Compressed air power engine assembly with compressed air supplementary return circuit

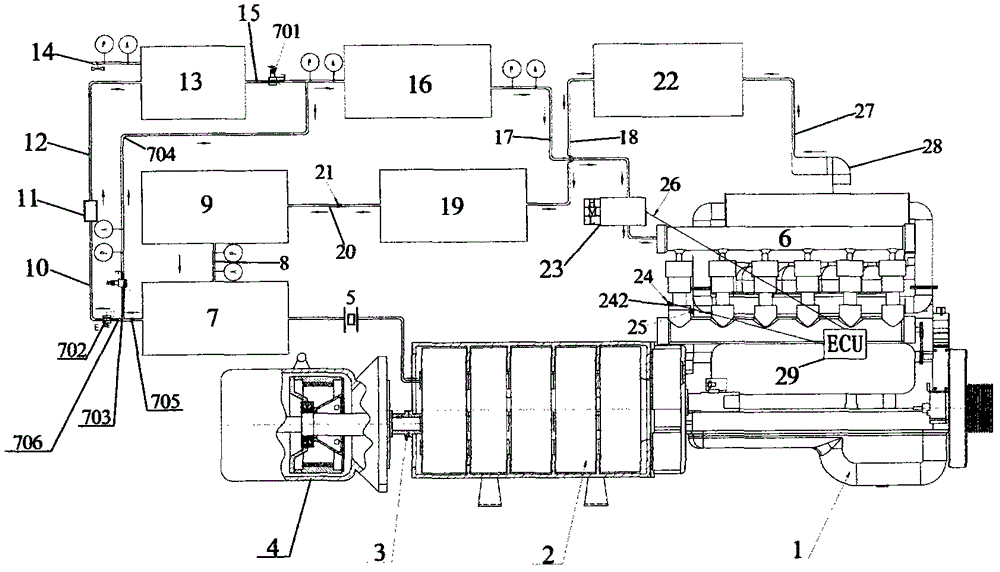

An engine assembly and compressed air technology, applied to engines, engine components, variable capacity engines, etc. based on the unidirectional flow principle, can solve problems such as wasting power strokes, reducing the application prospects of compressed air engines, and limiting engine efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

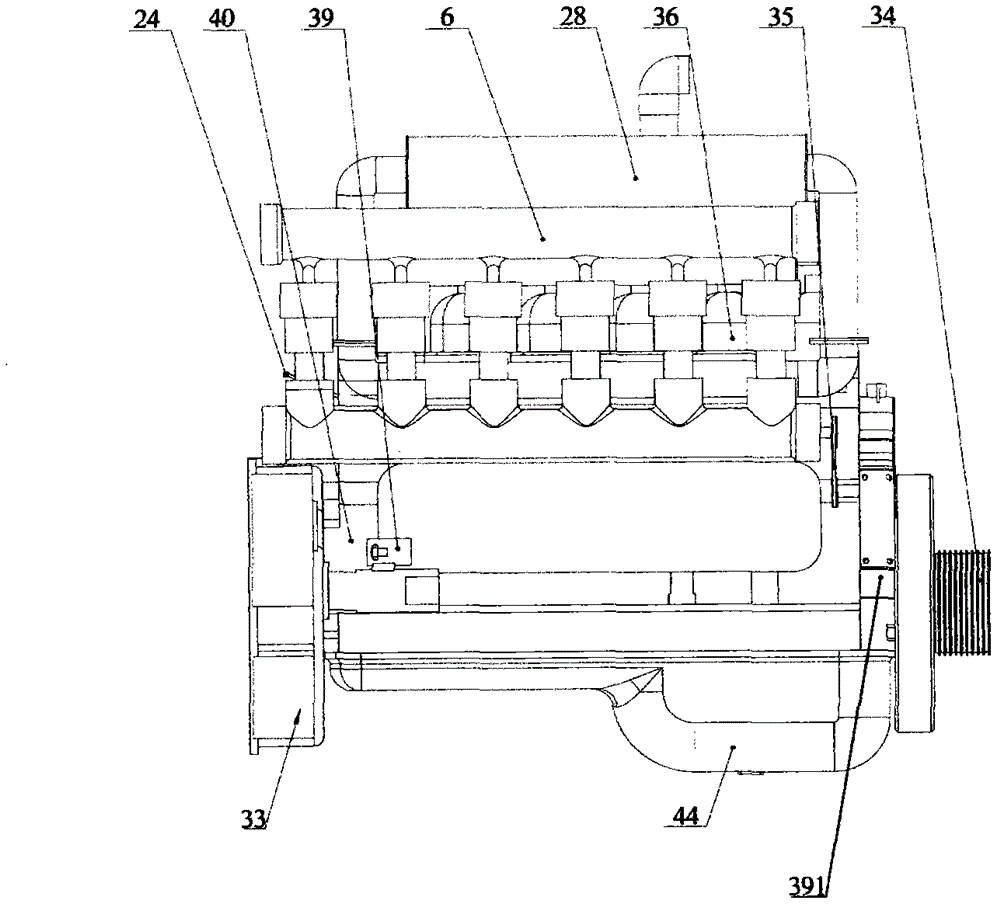

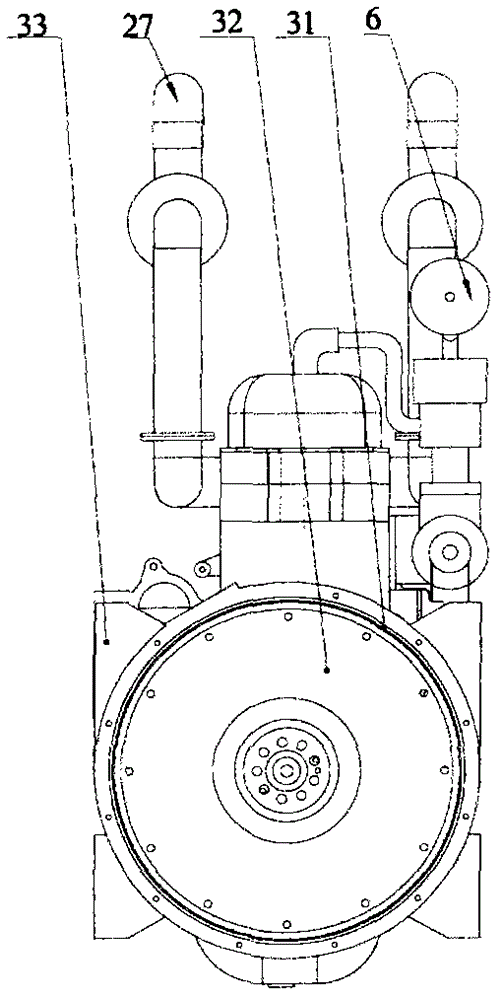

Embodiment Construction

[0055] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0056] Before describing the specific embodiment of the present invention in detail, the energy of the compressed air engine will be theoretically analyzed.

[0057] The working process of the compressed air engine is relatively simple, only the process of expanding the compressed air to do work. Such as Figure 12A as shown, Figure 1-5 It is the isothermal expansion process of compressed air, and 1-6 is the adiabatic expansion process of compressed air. The work done by compressed air in the engine cannot be a complete isothermal process, usually between the isothermal process and the adiabatic process. In order to improve the energy utilization rate of compressed air, a multi-stage adiabatic process can be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com