Numerical control pneumatic engine

A pneumatic engine and cylinder technology, applied in the field of powertrain, can solve the problems of high pressure air pressure energy loss, complex engine air distribution mechanism, difficult gas flow control, etc., to eliminate frost and ice blockage, easy control, energy Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

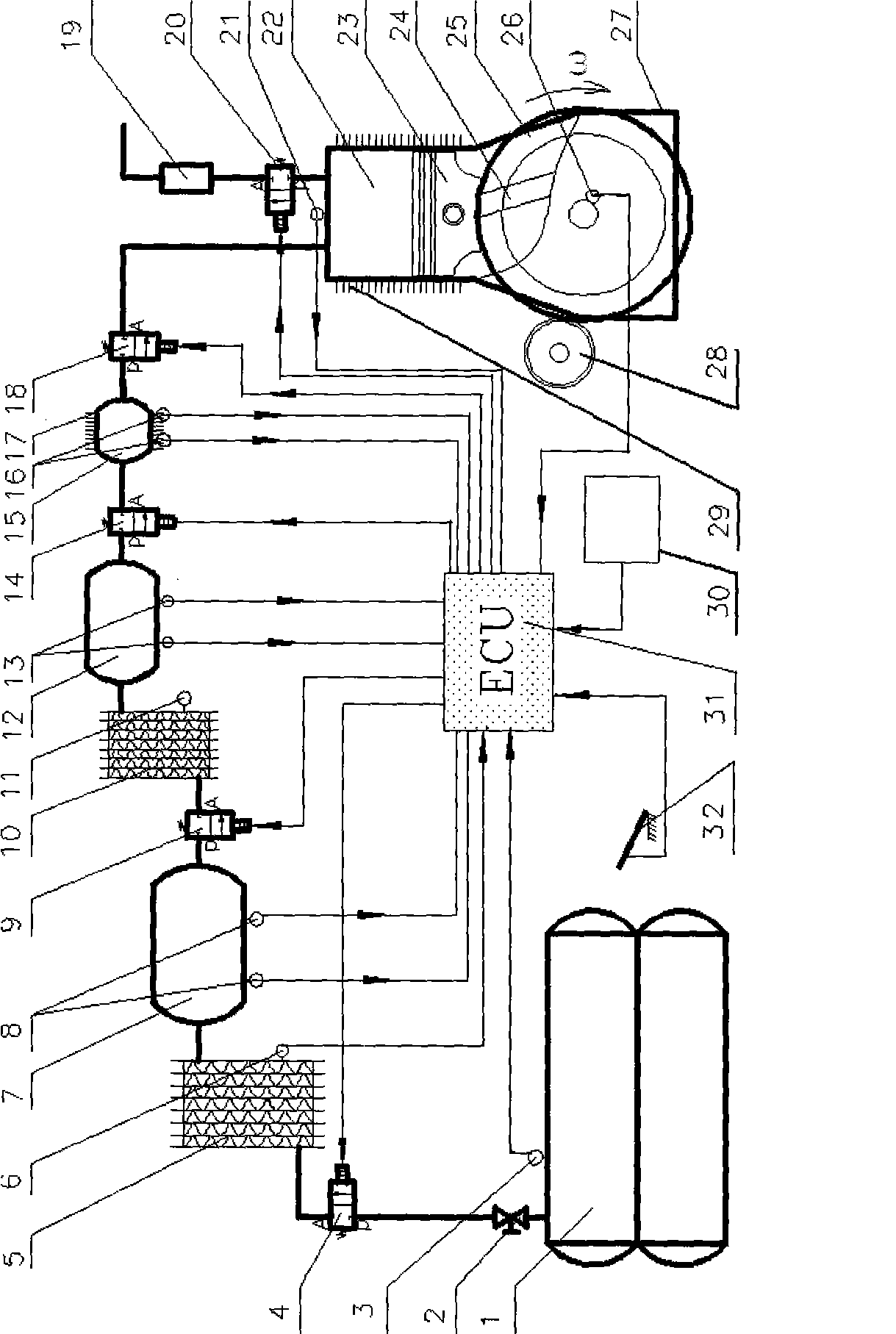

[0014] Such as figure 1 , the CNC pneumatic engine is mainly composed of three major systems: energy supply system, energy conversion system and control system, and its working process mainly includes: energy supply process and energy conversion process.

[0015] 1. Energy supply process

[0016] The energy supply system of the CNC pneumatic engine consists of a high-pressure gas storage tank 1, a manual valve 2, a control solenoid valve A 4, a primary heat exchanger 5, a primary decompression cylinder 7, a control solenoid valve B 9, and a secondary heat exchanger 10 , two-stage decompression cylinder 12, control solenoid valve C 14, quantitative pre-spray cylinder 15, and control solenoid valve D 18 are sequentially connected in series by relevant pipelines. The control system is composed of electronic control unit 31, signal acquisition equipment and execution equipment. Wherein the signal acquisition equipment includes various temperature, pressure and position sensors a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com