Pressure dies for dust-free drawing of aluminum-clad steel

A pressure die and pressure die technology, which is applied in the field of pressure die for dust-free drawing of aluminum clad steel, can solve the problems of enlargement, waste of manpower and material resources, etc., and achieve the effect of prolonging the life of the die, saving costs, and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

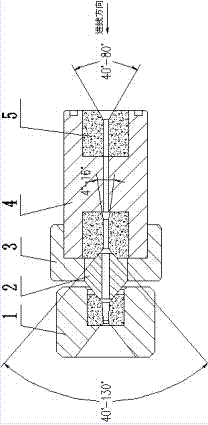

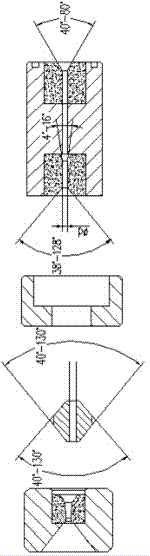

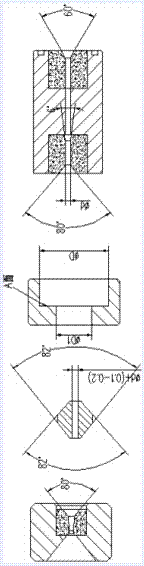

[0022] like Figure 4 As shown, the pressure die 4 is cylindrical, and hard alloy 5 is installed at both ends of the pressure die 4. The angles of the inner holes of the hard alloy 5 at one end are 60° in the direction of wire entry, and the angles of the inner holes of the hard alloy 5 at the other end are respectively 60°. The angle of the incoming wire direction is 6°, and the angle of the outgoing wire direction of the carbide 5 at the other end is 80°. A transition joint 2 is installed between the cylindrical pressure die 4 and the wire drawing die 1. The transition joint 2 is olive-shaped. In order to ensure that the transition joint and the wire drawing die are firmly connected and the lubricating medium does not leak, the two ends of the transition joint 2 are The taper is set to 82º. The inner hole diameter of the transition joint 2 is 0.10-0.20mm larger than the inner hole diameter of the pressure mold 4 . In order to ensure the coaxiality of the transition joint, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com