Aluminum rod hot shearing machine adopting linear guide rail structure

A technology of linear guides and hot shears, applied in shearing machine equipment, shearing devices, accessories of shearing machines, etc. Clearance increases and other problems, to achieve the effect of not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

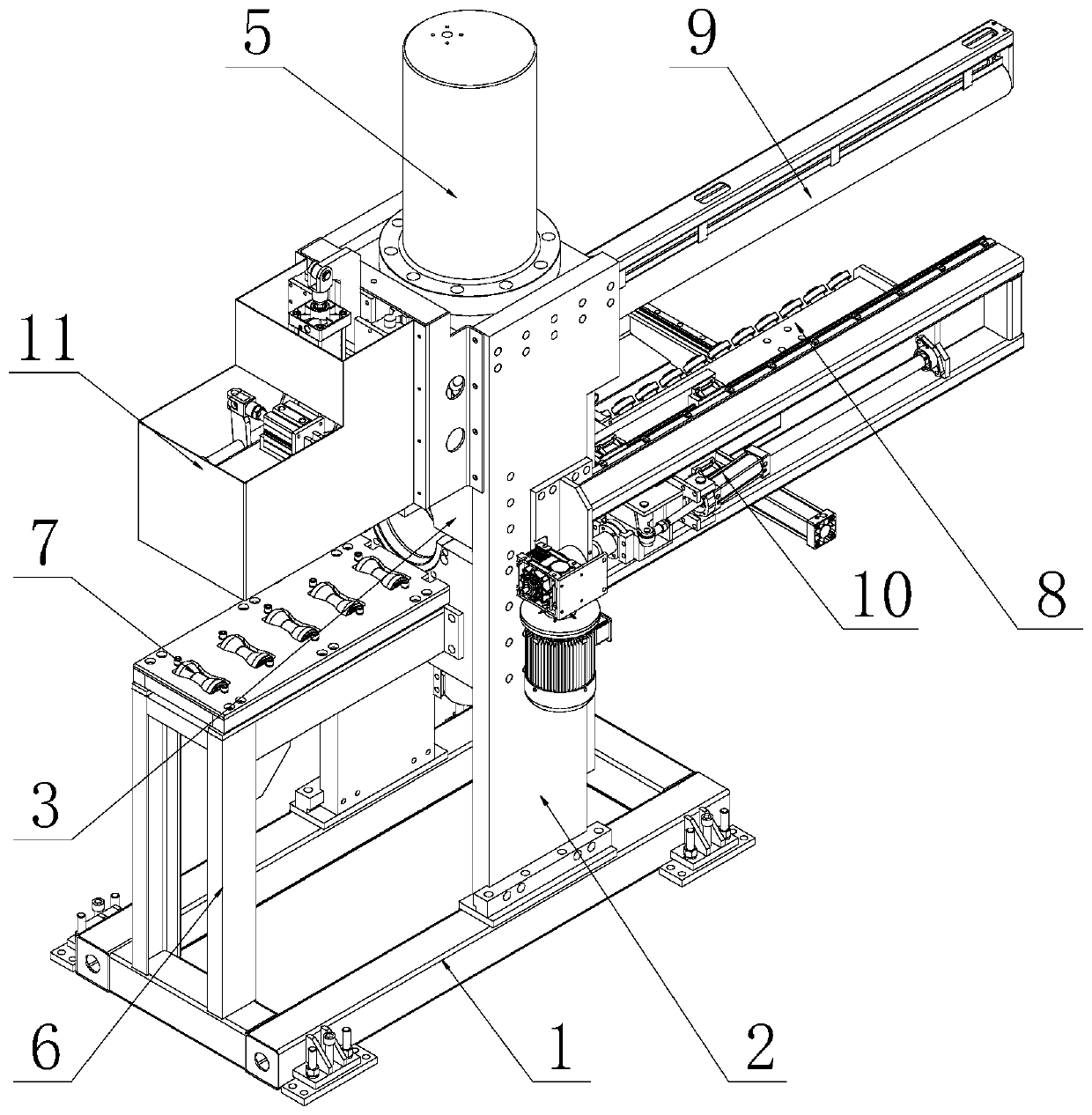

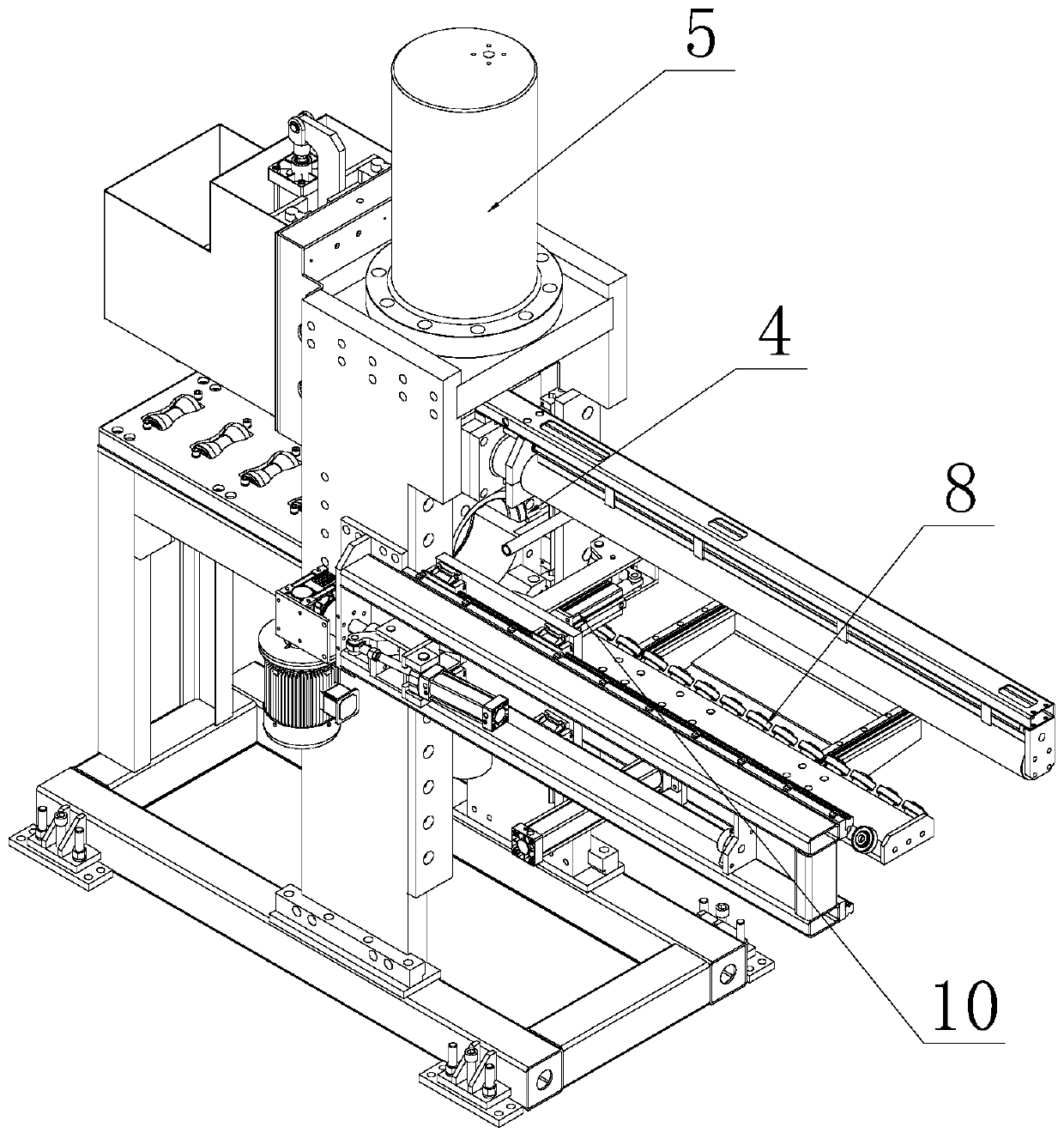

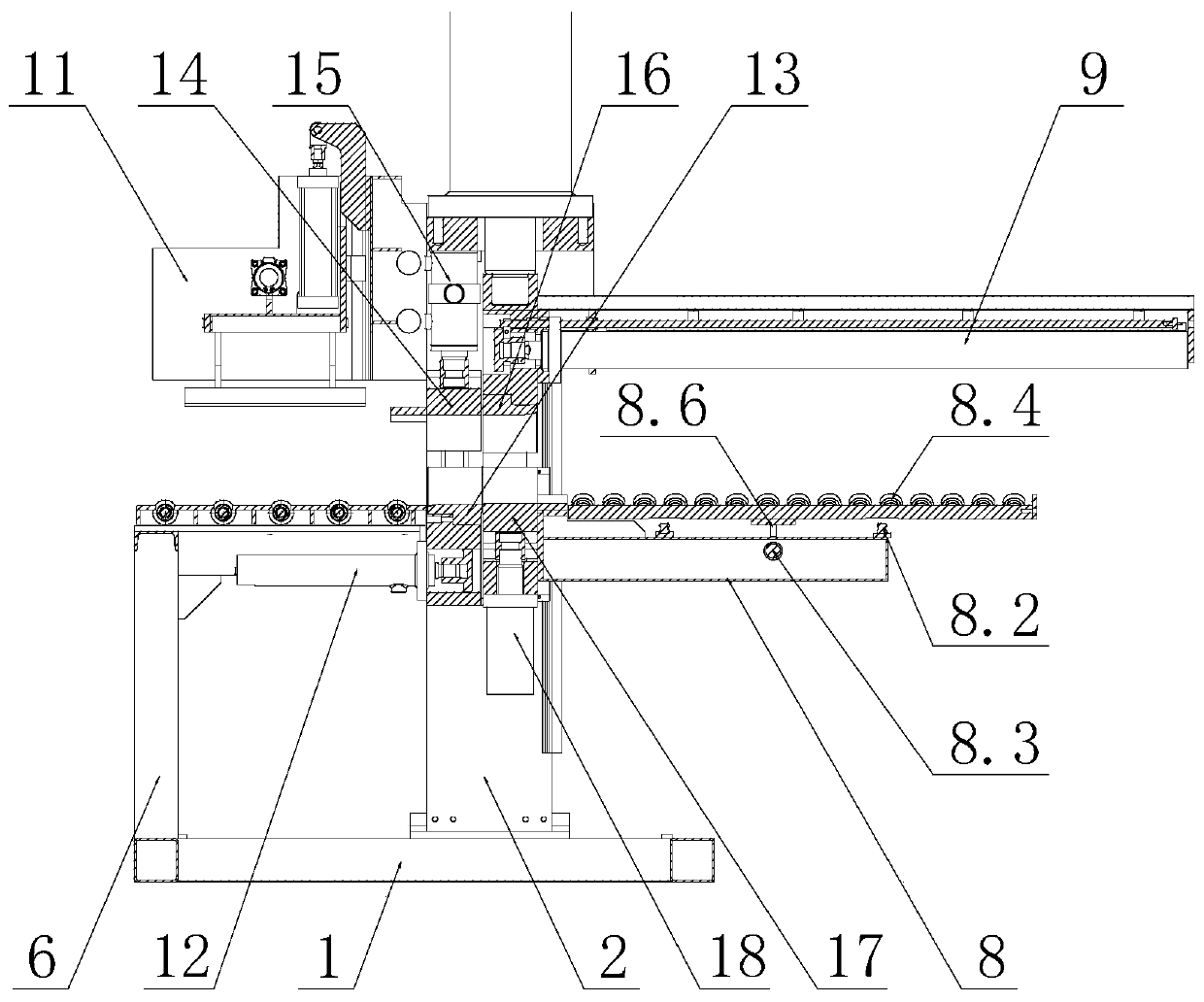

[0123] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0124] see Figure 1 to Figure 6 , a kind of aluminum bar heat shearing machine adopting linear guide rail structure in the present embodiment, it comprises base 1, and described base 1 is provided with frame 2, and described frame 2 is provided with fixed knife seat 3 and moving knife Seat 4, the top of the frame 2 is provided with a main oil cylinder 5, the lower end of the main oil cylinder 5 is connected with the movable knife seat 4, the main oil cylinder 5 can drive the movable knife seat 4 to move up and down, and the rear side of the frame 2 A rear roller frame 6 is provided, and a rear roller assembly 7 is arranged on the rear roller frame 6. The front side of the moving knife seat 4 is provided with a connecting rod translation mechanism 8 and a rod retracting mechanism 9, and the rod retracting mechanism 9 is located at the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com