A vanadium battery splicing graphite bipolar plate

A technology of bipolar plates and vanadium batteries, which is applied in the field of vanadium batteries, can solve the problems of increasing the amount of conductive bipolar plates, reducing the energy efficiency of the stack, and increasing the cost of materials, so as to reduce the internal leakage current of the battery, accelerate the crystallization speed, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of vanadium battery splicing graphite bipolar plate, its preparation process is as follows:

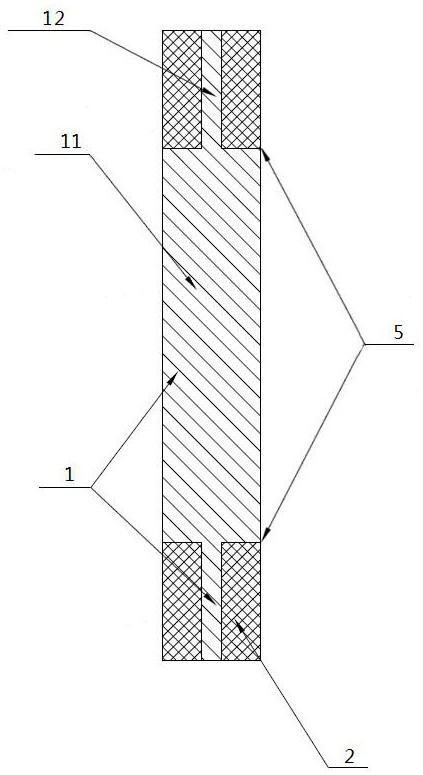

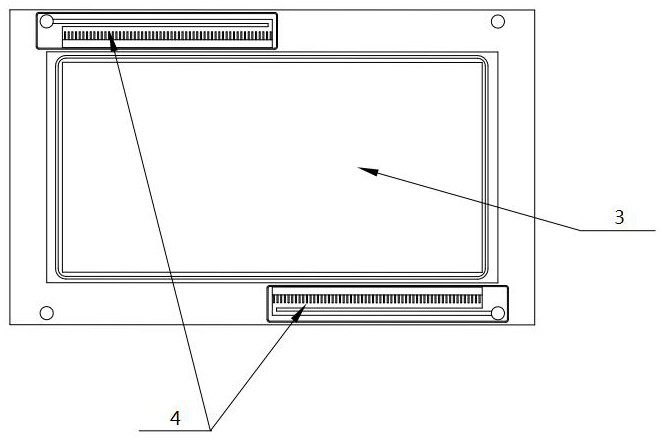

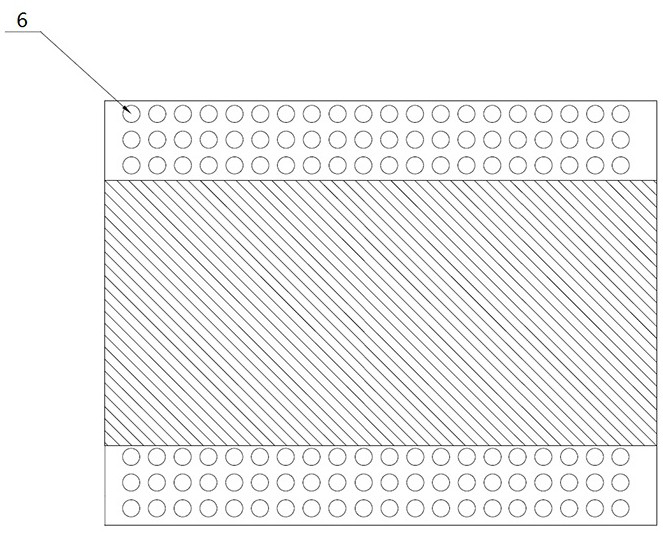

[0027] Preparation of conductive plate 1: put expanded graphite and conductive graphite powder into the mold according to the ratio of 90:10, apply a pressure of 30MPa, hold the pressure for 15 minutes, prepare the conductive plate base material, put the conductive plate base material on the engraving machine, The protruding strip structure 12 of the conductive plate 1 is processed and punched with circular holes with a diameter of 1 mm, and the circular holes are evenly arranged. The thickness of the square plate structure 11 of the conductive plate 1 is 1 mm, and the thickness of the protruding strip structure 12 is 0.4 mm.

[0028] Preparation of non-conductive plate 2: Mass fraction components of non-conductive plate 2: polypropylene PP 70%, silicon dioxide 30%. The above raw materials were weighed and mixed uniformly at high speed in a high-speed mixer, and a non-c...

Embodiment 2

[0031] A kind of vanadium battery splicing graphite bipolar plate, its preparation process is as follows:

[0032] Preparation of conductive plate 1: put expanded graphite and conductive graphite powder into the mold according to the ratio of 92:8, apply a pressure of 40 MPa, hold the pressure for 10 minutes, prepare the conductive plate base material, and put the conductive plate base material on the engraving machine, The protruding strip structure 12 of the conductive plate 1 is processed and punched with circular holes with a diameter of 1.5 mm, and the circular holes are evenly arranged. The thickness of the square plate structure 11 of the conductive plate 1 is 2 mm, and the thickness of the protruding strip structure 12 is 0.8 mm.

[0033] Preparation of the non-conductive plate 2: Mass fraction components of the non-conductive plate 2: polyethylene PE 80%, titanium dioxide 20%. The above raw materials were weighed and mixed uniformly at high speed in a high-speed mixe...

Embodiment 3

[0036] A kind of vanadium battery splicing graphite bipolar plate, its preparation process is as follows:

[0037] Preparation of conductive plate 1: put expanded graphite and conductive graphite powder into the mold according to the ratio of 95:5, apply a pressure of 40MPa, hold the pressure for 10 minutes, prepare the conductive plate base material, put the conductive plate base material on the engraving machine, The protruding strip structure 12 of the conductive plate 1 is processed and punched with circular holes with a diameter of 2.0 mm, and the circular holes are evenly arranged. The thickness of the square plate structure 11 of the conductive plate 1 is 3 mm, and the thickness of the protruding strip structure 12 is 1.2 mm.

[0038] Preparation of the non-conductive plate 2: Mass fraction components of the non-conductive plate 2: 70% epoxy resin, 20% titanium dioxide, and 10% silicate. The above raw materials were weighed and mixed in an internal mixer for 10 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com