Method for preparing compressed air by pneumatic air compressor

A technology of compressed air and compressor, which is applied in container filling methods, mechanical equipment, equipment loaded into pressure vessels, etc., can solve problems such as energy waste, and achieve the effects of reducing production costs, increasing gas transmission distance, and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

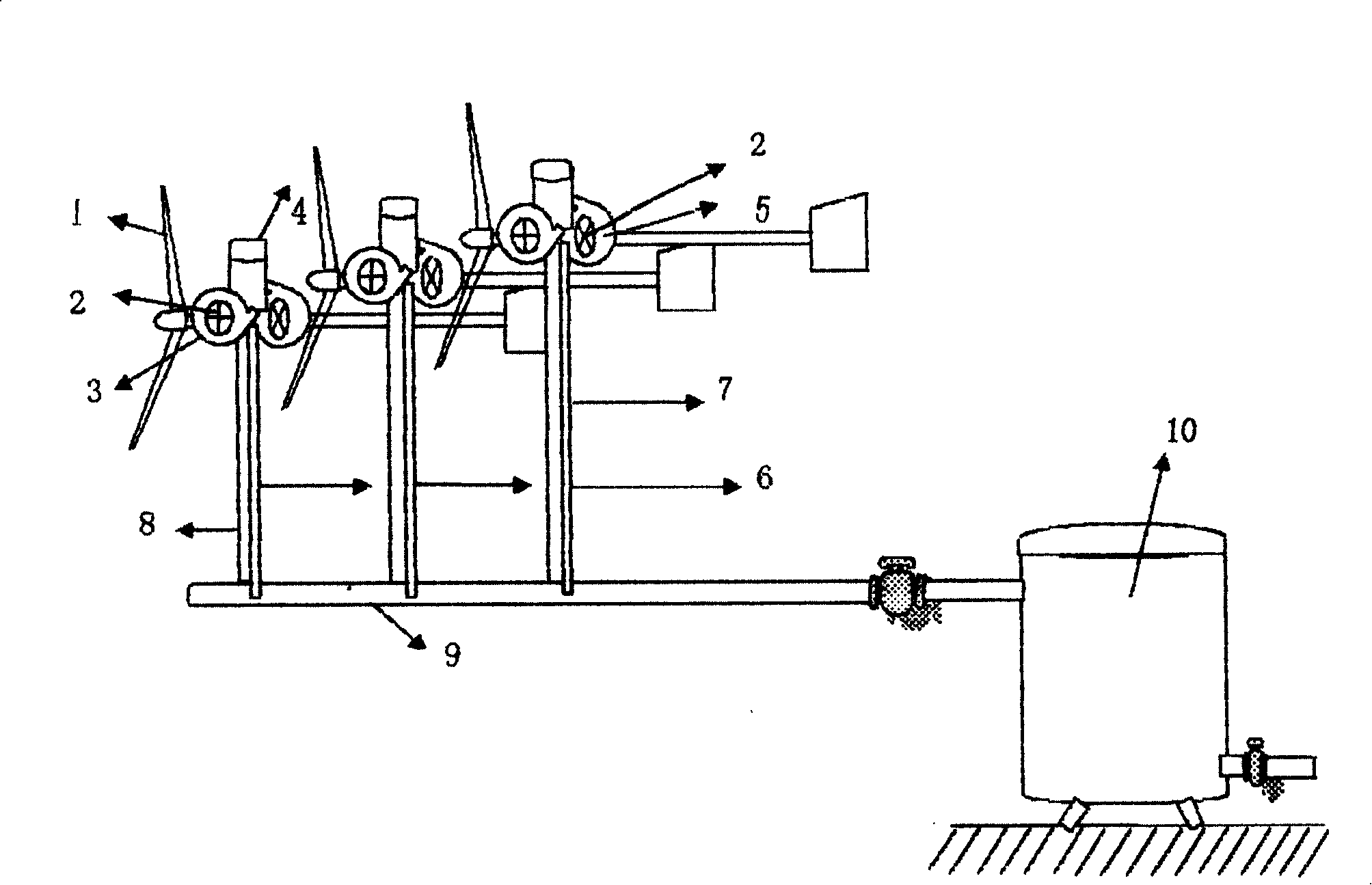

[0028] like figure 1 shown. In this embodiment, wind energy is collected and converted into kinetic energy by the air compressor group 4 arranged at the tuyere, and is connected with the speed regulator 2 arranged at the rear end of each wind turbine 1 to convert wind energy into kinetic energy and speed up; the speed governor 2 adopts The gear transmission speed regulating device is connected with each air compressor fan 3 and booster fan 5 in the air compressor fan group 6 arranged on one side of the central air pipeline 9, and the air compressor fan 3 inhales and compresses the air and outputs it to the return air tank In 4, the booster blower 5 inhales the compressed air from the air return tank 4 to pressurize and then the air compressor group 6 transports the pressurized compressed air to the central gas pipeline 9 through each branch gas pipeline 7; The air pipeline 9 delivers the compressed air to the air storage tank 10 for storage.

Embodiment 2

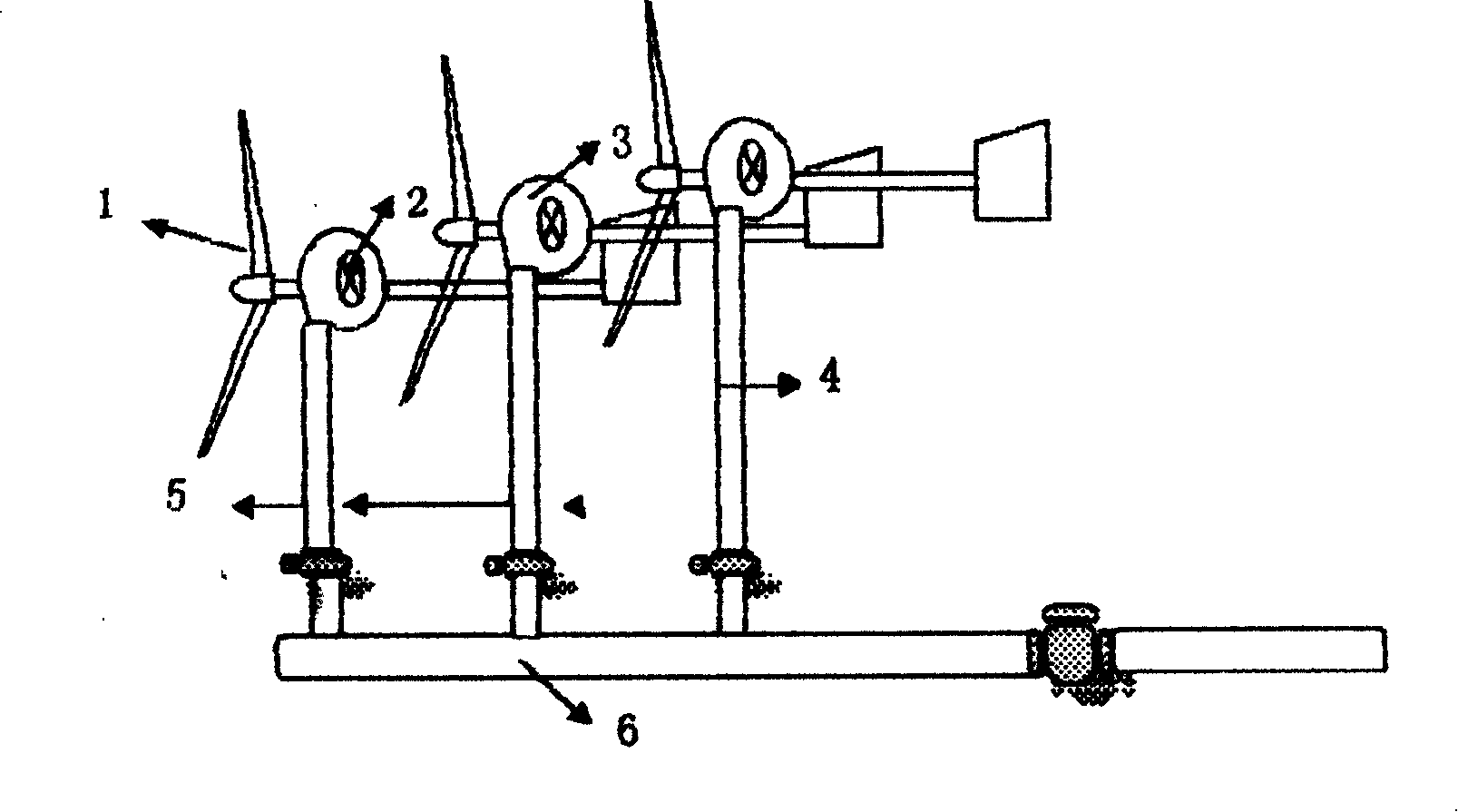

[0030] like figure 2 shown. In this embodiment, wind energy is collected and converted into kinetic energy by the air compressor group 4 arranged at the tuyere, and is connected with the speed regulator 2 arranged at the rear end of each wind turbine 1 to convert wind energy into kinetic energy and speed up; the speed governor 2 adopts The gear transmission speed regulating device is connected with each air compressor fan 3 in the air compressor fan group 6 arranged on one side of the central air pipeline 9, and the air is inhaled and compressed by the air compressor fan 3, and then pressurized by the air compressor fan group 6. The compressed air is transported to the central gas pipeline 9 through each branch gas pipeline 7; the central gas pipeline 9 delivers the compressed air to the user.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com