Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

A compressed air and engine technology, which is applied in the engine field of environmental heat energy recovery equipment, can solve the problems such as the reduction of the total efficiency of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

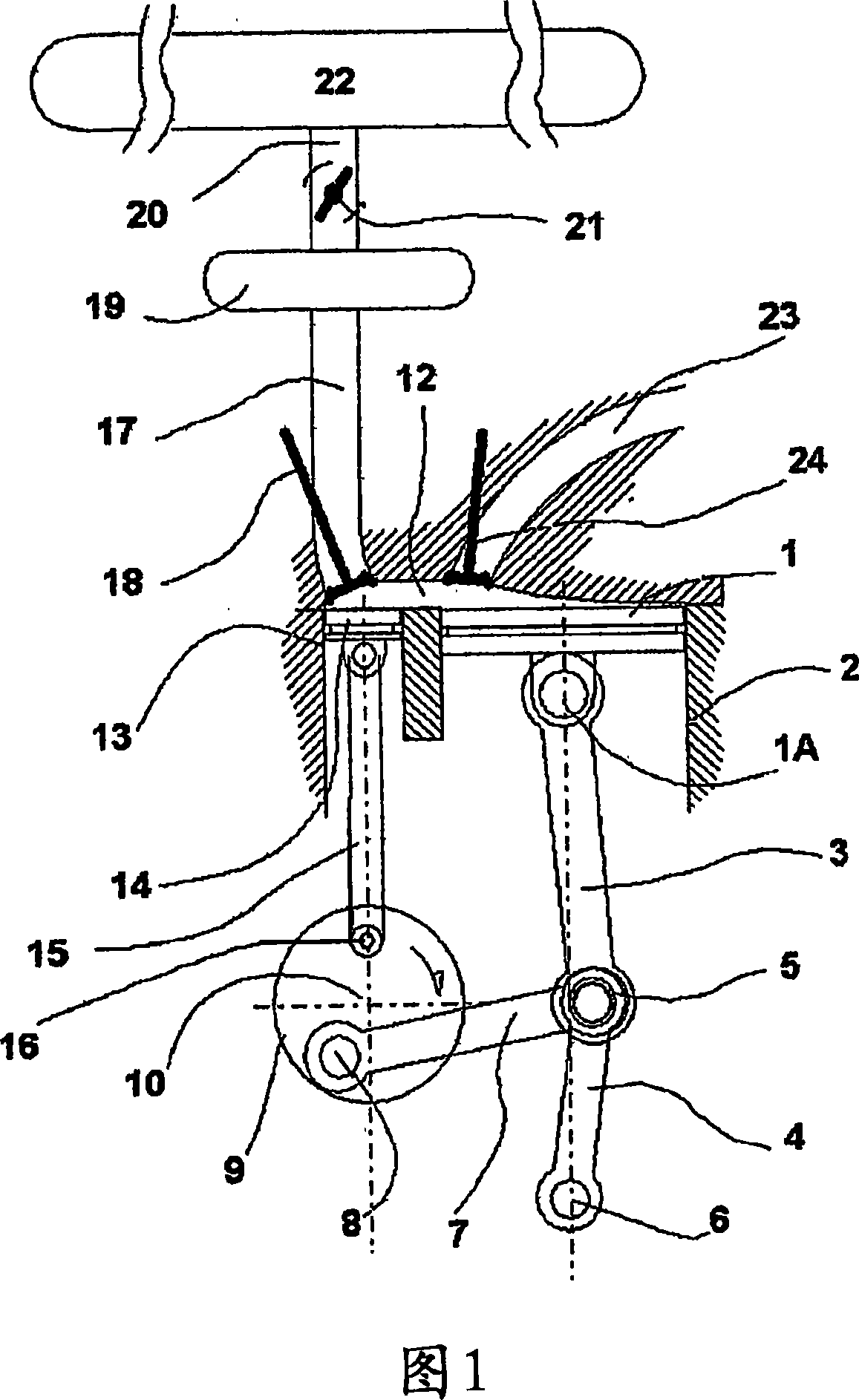

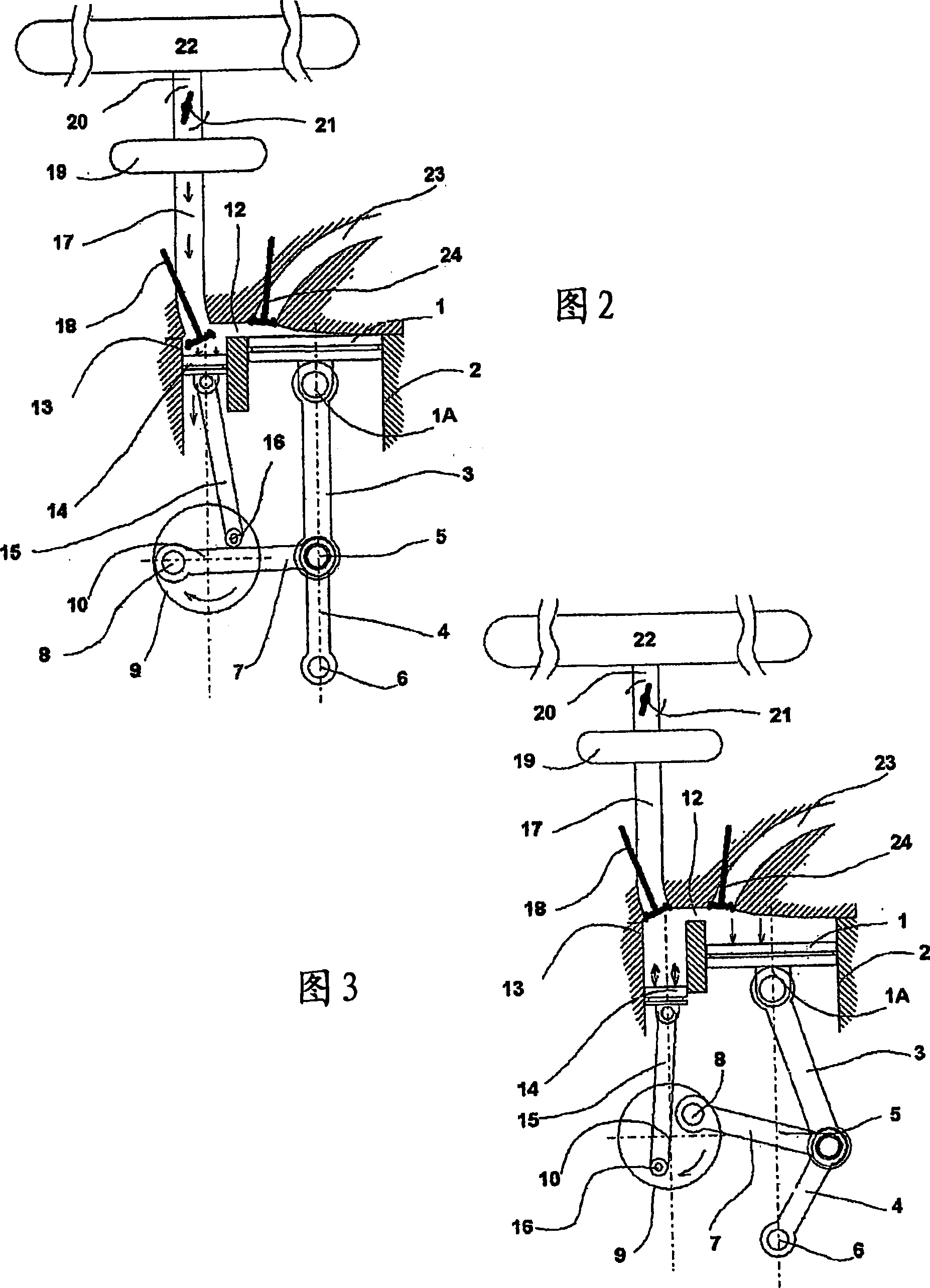

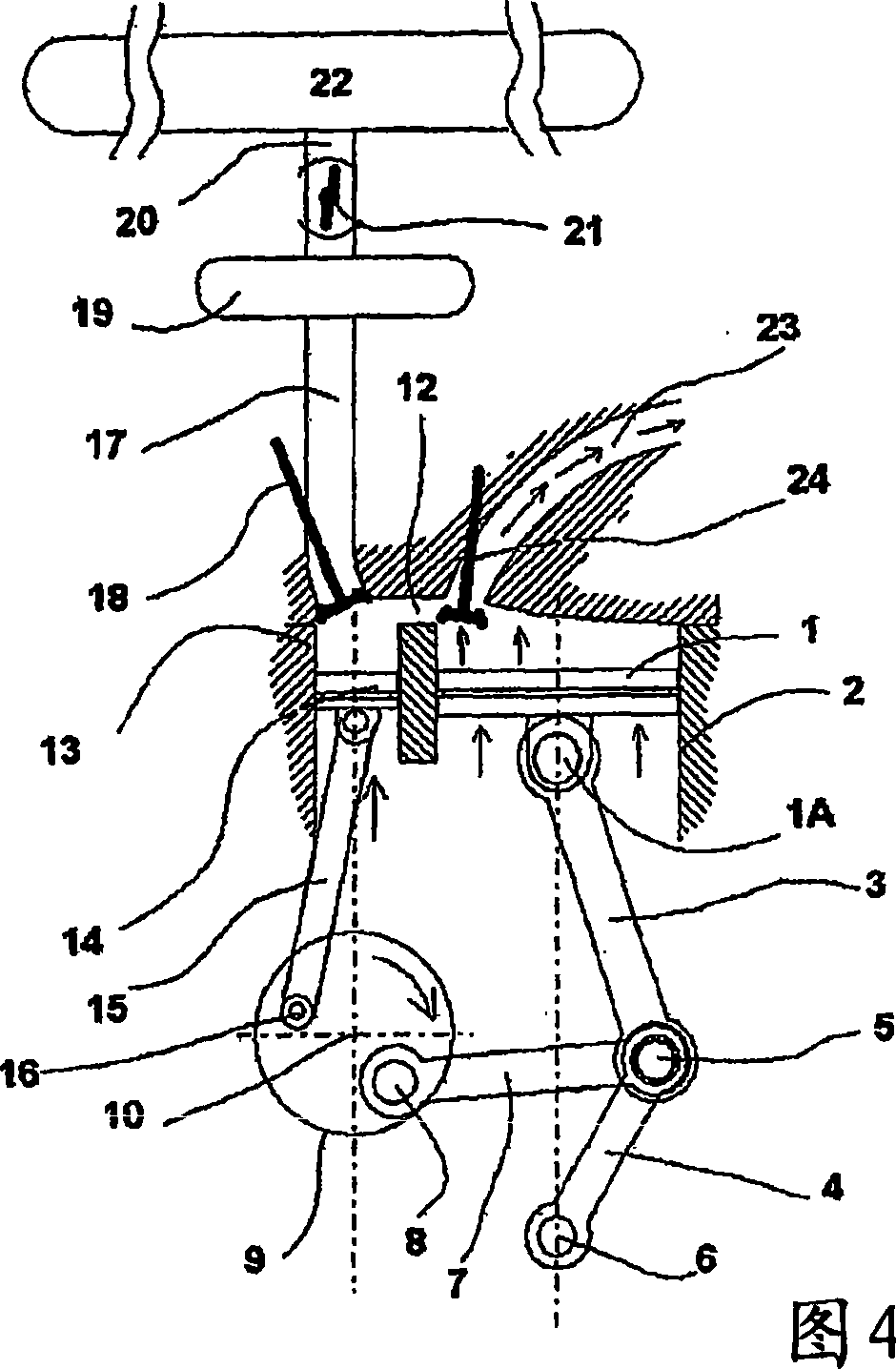

[0076] [76] Figure 1 shows an active chamber engine according to the invention, wherein the cylinder of the engine can be seen, in which slides said piston 1 (shown at its top dead center), said piston being driven by a Pressure lever control, sliding in a cylinder 2. Said piston 1 is connected by its shaft to the free end 1A of a pressure lever composed of an arm 3 articulated on a common axis 5 with the other arm 4 pivotally fixed on a stationary axis 6 . On the common shaft 5 with the two arms 3 and 4 is connected a control link 7 which is connected to the crank pin 8 of a crankshaft 9 which rotates about its axis 10 . When the crankshaft rotates, the control link 7 exerts a force on the common axis 5 of the two arms 3 and 4 of the pressure lever - thus allowing the piston 1 to move along the axis of the cylinder 2 , and during the working stroke, by rotating the crankshaft 9, the force exerted on said piston 1 is transmitted, thus causing the rotation of said crankshaft. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com