Device and method for installing collector ring of generator of wind turbine generator

A technology for installing devices and wind turbines, which is applied in the manufacture of motor generators, wind power generation, electromechanical devices, etc., and can solve the problems of damaged collector rings, difficult repairs, and unfavorable protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

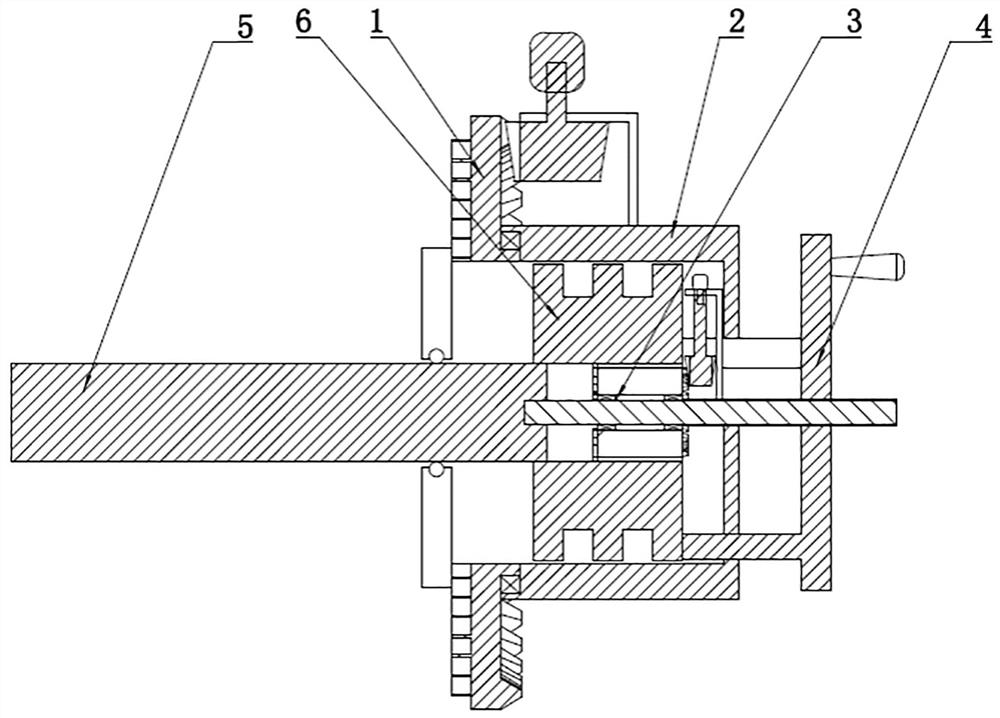

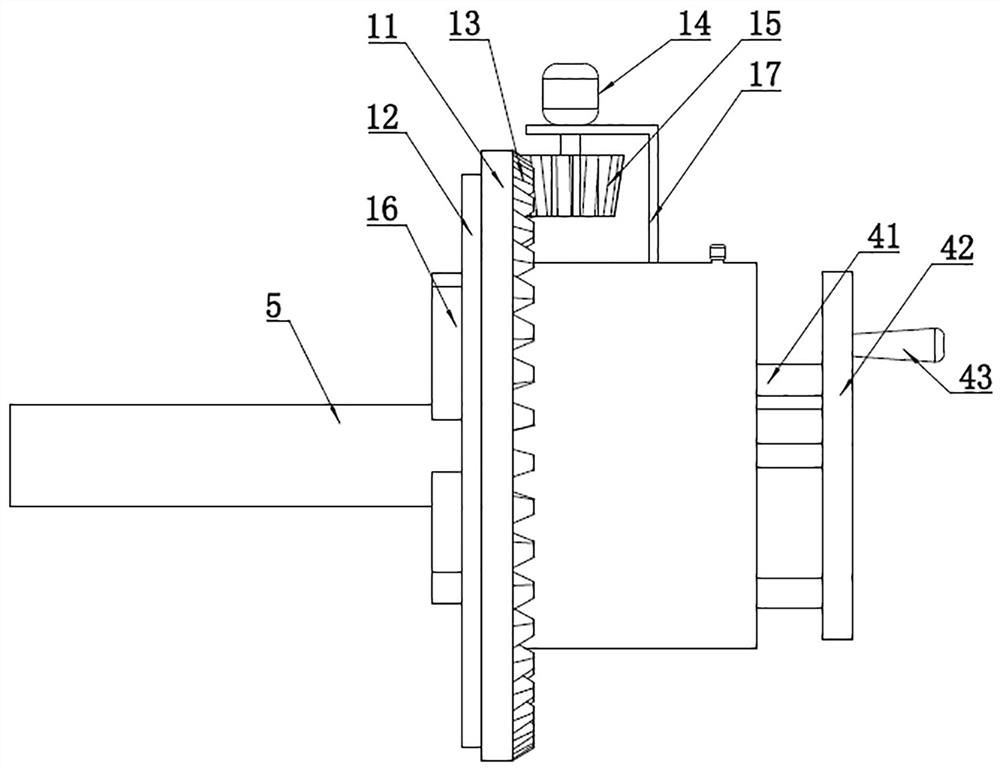

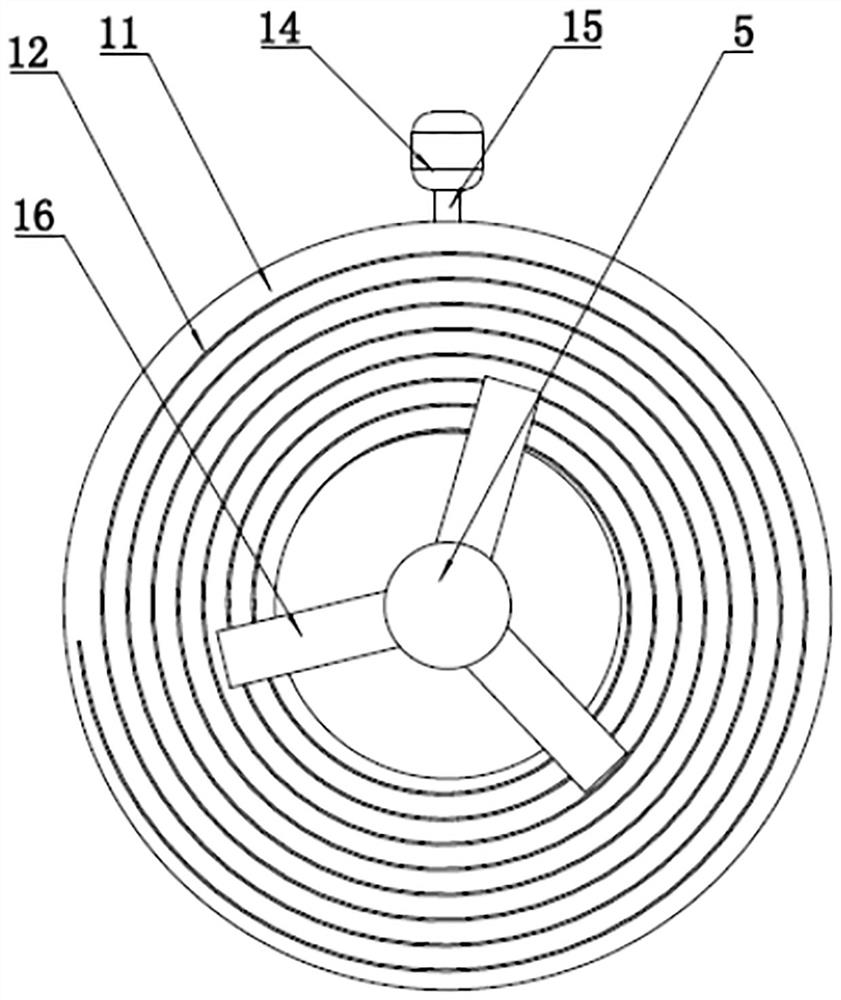

[0128] Such as Figure 7 As shown, a generator slip ring installation device for a wind power generating set includes a centering device 1, a sheath 2 fixedly connected to the centering device 1, and a push-off device fixedly connected to one side of the sheath 2 4 and the cylinder 44 fixedly connected to the pushing device 4; the centering device 1 is provided with a through hole; the sheath 2 is set on the collector ring 6; the centering device 1 and the The sheath 2 is coaxial; the collector ring 6 is provided with a support device 3 at one end; the support device 3 is fixedly connected to the sheath 2 through a connecting shaft 312; the cylinder 44 is fixed on the base of the generator on the stand,

[0129] The support device 3 is coaxial with the sheath 2 ; the centering device 1 is sleeved on the generator shaft 5 .

[0130] The difference from Embodiment 1 is that the handle 43 is cancelled, the fixed shaft 37 is cancelled, and the supporting device 3 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com