A method of vacuum brazing large-scale outer ring welding components

A welding assembly, large-scale technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of not meeting the needs of scientific research and trial production of large-sized outer ring welded assemblies, meet the vacuum brazing gap requirements, and optimize the process. parameters, the effect of avoiding base metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

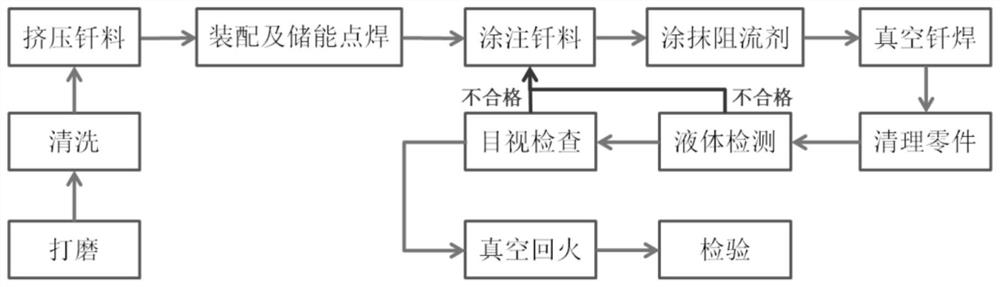

[0064] Step 8, cleaning parts: with compressed air, the white blocking agent on the surface of the parts is blown off clean. If the surface of the part is

Embodiment 2

[0081] Step 8, cleaning the parts: blowing off the white blocking agent on the surface of the parts with compressed air. If the surface of the part is

Embodiment 3

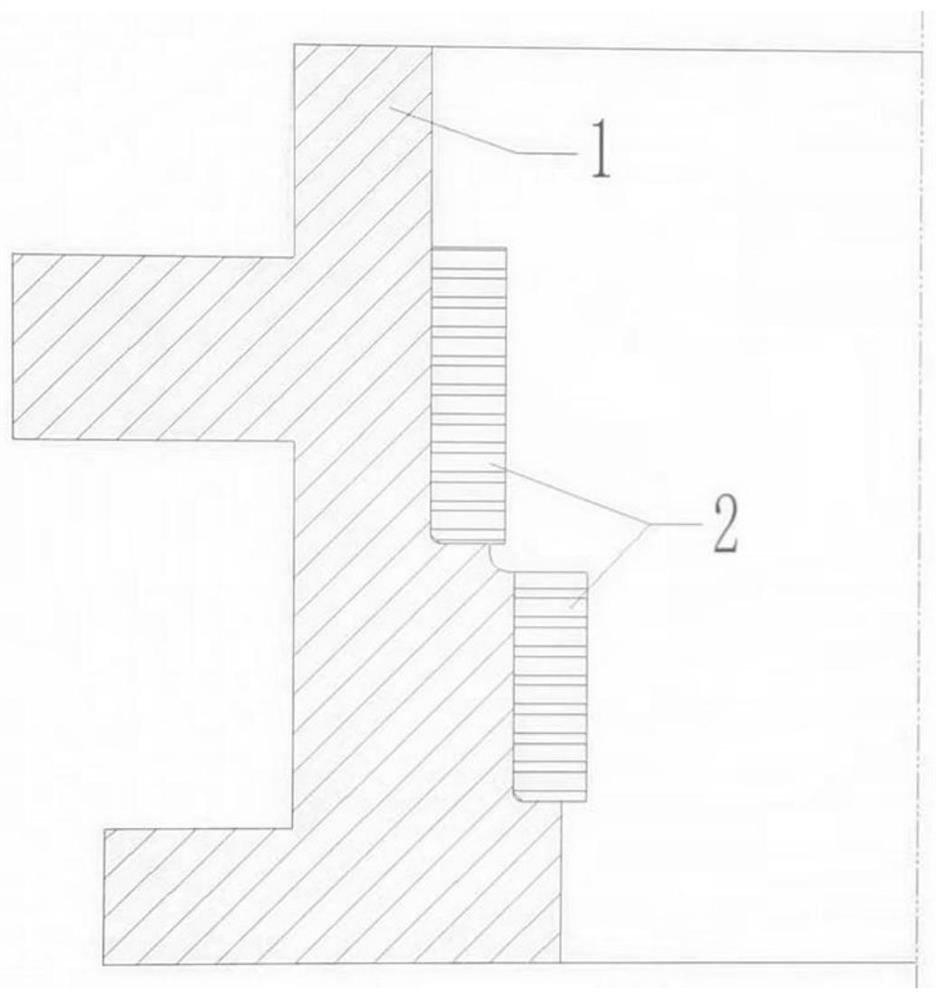

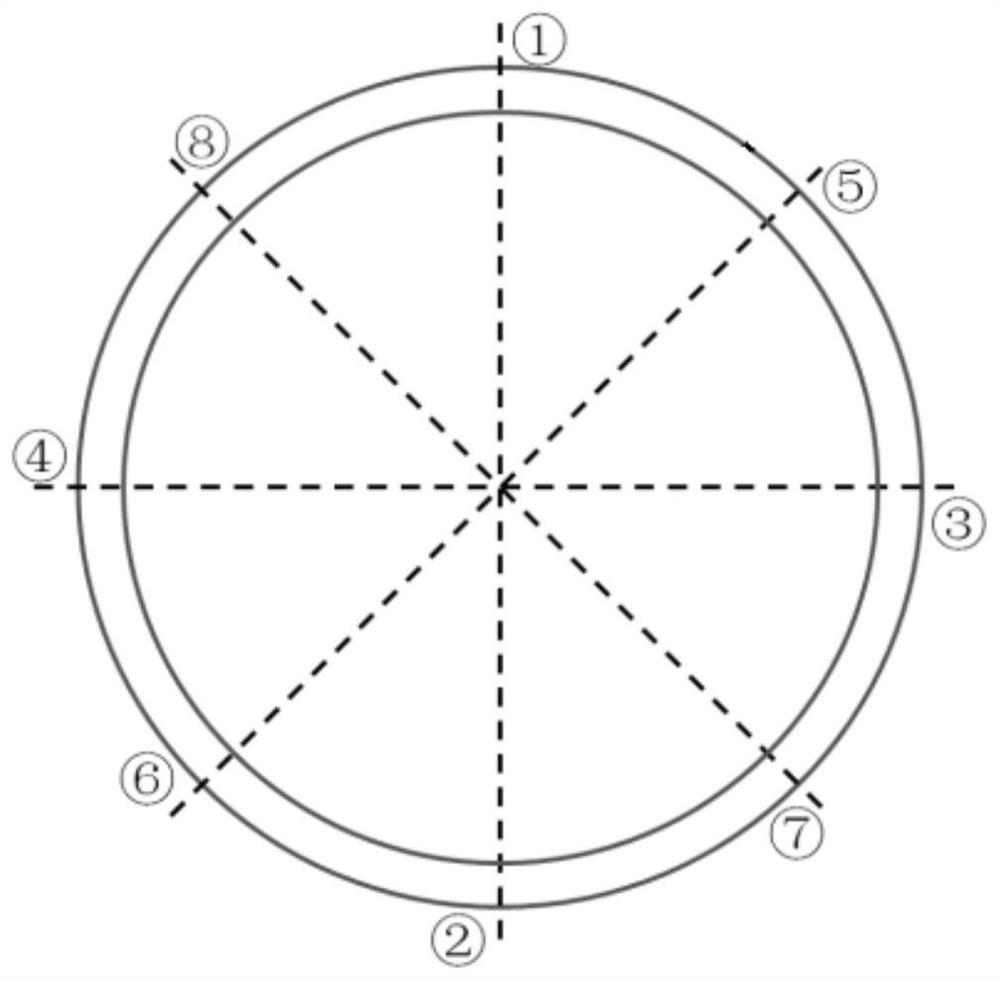

[0091] Step 4, assembly and energy storage spot welding: on the outer ring base 1, precoat a circle of prepared paste solder. Press the solder

[0098] Step 8, cleaning the parts: blowing off the white blocking agent on the surface of the parts with compressed air. If the surface of the part is

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com