A Low-Temperature Helium Transport Sealing Structure for a Superconducting Rotary Machine

A technology of sealing structure and rotating machinery, applied in the sealing of engines, the usage of superconductor elements, mechanical equipment, etc., can solve problems such as leakage and poor sealing effect, and achieve the effect of easy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

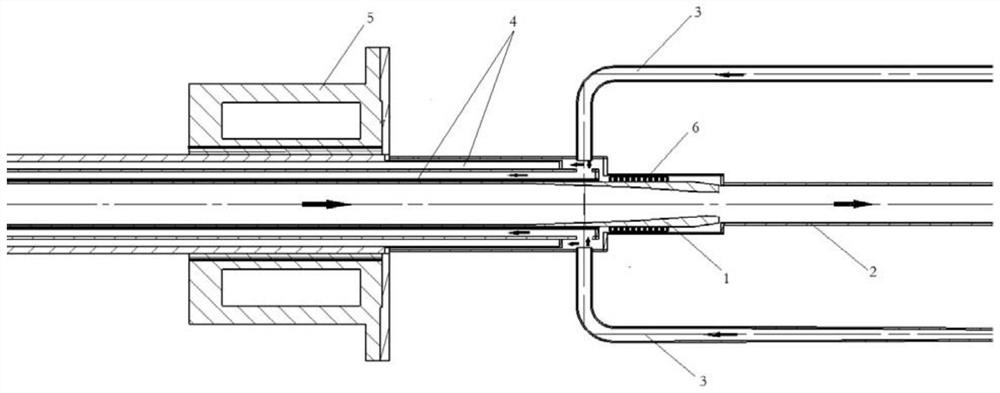

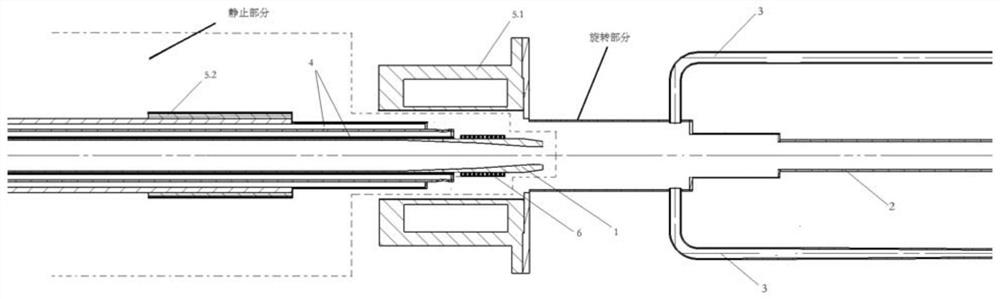

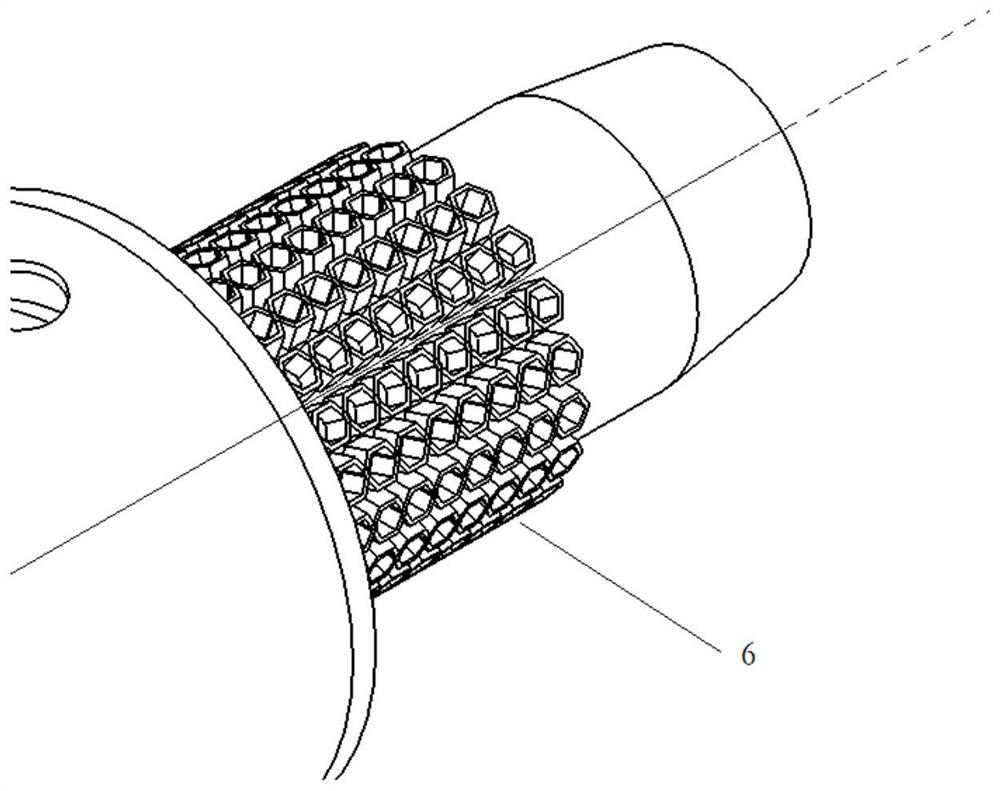

[0027] Such as figure 1 , 2 As shown, a superconducting rotary machine low-temperature helium transmission sealing structure, including a stationary inlet pipe 1, a rotating inlet pipe 2, a gas return pipe 3, a vacuum interlayer pipe 4, and a magnetic fluid sealing device 5 (rotating part 5.1, static part 5.2) , Honeycomb sealed structure 6. The low-temperature helium gas enters the rotating inlet pipe 2 from the cryogenic refrigerator through the static inlet pipe 1 and enters the superconducting rotating machine to cool the superconducting magnet. After the gas is heated, it returns to the refrigerator through the return pipe 3 and other circuits for cooling. Since the return air temperature is higher than the intake air temperature, in order to avoid energy loss, the inlet pipe and the return air pipe are insulated by a vacuum interlayer pipe 4, and the air intake and return air are isolated by a honeycomb sealing structure 6 at the static and rotating joints , to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com