Reinforced horizontal adjusting device and automobile electric seat comprising same

A technology of a leveling device and a box body, which is applied to vehicle seats, movable seats, vehicle parts, etc., can solve the problems of poor reliability, high wear degree, low tensile strength, etc., so as to improve the safety and reliability of use. , The effect of reducing processing error and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

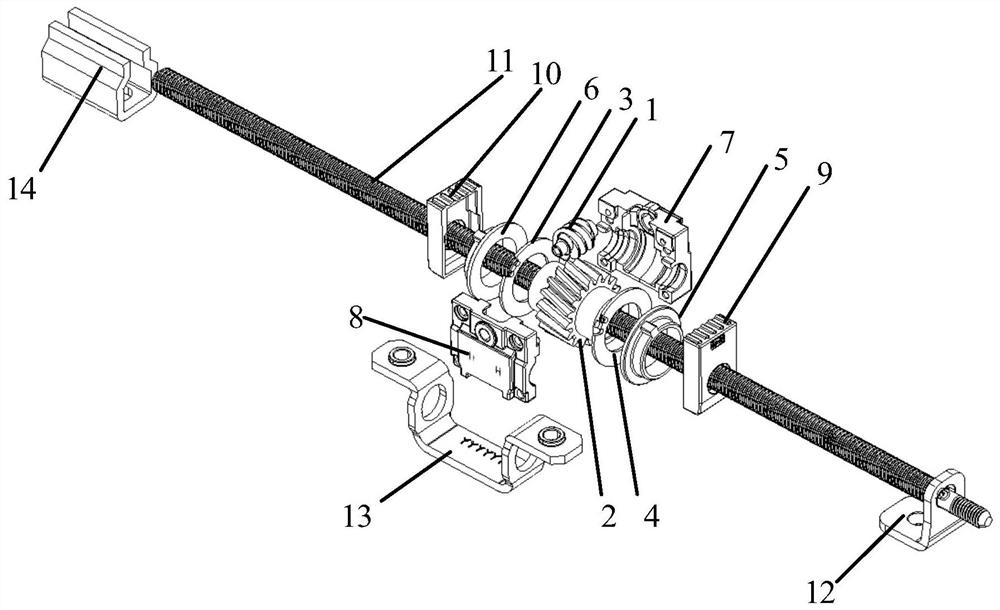

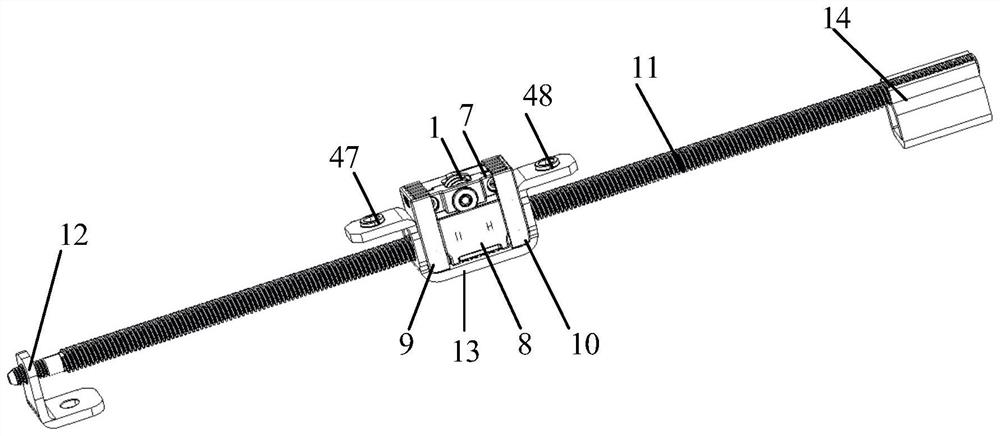

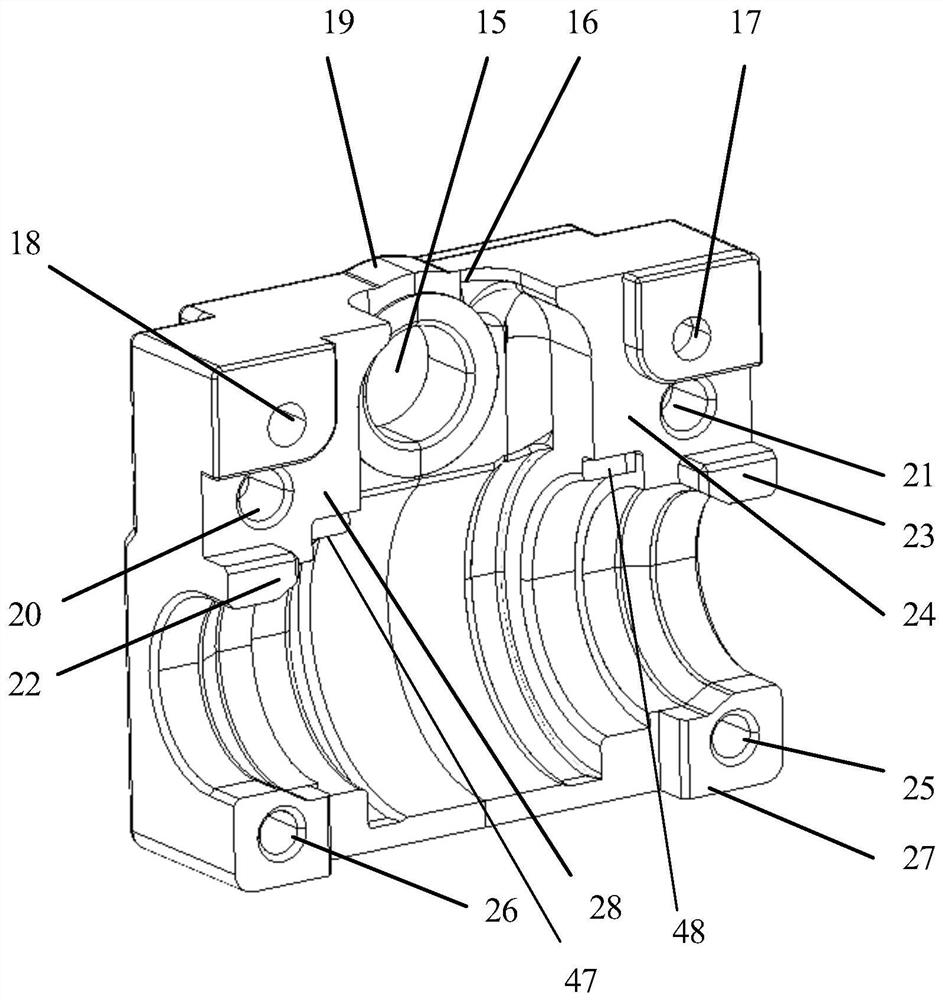

[0054] Such as Figure 1-Figure 5 As shown, this embodiment discloses a reinforced level adjustment device, including a first external box 7 and a second external box 8 arranged on the outside, and the first external box 7 is provided with threaded holes (threaded holes 17, Threaded hole 18, threaded hole 25 and threaded hole 26), the corresponding position of the second box body is provided with through hole (through hole 32, through hole 33, through hole 40, through hole 41), wherein, the first external box body 7 The position of the threaded holes (threaded hole 17, threaded hole 18, threaded hole 25 and threaded hole 26) has an outwardly protruding thickened portion 27, and the through holes of the second external box body 8 (through hole 32, through hole 33. The position where the through hole 40 and the through hole 41)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com