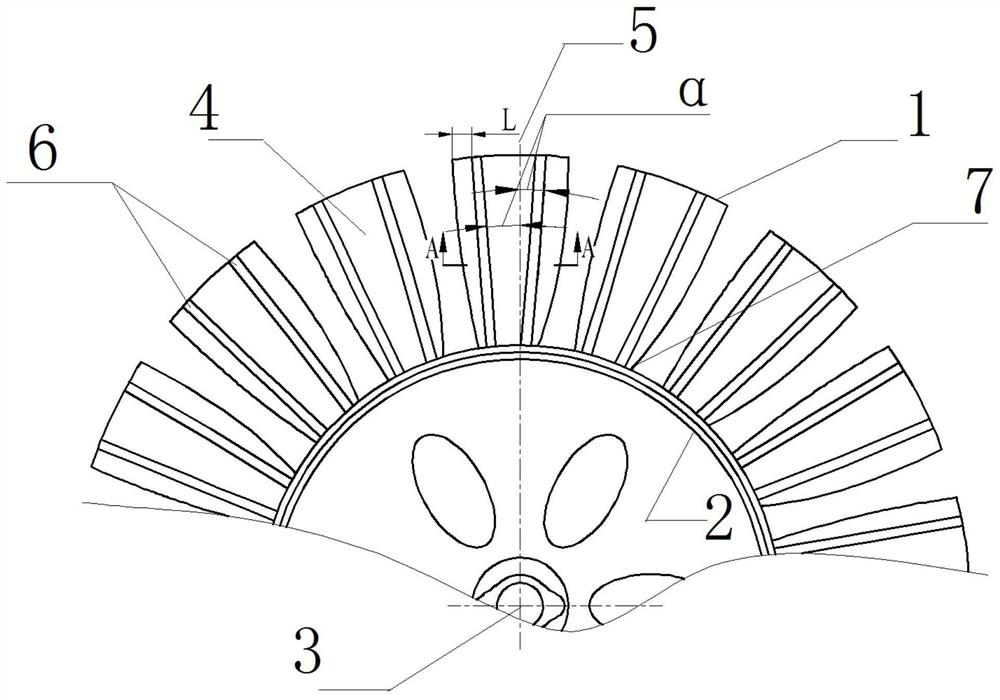

[0030] The core idea of the present invention is: during the milling process of the integral impeller of ultra-thin complex curved blades, special-shaped support ribs 6 are provided in the rough machining or semi-finishing process of the blade 4, and the special-shaped support ribs 6 meet the following conditions:

[0031] 1. The number and distribution of the special-shaped support ribs 6 are reasonable, and it is best to control a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com