Patents

Literature

44results about How to "Avoid eccentric rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

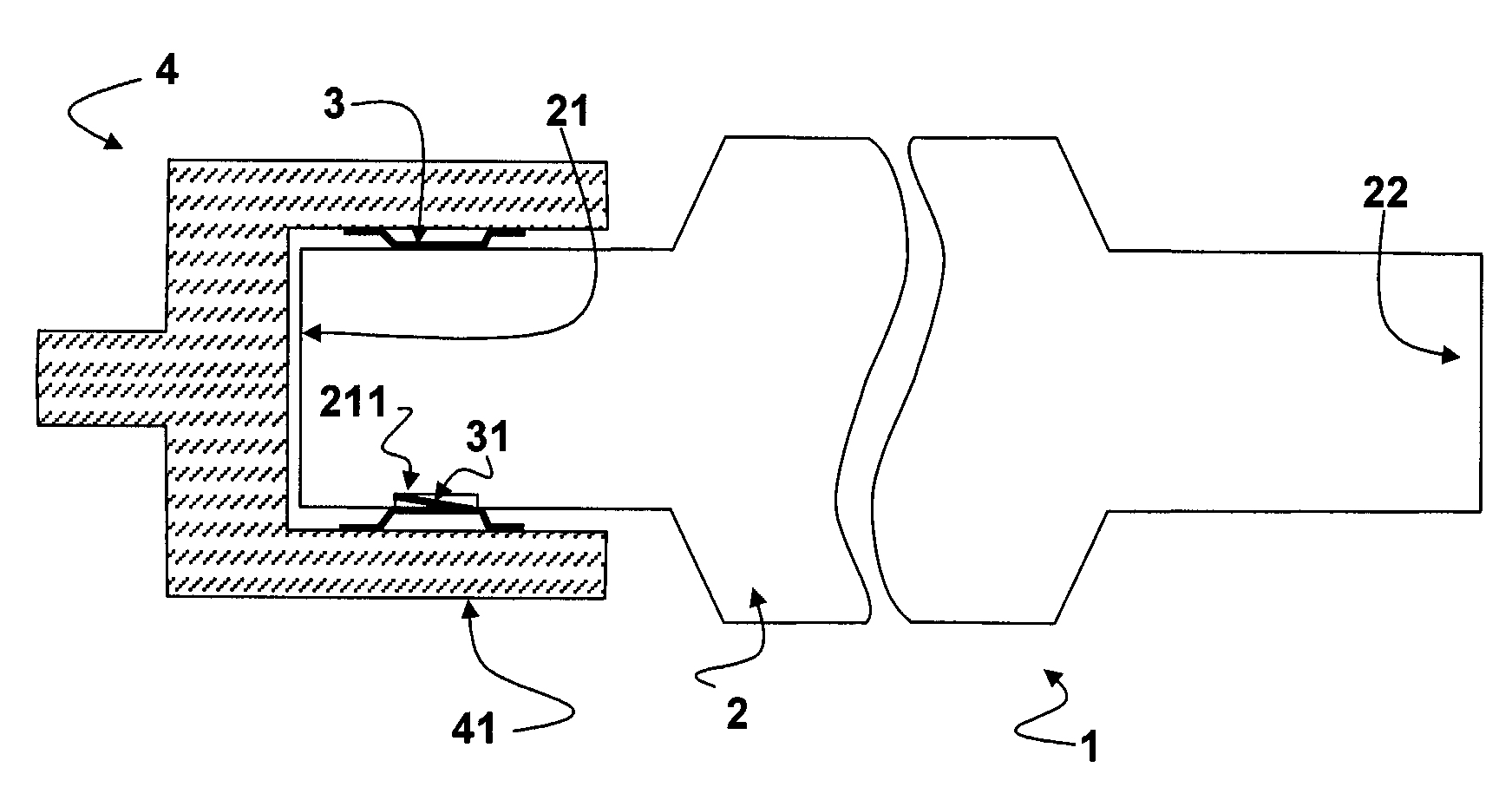

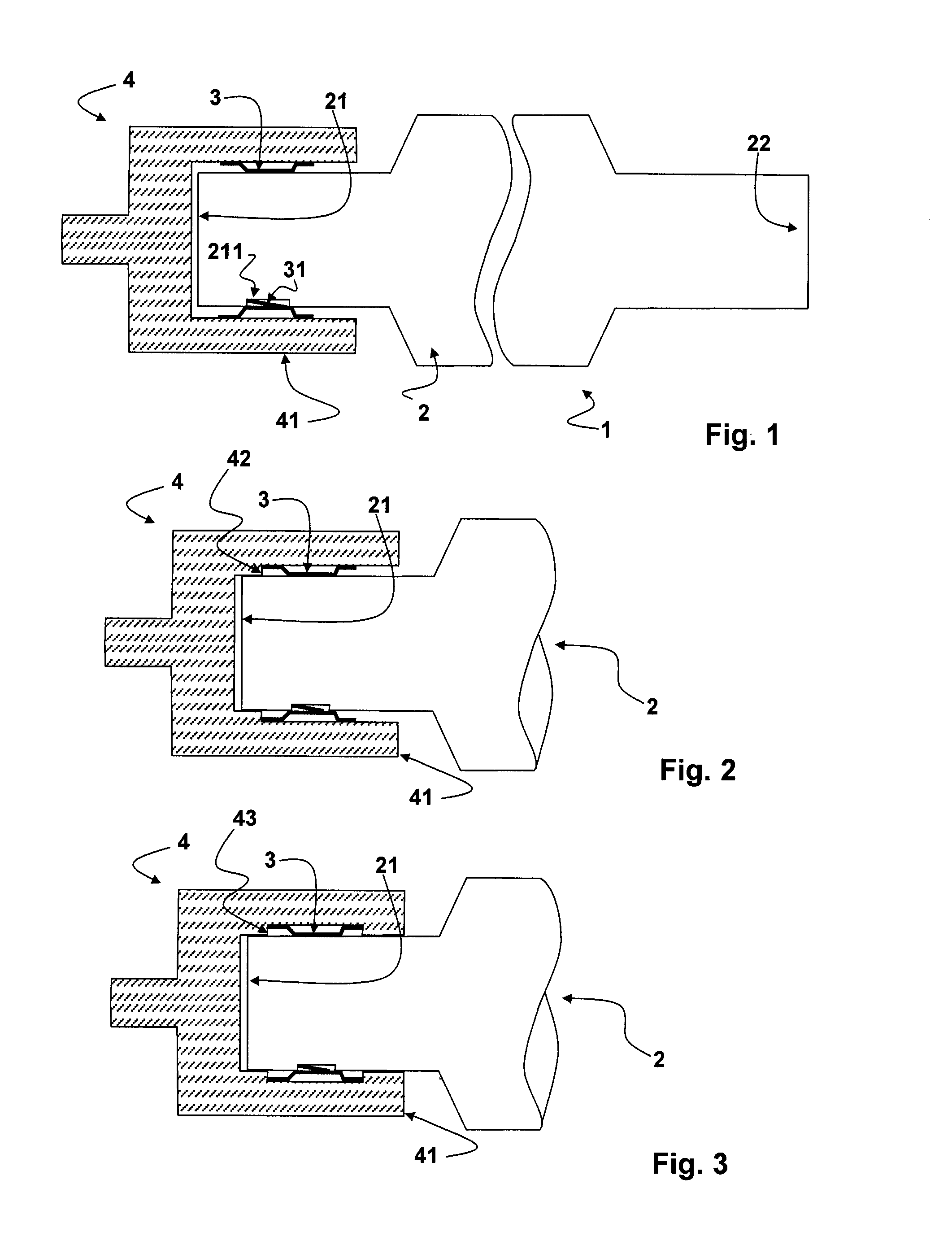

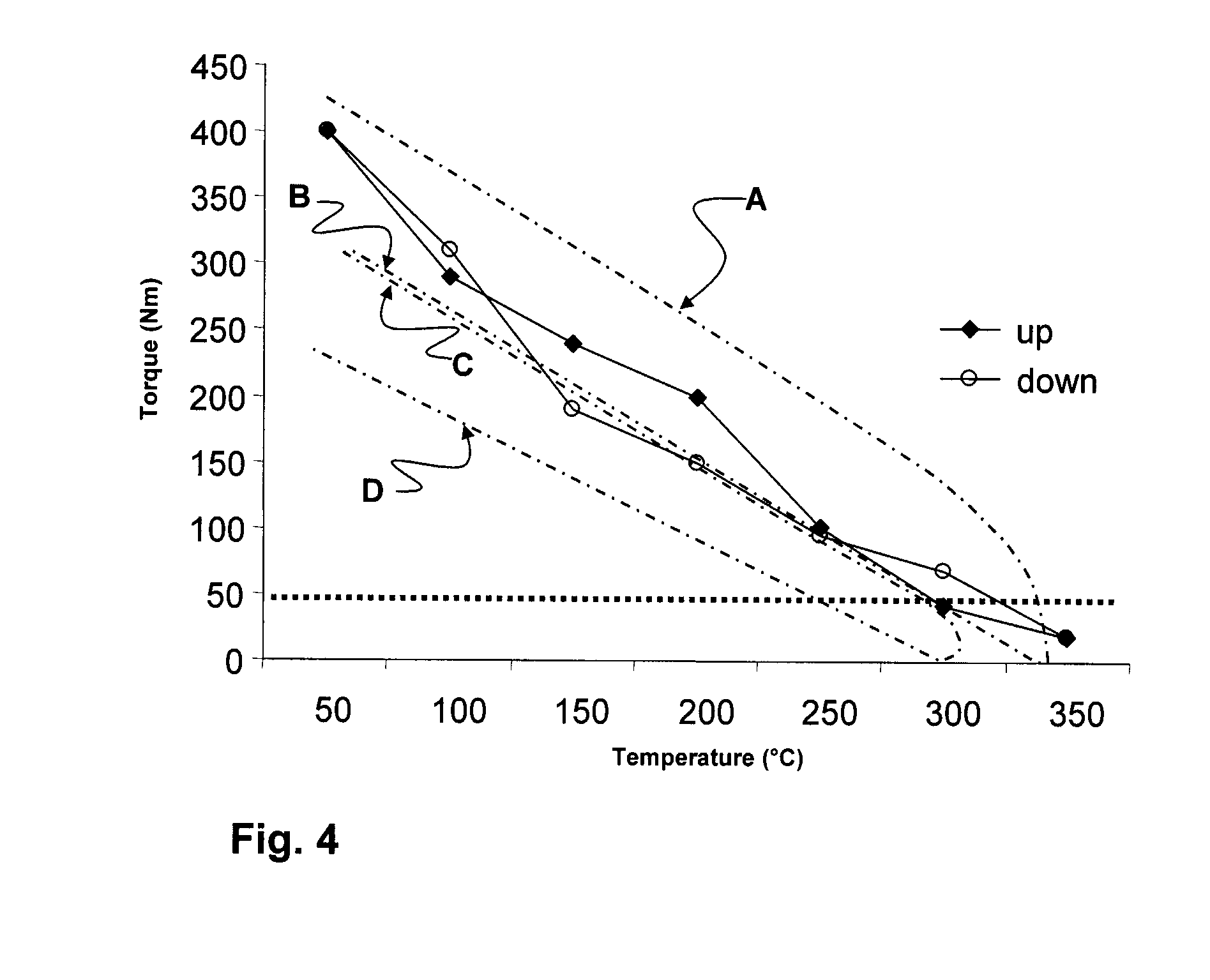

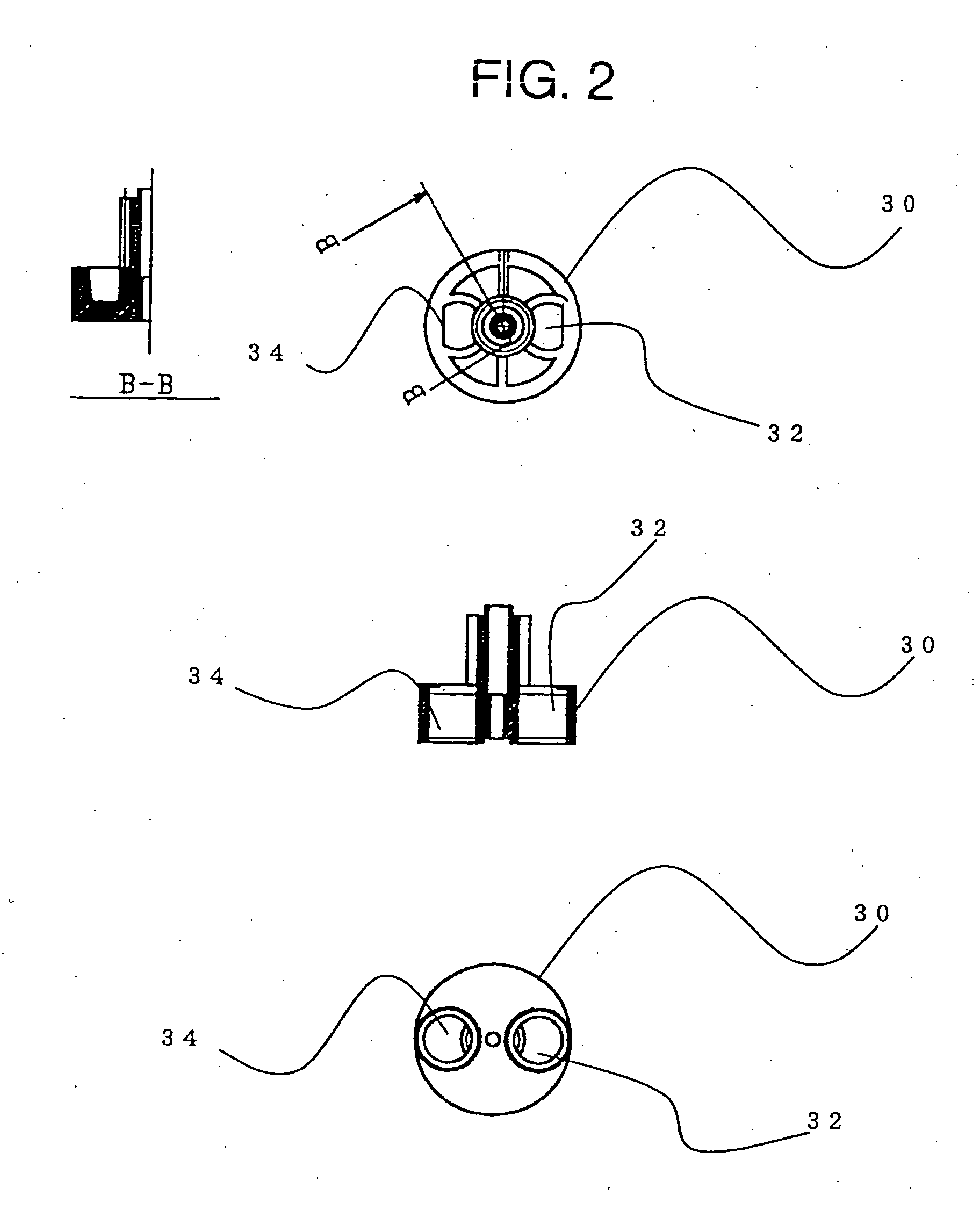

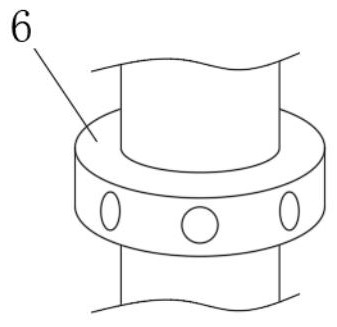

Conveyor Roll And Process For Its Assembly

ActiveUS20100126823A1Efficient transfer of torqueAvoid eccentric rotationShaft and bearingsCouplings for rigid shaftsEngineeringMechanical engineering

Conveyor rolls used in high temperature applications, and an end cap assembly for such rolls. The conveyor roll comprises a ceramic spool, an end cap and a tolerance ring. The end cap contains a metal ferrule and has an internal circumference adapted to fit over an end of the ceramic spool. A tolerance ring is interposed between each end of the ceramic spool and the end cap. The tolerance ring is composed of resilient metal having a plurality of circumferentially arranged corrugations. The conveyor roll can resist temporary overheating or blockage without damage.

Owner:VESUVIUS USA CORP

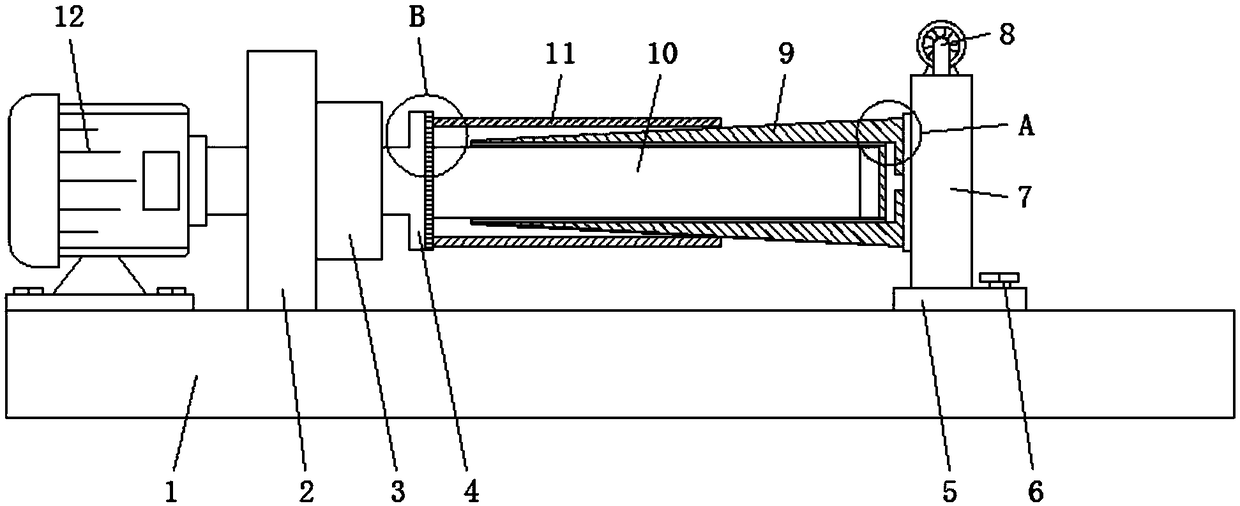

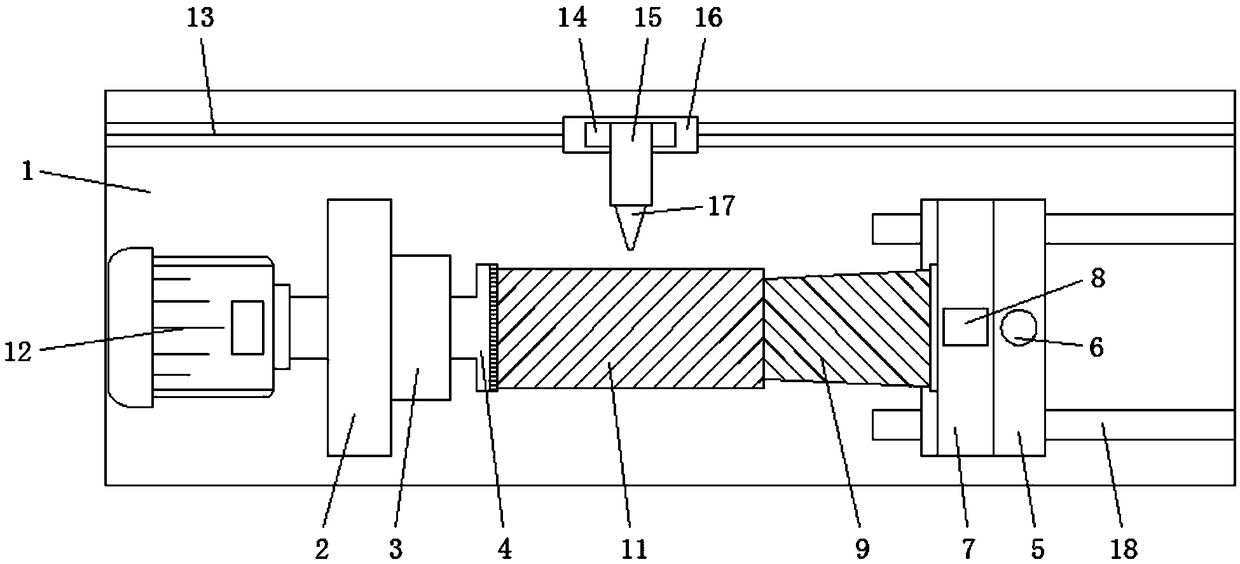

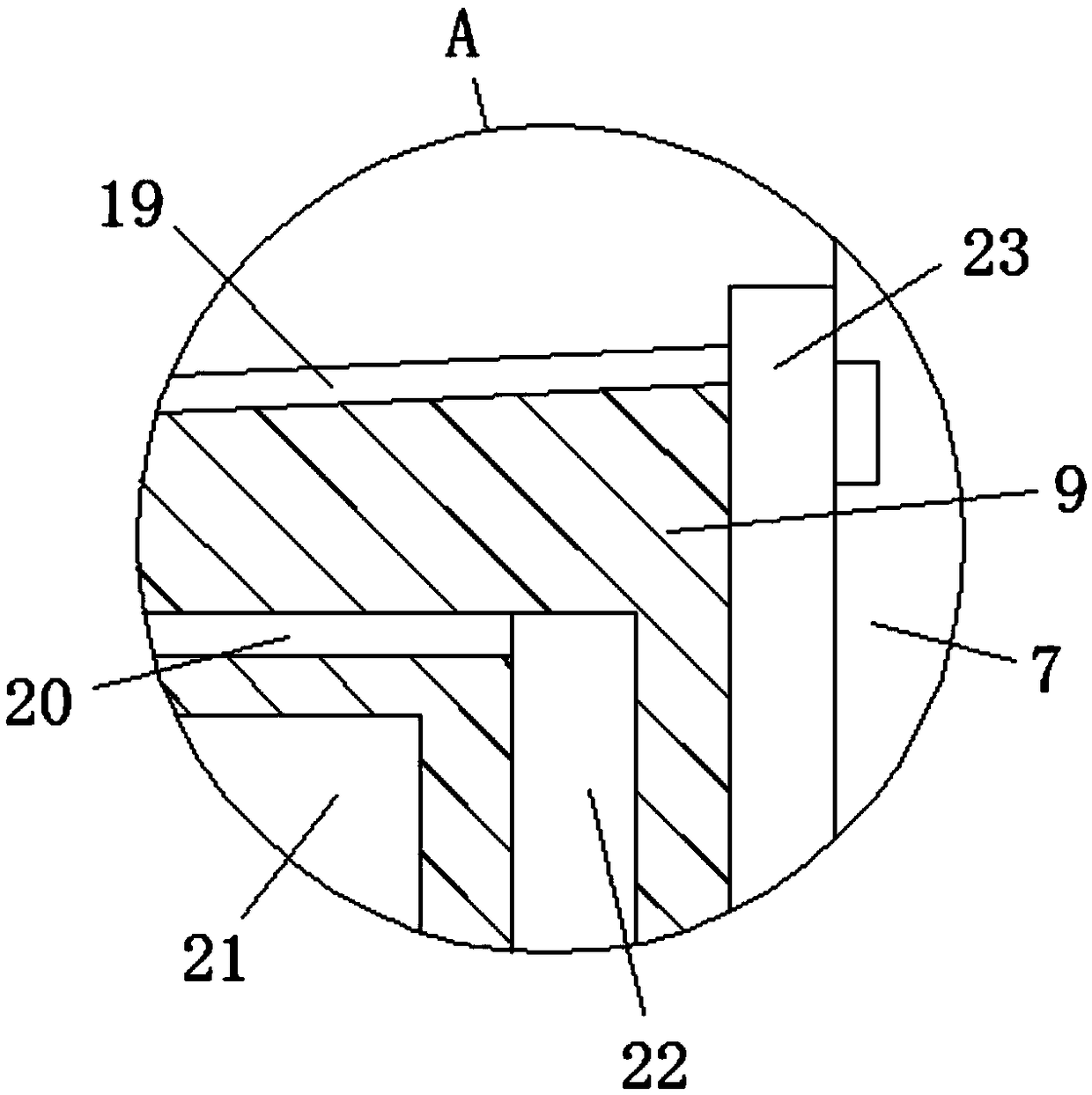

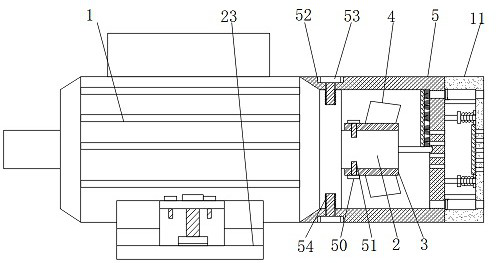

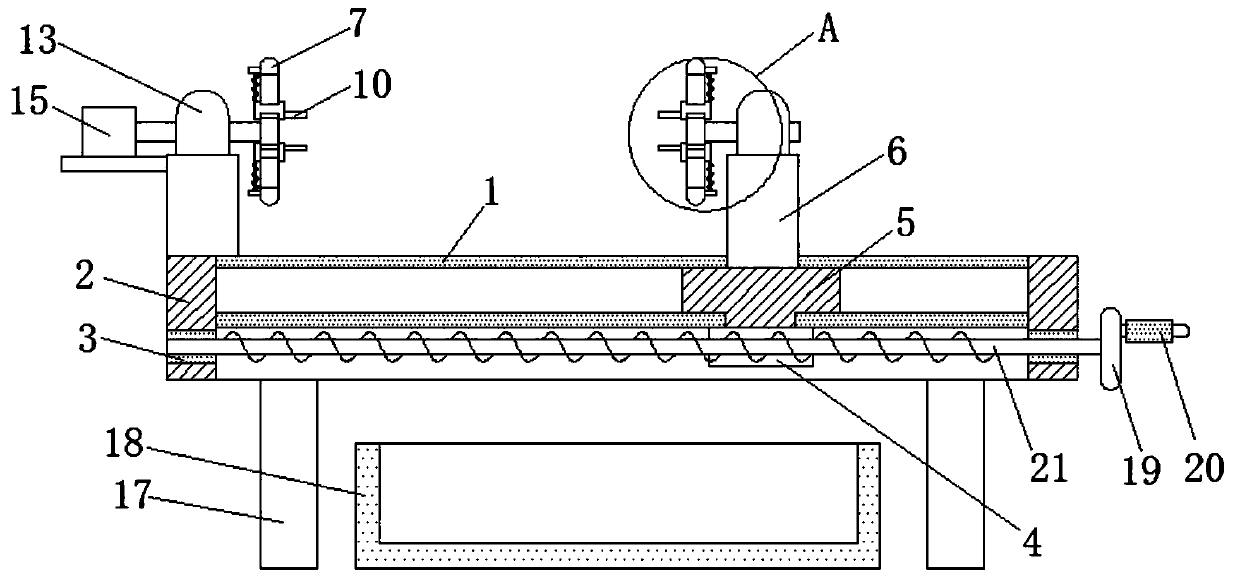

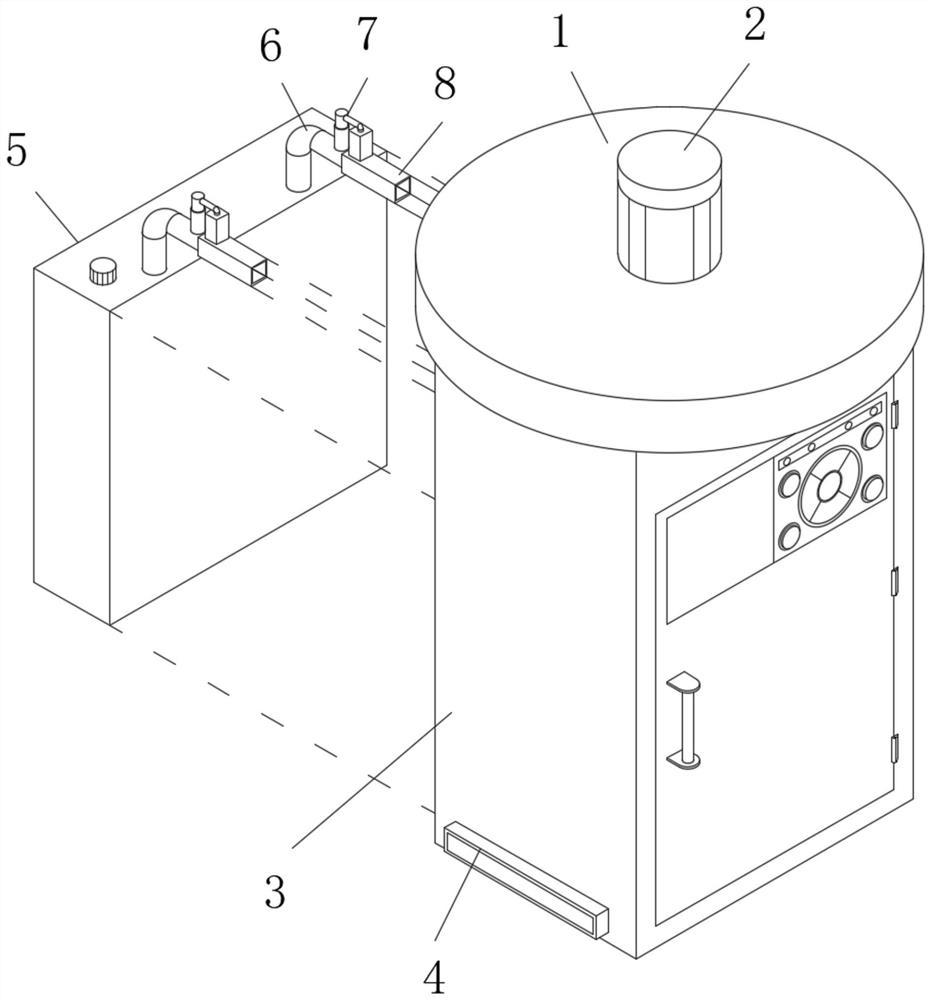

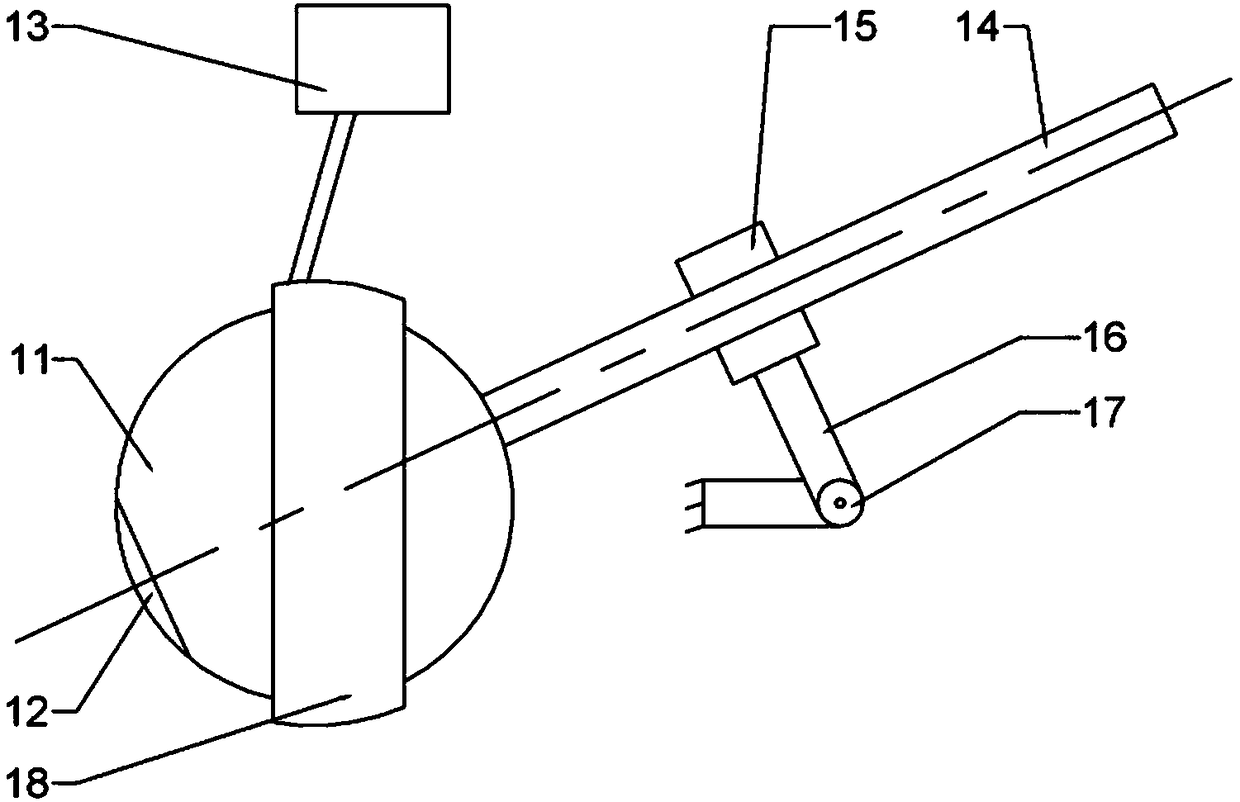

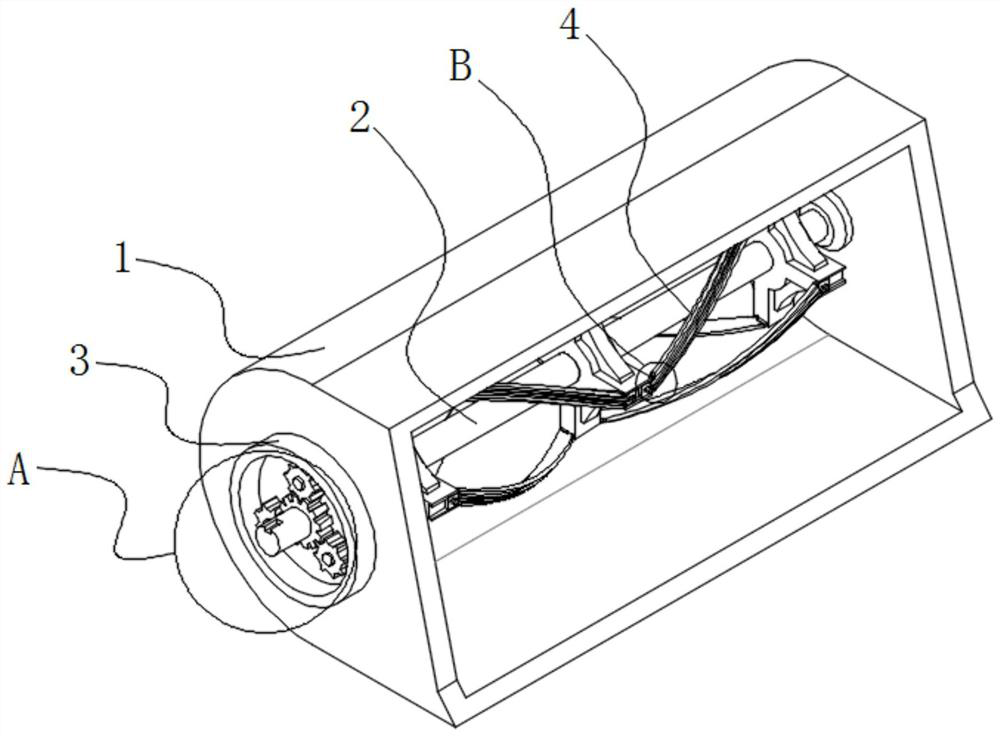

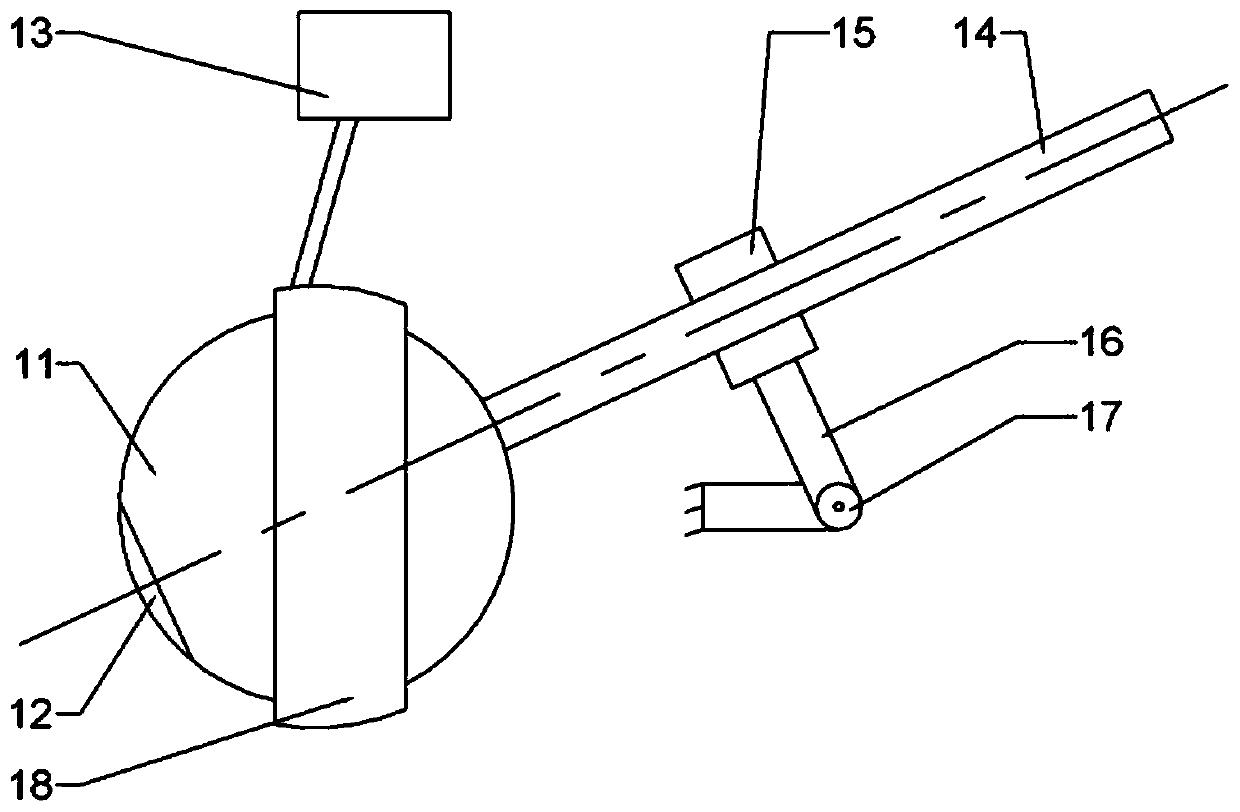

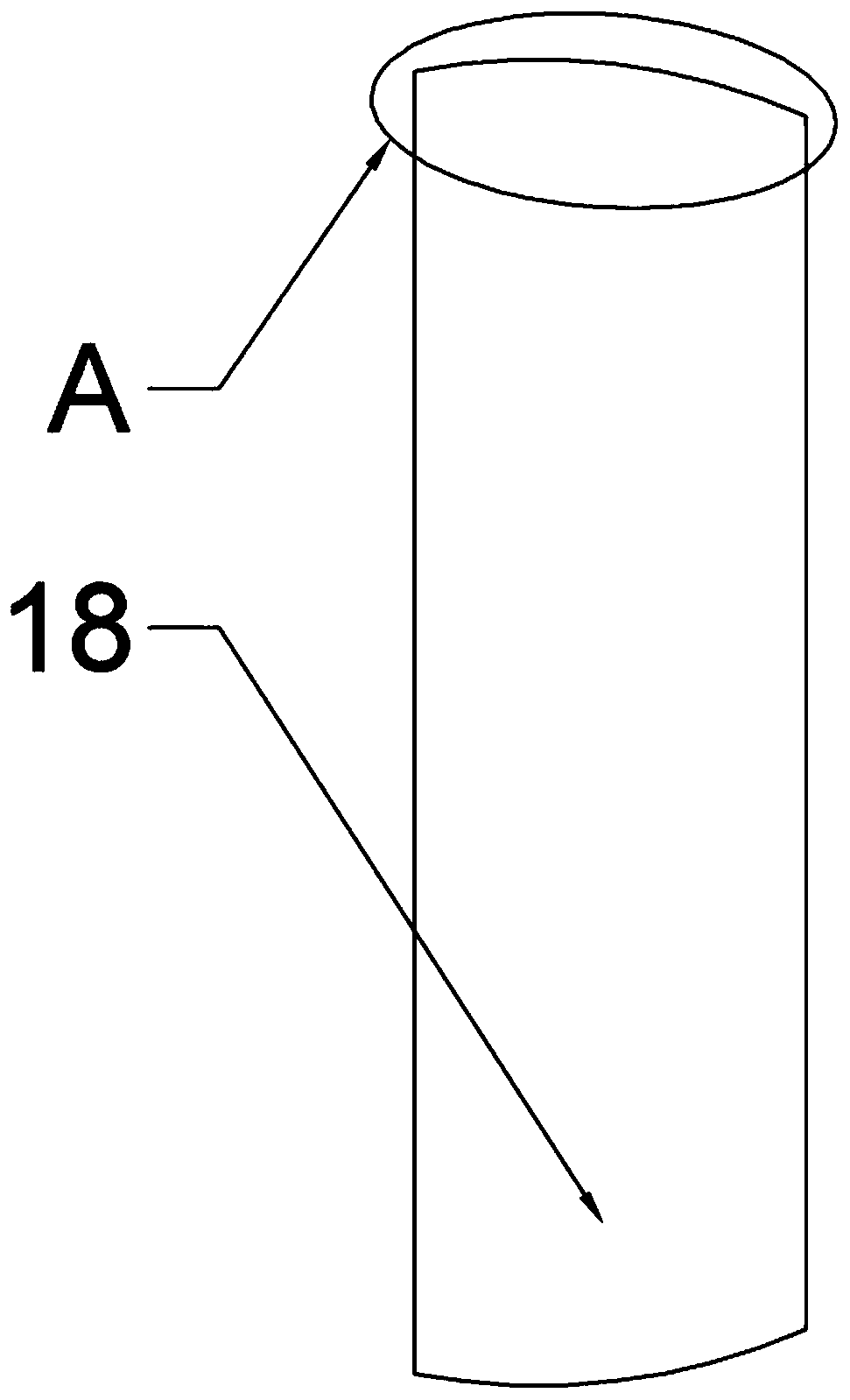

Ultrathin-wall part cutting device

ActiveCN109434528AEffectively fixedEffectively achieve fixationWork clamping meansLarge fixed membersEngineeringDrive motor

The invention discloses an ultrathin-wall part cutting device. The ultrathin-wall part cutting device comprises a base. A driving motor, a fixed plate and a first guide rail are mounted at the top endof the base anticlockwise in sequence. A three-jaw chuck is mounted on the outer wall of one side of the fixed plate and rotatably connected with the driving motor through a rotary shaft. A linear motor is slidably connected to the top end of the first guide rail. A cutting device body is mounted at the top end of the linear motor. The driving motor and the linear motor are both electrically connected with an external power supply. The ultrathin-wall part cutting device is provided with a connecting piece, a mounting plate, a clamping sleeve and a driving rotary shaft. During installation, apart can be efficiency fixed through cooperation of the clamping sleeve and the driving rotary shaft, wherein firstly, locating sleeving is conducted through the driving rotary shaft; secondly, the clamping sleeve implements clamping and sleeving through movement of a mounting plate so that the part can be effectively clamped between the connecting piece and the clamping sleeve, and then fixationon the part is realized.

Owner:BAOJI UNIV OF ARTS & SCI

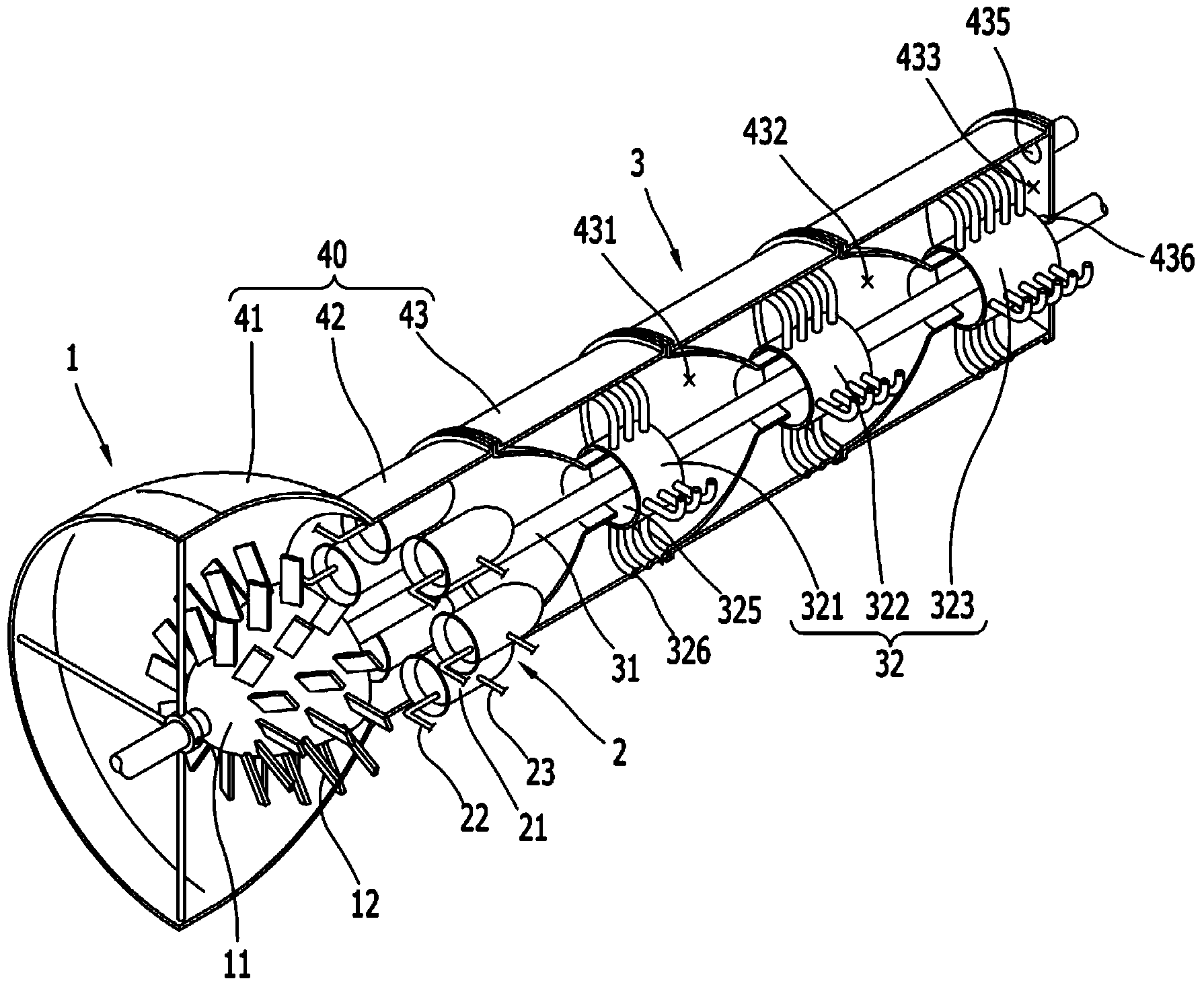

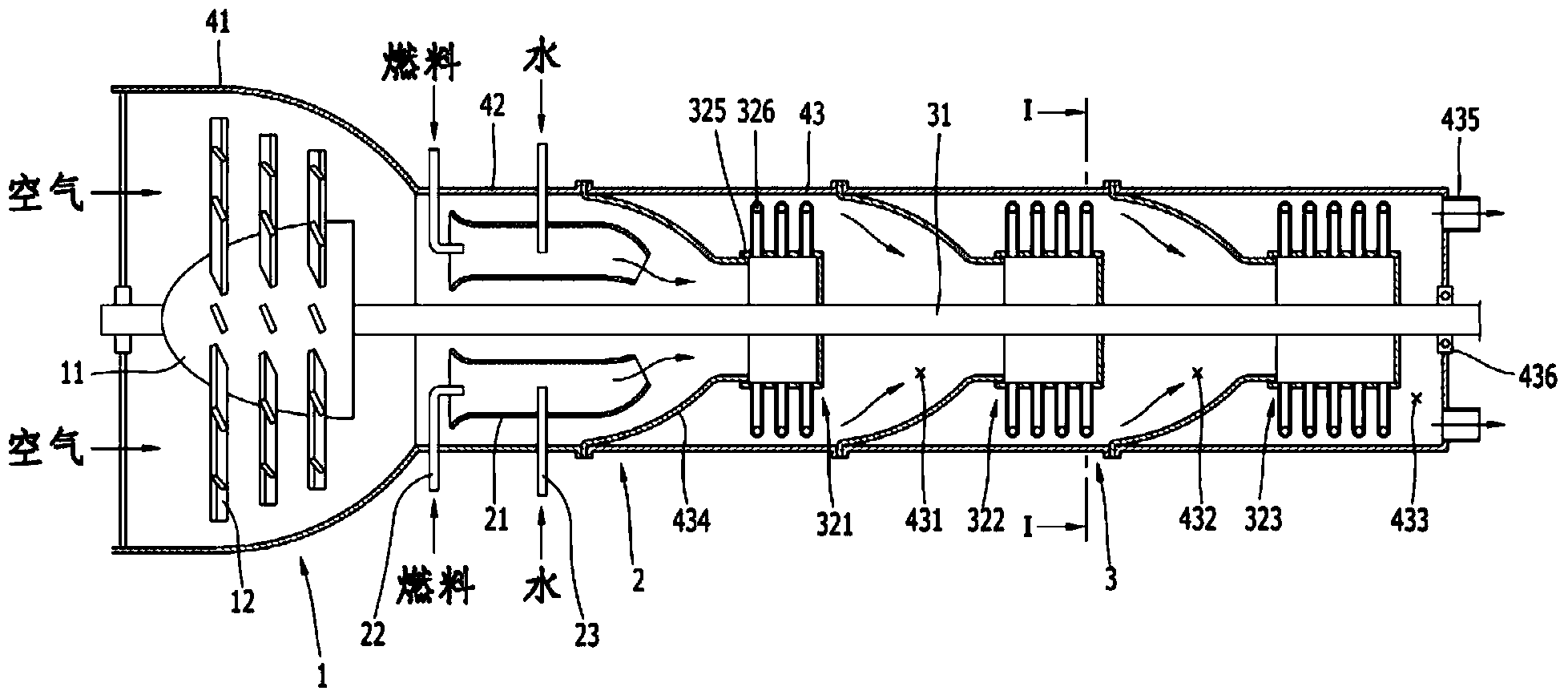

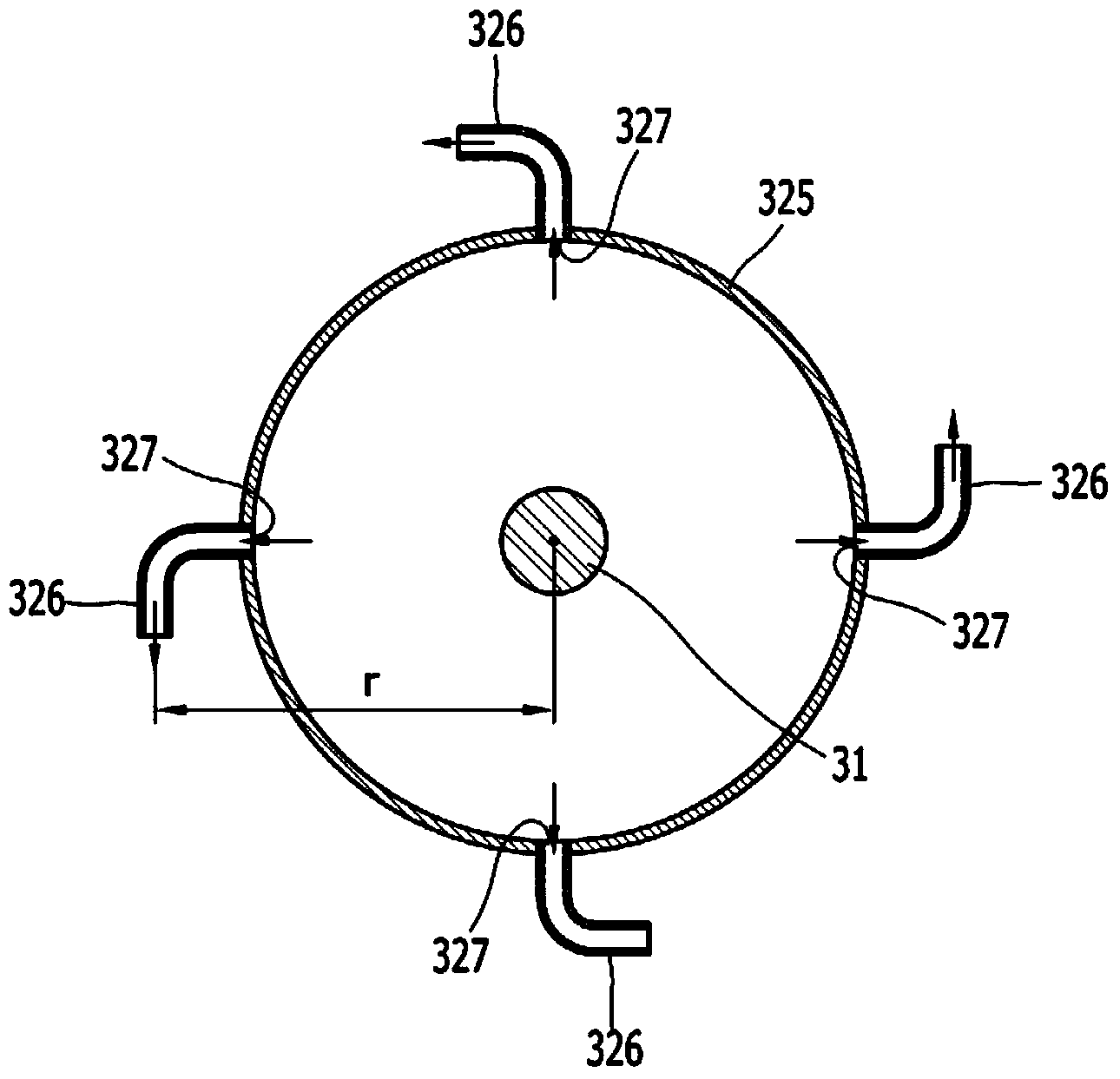

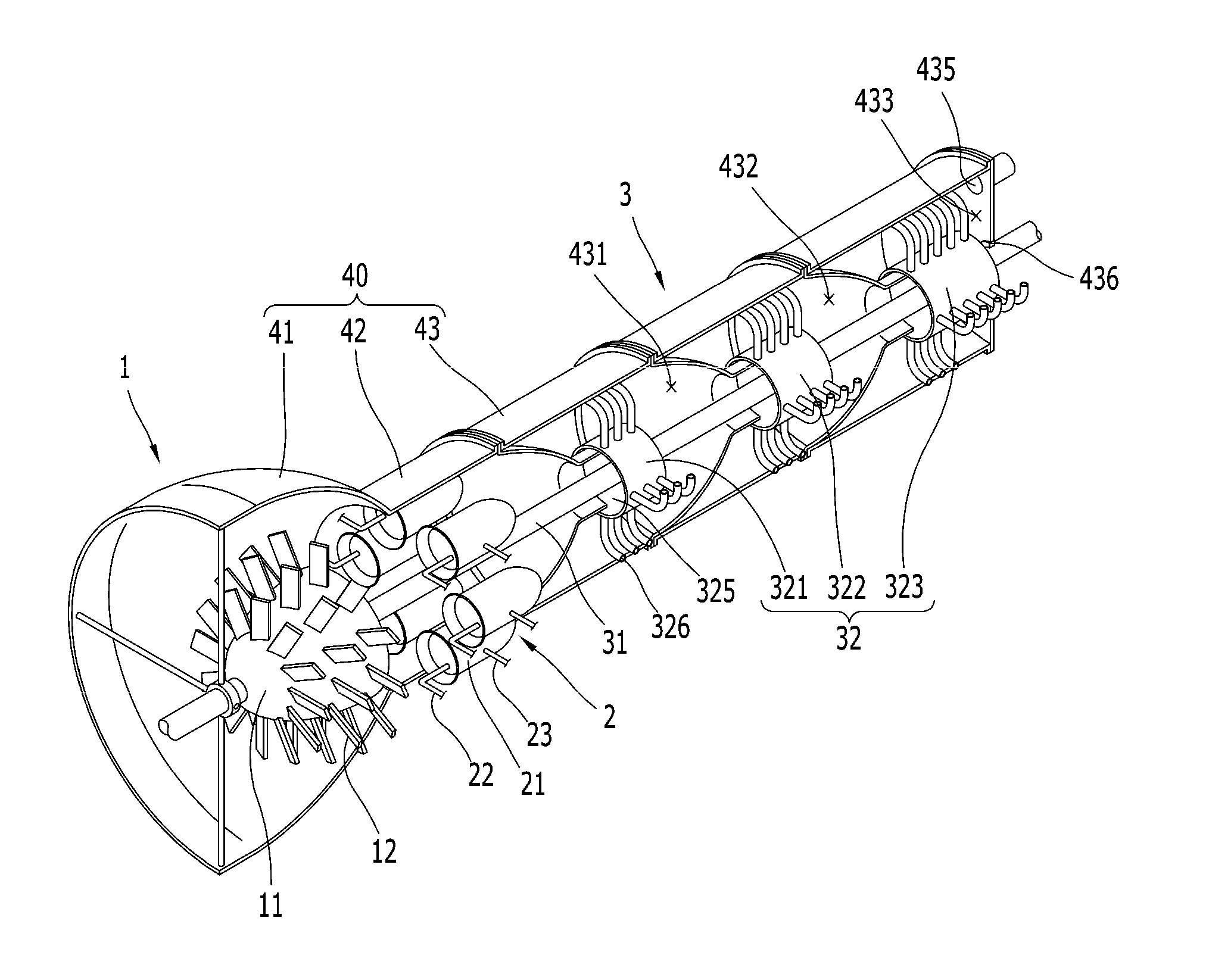

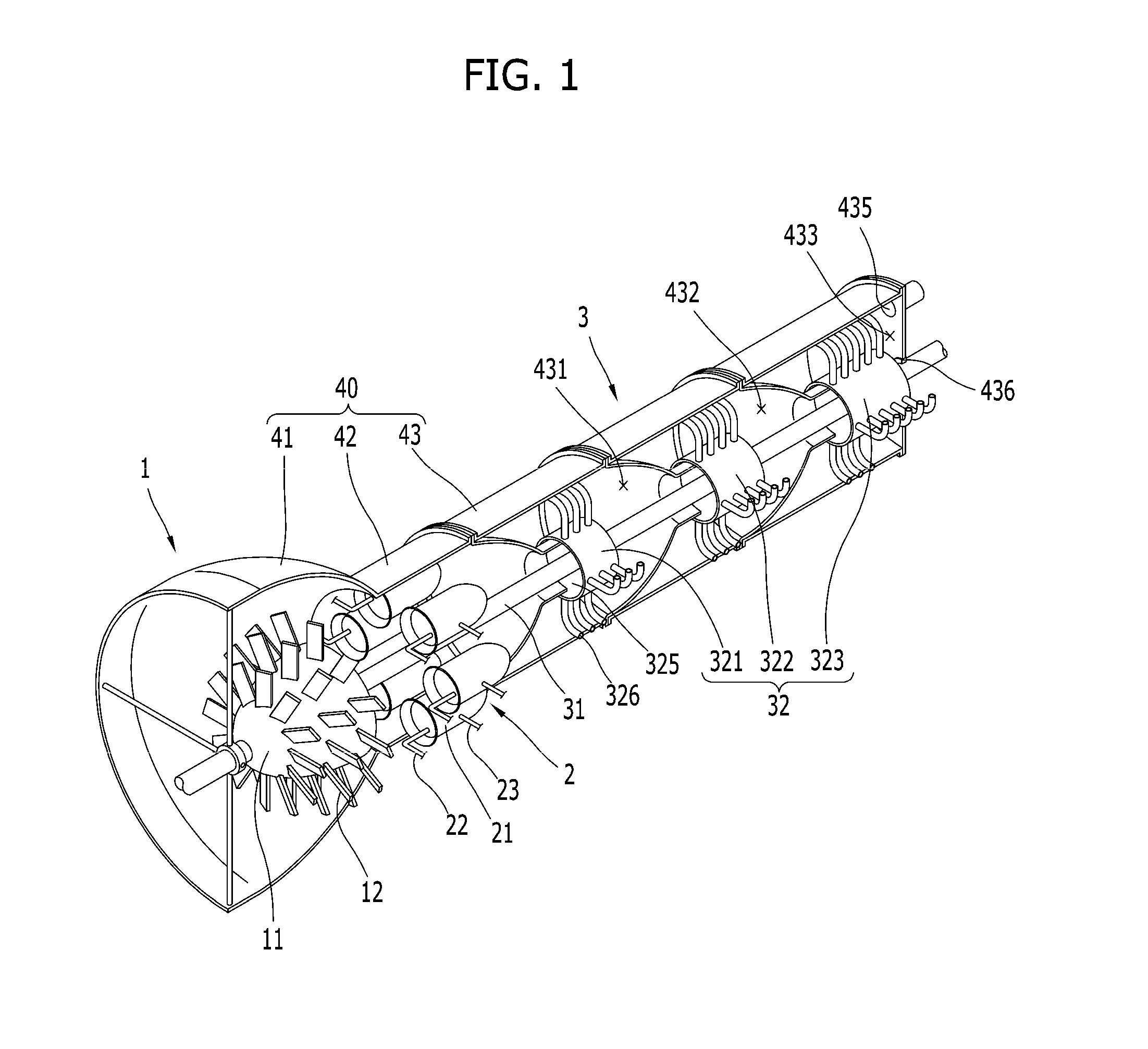

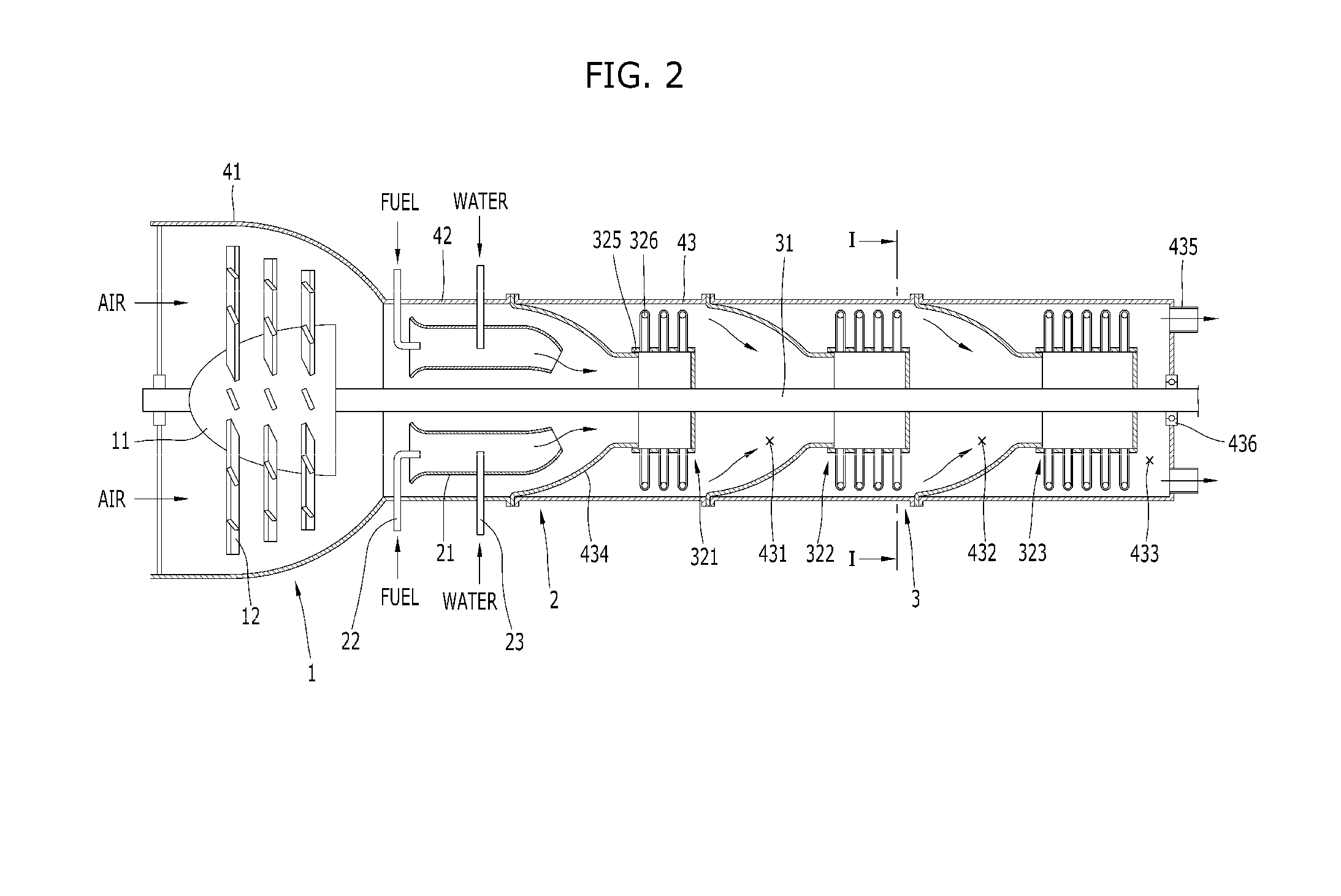

Gas turbine

InactiveCN103415684AImprove rotational energy conversion efficiencyReduce manufacturing costGas turbine plantsStatorsManufacturing cost reductionFlow resistivity

The present invention relates to a gas turbine. According to the present invention, gas may be injected in the circumferential direction in order to rotate the turbine shaft using a repulsive force, thereby improving the efficiency of the conversion of rotational energy of the turbine and reducing manufacturing costs. Also, the flow resistance to the gas may be reduced, pressure leakage may be prevented, and energy loss may be reduced so as to manufacture an inexpensive turbine having high efficiency. In addition, when turbines having capacities different from each other are manufactured, parts may be easily shared with each other, and the eccentric rotation of the turbine shaft may be prevented to significantly improve durability. Also, an air compression part, a gas expansion part, and a power generation part may be modularized, and fuel and water may be supplied together. Thus, overheating of the gas expansion part may be prevented to prevent air from being excessively expanded, and vapor may be generated to improve rotational force in addition to the impellent power of the turbine. Also, the gas turbine may be manufactured using a relatively inexpensive metal material instead of expensive high temperature ablative materials in order to reduce manufacturing costs.

Owner:金其太

Gas turbine

InactiveUS20130318974A1Improve conversion efficiencyReduce manufacturing costGas turbine plantsReaction enginesAir compressionTurbine

Disclosed is a gas turbine which includes: a gas expansion part that expands gas; a power generation part that generates a rotational force due to the gas expanded by the gas expansion part and has a turbine shaft so as to transfer the rotational force; and an air compression part that is combined with the turbine shaft of the power generation and rotates and compresses air so as to supply compressed air to the gas expansion part. The power generation part generates the rotational force when a nozzle assembly having at least one injection hole so as to inject the gas in a circumferential direction is combined with the turbine shaft and the gas is injected in the circumferential direction via the at least one injection hole.

Owner:KIM KI TAE

Energy-saving asynchronous motor with dustproof and heat dissipation functions

ActiveCN111835146AImprove cooling effectReduce maintenance rateCooling/ventillation arrangementSupports/enclosures/casingsPhysicsEngineering

Owner:JIANGSU HENGKANG ELECTRICAL

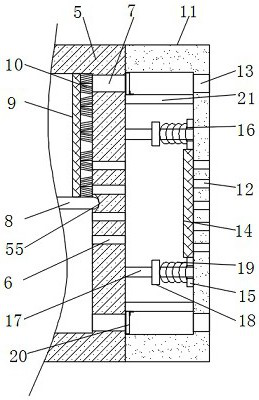

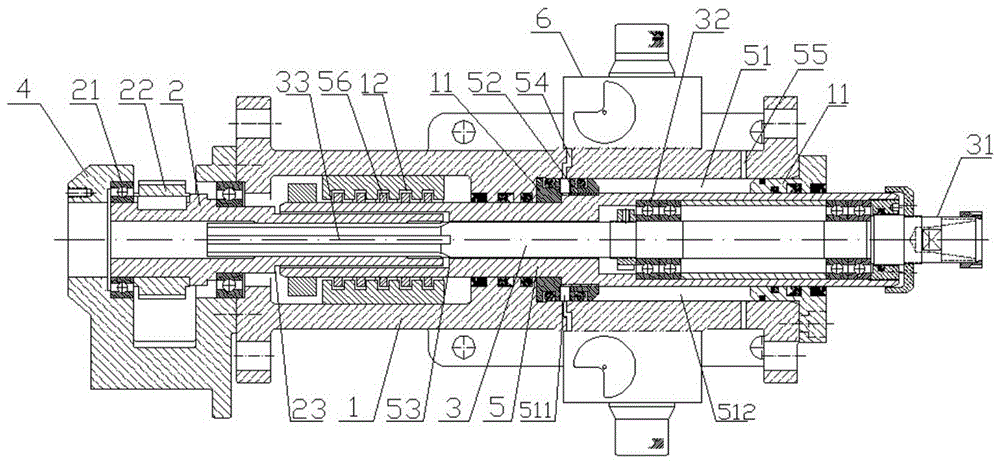

Hydraulic power head

ActiveCN106475832AEasy to adjustConvenient hydraulic travel speed control valveFeeding apparatusDriving apparatusPistonDrill bit

The invention relates to a hydraulic power head. The hydraulic power head comprises a shell, a driving shaft sleeve and a driven shaft, wherein the driving shaft sleeve and the driven shaft sleeve are rotationally connected in the shell, one end of the driven shaft is sleeved with one end of the driving shaft sleeve in a sliding mode in the axial direction, one end of the driving shaft sleeve and one end of the driven shaft are subjected to linkage rotation in the radial direction, the other end of the driving shaft sleeve extends out of the shell, and a stabilizing sleeve is rotationally connected to the other end of the driving shaft sleeve through a first bearing; the stabilizing sleeve is fixedly connected with the shell, a synchronous belt wheel is fixedly arranged on the portion, between the stabilizing sleeve and the shell, of the driving shaft sleeve in a sleeving mode, and the synchronous belt wheel and a rotating shaft of an external motor are subjected to linkage through a synchronous belt; a drill chuck which is detachably connected with a drill bit is arranged at the other end of the driven shaft, the middle of the driven shaft is sleeved with a driven shaft sleeve, the driven shaft sleeve is fixedly arranged outside the driven shaft in a sleeving mode through multiple inner rings, and second bearings are rotationally connected in the radial direction and subjected to linkage sliding in the axial direction, wherein an outer ring of each second bearing is fixed to the inner wall of the driven shaft sleeve; and a sealed annular oil cylinder is formed by the driven shaft sleeve and the inner wall of the shell in an enclosing mode, and a piston which is fixedly arranged outside the driven shaft sleeve in a sleeving mode slides in the oil cylinder in a sealing mode.

Owner:福州兴诺机械工业有限公司

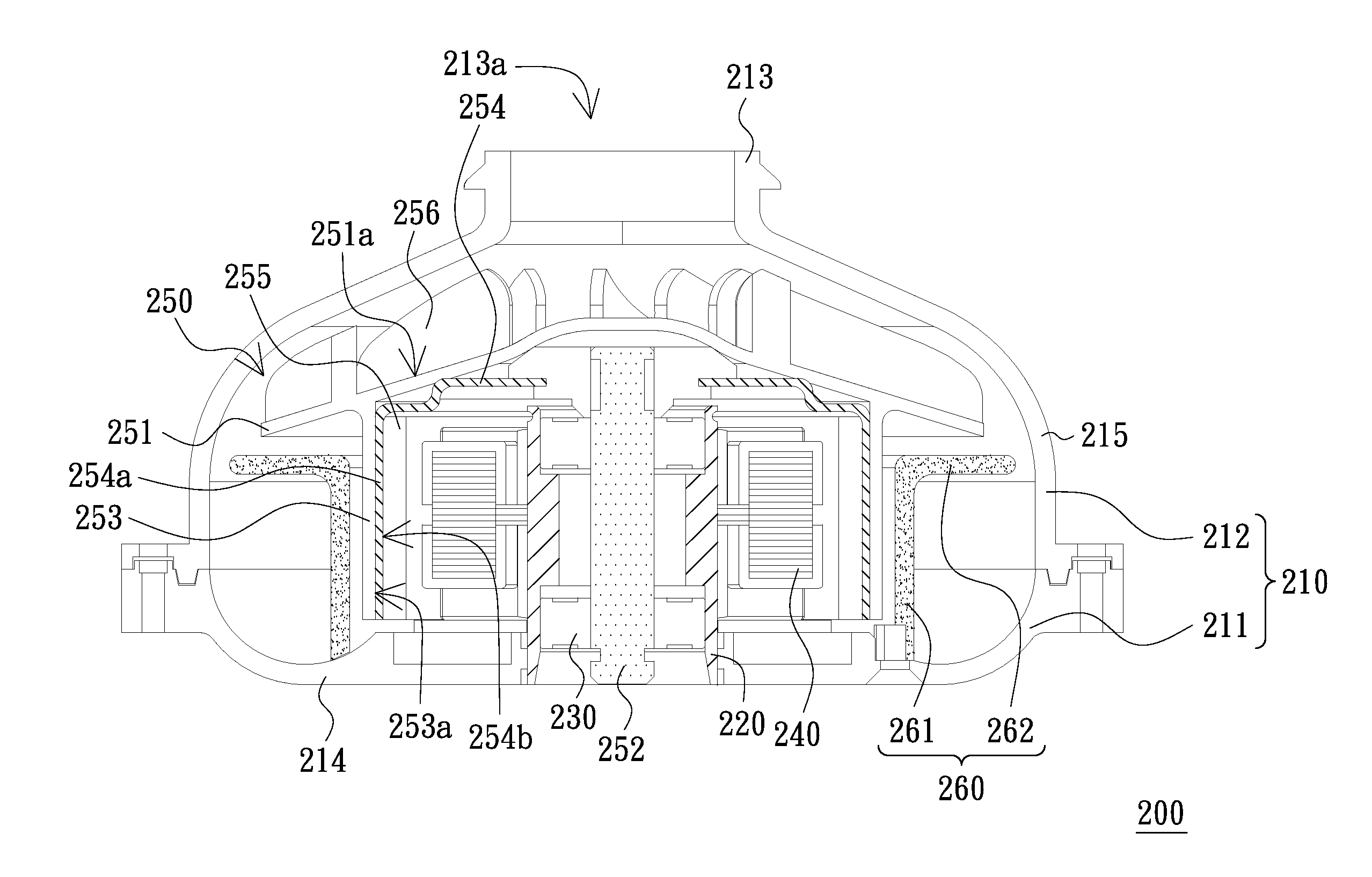

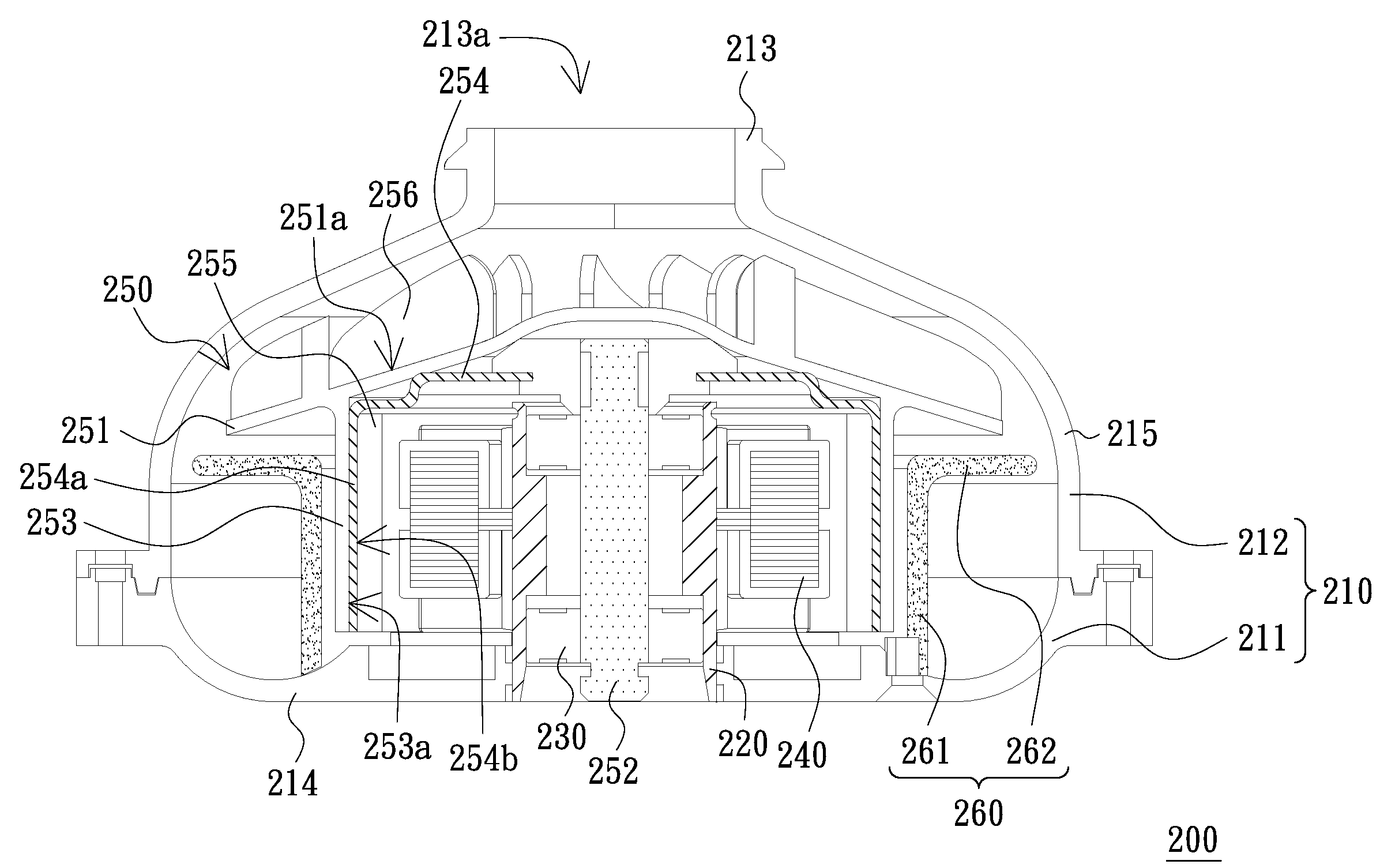

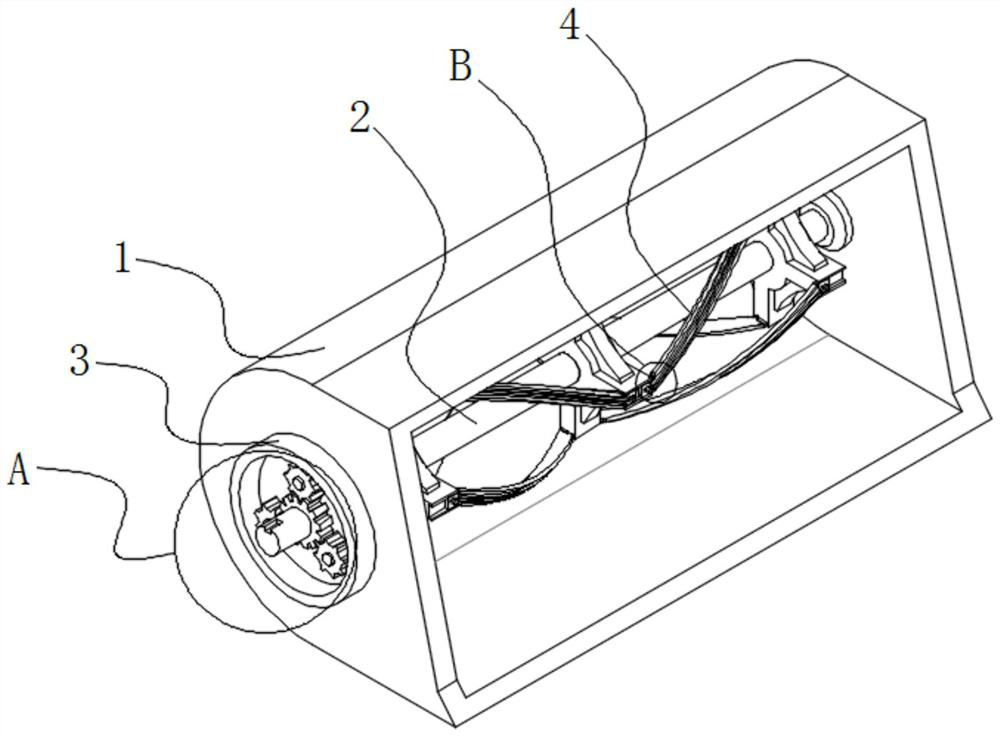

Brushless fan motor and positive airway pressure breathing apparatus using the same

InactiveUS20120180792A1Reduce noisePositive airway pressureRespiratorsOperating means/releasing devices for valvesPositive airway pressureEngineering

A brushless fan motor includes a case, a tubular part disposed in the case and fixed at a bottom of the case, at least a bearing disposed in the tubular part, a toric coil surrounding the tubular part, and a rotating assembly. The rotating assembly includes a turntable, a rotating shaft, a loading ring, a permeability metal element and a toric radial magnet. The turntable has a top surface and fan blades disposed on the top surface. The rotating shaft is disposed through the bearing and connected to the turntable. The loading ring connected to the turntable surrounds the toric coil. The permeability metal element includes an annular part fixed at an inner wall of the loading ring. The toric radial magnet is fixed at an inner wall of the annular part. A positive airway pressure breathing apparatus using the brushless fan motor is also provided.

Owner:LEAD DATA

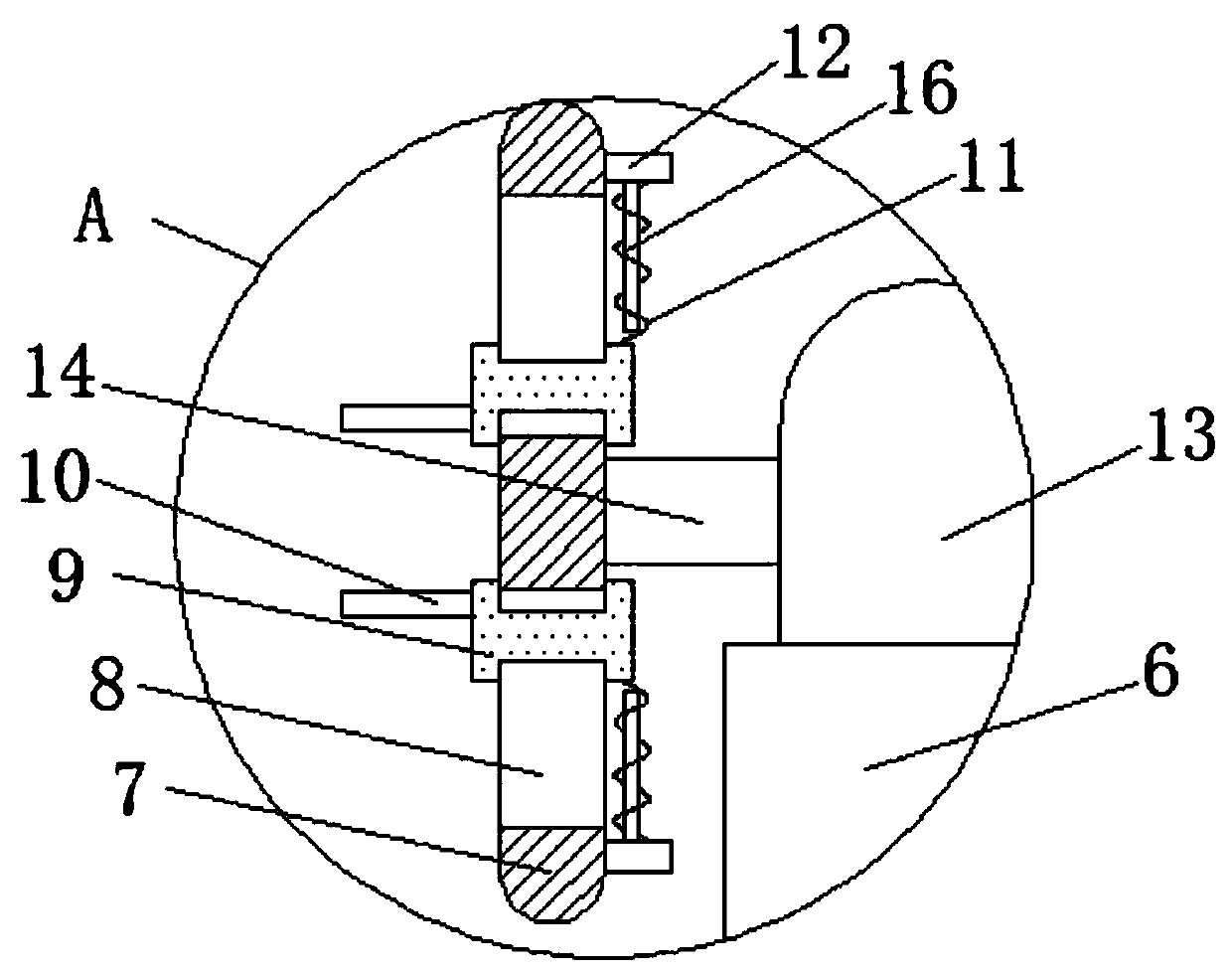

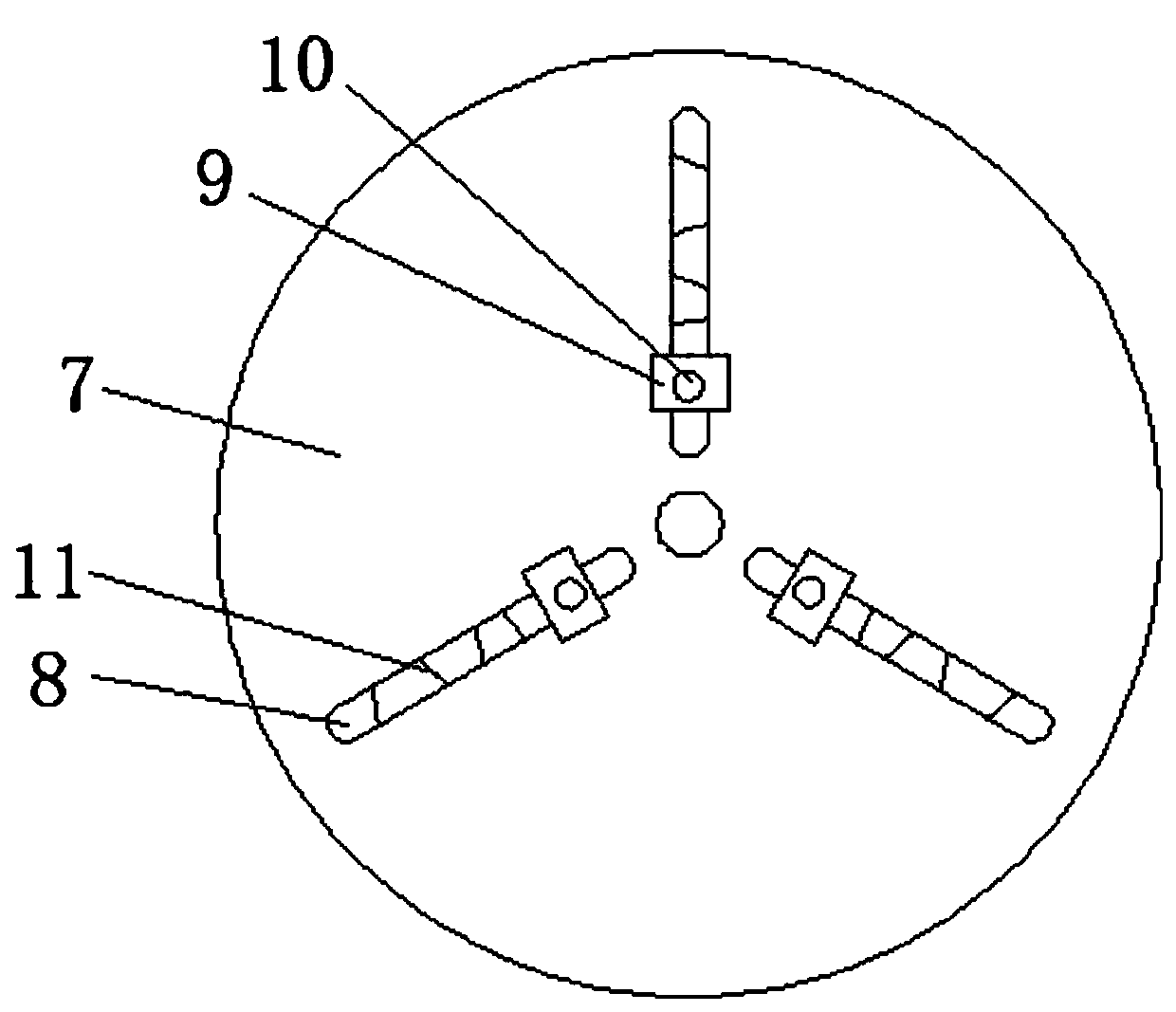

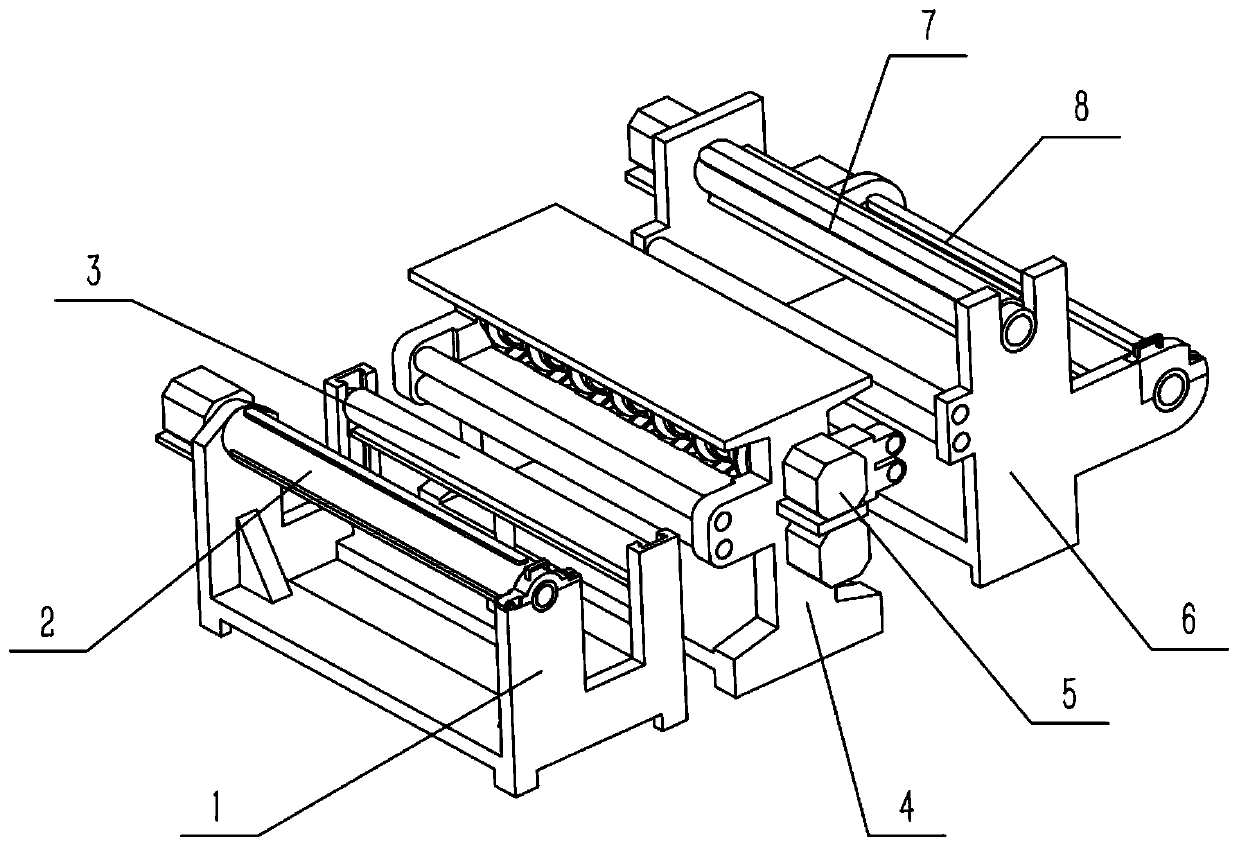

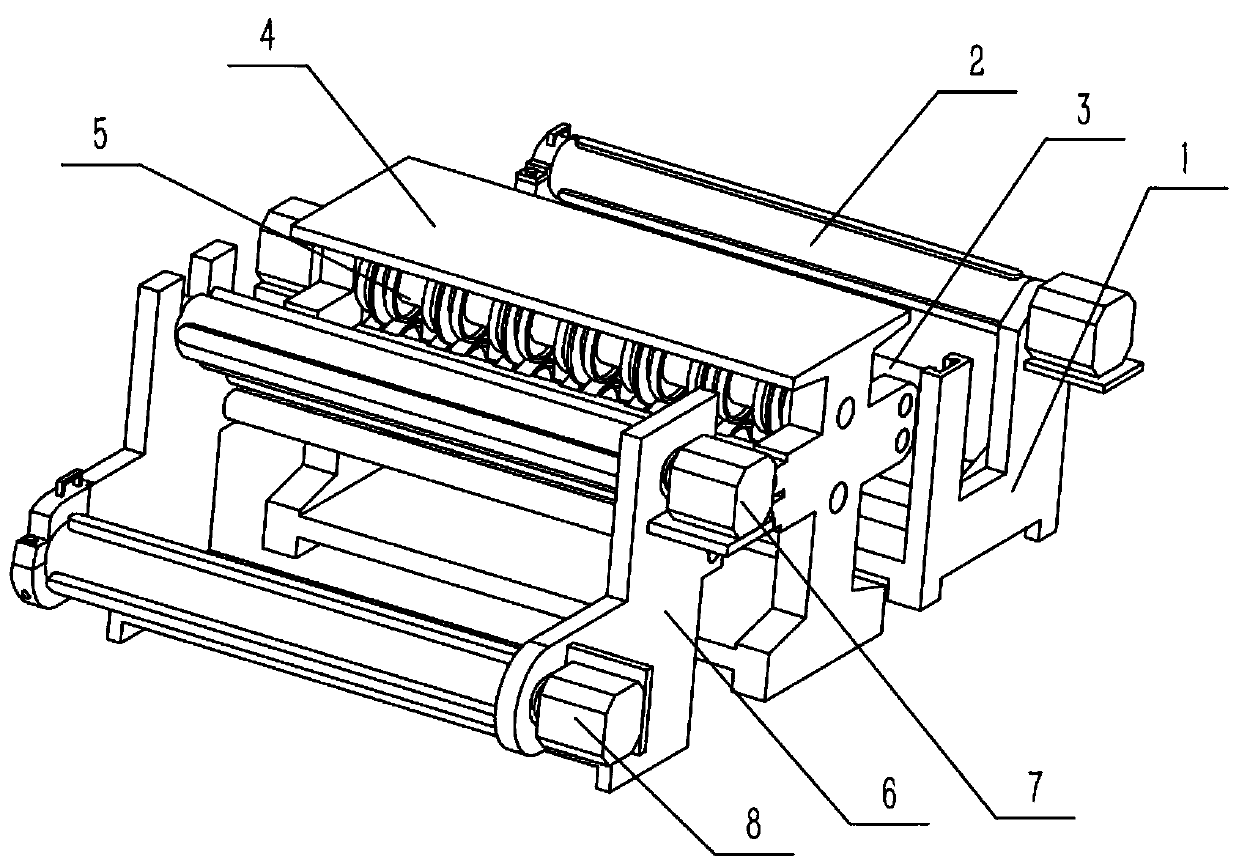

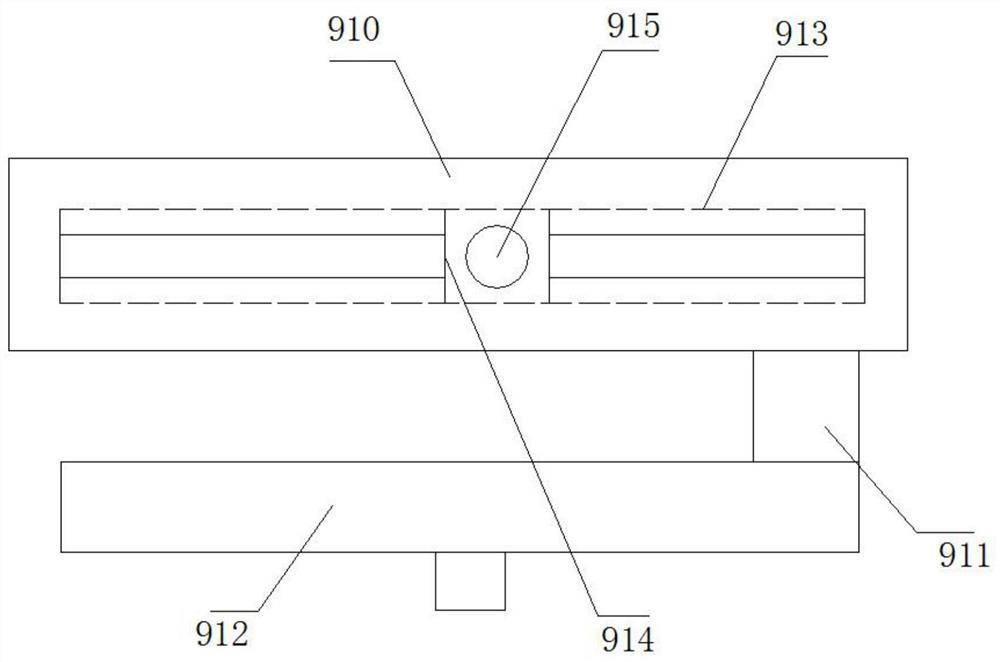

Clamping device for spring brush welding

InactiveCN110369937AThe distance is easy to adjustAvoid eccentric rotationWelding/cutting auxillary devicesAuxillary welding devicesSheet steelCoupling

The invention discloses a clamping device for spring brush welding. The clamping device comprises steel channels, wherein two groups of steel channels are arranged, the two ends of the two groups of steel channels are welded through a steel plate, bearings are arranged inside the steel plate, and a screw rod is in interference connection to inner rings of the bearings; a straight thread sleeve isconnected to external threads of the screw rod, a sliding block is welded to the top of the straight thread sleeve, and the sliding block is slidably connected to the interiors of the two groups of steel channels; fixing rods are correspondingly welded to the tops of the sliding block and the steel plate, and a bearing seat is arranged at the top of each fixing rod through a bolt; and a fixing block is welded to one side of each clamping plate, and the other end of a rotating shaft is arranged on an output shaft of a motor through a coupler. The clamping device for the spring brush welding ismainly composed of the steel channels, the screw rods, the clamping plates, clamping jaws, stretching springs, the motor and the like, the screw rods are rotated to drive the straight thread sleeve for moving, so that the distance between the two groups of clamping plates can be adjusted, and the clamping work of spring brushes with different lengths can be adapted.

Owner:安徽杉森刷业有限公司

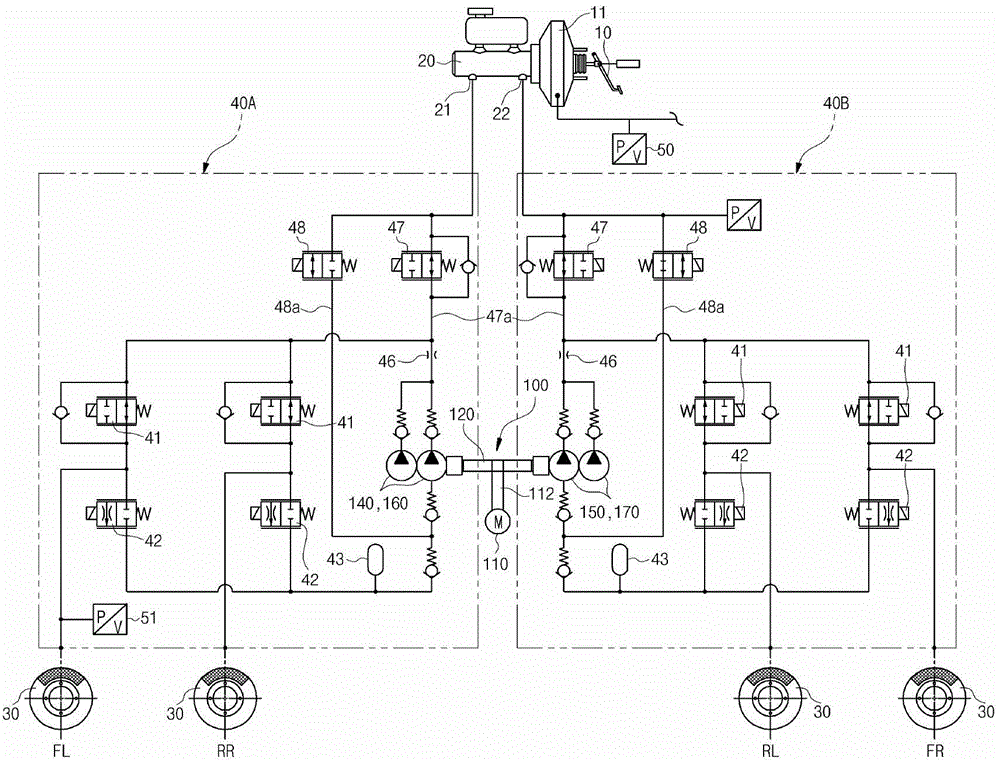

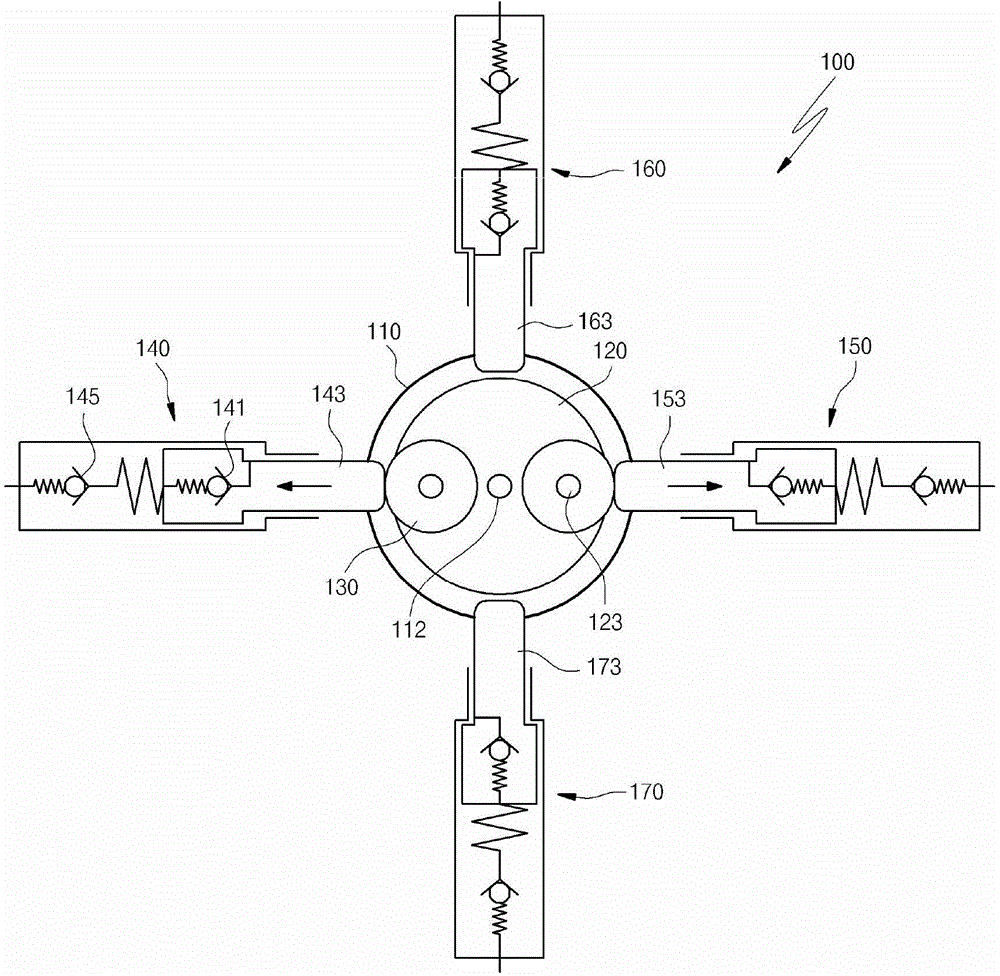

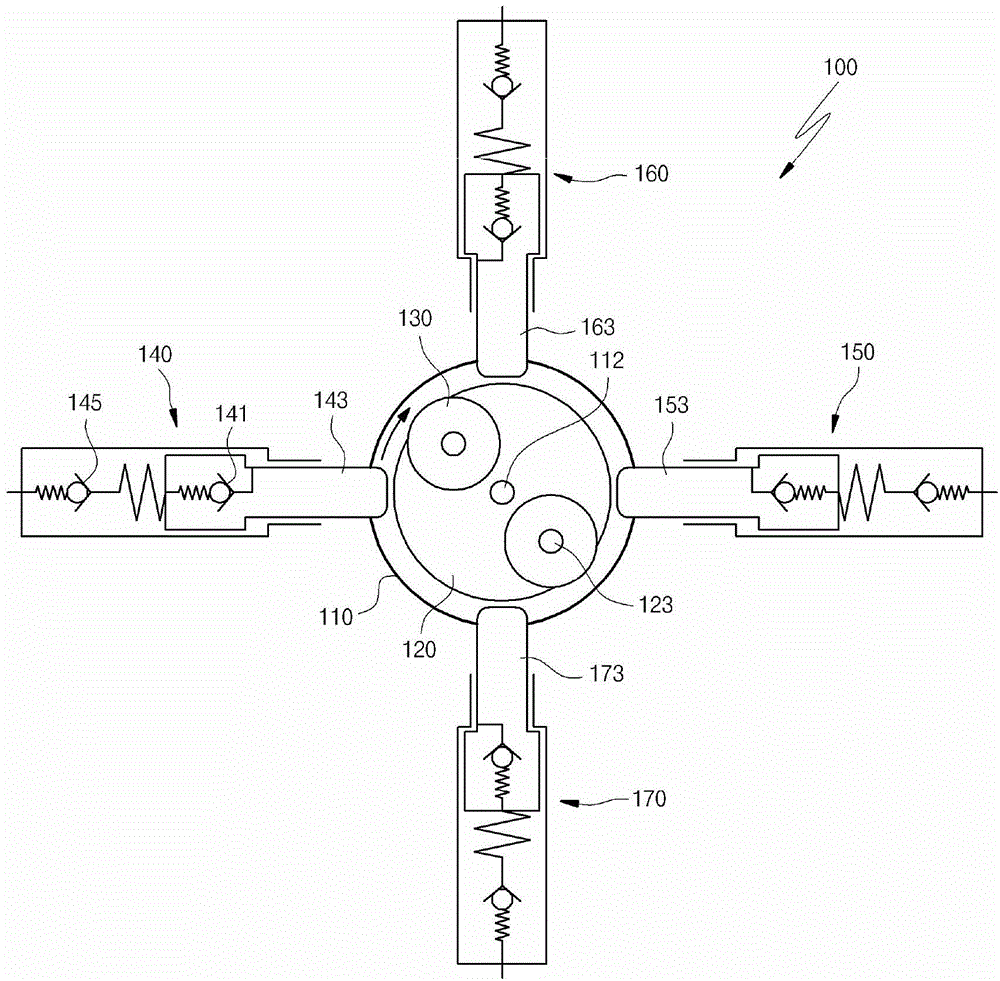

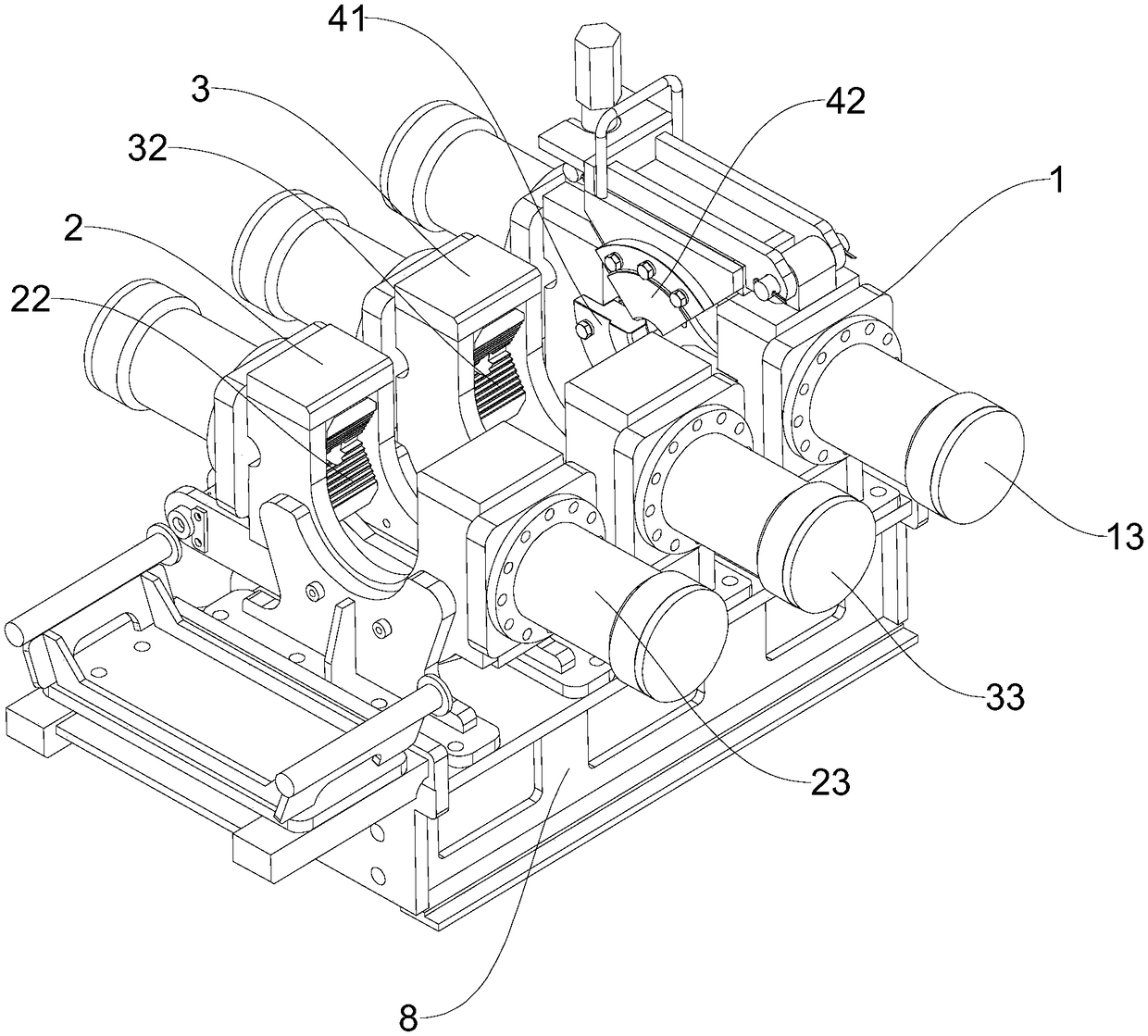

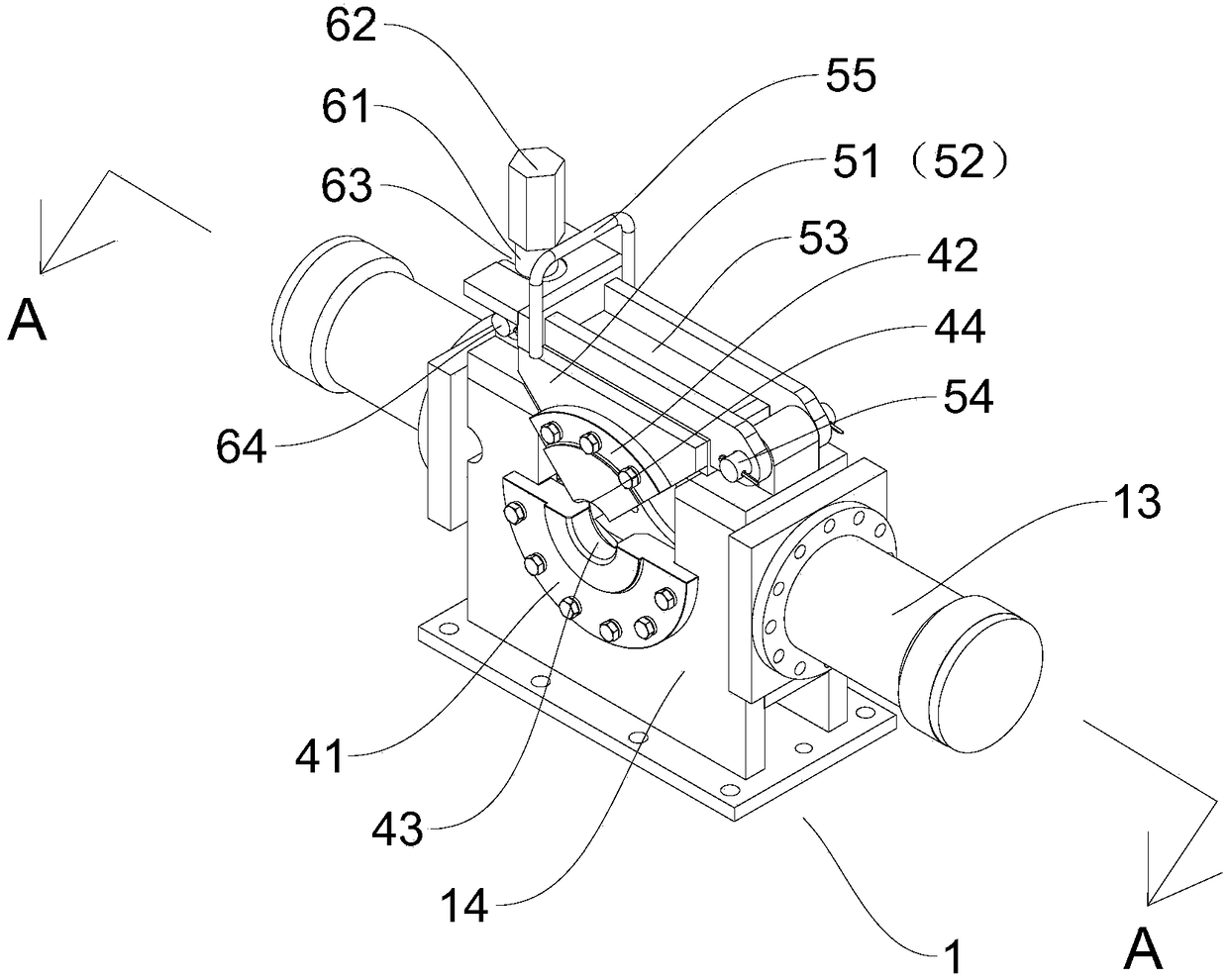

Pump unit of electronic control brake system

ActiveCN104340194AReduce vibrationReduce noiseHydrostatic brakesBraking action transmissionRotational axisEngineering

Owner:HL MANDO CORP

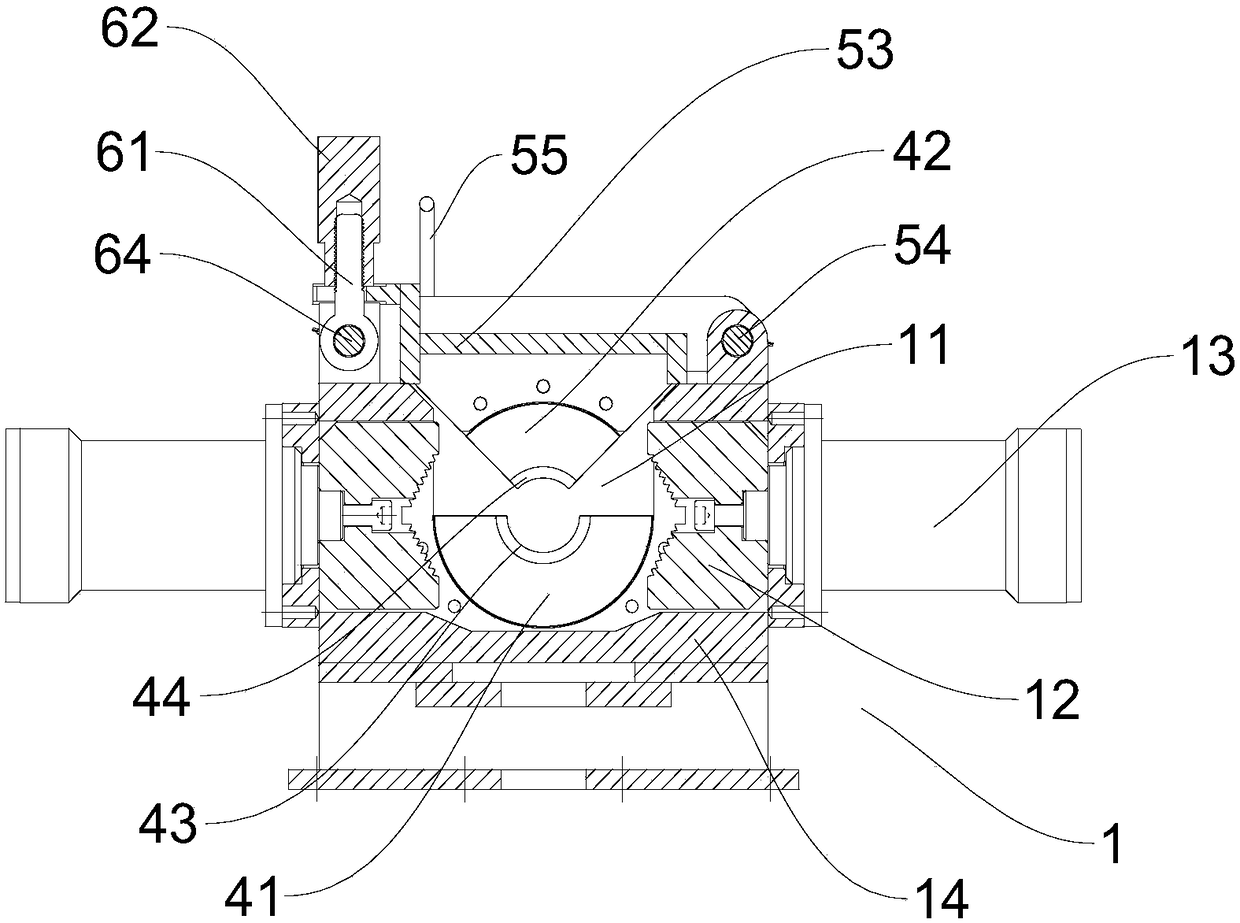

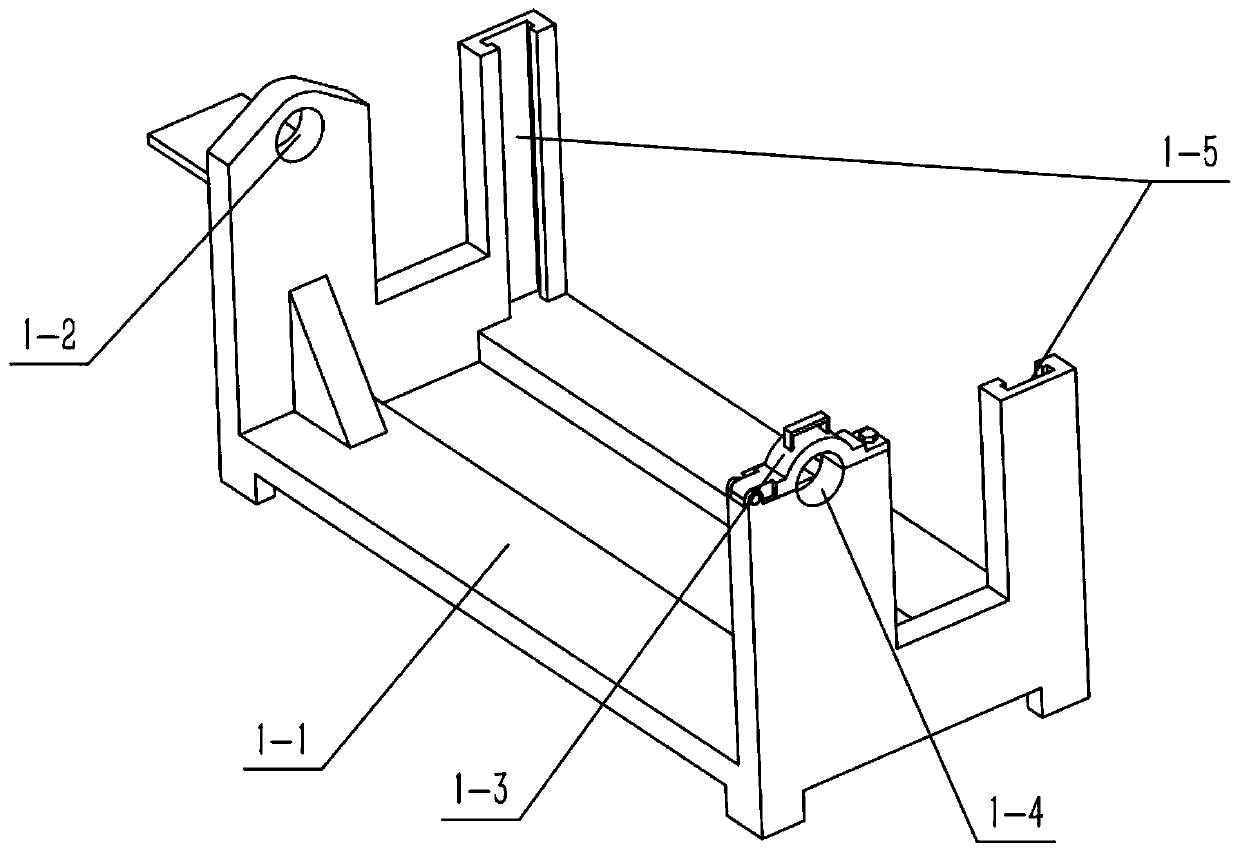

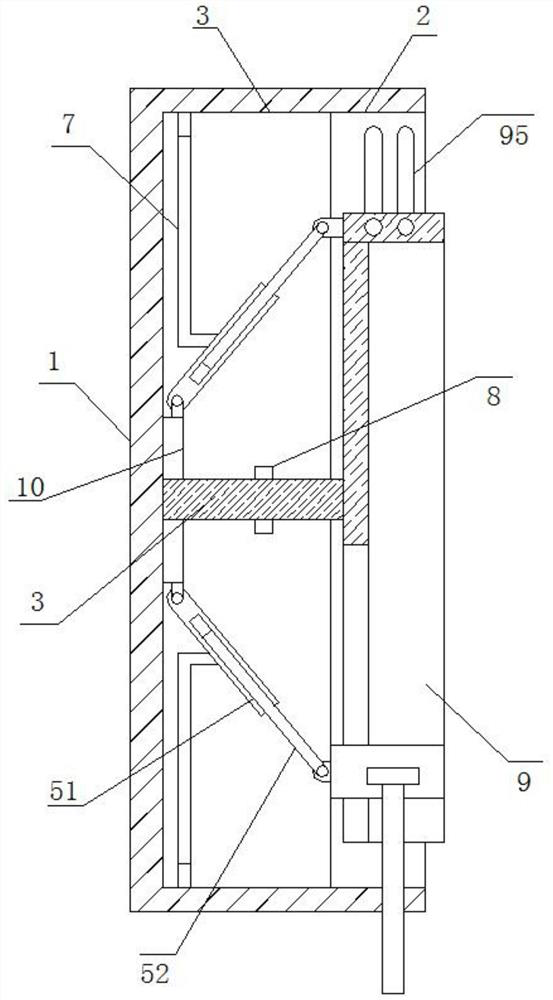

Drill pipe dismounting mechanism

ActiveCN108222864AAvoid eccentric rotationExtended service lifeDrilling rodsDrilling casingsBlock matchPetroleum engineering

The invention relates to a drill pipe dismounting mechanism comprising a positioning device, a fixing device and an actuating device, wherein the positioning device is used for limiting dismounting position of a drill pipe, the fixing device is used for limiting movement of the drill pipe at the dismounting position, and the actuating device is used for driving the drill pipe at the dismounting position to rotate around its axis. Besides, the positioning device comprises a fixed block and a moving block matched with each other for limiting the preset axis, the fixed block is fixed relative tothe fixing device, the moving block is selectively fixed relative to the fixing device, so that the drill pipe is allowed to enter or exit the dismounting position, and further, the moving block and the fixed block are matched to limit moving of the drill pipe; when the drill pipe is at the dismounting position, its axis and the preset axis coincide. In application of the drill pipe dismounting mechanism, offset of the axis of the drill pipe is prevented during dismounting, and deformation or damage of the drill pipe during dismounting is then avoided.

Owner:BEIJING XINNENGZHENGYUAN INTELLIGENT EQUIP CO LTD

Brushless fan motor and positive airway pressure breathing apparatus using the same

InactiveUS8347884B2Reduce noisePositive airway pressureRespiratorsOperating means/releasing devices for valvesPositive airway pressureElectric machine

Owner:LEAD DATA

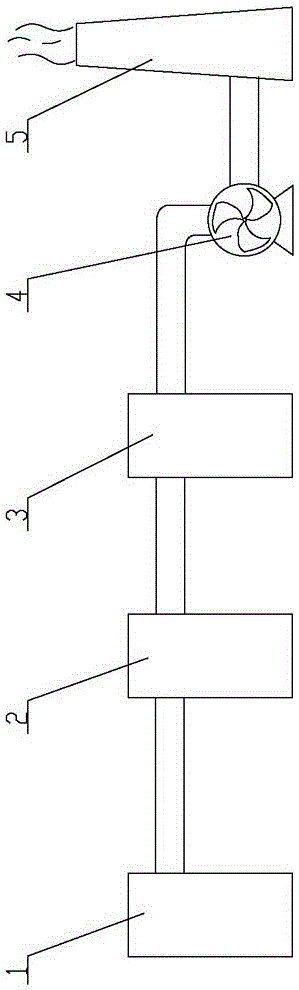

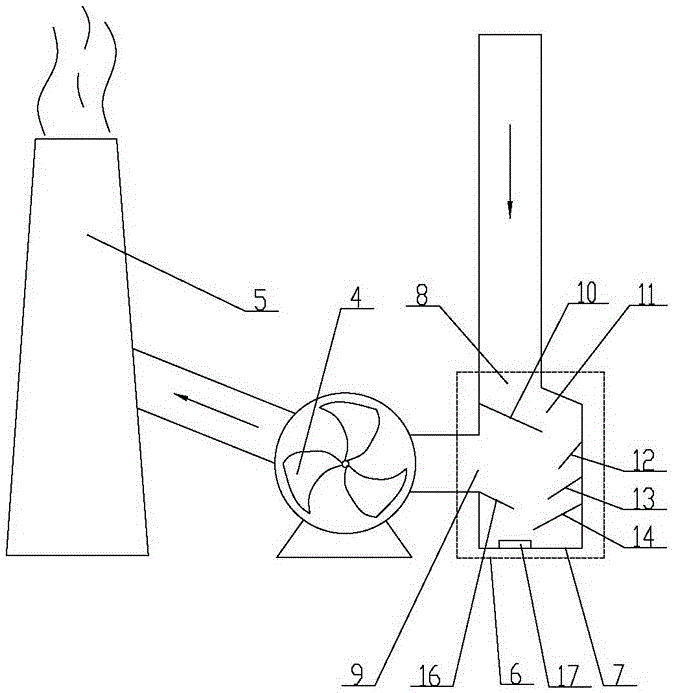

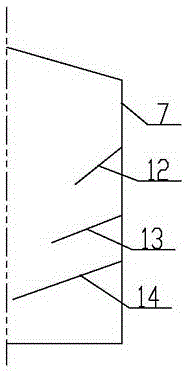

Draught fan dewaterer and boiler room

InactiveCN106422541APrevent rustAvoid corrosionLighting and heating apparatusDispersed particle separationImpellerCorrosion

The invention relates to the technical field of boilers, in particular to a draught fan dewaterer and a boiler room. The draught fan dewaterer comprises a tank, a smoke inlet is arranged at the upper end of the tank, a smoke outlet is arranged on the left side of the tank, a flow guide plate with a high left side and a low right side is arranged on the inner wall of the left side, above the smoke outlet, of the tank, and a smoke channel is formed between the upper end face of the flow guide plate and the inner wall of the right side of the tank. The draught fan dewaterer is mounted in front of a draught fan, and comprises the flow guide plate, a dewatering pore plate and a mud guard which are mounted in the tank; the flow guide plate and the dewatering pore plate work together to enable smoke, passing through the flow guide plate and the dewatering pore plate, to form 'S'-shaped rotational flow, and vapor, dust and acid are separated from the smoke according to the centrifugal principle, so that rusting and corrosion of the draught fan are avoided, the service life of the draught fan is prolonged, and working stability of the draught fan is improved; the dust is prevented from being adsorbed onto blades, eccentric rotation of impellers is avoided, normal production of enterprises is guaranteed, and maintenance cost is reduced.

Owner:XINJIANG NORTH TIANHENG ENERGY SAVING TECH CO LTD

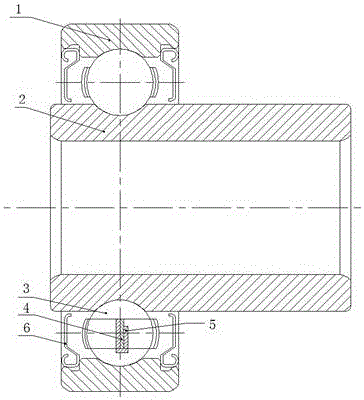

Bearing special for rowing machine

InactiveCN106122277AReduce fit slippageExtended service lifeBearing componentsEngineeringRowing Machines

The invention relates to a bearing special for a rowing machine. The bearing comprises an outer ring, an inner ring, rolling bodies, a first holder, a second holder, a dustproof cover and a connecting mandrel. The rolling bodies are connected with the outer ring and the inner ring and positioned through the first holder and the second holder so that the rolling bodies can be evenly separated. The inner ring is installed and fixed through the connecting mandrel. The width of the inner ring is far larger than that of the outer ring. A dustproof groove is formed in the outer ring. The dustproof cover is arranged in the dustproof groove. According to the bearing special for the rowing machine, the phenomenon of skidding generated when a shaft and the bearing are matched is greatly reduced, rotation eccentricity can be effectively prevented due to the application of the first holder and the second holder, and therefore it is guaranteed that the bearing and the whole component can normally work and run. The bearing is simple in structure and compact and reasonable in design, and the service life of the bearing is prolonged.

Owner:WUXI CHENGSHI BEARING

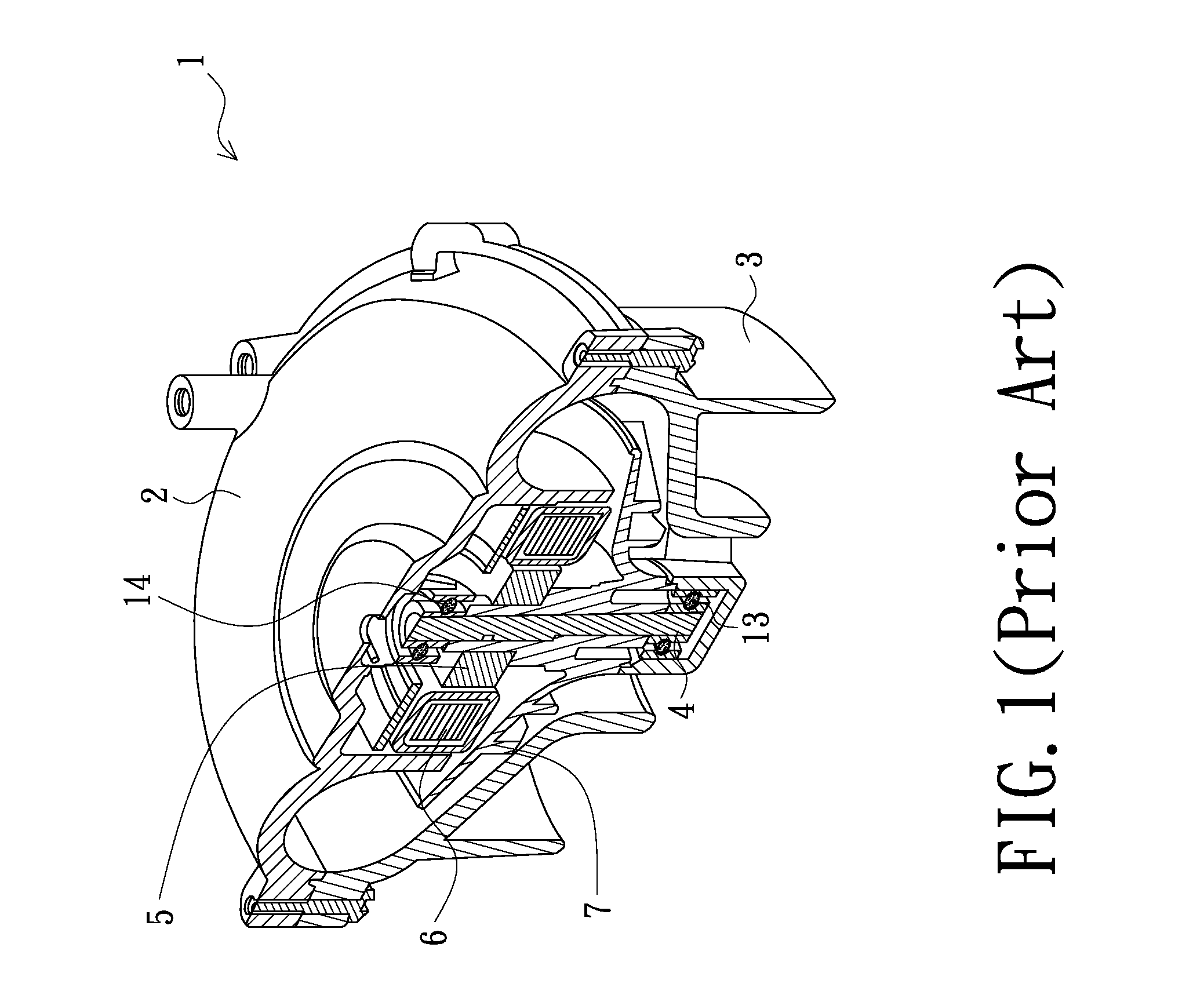

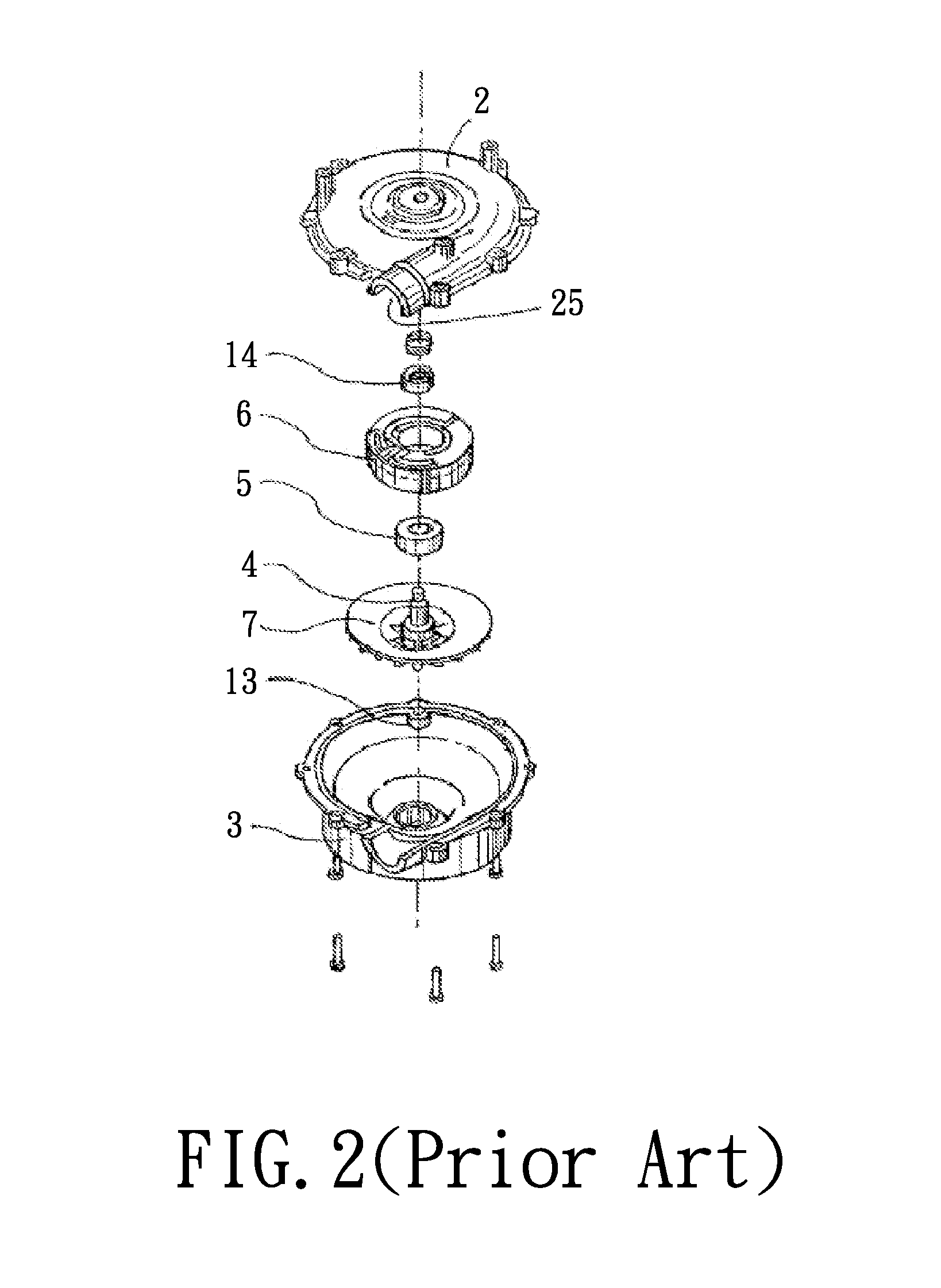

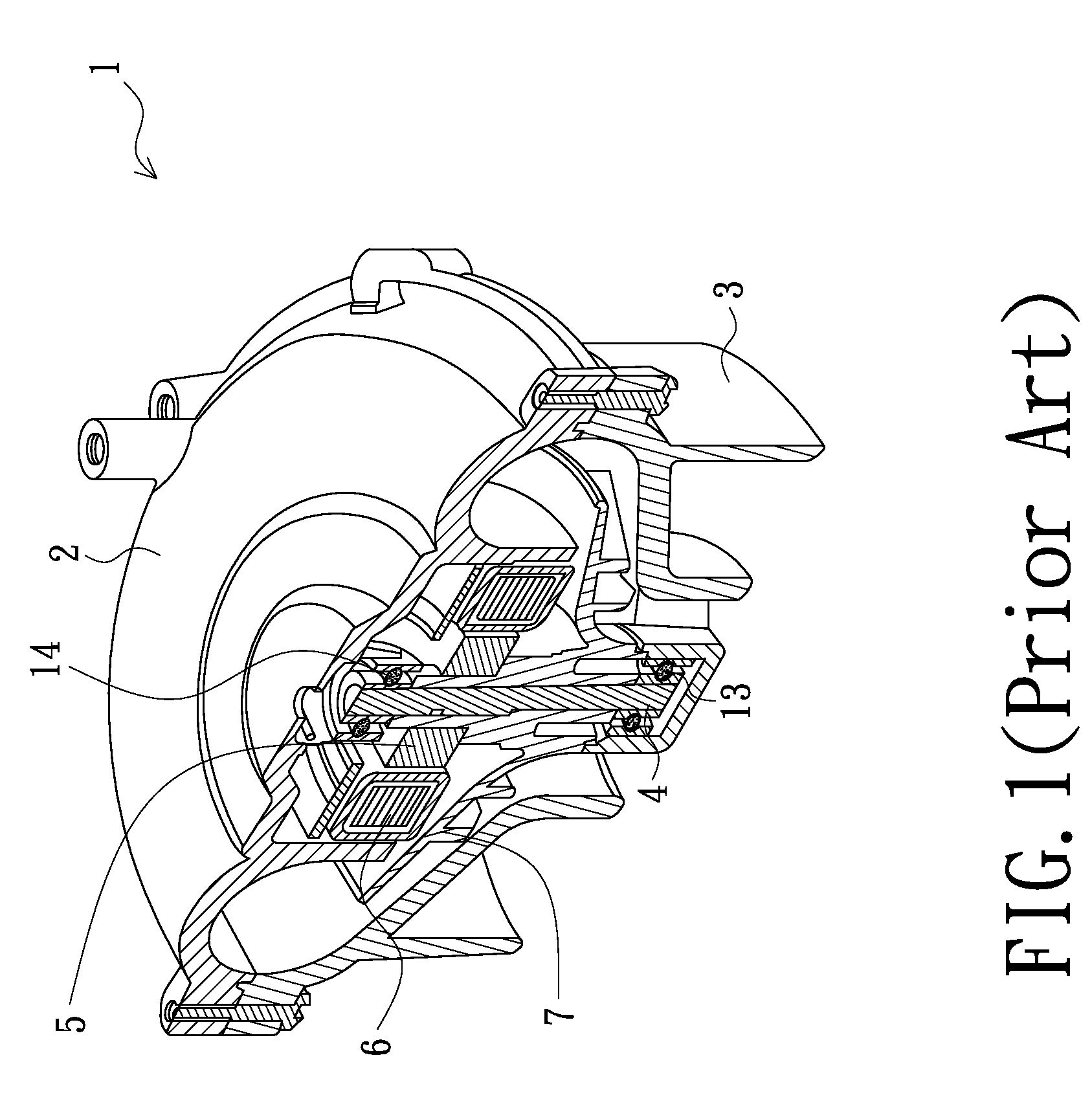

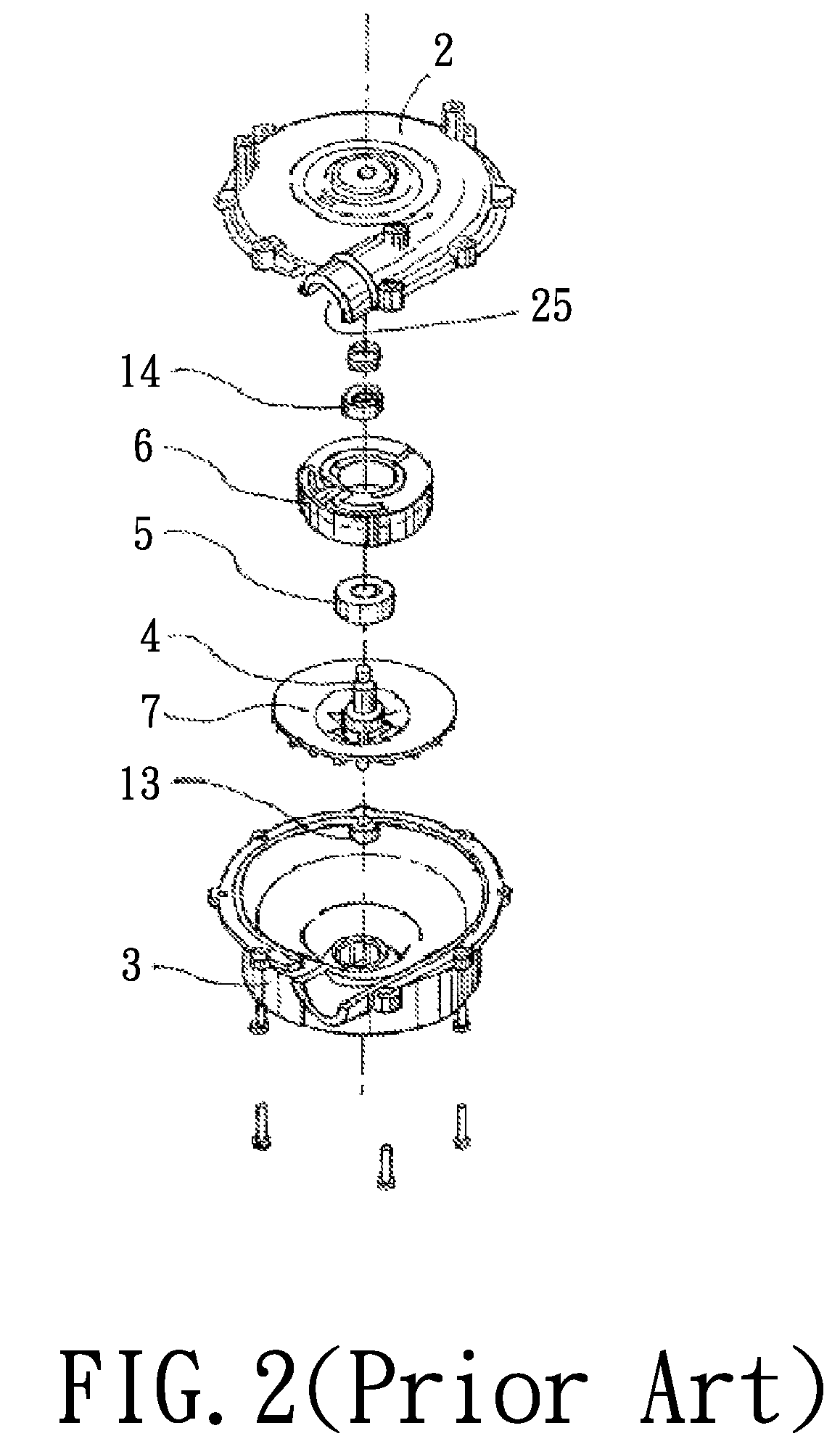

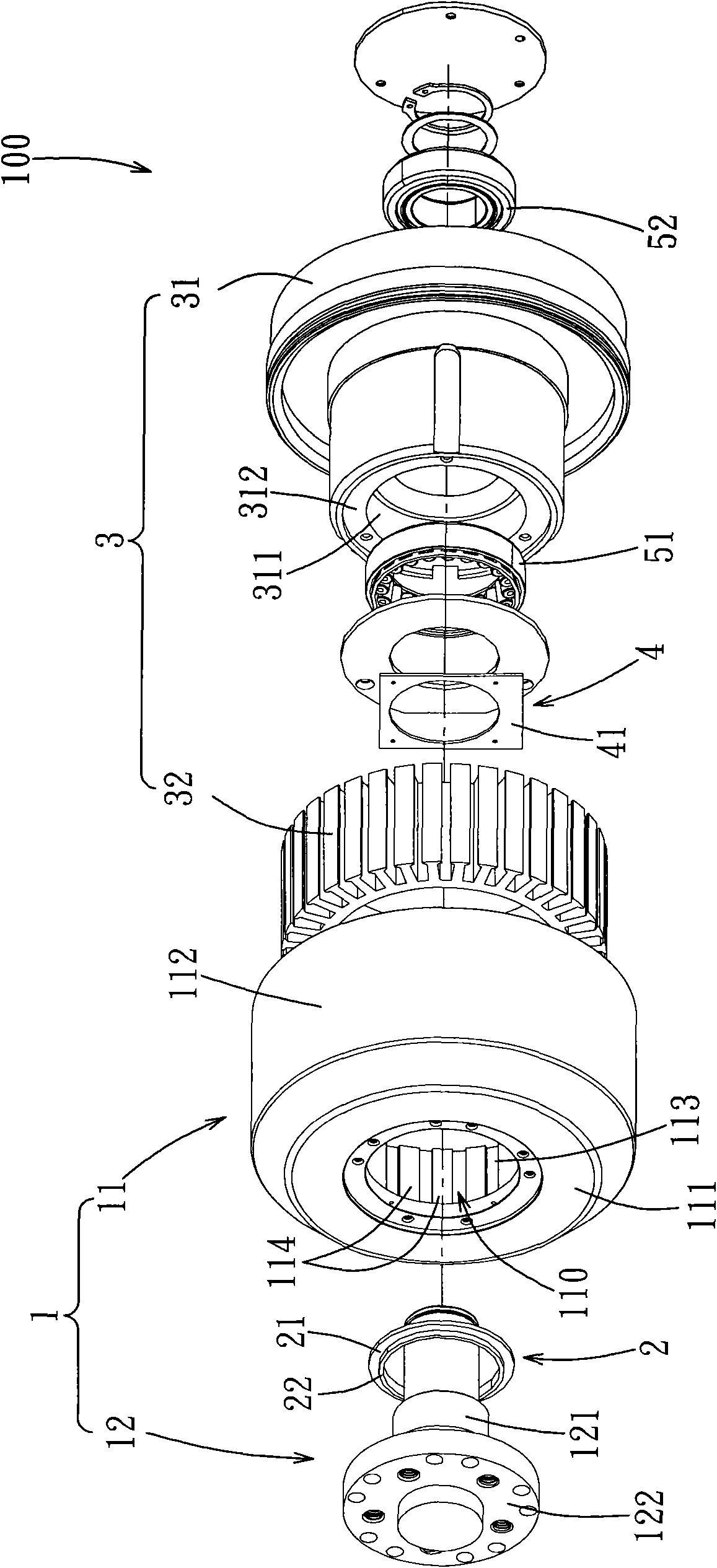

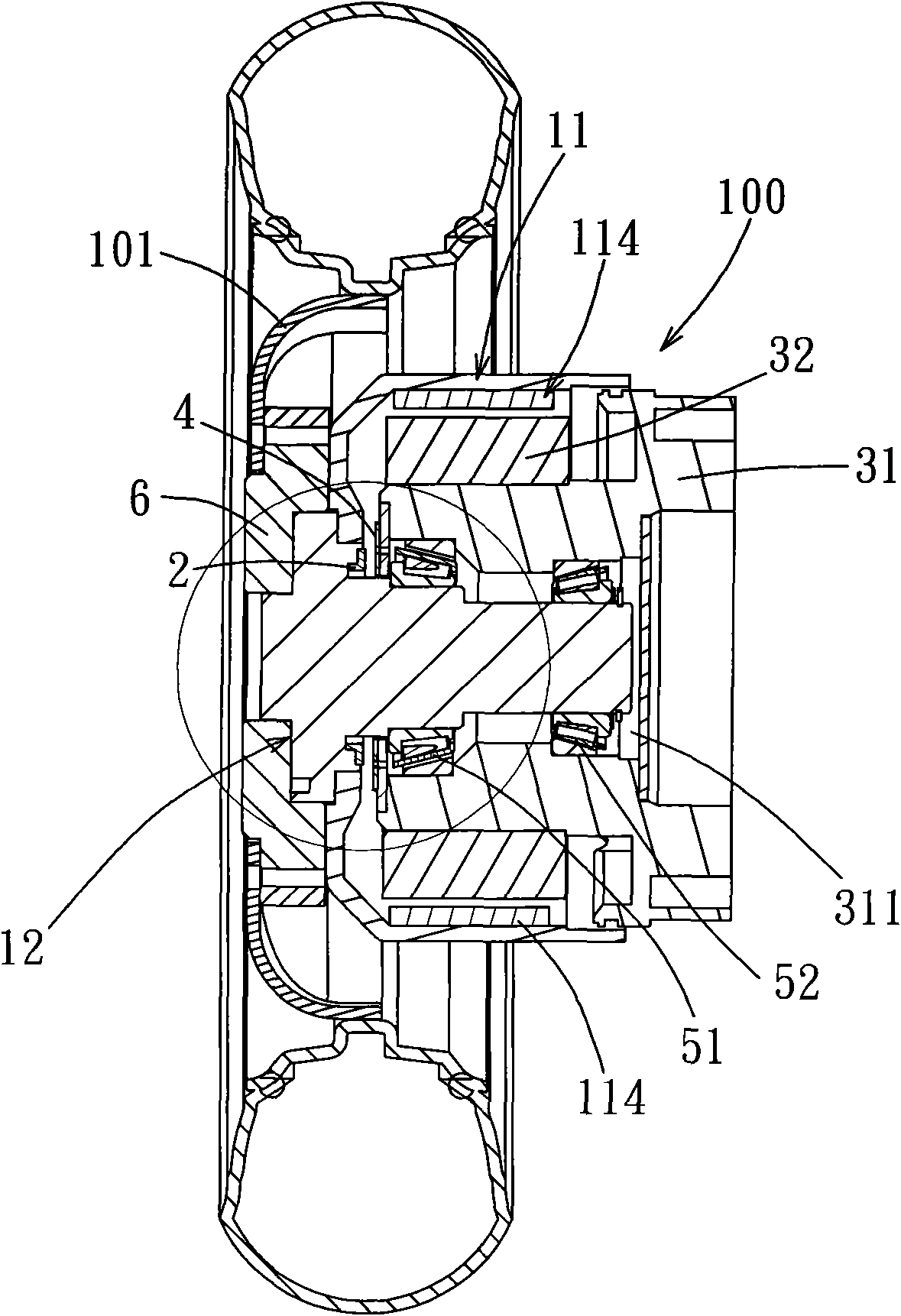

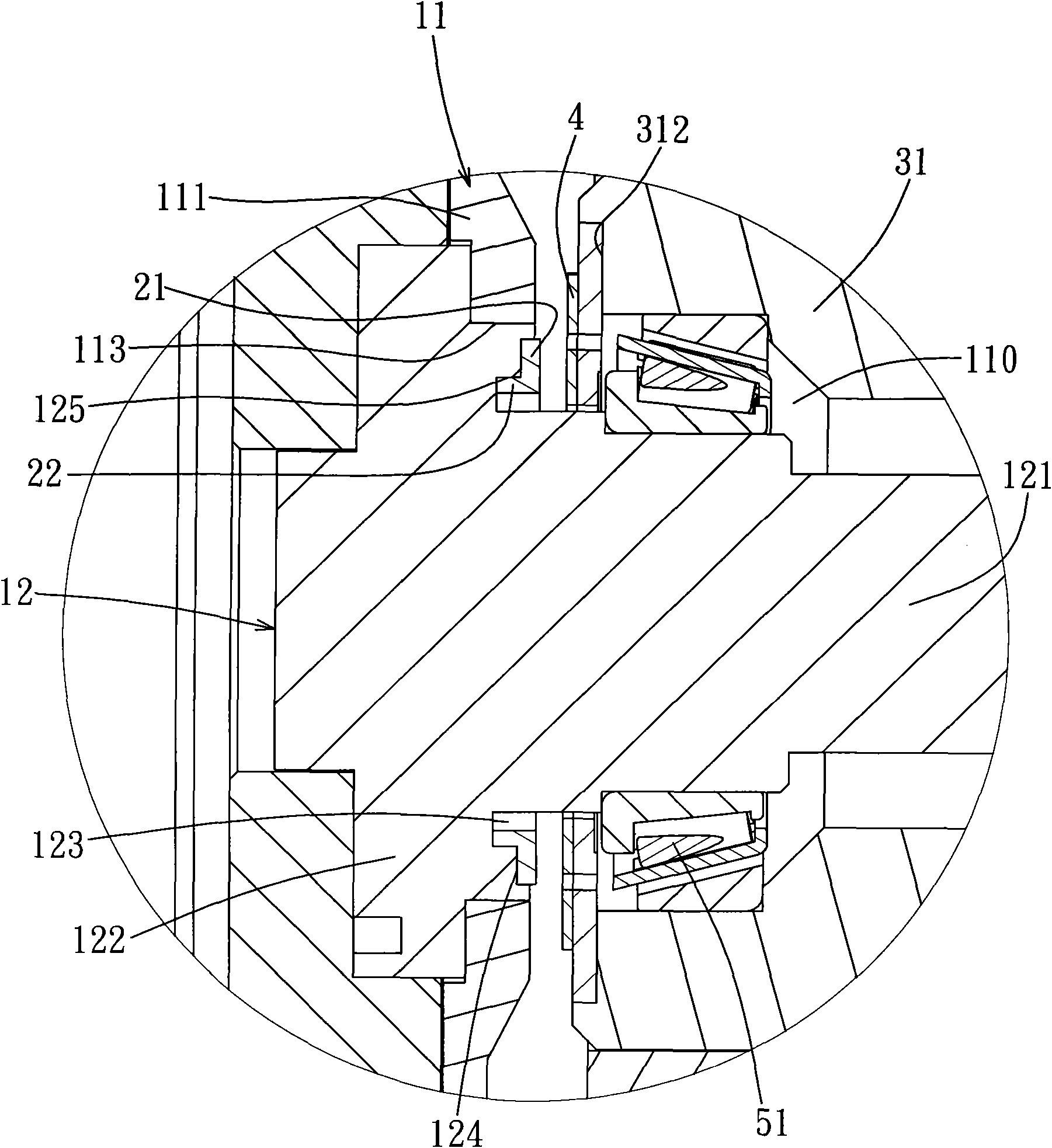

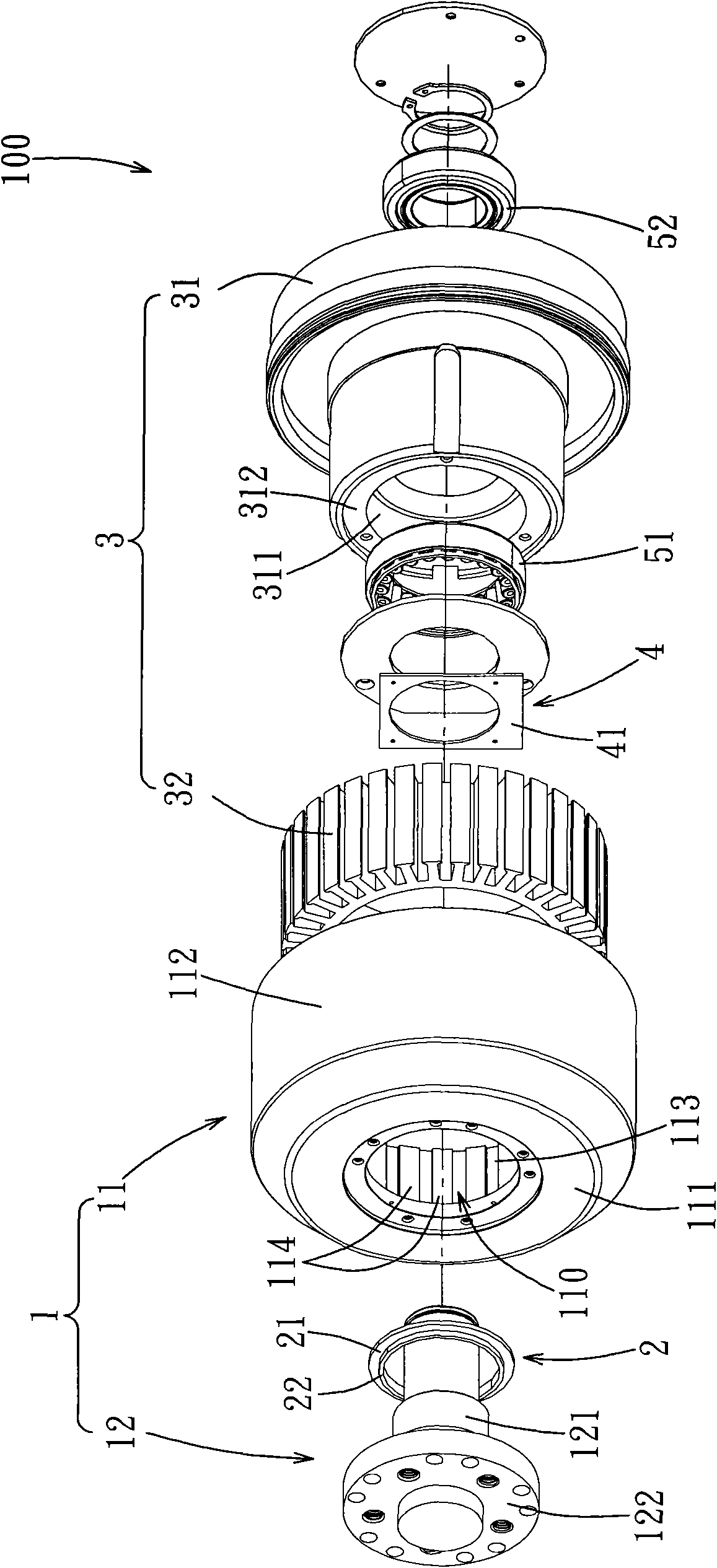

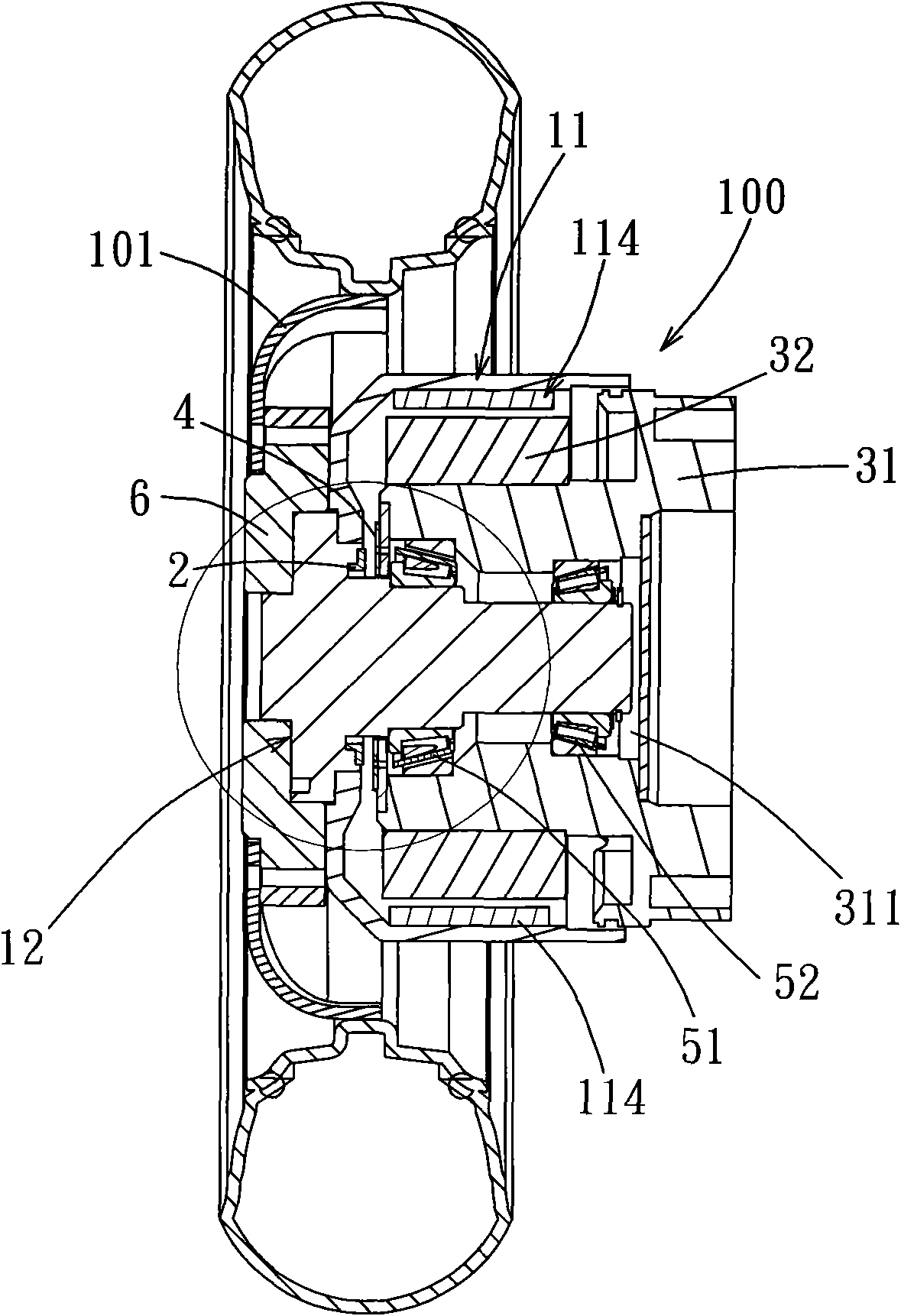

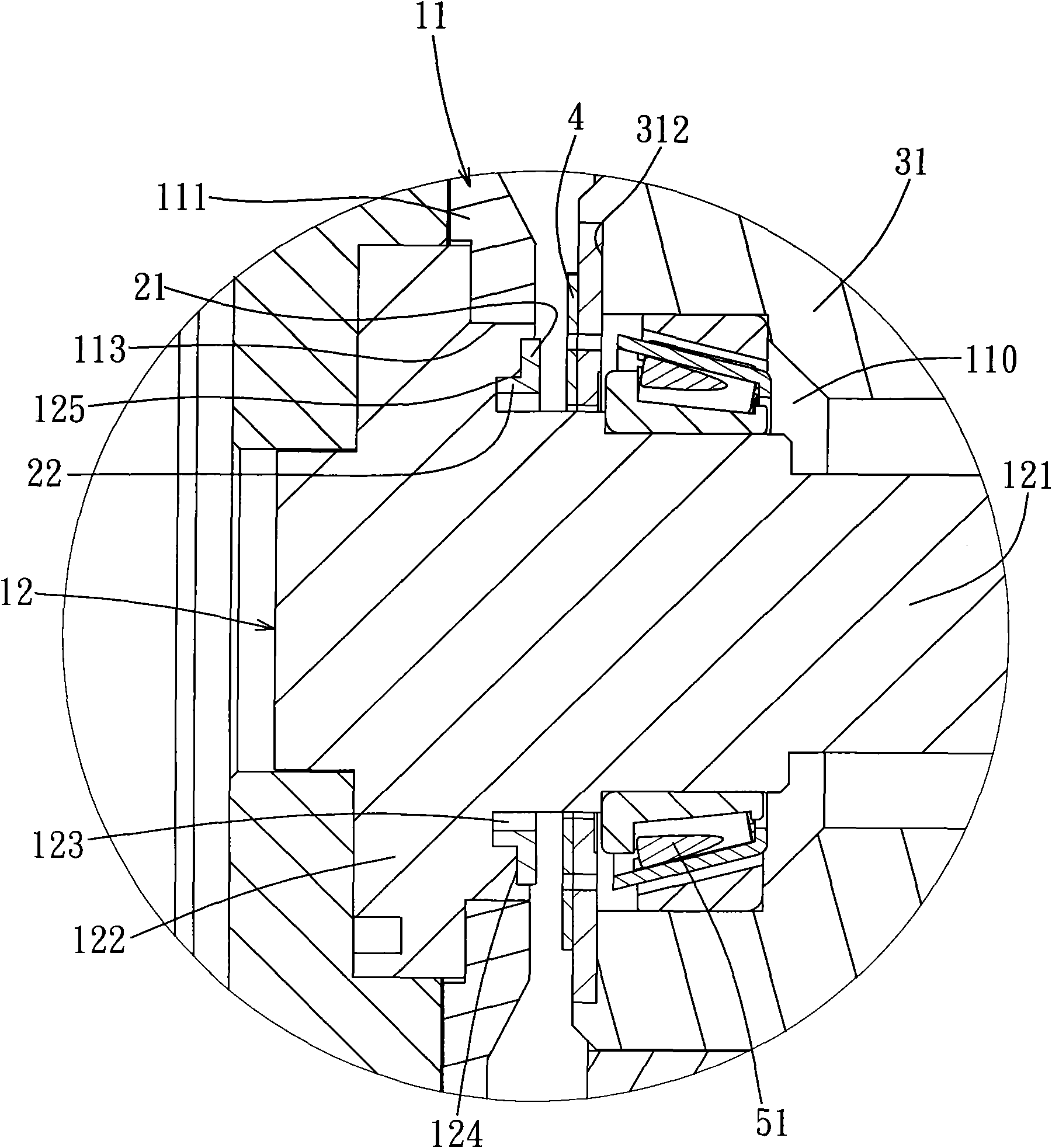

Hub motor

InactiveCN102403863AImprove structural stabilityAvoid eccentric rotationMagnetic circuit rotating partsMagnetic circuit stationary partsStatorEngineering

The invention relates to a hub motor comprising a stator unit, a rotor unit, a magnetic ring and a sensing circuit unit. The rotor unit is provided with a shaft part which can be relatively and rotatably penetrates through the stator unit; the magnetic ring and the sensing circuit unit are arranged on the rotor unit and the stator unit respectively and are correspondingly positioned at intervals between the rotor unit and the stator unit; and the magnetic ring is provided with a first ring piece extending radially and a second ring piece which is connected with the first ring piece and extends axially. With the structural design of the magnetic ring, the problems of eccentric rotation and axial displacement generated in the process that the magnetic ring rotates with the rotor unit can beavoided; and as the magnetic ring and the sensing circuit unit are arranged between the rotor unit and the stator unit and are wrapped and fixed by both the rotor unit and the stator unit, on the onehand, the structure stability that the magnetic ring is combined with the rotor unit is increased so as to resist the centrifugal force generated by high speed rotation, and on the other hand, the magnetic ring can be prevented from being polluted and interfered by the outside, and the cost for additional arrangement of an outer cover is saved.

Owner:TAIWAN ELECTRIC PROPULSION SYST CORP

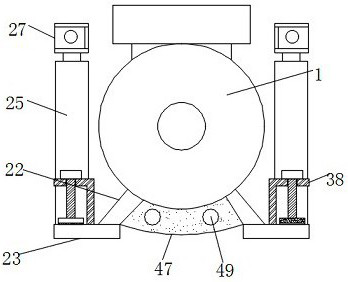

Automatic textile fiber cloth dividing and cutting machine

The invention relates to the technical field of automatic fiber cloth dividing and cutting equipment, in particular to an automatic textile fiber cloth dividing and cutting machine. The automatic textile fiber cloth dividing and cutting machine comprises a supporting mechanism I, a supporting mechanism II and a supporting mechanism III, wherein the supporting mechanism I, the supporting mechanismII and the supporting mechanism III are sequentially arranged on the ground from front to back. The automatic textile fiber cloth dividing and cutting machine further comprises a cloth feeding mechanism, a tightening mechanism, a slitting mechanism, a cloth rolling mechanism I and a cloth rolling mechanism II, the cloth feeding mechanism is fixedly connected to the upper side of the front end of the supporting mechanism I, the tightening mechanism are slidably connected to the rear end of the supporting mechanism I, the slitting mechanism is rotatably connected in the supporting mechanism II,the cloth rolling mechanism I is fixedly connected to the upper side of the front end of the supporting mechanism III, and the cloth rolling mechanism II is fixedly connected to the rear end of the supporting mechanism III, so that installation and fixation requirements of cloth rolling pipes with different sizes can be met, the phenomenon of eccentric rotation of the cloth rolling pipes cannot occur, the time loss caused by replacing a rotating roller is reduced, the working modes are more, and the working efficiency is improved.

Owner:郑春辉

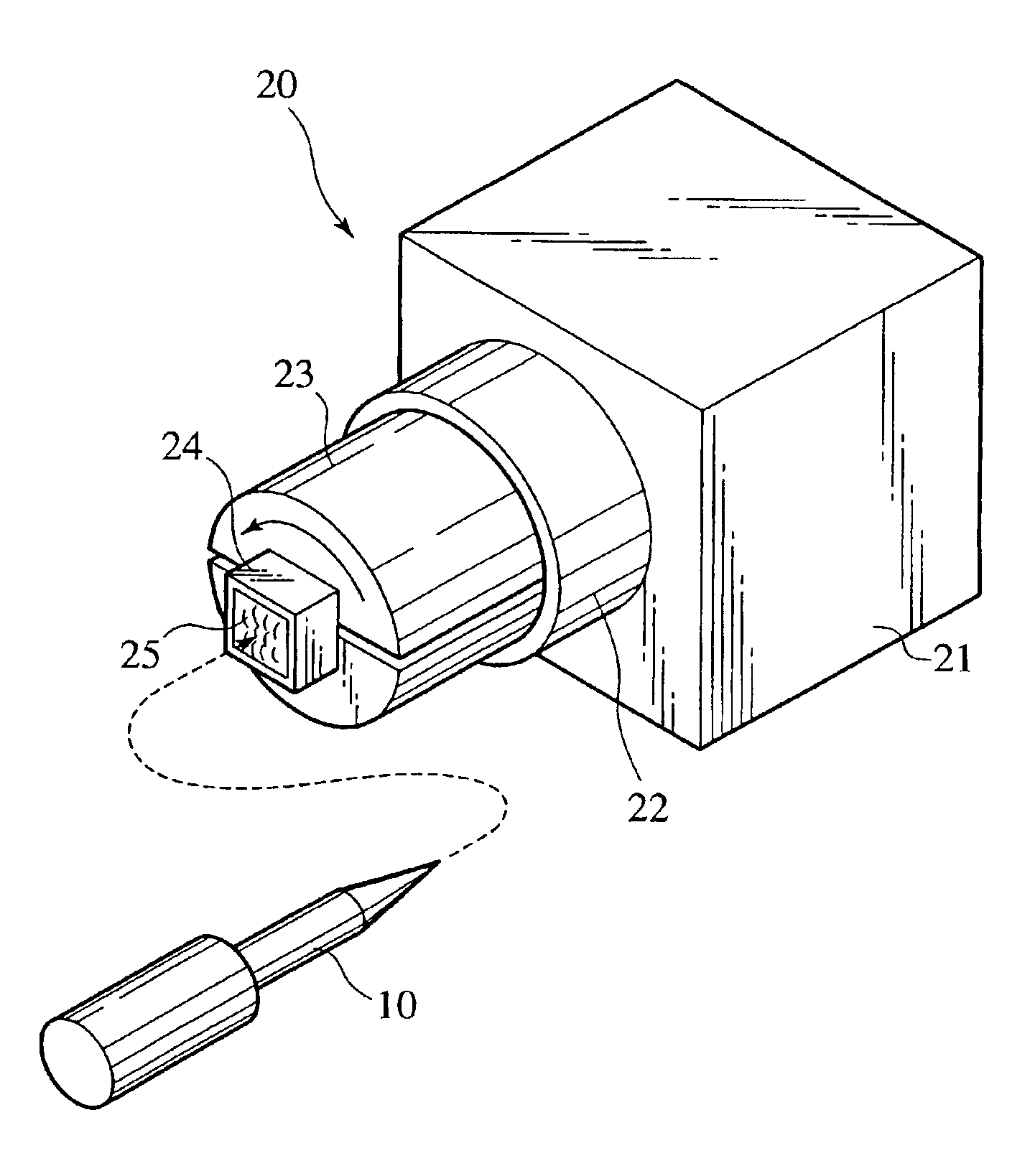

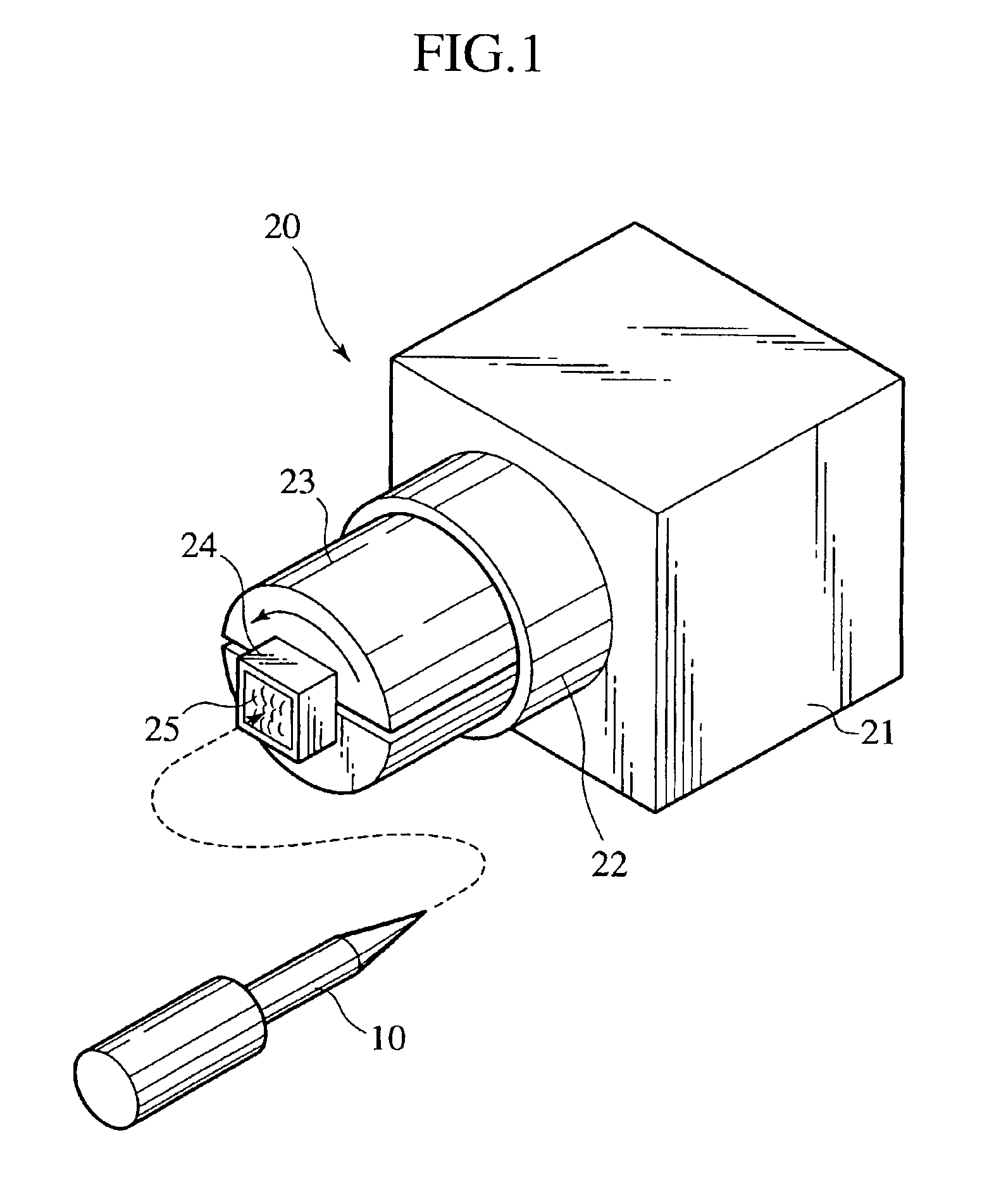

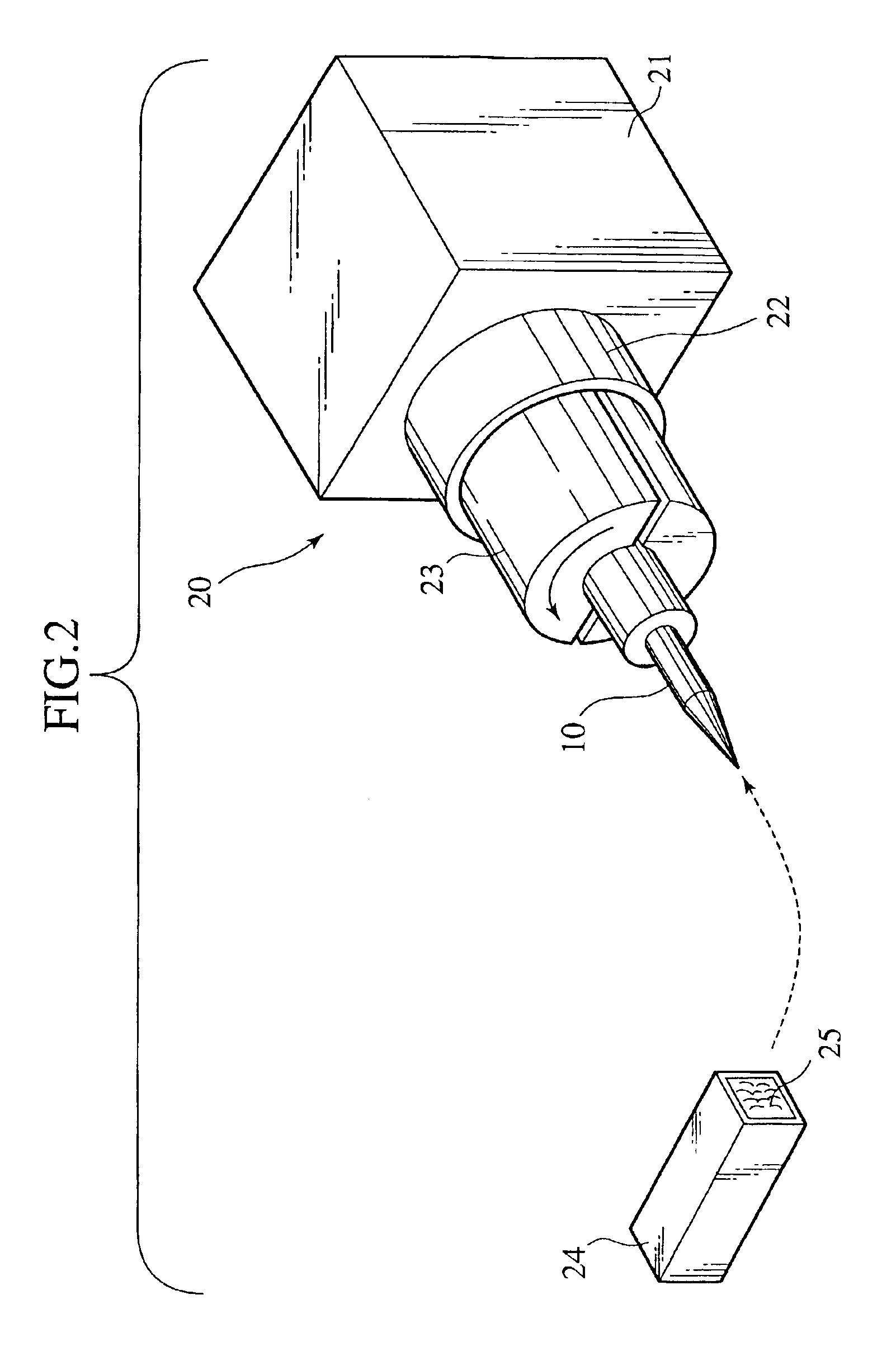

Cleaning apparatus for electrodes of optical fiber fusion splicer

InactiveUS6886999B2Easy to cleanAvoid eccentric rotationCleaning using toolsCoupling light guidesEngineeringBiomedical engineering

Owner:THE FUJIKURA CABLE WORKS LTD

Disinfection device for nursing

ActiveCN113499459AEffective DisinfectionClose contact and squeezeLavatory sanitoryHeatGear wheelWater vapor

The invention relates to a disinfection device for nursing, and the device comprises a machine shell; a top disc is fixedly mounted at the top of the machine shell, a water outlet is formed in the side wall of the machine shell, a driving motor is fixedly mounted at the top of the top disc, and a mounting main shaft is fixedly mounted at one end of an output shaft of the driving motor; a transmission lead screw is rotationally mounted on the inner wall of the top disc, a driving gear and a driven gear are fixedly mounted outside the mounting main shaft and the transmission lead screw correspondingly, and the driving gear and the driven gear are connected in a meshed mode. The heat recovery box is arranged outside the device, waste heat in the device can be effectively collected, waste is avoided, water vapor generated by waste heat recovery can be used for conducting reverse compensation and disinfection on the interior of the device, additional driving energy is not needed, energy is saved, the disinfection effect can be improved, and meanwhile, due to the design of the gas control mechanism, automatic operation of gas control can be achieved, manual management is not needed, intellectualization is achieved through a physical structure, and the using effect is improved.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

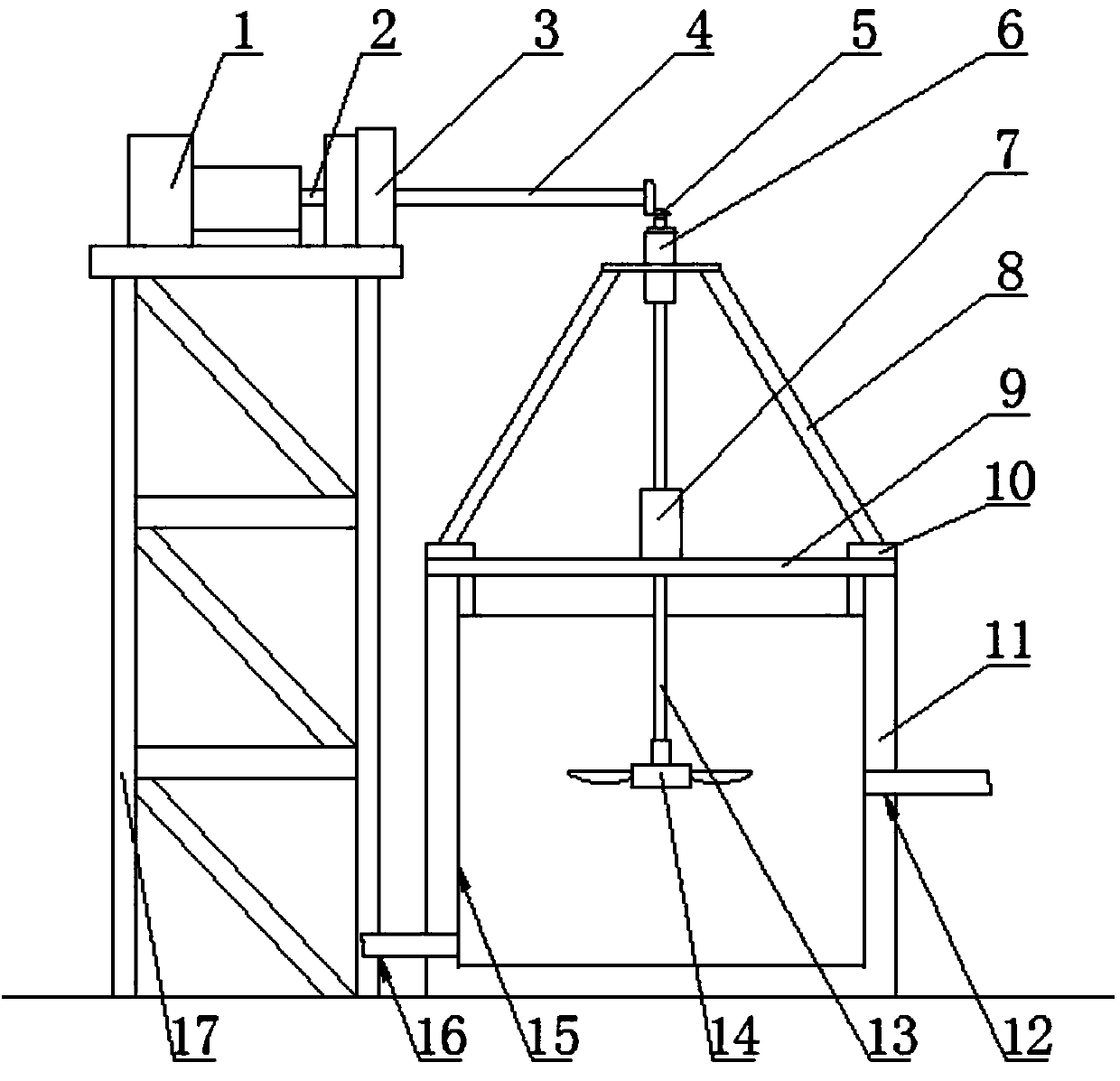

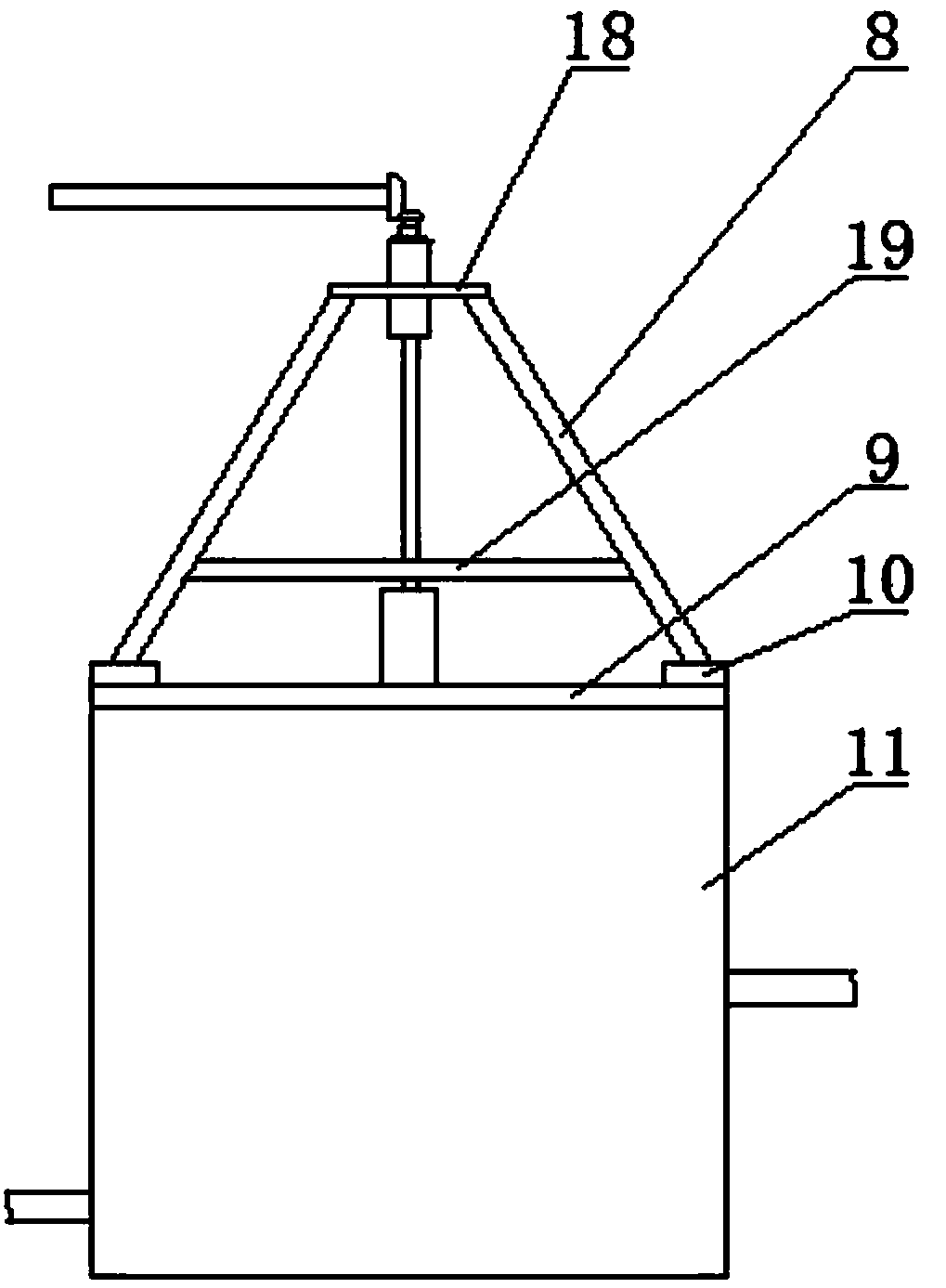

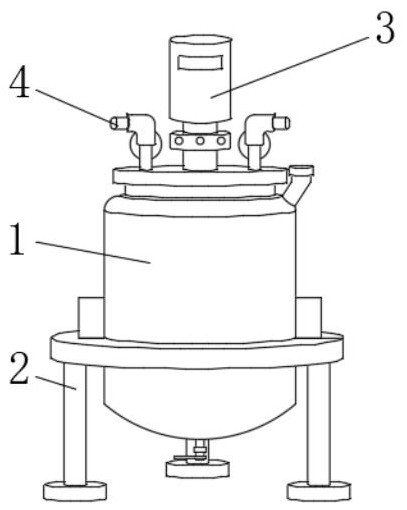

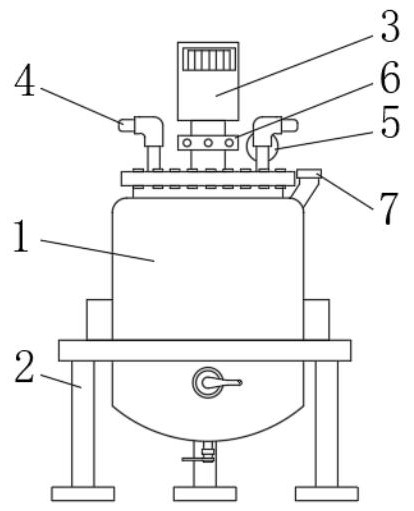

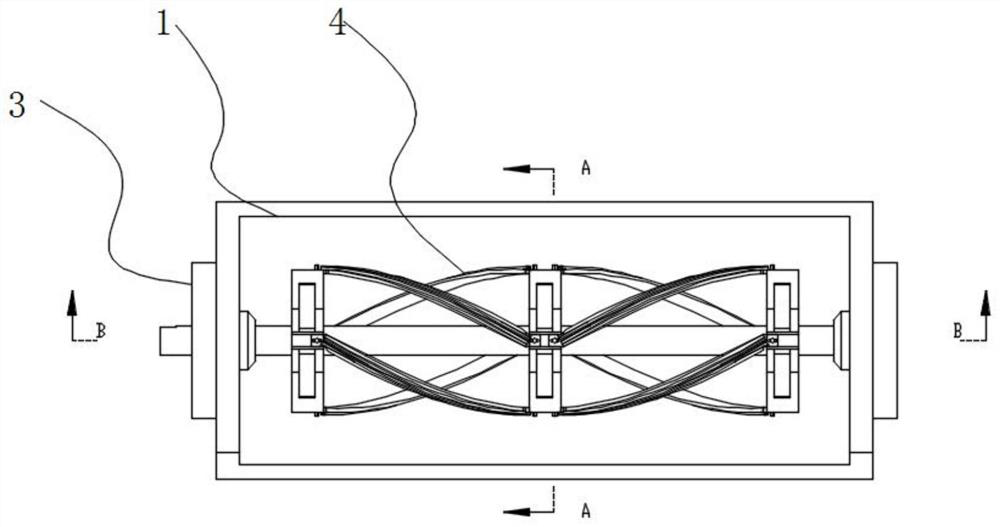

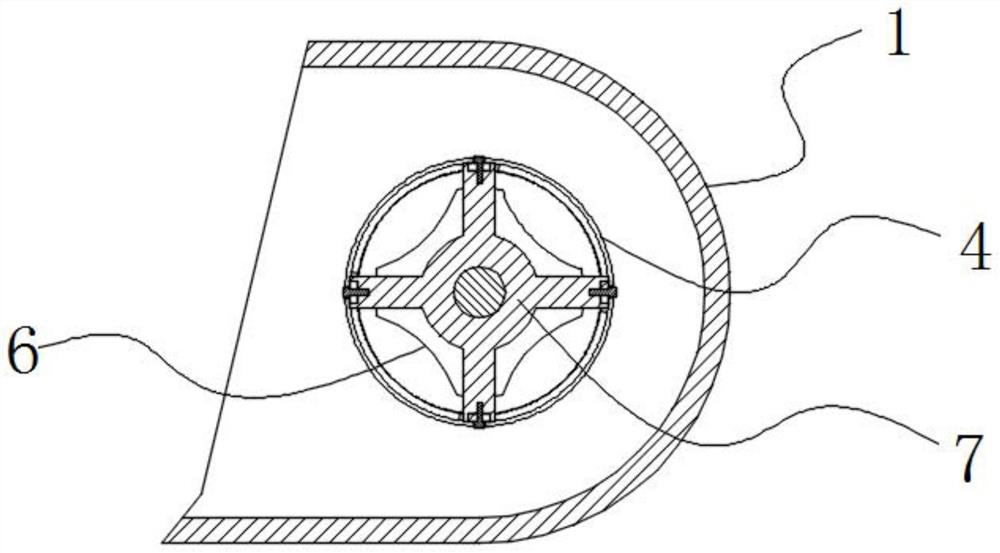

Mold surface TD treatment raw material pre-mixing stirring apparatus

InactiveCN107790018AImprove rigidityImprove stabilityRotary stirring mixersTransportation and packagingEngineeringPower take-off

The invention relates to the field of mold manufacturing, particularly to a mold surface TD treatment raw material pre-mixing stirring apparatus, which comprises a wide-mouth pre-mixing barrel for holding a raw material, wherein a material inlet and a material outlet are respectively arranged in the side walls of the pre-mixing barrel, a sealing cover is movably embedded on the inner edge of the wide mouth of the pre-mixing barrel, the upper end surface of the sealing cover is provided with a frustum type rack, the upper end of the rack is provided with a flat end surface, the upper end of a rotation shaft is rotatably installed in the flat end surface of the rack, the lower end of the rotation shaft penetrates through the sealing cover, and extends into the pre-mixing barrel, a pluralityof pre-mixing paddle blades are uniformly arranged on the outer edge of the lower end portion of the rotation shaft at intervals, and the upper end portion of the rotation shaft is connected to the output end of a power output device.

Owner:天津开山金属模具科技有限公司

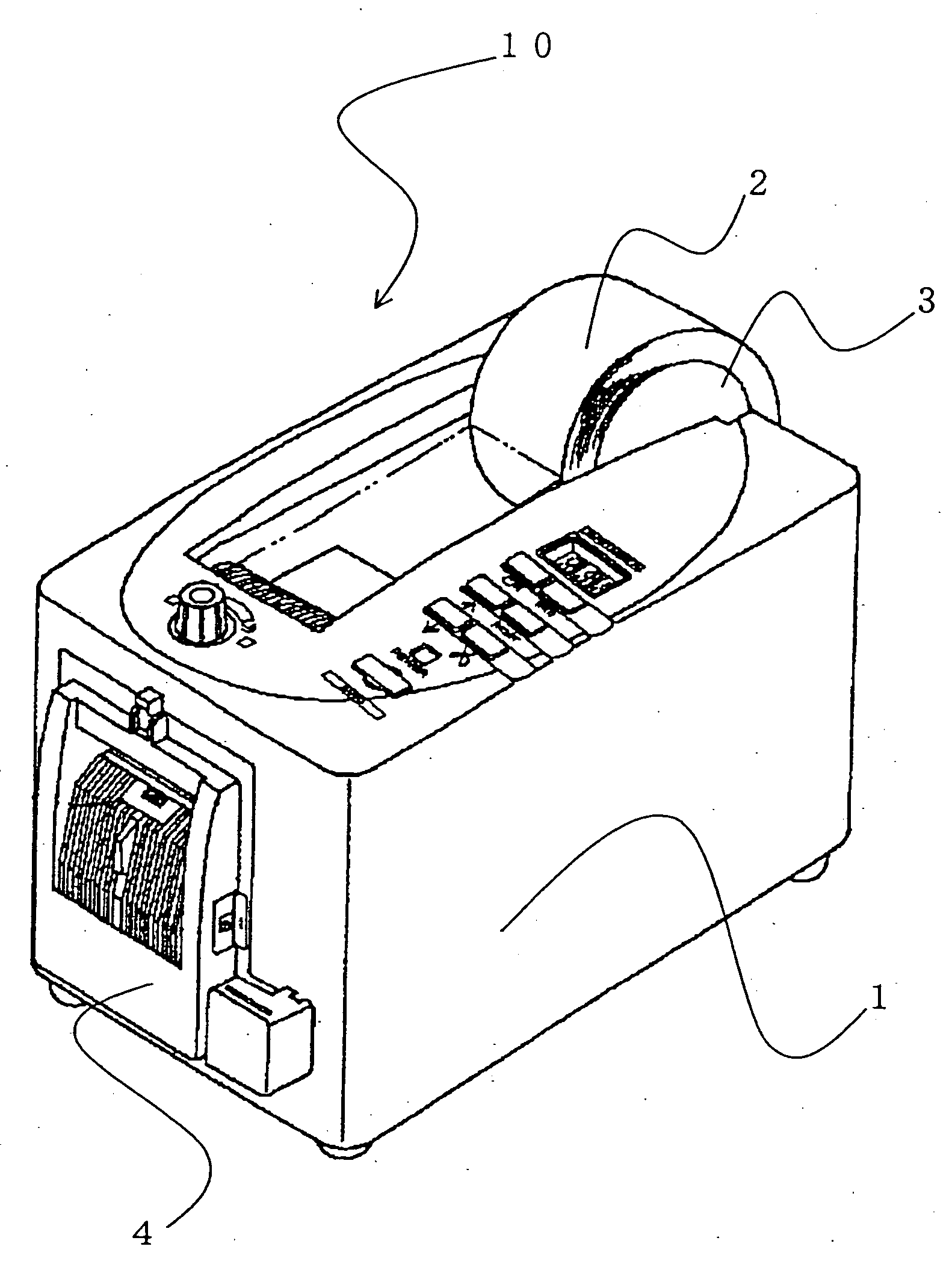

Electrically-driven tape cutter

InactiveUS20060048622A1Avoid eccentric rotationMetal working apparatusArticle deliveryLeading edgeGear wheel

The invention provides an improved electric tape cutter in which a pinion gear with an attached magnet that is connected to a drive source is embedded with a member having a weight equal to that of the magnet at a location that is symmetrical to the location at which the magnet is mounted, with respect to a center axis of rotation, imparting balanced rotation that enables eccentric rotation of the pinion gear to be prevented, preventing noise and apparatus malfunction. The electric tape cutter, which feeds a leading edge of adhesive tape wound on a reel from a delivery outlet and cuts it to an appropriate length with an electrically driven blade provided at the delivery outlet, has a configuration wherein, in order to prevent eccentric rotation of a pinion gear that has a magnet affixed thereto and is connected to a drive source, a fitted member of equal weight to the magnet is embedded in the pinion gear at a location that is symmetrical to the position at which the magnet is provided, with the axis of rotation of the pinion gear therebetween.

Owner:KTF

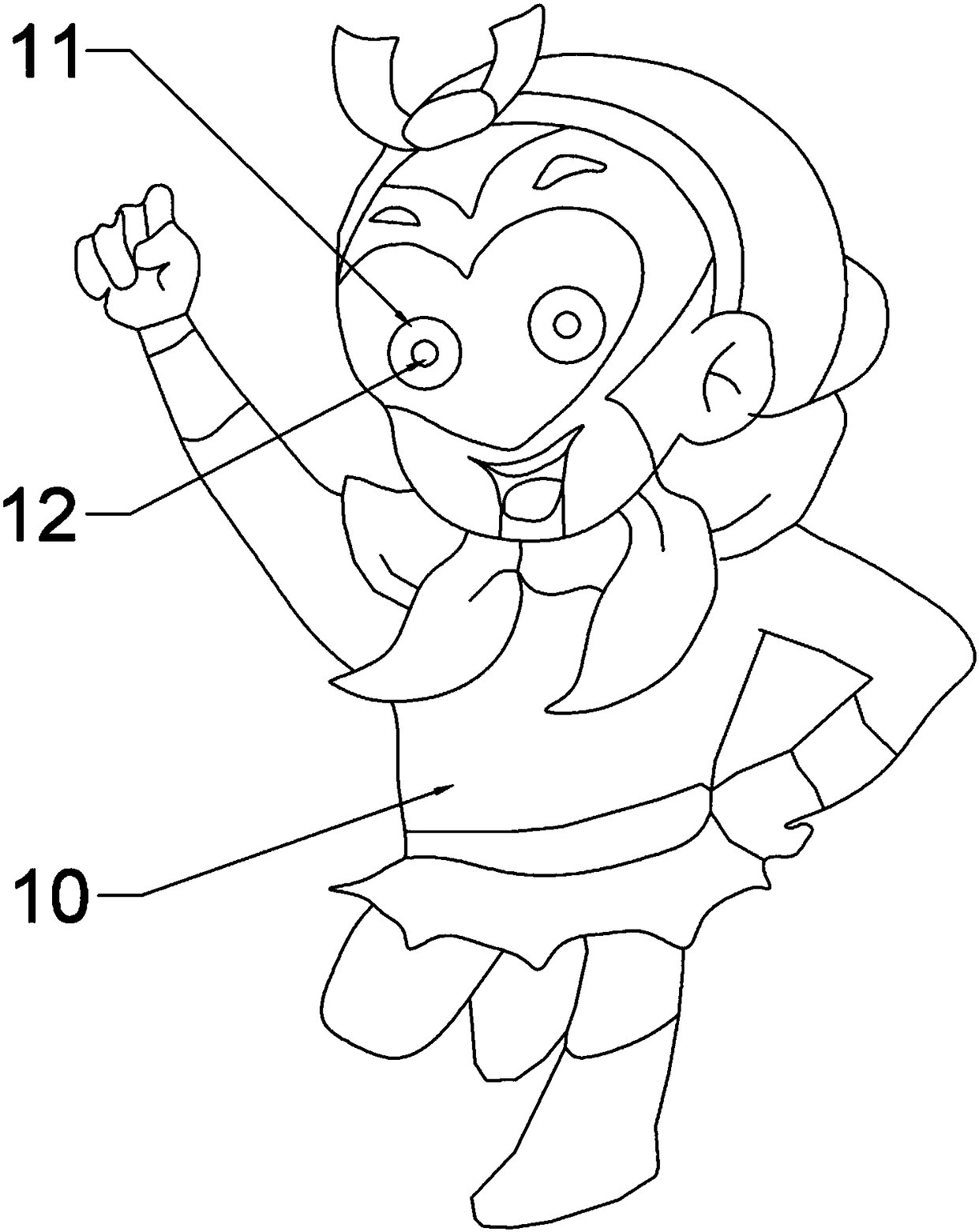

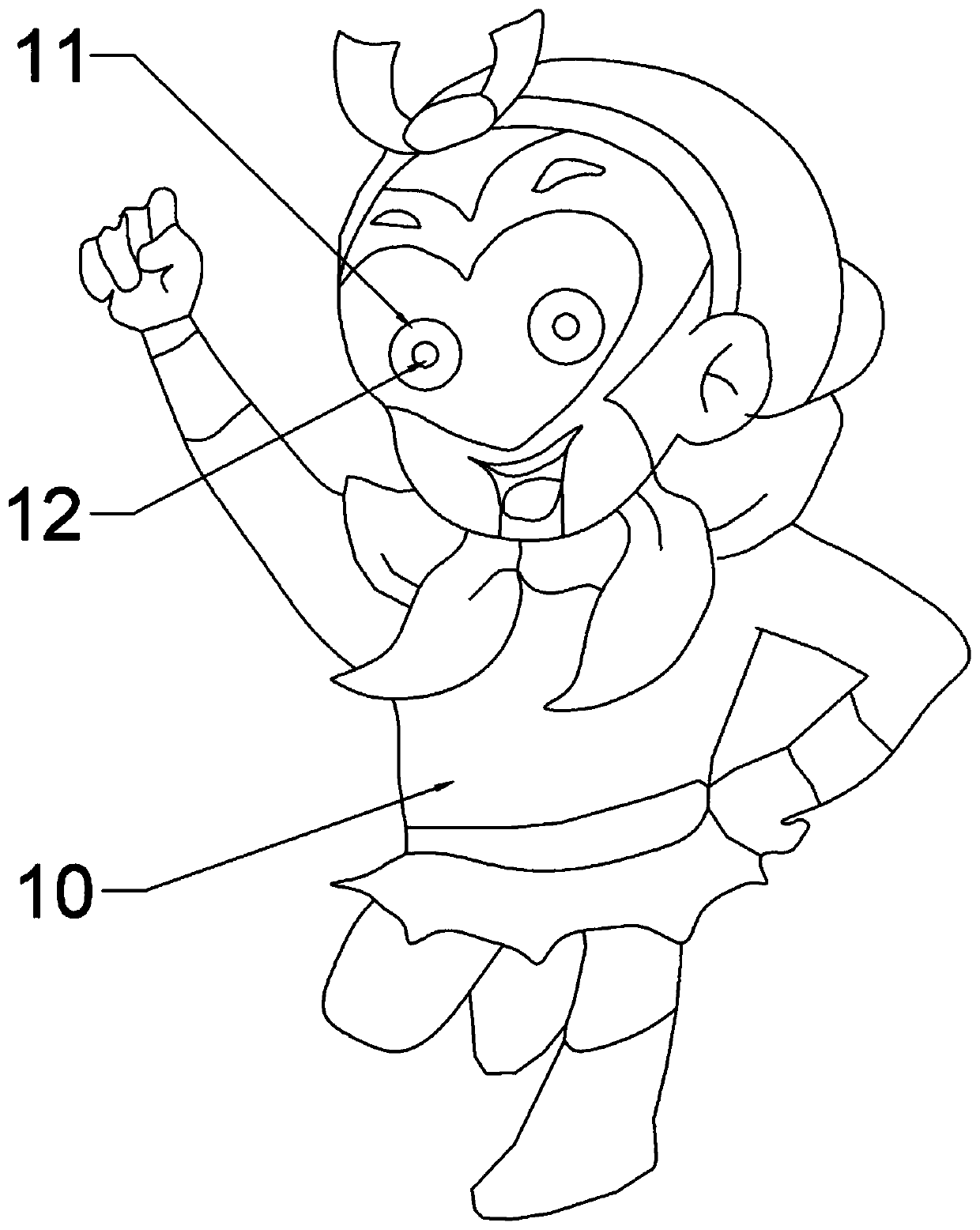

Multifunctional interactive robot

The invention discloses a multifunctional interactive robot. The multifunctional interactive robot comprises a robot body and two projection mechanisms located at the eye parts of the robot body. Eachprojection mechanism is mounted at the corresponding eye part of the robot, and the projection angle is controlled by a servo steering machine, so that the rich projection combination is achieved, for example, two images are spliced together to form an ultra-wide picture, or the two images are projected separately to form different pictures, more information is fed back to a user, enjoyment is high, and playability is high.

Owner:重庆门罗机器人科技有限公司

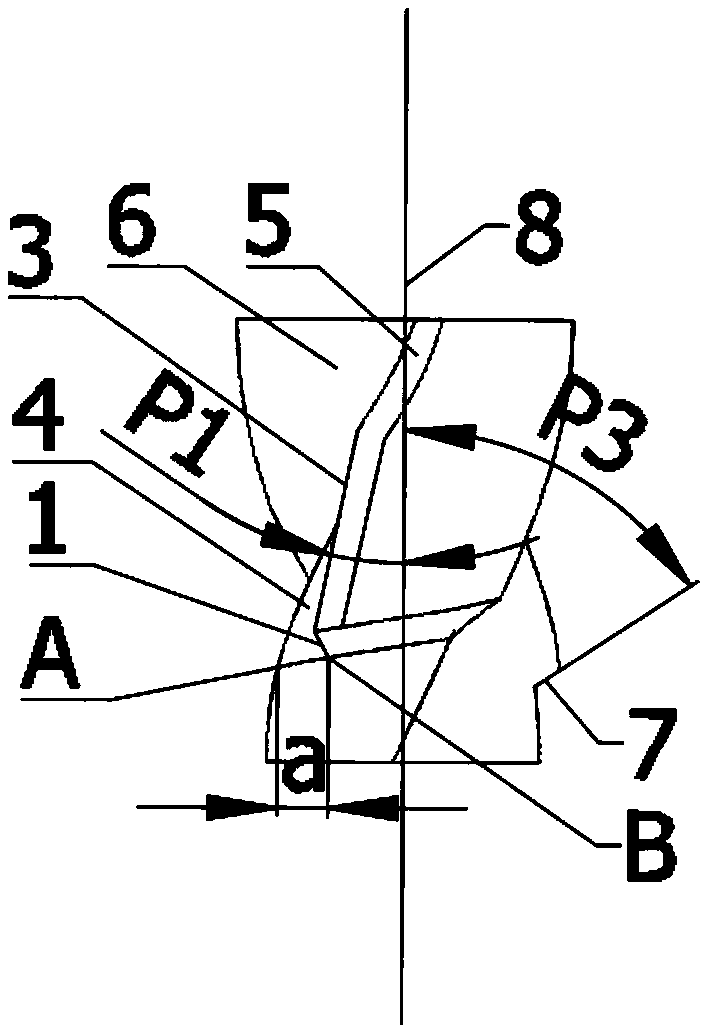

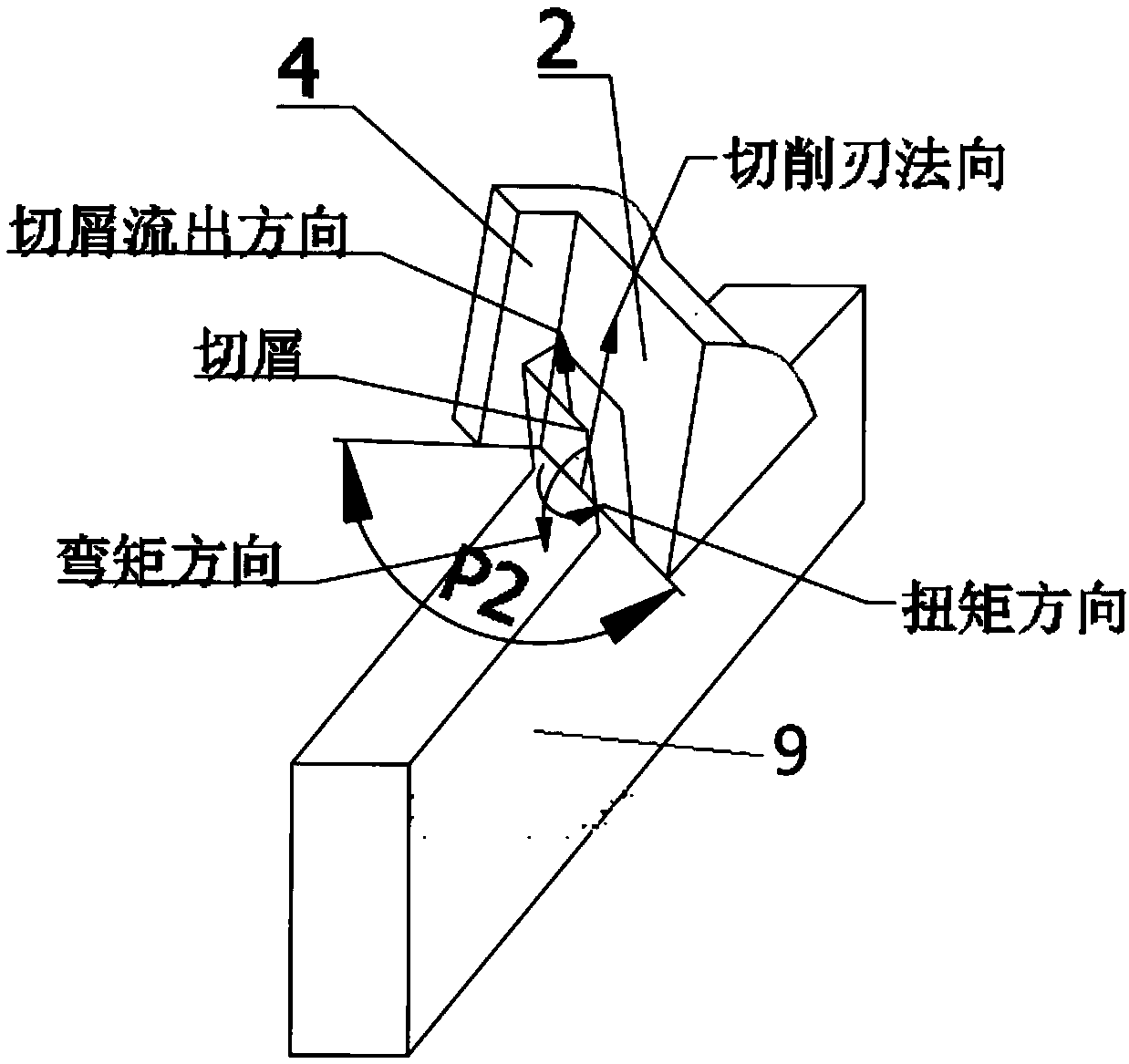

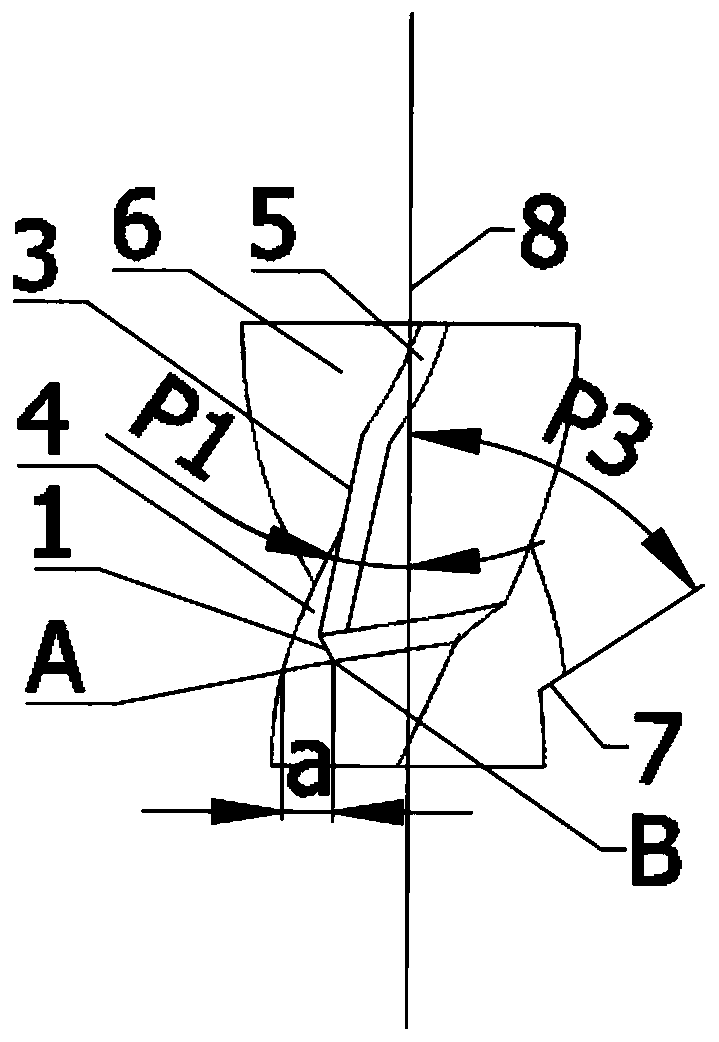

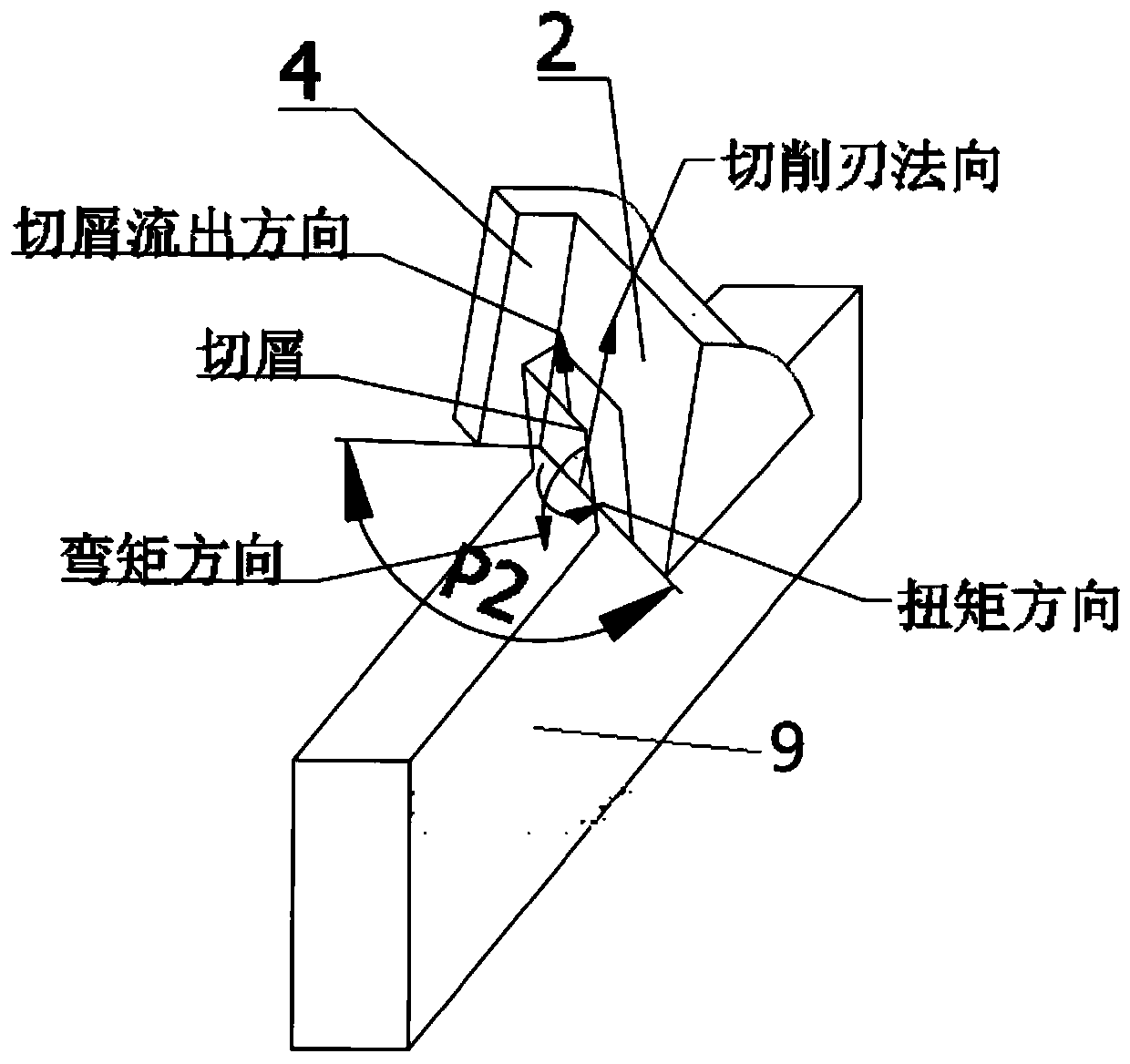

Chip breaking structure of reducing position cutting edge of stepped drill

ActiveCN109128306AIncrease chip stressAvoid scratchesTransportation and packagingStepped drillsTorsional deformationEngineering

The invention belongs to the technical field of drilling tools in machining and relates to a chip breaking structure of a reducing position cutting edge of a stepped drill. The chip breaking structureis composed of a step reducing position cutting edge, a chip breaking cutter face, a chip breaking edge, a stop face, an edge strip, a chip discharging groove and a step back section end face. According to the chip breaking structure, traditional continuous spiral edge cutting is changed into step edge joint cutting, arc front cutter faces are changed into straight cutter faces mutually forming an angle, and a chip breaking space is formed. The front cutter faces mutually forming the angle enable cutting chips to bend and undergo torsional deformation, the stress of the cutting chips is increased, the breaking strength of the cutting chips is easier to reach, and therefore metal chip breaking and chip smashing are effectively achieved. The scratches, caused by continuous cutting chips, ofa hole wall are restrained, and cutter rotation deviation caused by twining of the cutting chips is reduced. The chip breaking structure facilitates to greatly improve the hole forming quality of thestep drill, reduces the machining cost and has good engineering application prospect.

Owner:DALIAN UNIV OF TECH +1

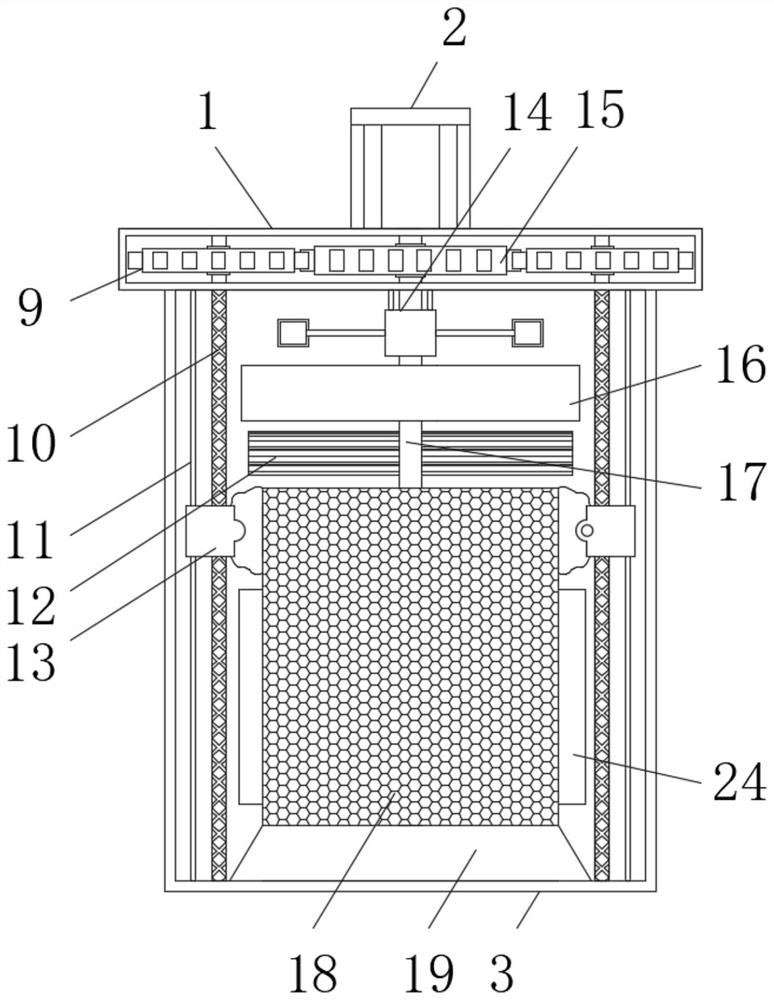

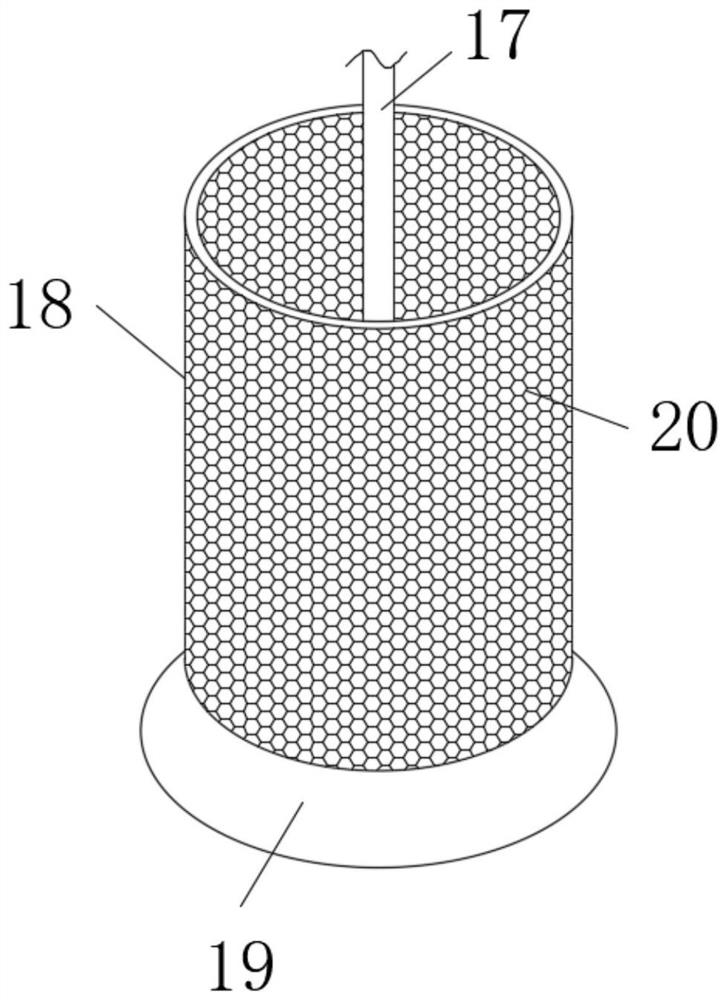

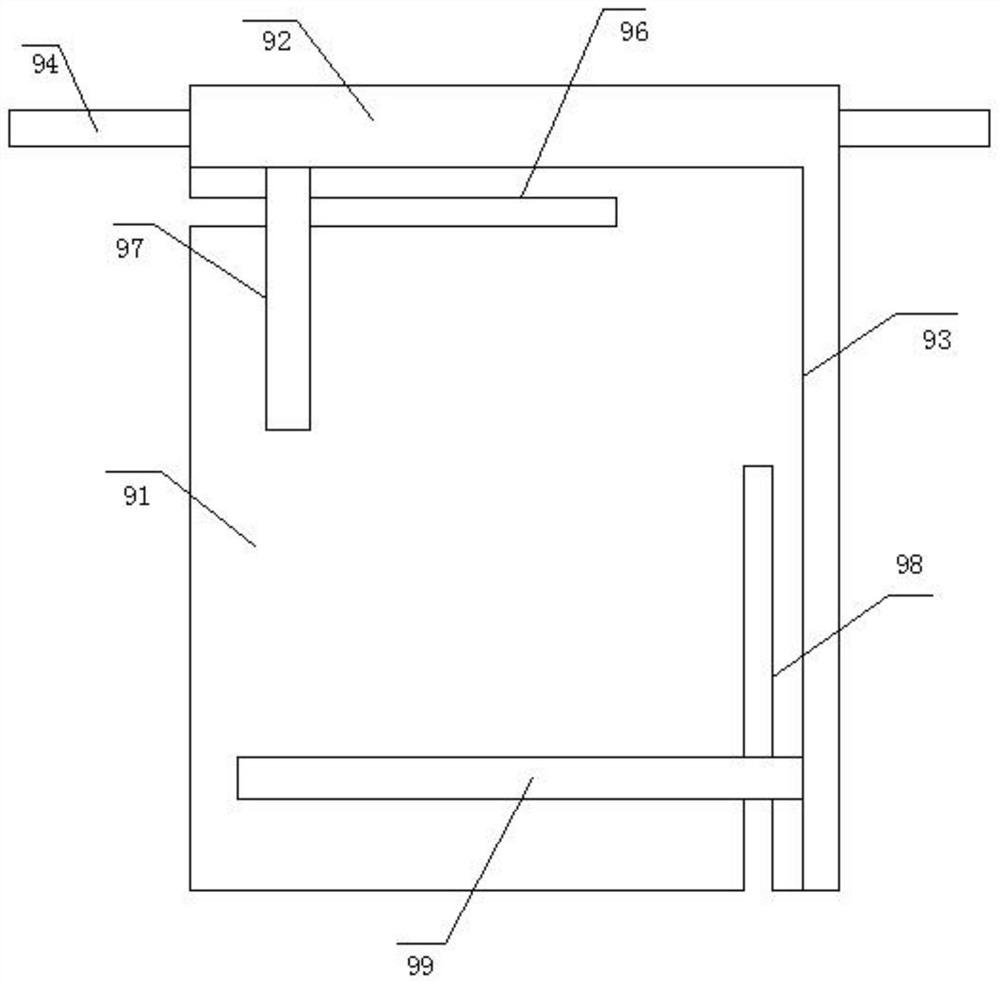

Production equipment for polyurethane raw material used for manufacturing soft volleyballs

InactiveCN113680297AAvoid eccentric rotationReduce noiseChemical/physical/physico-chemical processesProcess engineeringMaterials science

The invention relates to the technical field of polyurethane raw material production, and discloses production equipment for a polyurethane raw material used for manufacturing soft volleyballs. The equipment comprises a shell, wherein the bottom of the shell is movably connected with a support frame, the top of the shell is fixedly connected with a motor box, the top of the shell is fixedly connected with an air inlet, a gas pressure meter is fixedly connected to the top of the shell, and a connecting block is fixedly connected to the outer side of the motor box. When the production equipment for the polyurethane raw material used for manufacturing the soft volleyballs works, through an arranged triggering mechanism and an extruding mechanism arranged in a matched mode, the triggering mechanism senses eccentric motion of an output shaft in the using process of the equipment, an internal circuit is switched on, so the extruding mechanism evenly achieves Ampere force to limit the output shaft; and therefore, when a gap between a shaft sleeve and a bearing is too large due to excessive abrasion of the bearing, eccentric rotation of the output shaft is avoided, damage to a reaction kettle during work is prevented, noise generated during work of the reaction kettle is reduced, and the service life of the reaction kettle is prolonged.

Owner:南通金宝路体育用品有限公司

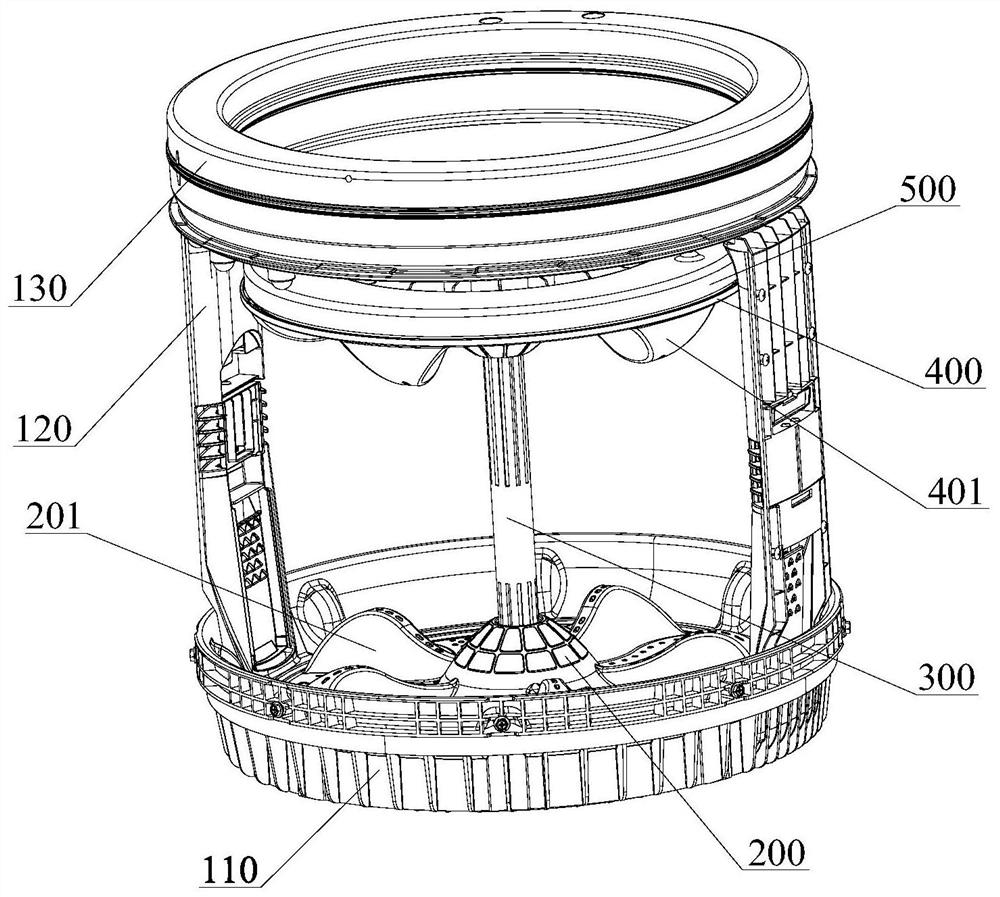

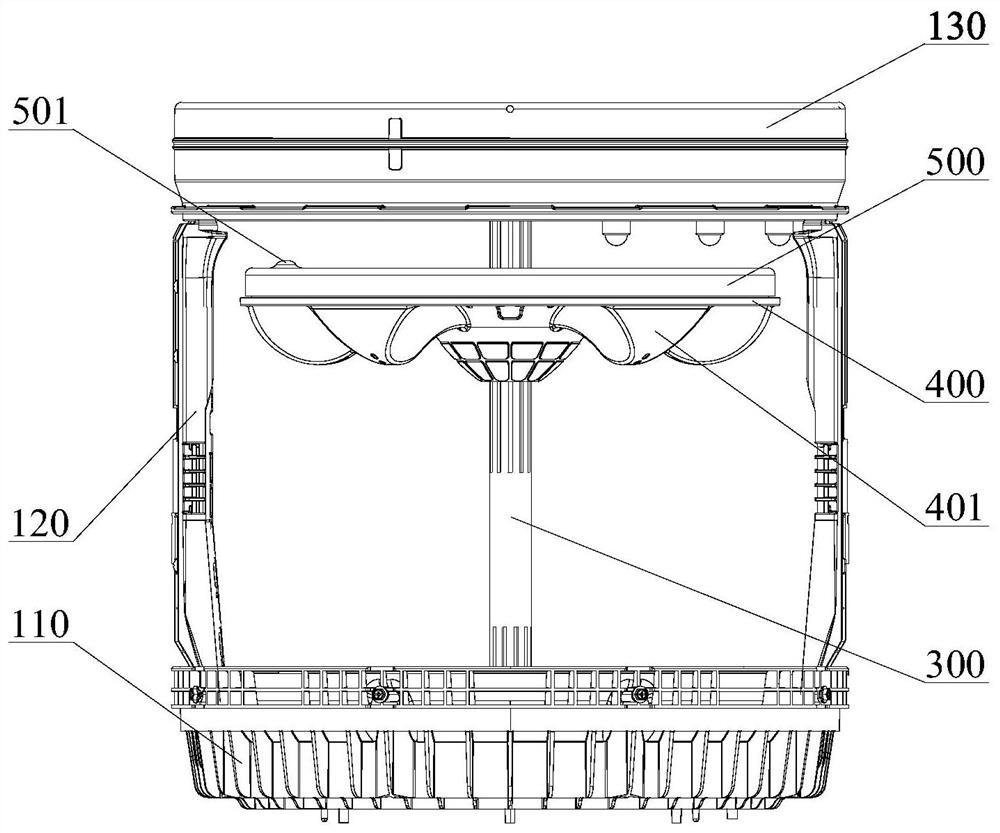

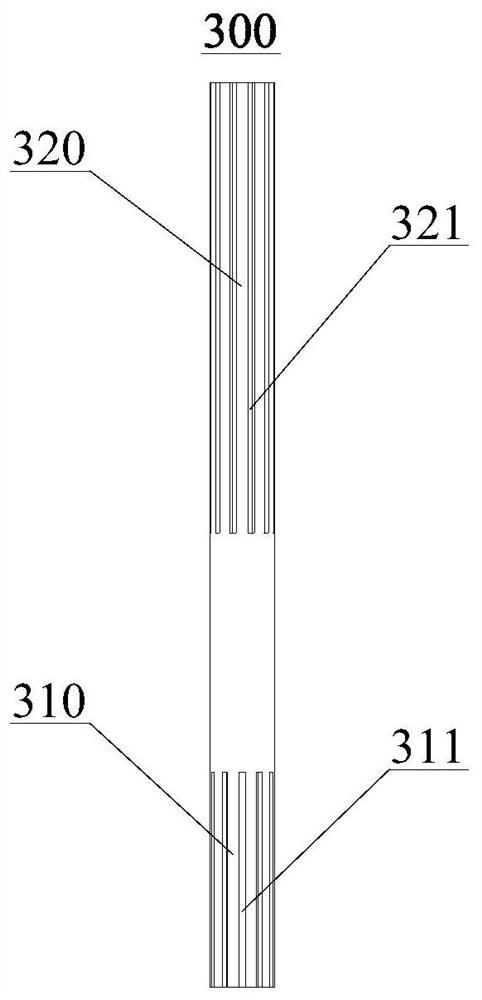

Impeller assembly and washing machine

PendingCN113818180AEnhanced washing powerImprove cleanlinessWashing machine with receptaclesTextiles and paperImpellerProcess engineering

The invention belongs to the technical field of washing machines, and discloses an impeller assembly and a washing machine. The impeller assembly comprises a first impeller, a second impeller arranged above the first impeller, and a connecting piece used for connecting the first impeller and the second impeller, wherein the second impeller is installed on the connecting piece in a relative movement mode, and the second impeller moves close to or away from the first impeller relative to the connecting piece. According to the impeller assembly, the first impeller and the second impeller are connected through the connecting piece, and the second impeller can move relative to the connecting piece; the impeller assembly is applied to the washing machine; the position of the second impeller can be adjusted in an inner barrel, and therefore the second impeller can be located at the height close to the water surface at different washing water levels; the first impeller and the second impeller simultaneously stir water flow from the bottom and the top in the clothes washing process, so that the cleaning effect is enhanced; and meanwhile, the second impeller can shield the water flow, so that the water splashing problem in the clothes washing process is prevented.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

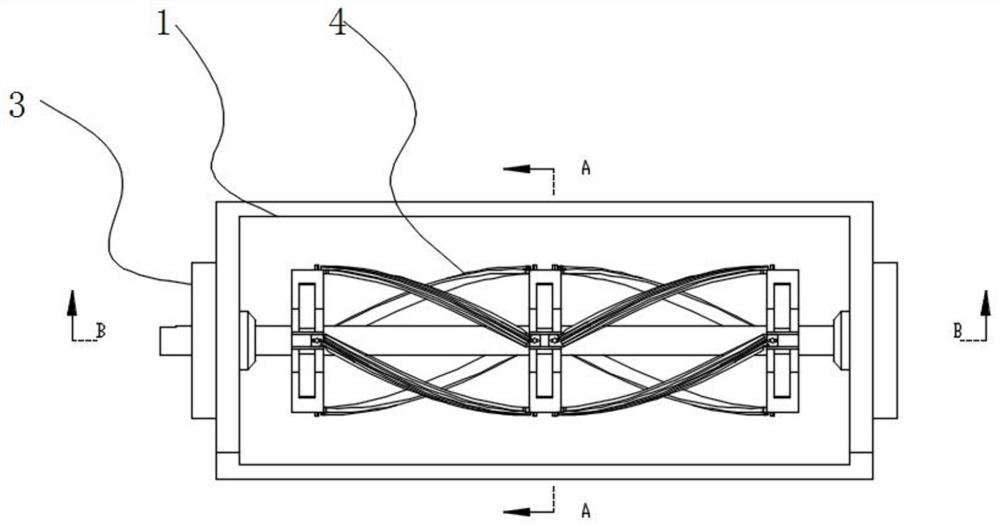

Loader hopper for concrete mixing

ActiveCN112497487ASmooth rotationAvoid eccentric rotationCement mixing apparatusGear wheelImpact resistance

The invention discloses a loader hopper for concrete mixing, and relates to the technical field of concrete loaders. The device comprises a hopper and a stirring shaft, wherein the hopper is rotationally connected with the stirring shaft; and the stirring shaft penetrates through the hopper. According to the loader hopper, through use of a center gear and planetary gears, the situation of eccentric rotation during high load rotation is avoided, and the service life of rotating shafts is prolonged; through use of mounting frames, stirring frames and switching blocks, a plurality of mounting frames can be adopted by the structure, and meanwhile, a plurality of spiral stirring frames are connected between the mounting frames, so that compared with a traditional stirring hopper, the loader hopper has the advantages that the number of the stirring frames is increased, meanwhile, the lengths of the stirring frames are reduced, and the impact resistance of the stirring frames during stirringis better; furthermore, if the stirring frames are impacted by external force, the switching blocks can be extruded, and then the switching blocks can slide for a certain distance in corresponding mounting grooves to release pressure, so that the stirring frames are protected; and through use of sliding parts and springs, the sliding parts can buffer the impact on the stirring frames and fasteningscrews, and the stirring frames are protected.

Owner:莱州市三能工贸有限公司

Multifunctional interactive robot

Owner:重庆门罗机器人科技有限公司

A Chip Breaking Structure of the Cutting Edge at the Variable Diameter Position of Step Drill

ActiveCN109128306BRealize all-round deformationReduce toughnessTransportation and packagingStepped drillsStructural engineeringTorsional deformation

The invention belongs to the technical field of drilling tools in machining and relates to a chip breaking structure of a reducing position cutting edge of a stepped drill. The chip breaking structureis composed of a step reducing position cutting edge, a chip breaking cutter face, a chip breaking edge, a stop face, an edge strip, a chip discharging groove and a step back section end face. According to the chip breaking structure, traditional continuous spiral edge cutting is changed into step edge joint cutting, arc front cutter faces are changed into straight cutter faces mutually forming an angle, and a chip breaking space is formed. The front cutter faces mutually forming the angle enable cutting chips to bend and undergo torsional deformation, the stress of the cutting chips is increased, the breaking strength of the cutting chips is easier to reach, and therefore metal chip breaking and chip smashing are effectively achieved. The scratches, caused by continuous cutting chips, ofa hole wall are restrained, and cutter rotation deviation caused by twining of the cutting chips is reduced. The chip breaking structure facilitates to greatly improve the hole forming quality of thestep drill, reduces the machining cost and has good engineering application prospect.

Owner:DALIAN UNIV OF TECH +1

Hub motor

InactiveCN102403863BImprove structural stabilityAvoid eccentric rotationMagnetic circuit rotating partsMagnetic circuit stationary partsAxial displacementEngineering

The invention relates to a hub motor comprising a stator unit, a rotor unit, a magnetic ring and a sensing circuit unit. The rotor unit is provided with a shaft part which can be relatively and rotatably penetrates through the stator unit; the magnetic ring and the sensing circuit unit are arranged on the rotor unit and the stator unit respectively and are correspondingly positioned at intervals between the rotor unit and the stator unit; and the magnetic ring is provided with a first ring piece extending radially and a second ring piece which is connected with the first ring piece and extends axially. With the structural design of the magnetic ring, the problems of eccentric rotation and axial displacement generated in the process that the magnetic ring rotates with the rotor unit can be avoided; and as the magnetic ring and the sensing circuit unit are arranged between the rotor unit and the stator unit and are wrapped and fixed by both the rotor unit and the stator unit, on the one hand, the structure stability that the magnetic ring is combined with the rotor unit is increased so as to resist the centrifugal force generated by high speed rotation, and on the other hand, the magnetic ring can be prevented from being polluted and interfered by the outside, and the cost for additional arrangement of an outer cover is saved.

Owner:TAIWAN ELECTRIC PROPULSION SYST CORP

A loader hopper for concrete mixing

ActiveCN112497487BSmooth rotationAvoid eccentric rotationCement mixing apparatusGear wheelIndustrial engineering

The invention discloses a loader hopper used for concrete mixing and relates to the technical field of concrete loaders. The invention includes a hopper and a stirring shaft, the hopper is connected to the stirring shaft in rotation, and the stirring shaft passes through the hopper; the invention avoids eccentric rotation when rotating under high load by using a central gear and a planetary gear, and improves the service life of the rotating shaft The present invention is by using mounting frame, stirring frame and adapter block, and this structure adopts multiple mounting frames, connects some spiral type stirring frames between mounting frames simultaneously, increases the quantity of stirring frame compared with traditional mixing hopper, simultaneously The length of the stirring frame is shortened, so that the stirring frame has better impact resistance during stirring, and if the stirring frame is impacted by an external force, the adapter block can be squeezed, and then the adapter block can slide in the installation groove for a certain distance to relieve pressure and protect Stirrer; by using a slide and a spring, the slide can cushion the impact of the stirrer and fastening screws to protect the stirrer.

Owner:莱州市三能工贸有限公司

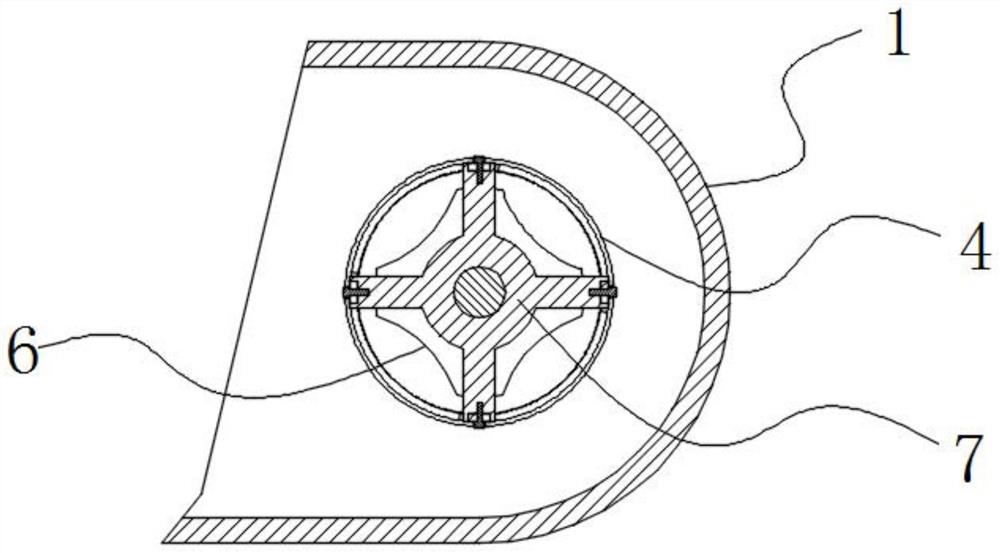

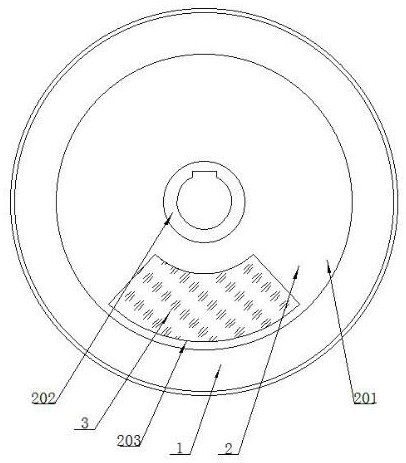

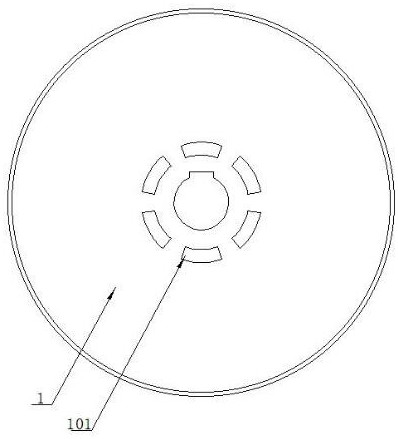

Fluorescent wheel reliable in work

InactiveCN112305749AAdjust the center of gravityAvoid eccentric rotationProjectorsOptical elementsCircular discPhosphor

The invention relates to a fluorescent wheel reliable in work. The device comprises a circular base plate and a phosphor attached to one side of the circular base plate, the other side of the circularbase plate is connected with a balance shaft sleeve used for adjusting the gravity center of the circular base plate, and the balance shaft sleeve comprises a disc part connected with the circular base plate and a connecting sleeve coinciding with the center of the circular base plate. The connecting sleeve is used for being connected with an output shaft of an external driving motor. Due to theexistence of the balance shaft sleeve, transmission connection between the circular base plate and the external motor can be guaranteed, the gravity center of the circular base plate can be effectively adjusted, and eccentric rotation of the circular base plate is avoided.

Owner:高邮市电塑厂

Three-jaw turning tool for machining cuboid workpiece

ActiveCN112318176ARealize clamping operationImplement horizontal positioning operationsWork clamping meansPositioning apparatusPhysicsEngineering

The invention belongs to the technical field of turning tools, and particularly relates to a three-jaw turning tool for machining a cuboid workpiece. The tool comprises a main body of a cylindrical structure. A mounting groove of a rectangular structure is formed in one end of the main body, and a storage groove coaxial with the main body is formed in the end, stretching into the main body, of themounting groove. A positioning rod coaxial with the main body is fixedly connected to the inner side wall on the side, away from the mounting groove, of the storage groove, the outer ring of the end,away from the storage groove, of the positioning rod is fixedly sleeved with a fixing disc, transverse guide mechanisms symmetrically arranged along the positioning rod are hinged to the two sides ofthe outer ring of the fixing disc, and two vertical guide mechanisms which are symmetrically arranged along the positioning rod are mounted on the sides, close to each other, of two transverse guidemechanisms. With the three-jaw turning tool for machining the cuboid workpiece, eccentric rotation of a workpiece is effectively avoided, the amplitude of vibration of the workpiece due to eccentricity is reduced, the stability of the workpiece after being clamped for machining is improved, the workpiece clamping error is small, and meanwhile tool is suitable for positioning and clamping operationon workpieces of different sizes.

Owner:安徽士必达液压器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com