Deviation correcting device for elevator traction belt

A deviation correction device and elevator dragging technology, applied in the field of elevators, can solve problems such as manufacturing difficulties, shortened service life, and high cost, and achieve the effects of reducing manufacturing precision, reducing assembly difficulties, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, but the present invention is not limited to this specific example.

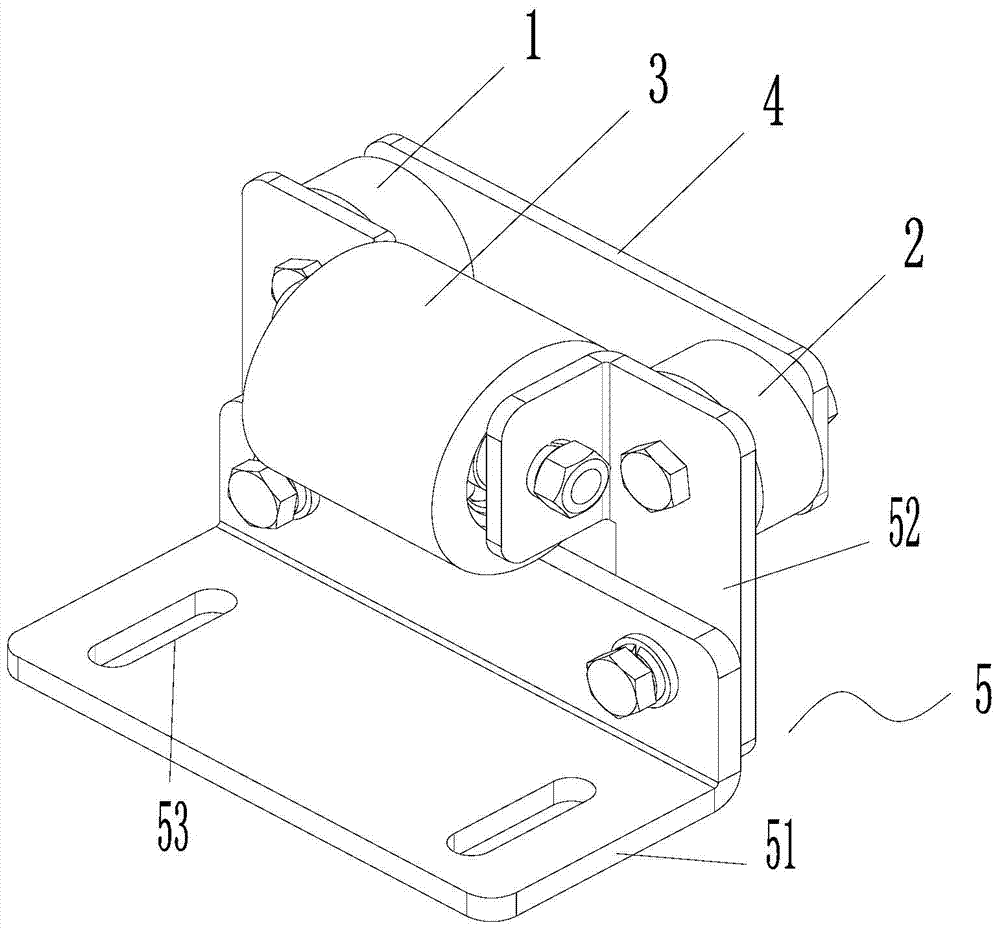

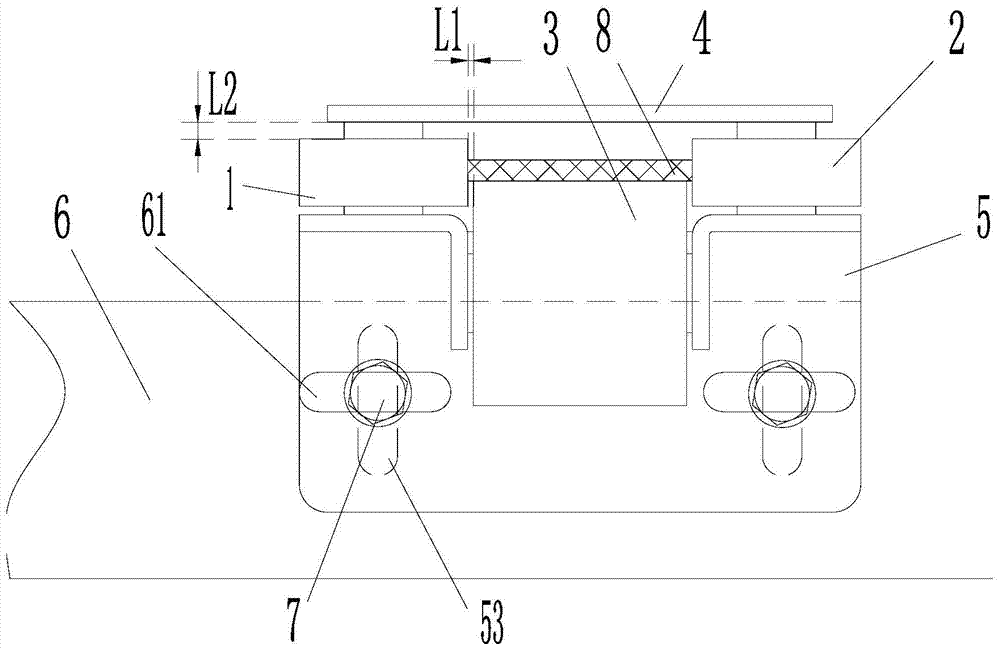

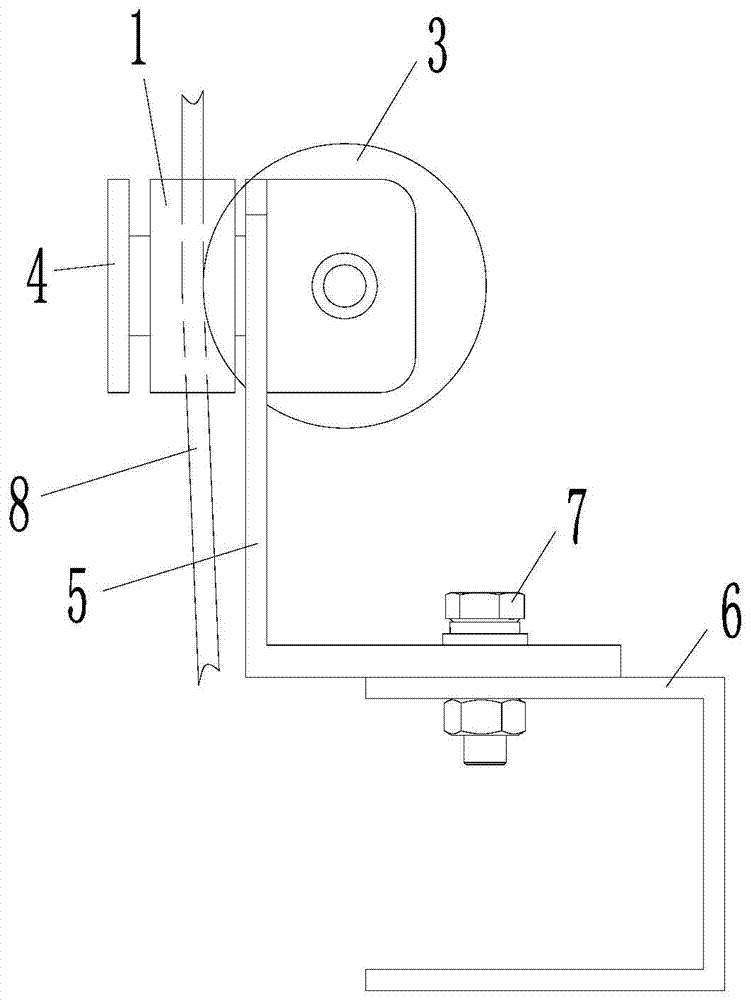

[0023] Such as Figure 1-Figure 3 As shown, a deviation correcting device for an elevator traction belt according to the present invention includes a baffle plate 4, a mounting seat 5, a bracket 6, a first roller 1, a second roller 2, and a pressing roller 3, etc.

[0024] The mounting seat 5 includes a bottom surface 51 and a mounting surface 52 perpendicular to the bottom surface 51 for mounting the rollers. In this embodiment, preferably, the position for installing the pinch roller 3 in the installation surface 52 adopts an elastic metal plate. After the pinch roller 3 is installed on it, the elevator traction belt 8 can be elastically compressed, allowing the traction During the operation of the leading belt 8, the pressing roller 3 is forced to produce a displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com