Square lithium ion battery pole anti-rotation structure and manufacturing method thereof

A lithium-ion battery, anti-rotation technology, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of difficult assembly, increased pole mass, high cost, low processing cost, reduced assembly difficulty, Easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

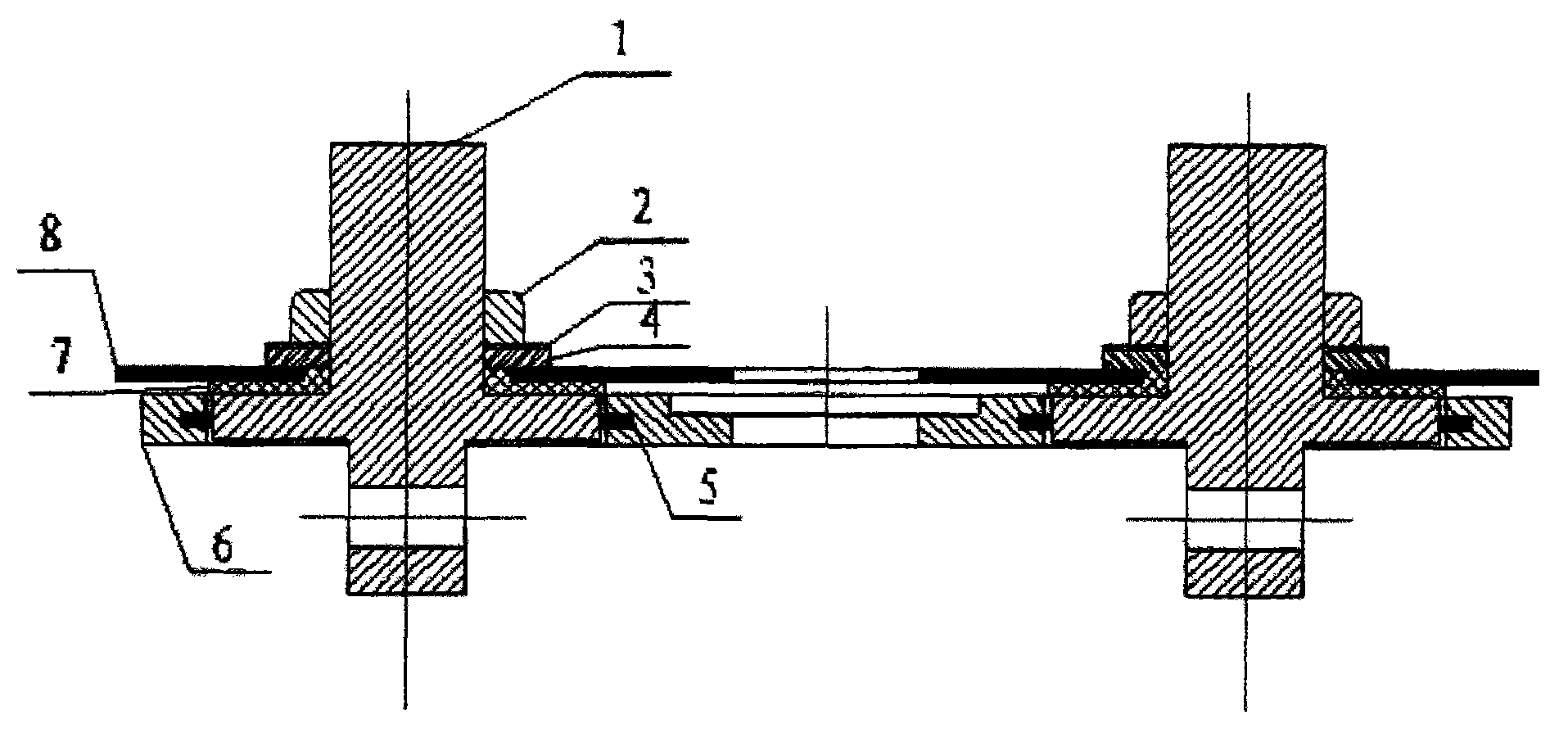

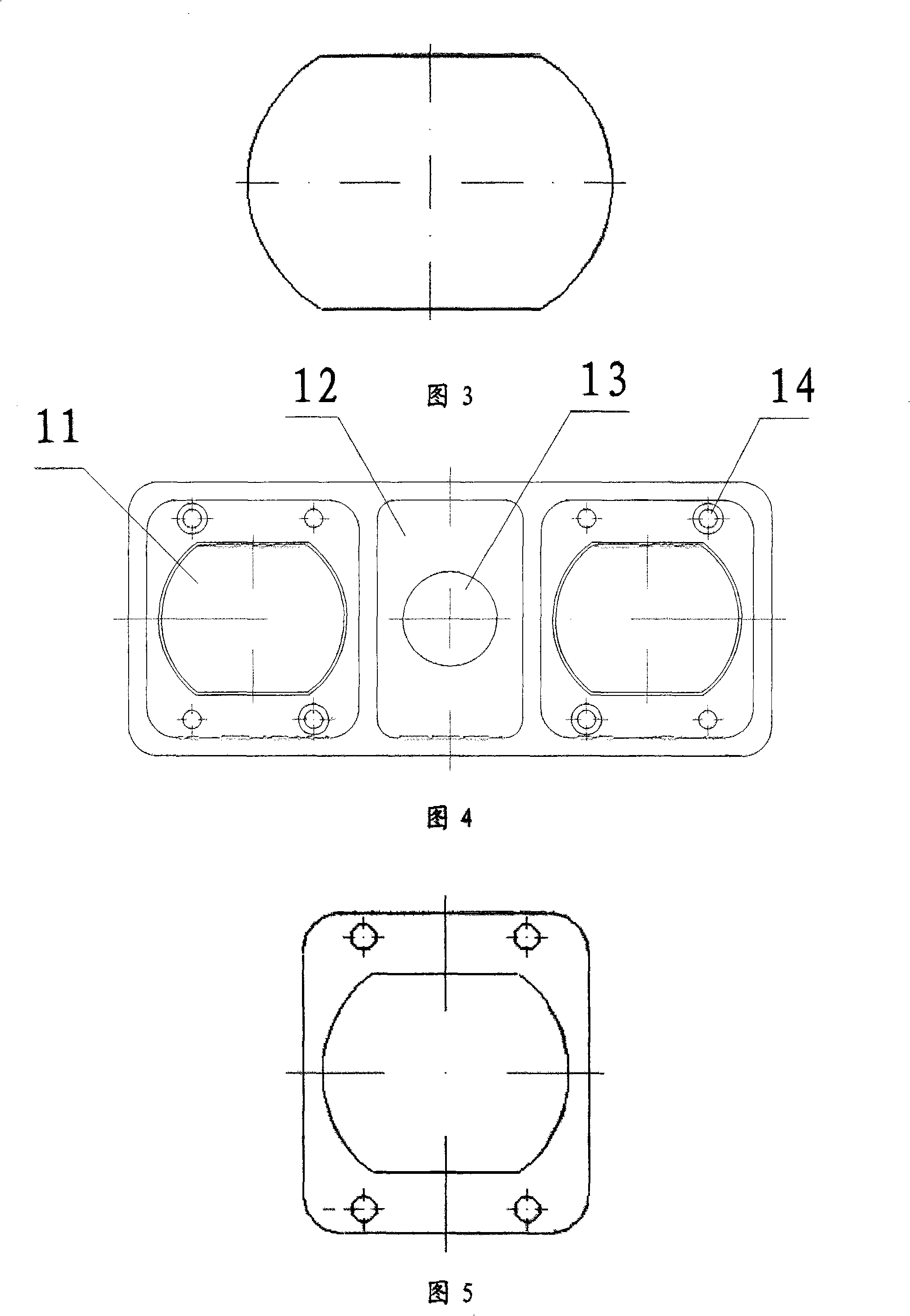

[0031] Combine below figure 1 The embodiment shown in -5 specifically illustrates the present invention.

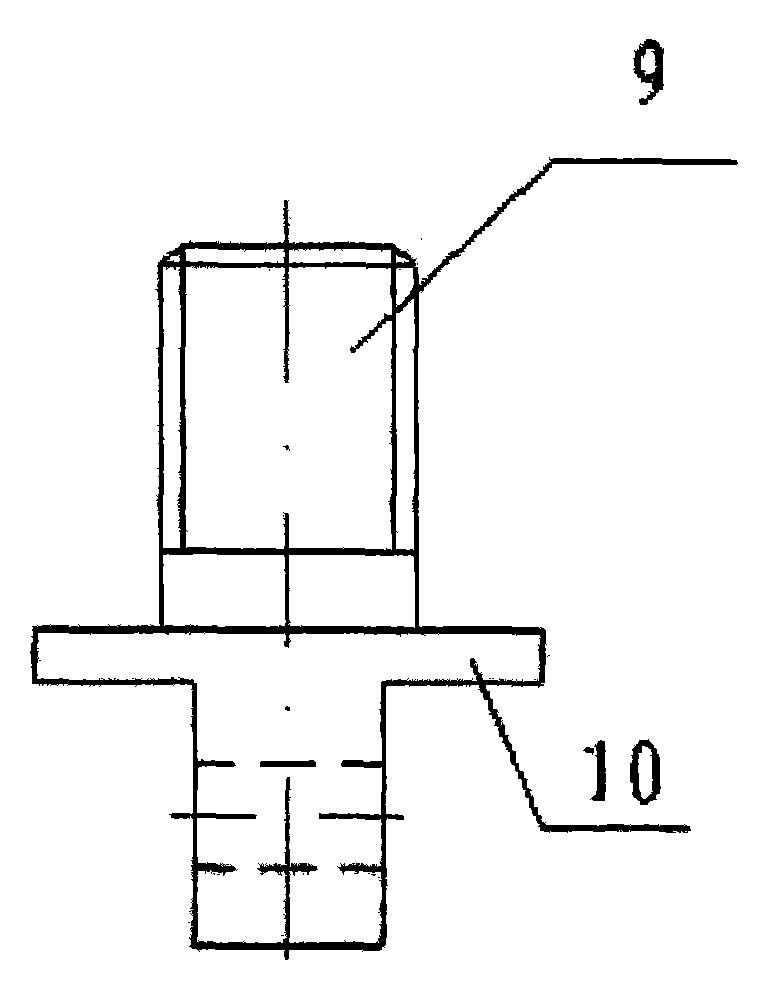

[0032] First of all, the metal material is processed figure 2 The combined structure of the fastening bolt 9 and the self-locking platform 10 shown, as the pole 1, the self-locking platform 10 of the pole can be a regular hexagon, a racetrack, or other polygons. Among them, the regular hexagon can be directly processed by the hexagonal bar; the racetrack shape is easy to process, and although the weight is heavy, it is beneficial to the heat dissipation of the negative pole.

[0033] Then, process the inner metal insert 5 of the anti-rotation bracket shown in Figure 5 with metal materials. The inner insert is rectangular and contains a non-circular hole 11 and four positioning circular holes 14, wherein the non-circular holes serve as poles. The post hole 11 , the non-circular hole 11 corresponds to the shape of the pole, and closely fits with the self-locking platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com