Engine based kinetic energy recovery system for vehicles

a technology of kinetic energy recovery and engine, applied in the direction of hybrid vehicles, positive displacement liquid engines, electrical control, etc., can solve the problems of high energy waste, prior attempts to provide for the recapture of energy for reuse, and difficult economic justification at low energy prices, so as to improve the efficiency of motor vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]FIG. 1 illustrates in a perspective view a truck tractor 10 comprising a cab 11 mounted on a chassis 12. A plurality of wheels 13 depend from the chassis. Tractor 10 includes conventional major systems for a vehicle, including a drive train having a diesel engine and a transmission. Tractor 10 also includes air powered drive train boosters as described below. The invention is preferably applied to medium and large trucks which have compressed air systems for brake operation or for starting. These vehicles are typically equipped with a multi-cylinder diesel, which is often adapted for engine compression braking, and compressed air tanks. It will be understood that while the invention is preferably applied to diesels, it would also work, with modification, on internal combustion engines using spark initiated combustion. It may also be advantageously applied to delivery trucks and other vehicles used heavily for stop and go driving.

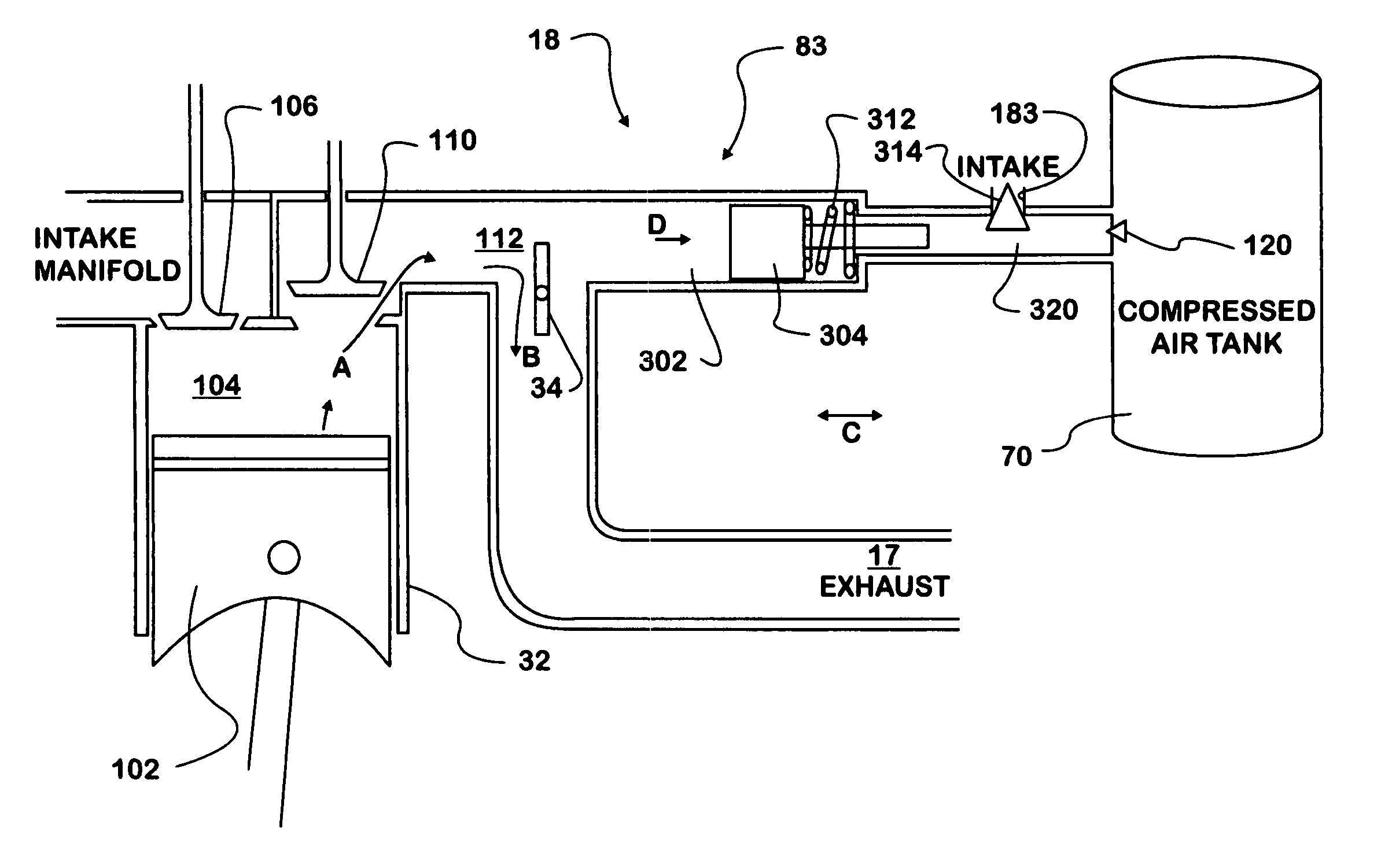

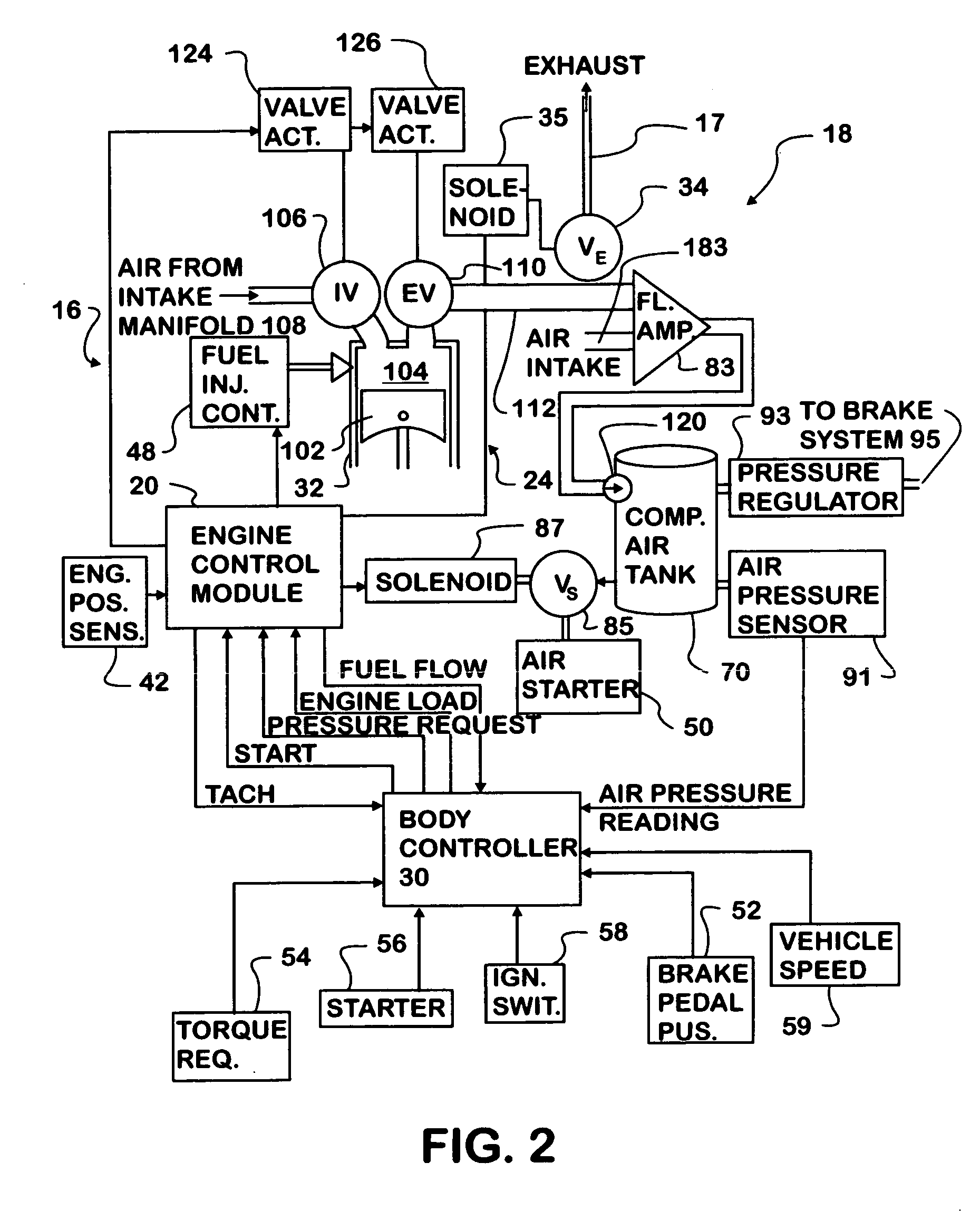

[0023] Referring now to FIG. 2 an engine air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com