Patents

Literature

32results about How to "Realize clamping operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

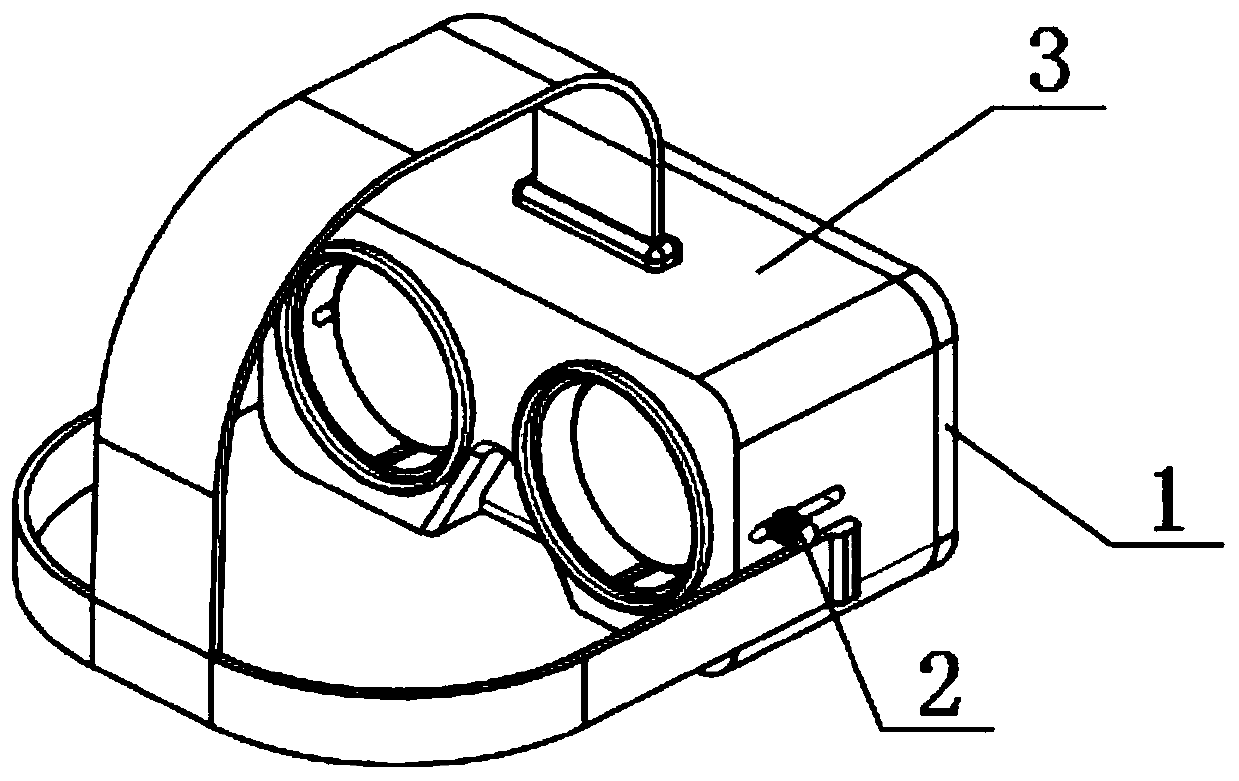

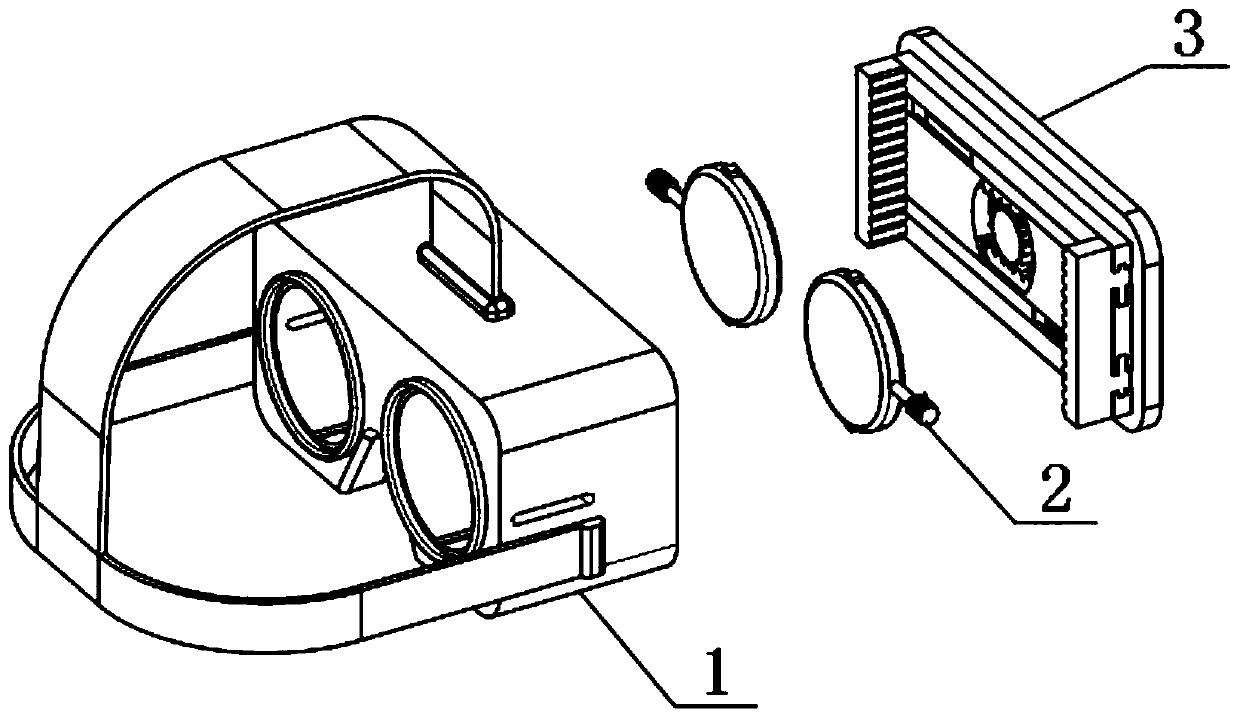

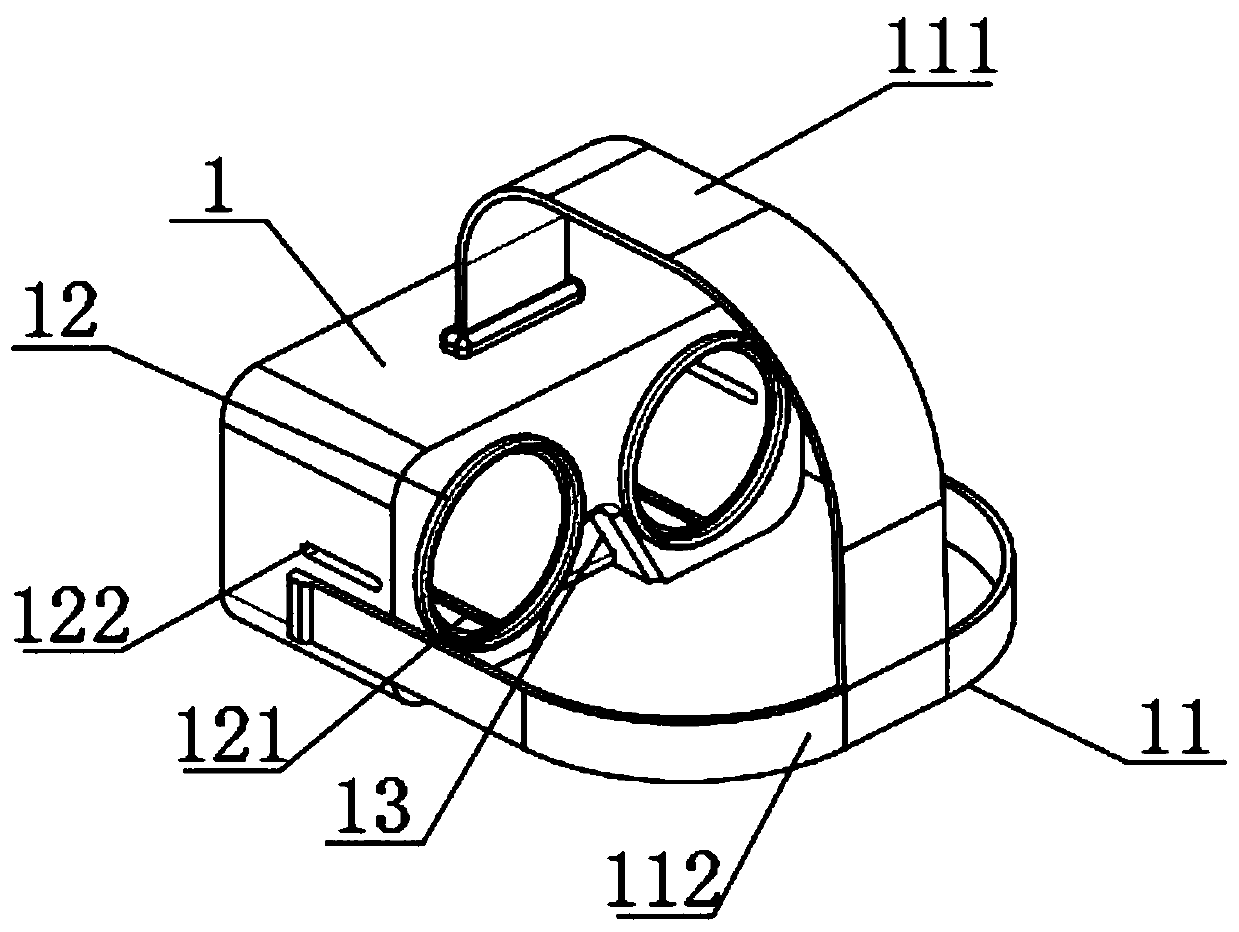

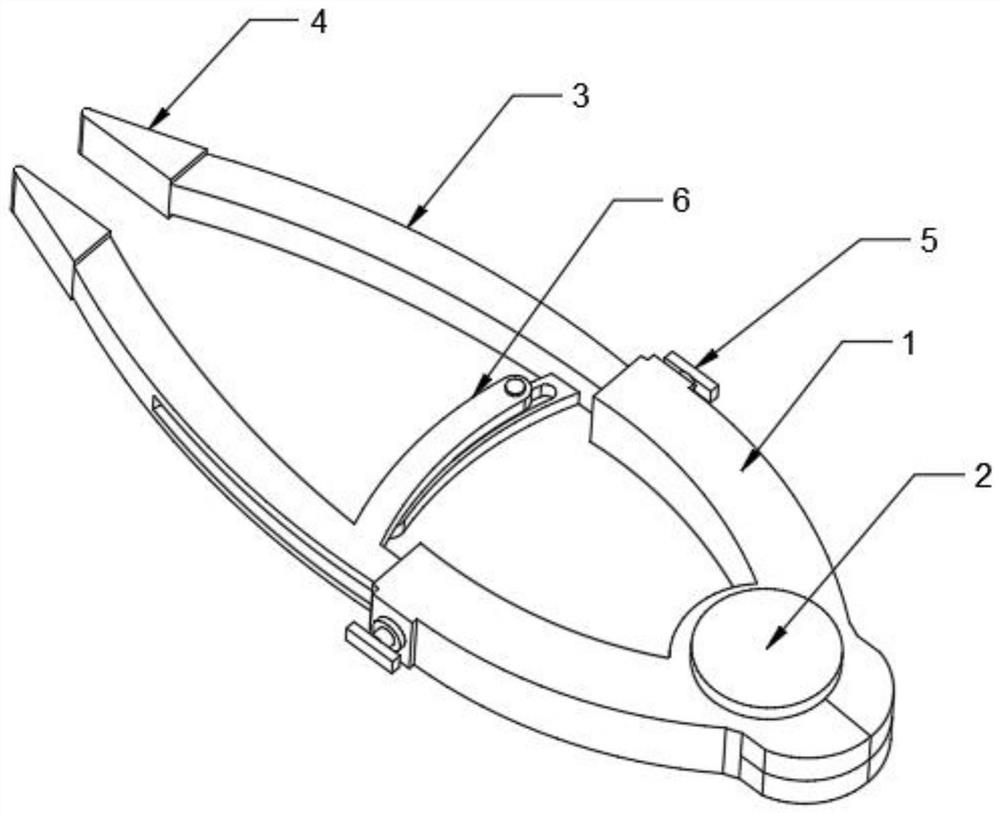

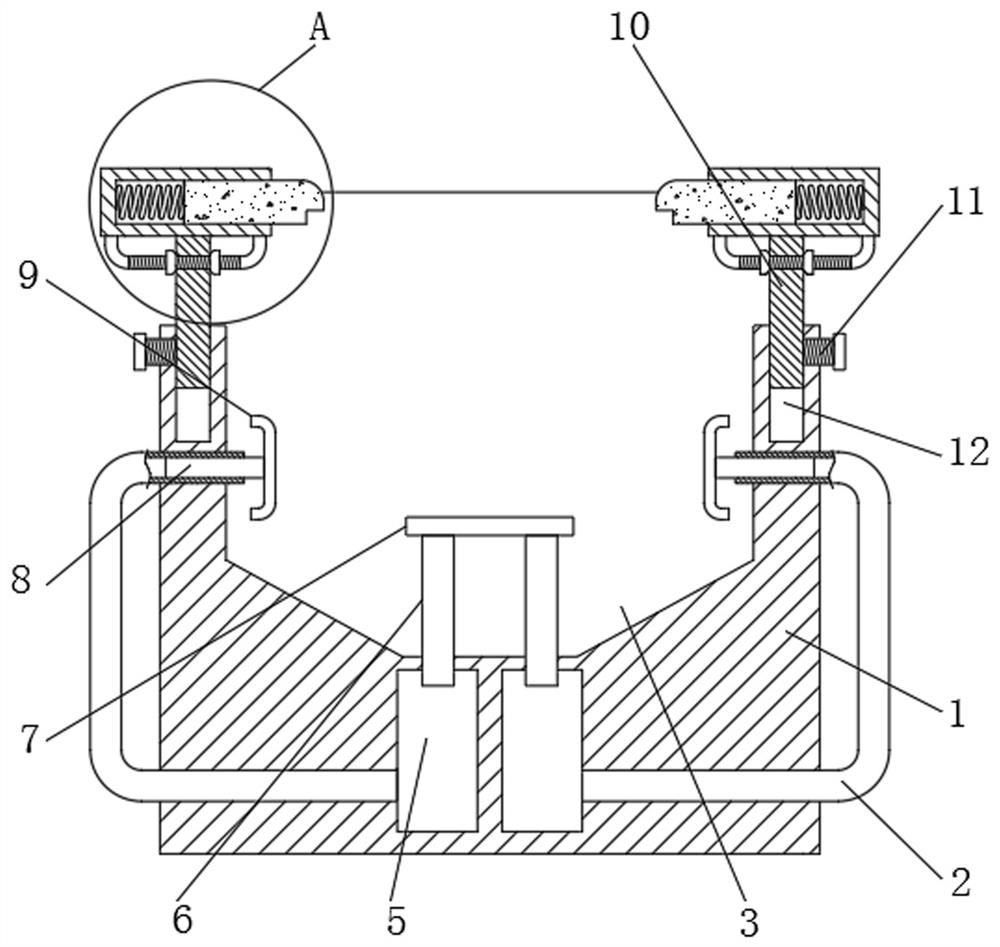

VR glasses convenient to carry and use

InactiveCN111258066AEasy to installEasy focus adjustmentTelephone set constructionsOptical elementsEyewearEngineering

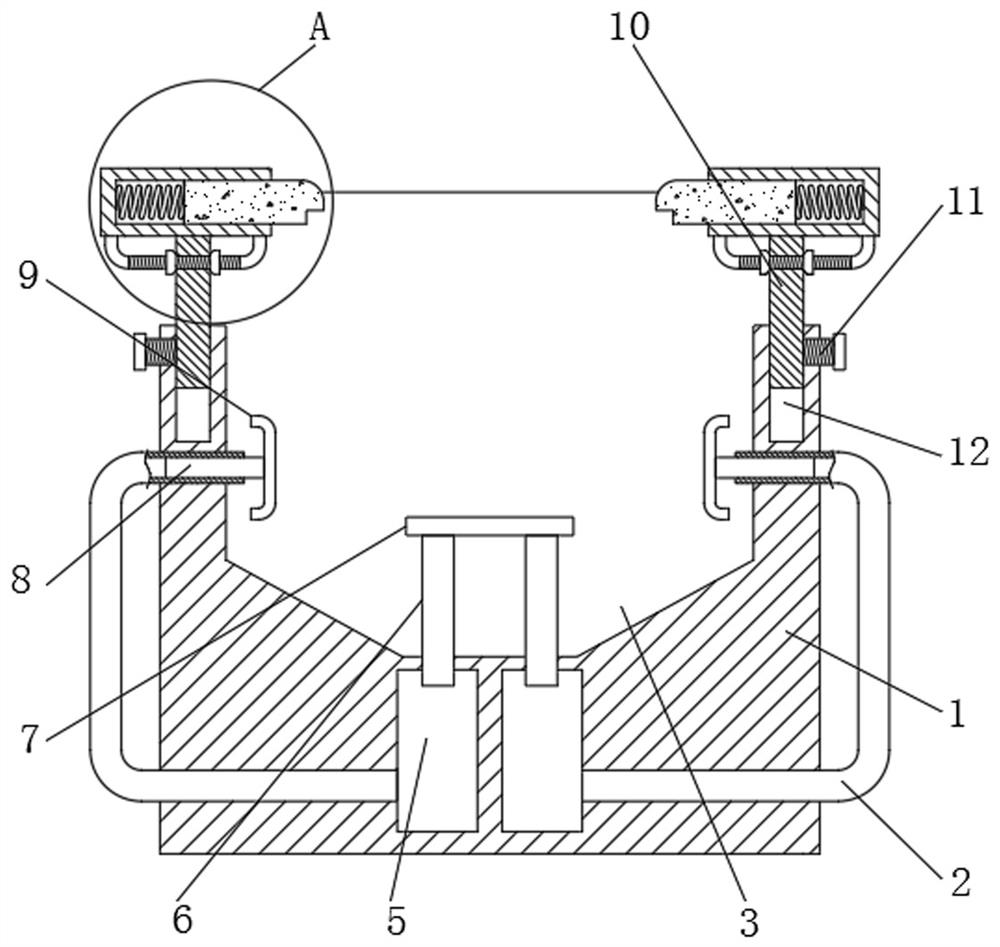

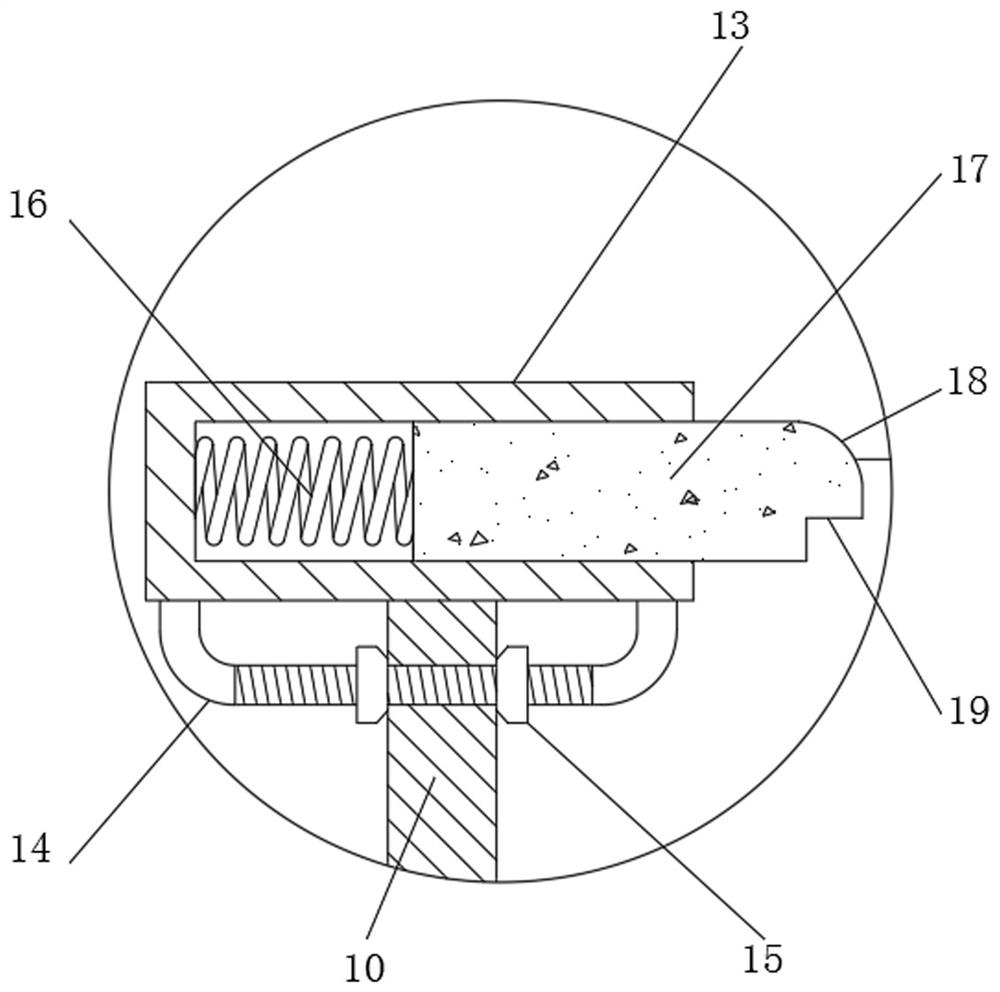

The invention discloses VR glasses convenient to carry and use. The VR glasses comprise a mounting base, wherein lens mounting through holes are symmetrically formed at a side surface of the mountingbase in a penetrating mode, a clamping limiting groove is formed at the other side surface of the lens mounting through hole, a focal length adjusting assembly is arranged on an inner side of the lensmounting through hole, the focal length adjusting assembly is movably connected with the mounting base, a mobile phone clamping mechanism is arranged on an inner side of a clamping limiting groove, the mobile phone clamping mechanism is fixedly connected with the mounting base in an inserted mode, the mobile phone clamping mechanism comprises a base, clamping pieces and adjusting pieces, the clamping pieces are symmetrically arranged at two ends of the base, the clamping pieces are movably connected with the base in an inserted mode, and the adjusting pieces are arranged on the side surface of the base. The VR glasses are advantaged in that the VR glasses has characteristics of reasonable structure and convenience in use, a mobile phone can be quickly and stably clamped through the arranged mobile phone clamping mechanism, and the VR glasses are more convenient to carry due to the fact that special projection equipment does not need to be arranged.

Owner:温州明澈眼镜科技有限公司

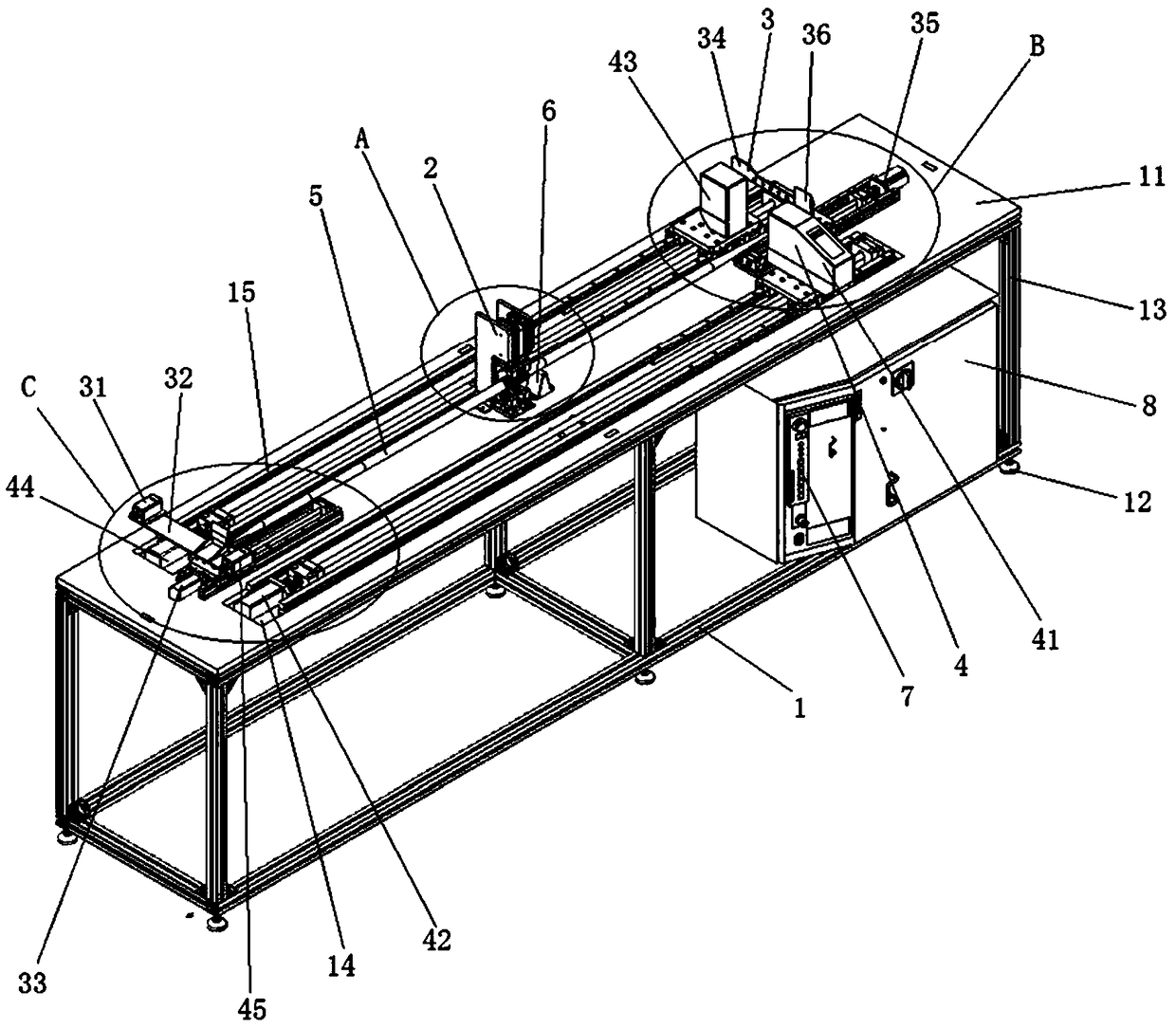

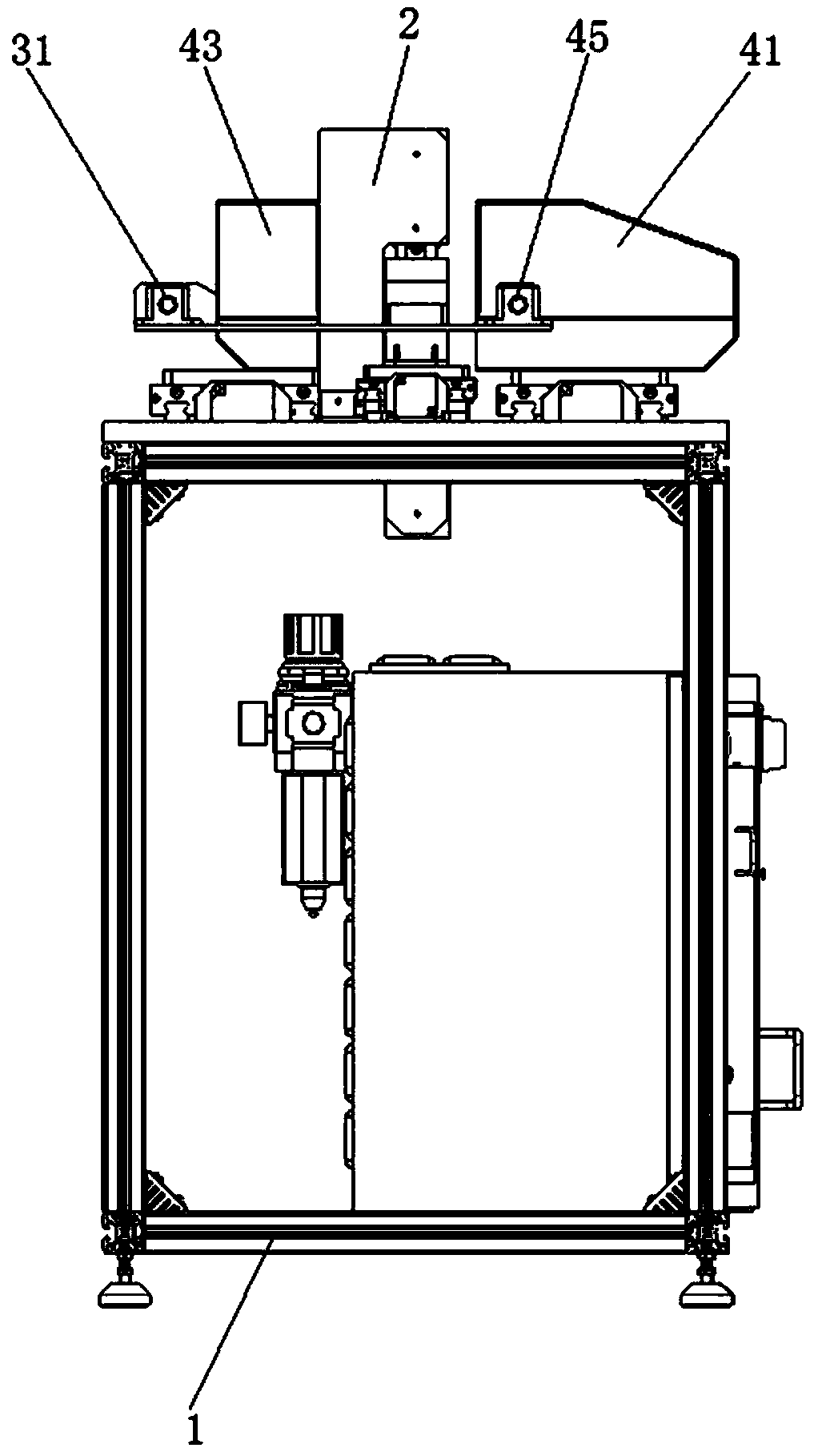

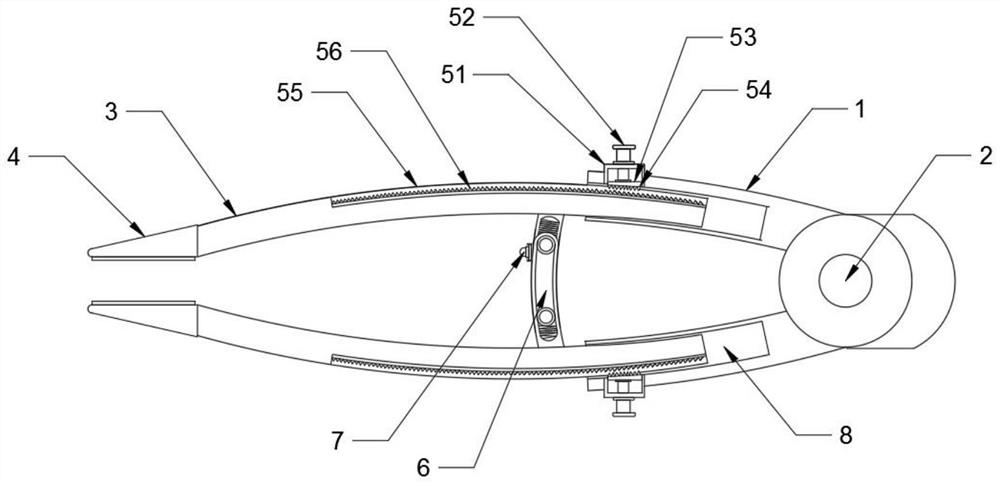

Javelin detection device

PendingCN109405750AAccurate measurementEasy to measureUsing optical meansMechanical engineeringEngineering

The invention discloses a javelin detection device, and the device comprises a frame body. A pneumatic clamping device, javelin distance measuring devices which are disposed at two sides of the pneumatic clamping device and are used for measuring the length of a javelin and javelin diameter measuring devices which are disposed at two sides of the javelin and are used for measuring the diameter ofthe javelin are disposed above the frame body. A controller for controlling the overall operation of the control device is disposed below the frame body. A controlled end of the pneumatic clamping device, controlled ends of the javelin distance measuring devices and controlled ends of the javelin diameter measuring devices are connected to the output end of the controller. According to the invention, the frame body is provided with the pneumatic clamping device for achieving the clamping of the javelin, and then javelin distance measuring devices which are disposed at two sides of the pneumatic clamping device are used for measuring the length of the javelin, and finally the javelin diameter measuring devices which are disposed at two sides of the javelin are used for measuring the diameter of the javelin, thereby achieving the precise, simple, convenient and efficient measuring of the length and diameter of the javelin and enabling the javelin to be quickly matched with an athlete.

Owner:HEBEI SILVER ARROW SPORTING GOODS CO LTD

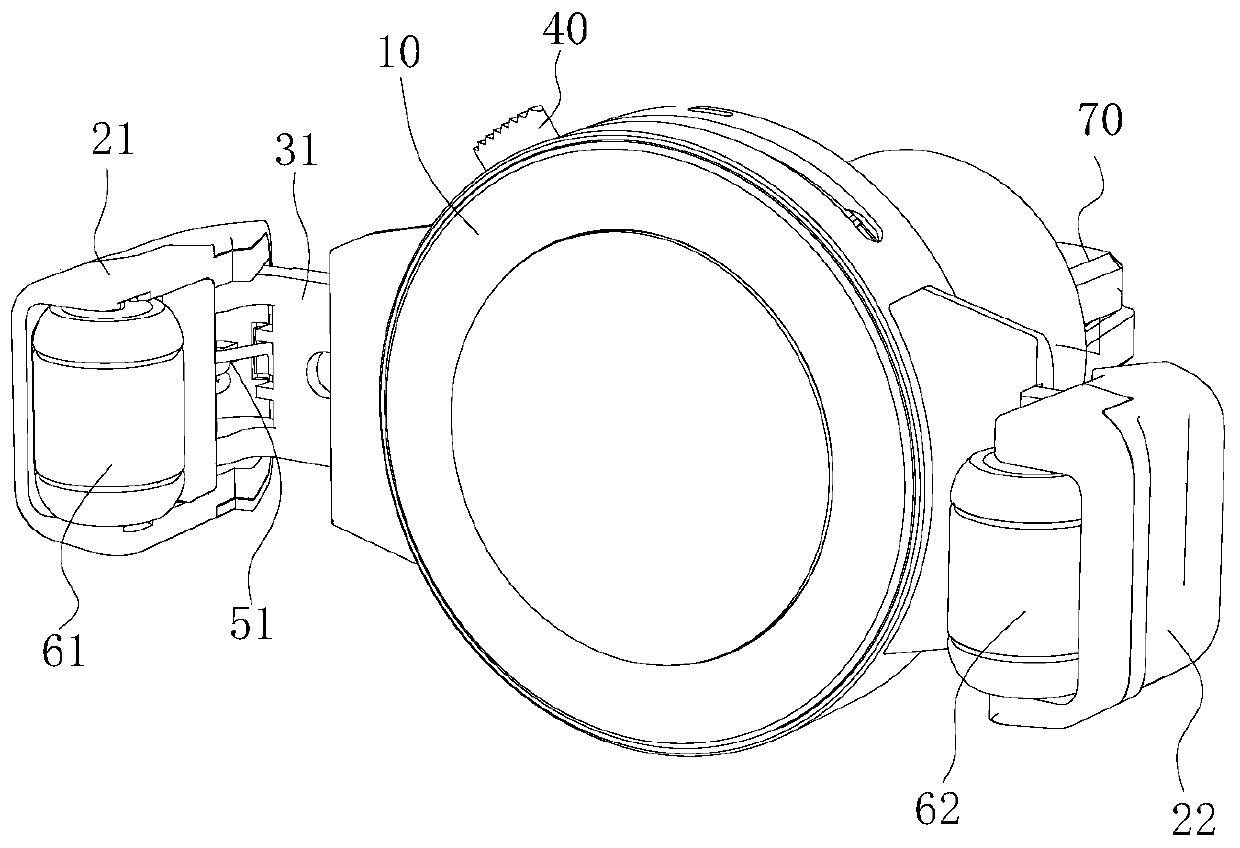

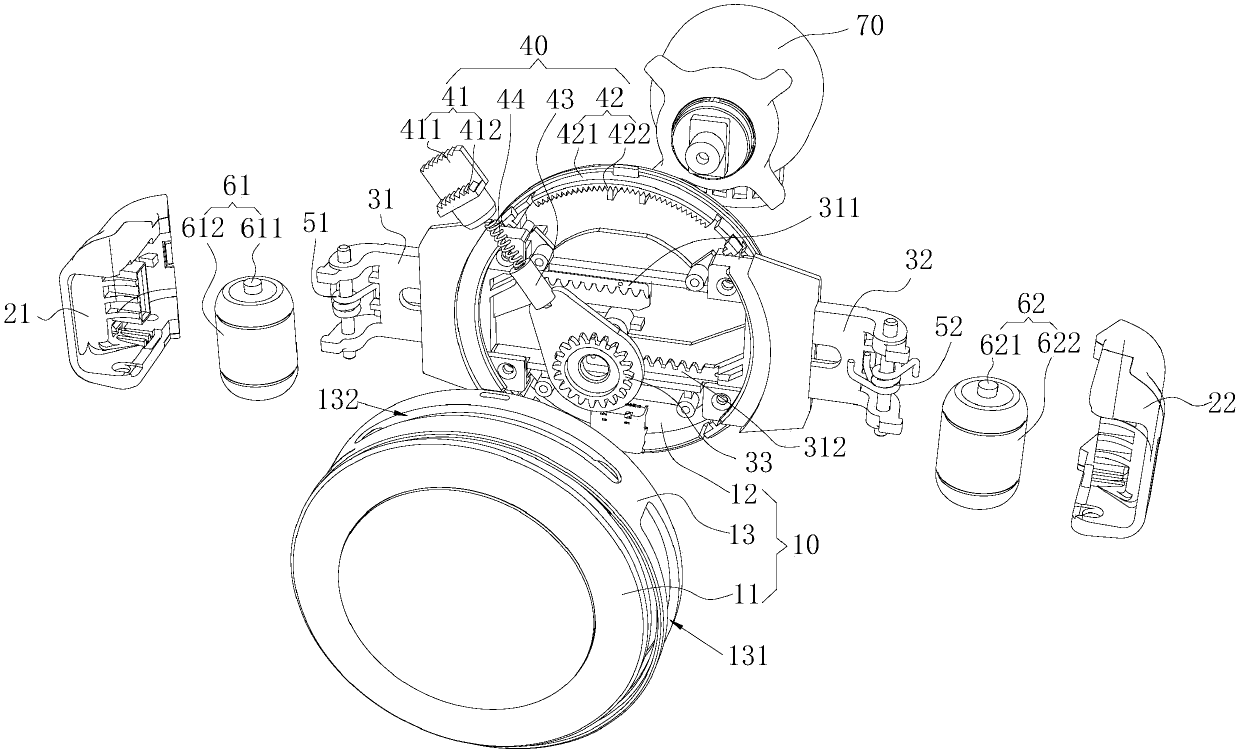

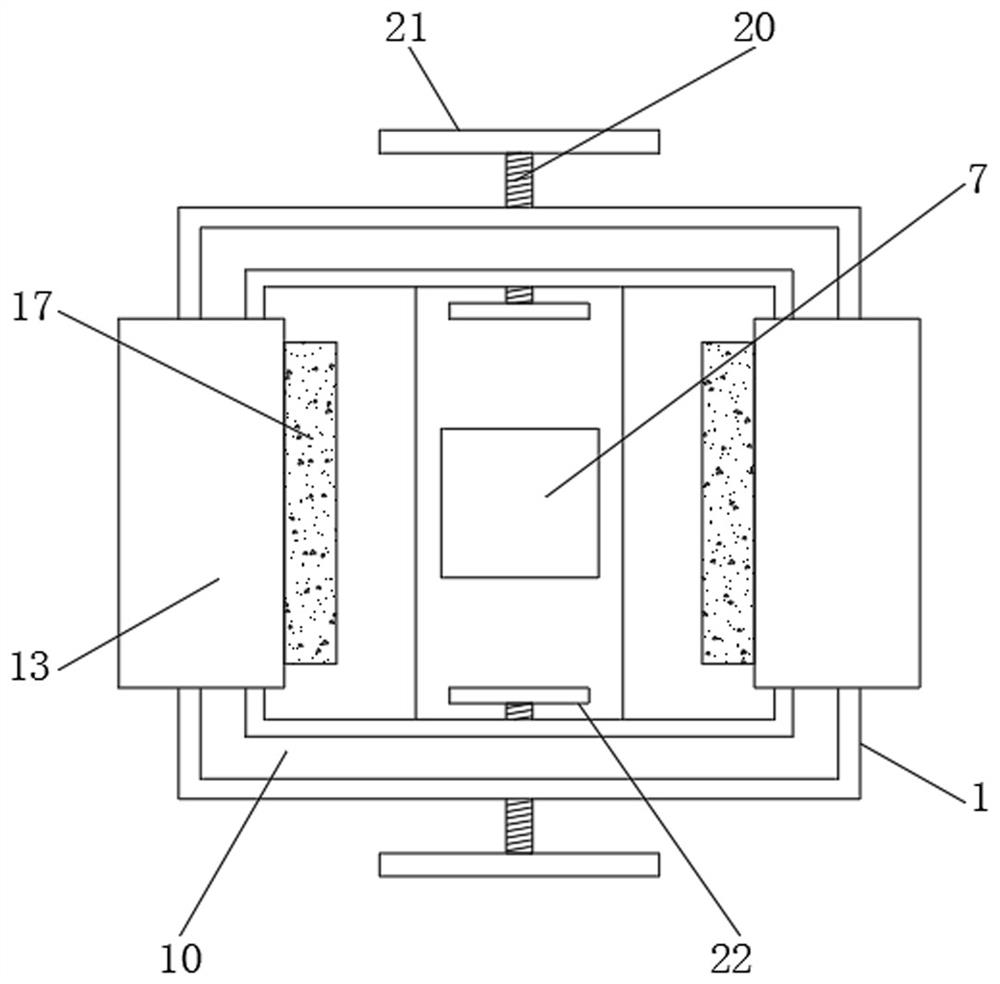

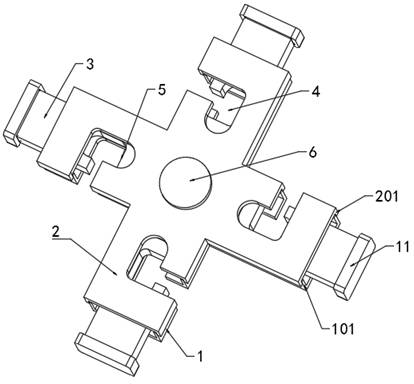

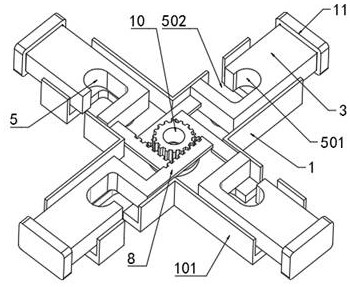

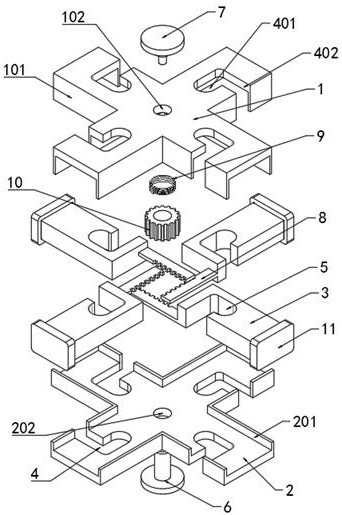

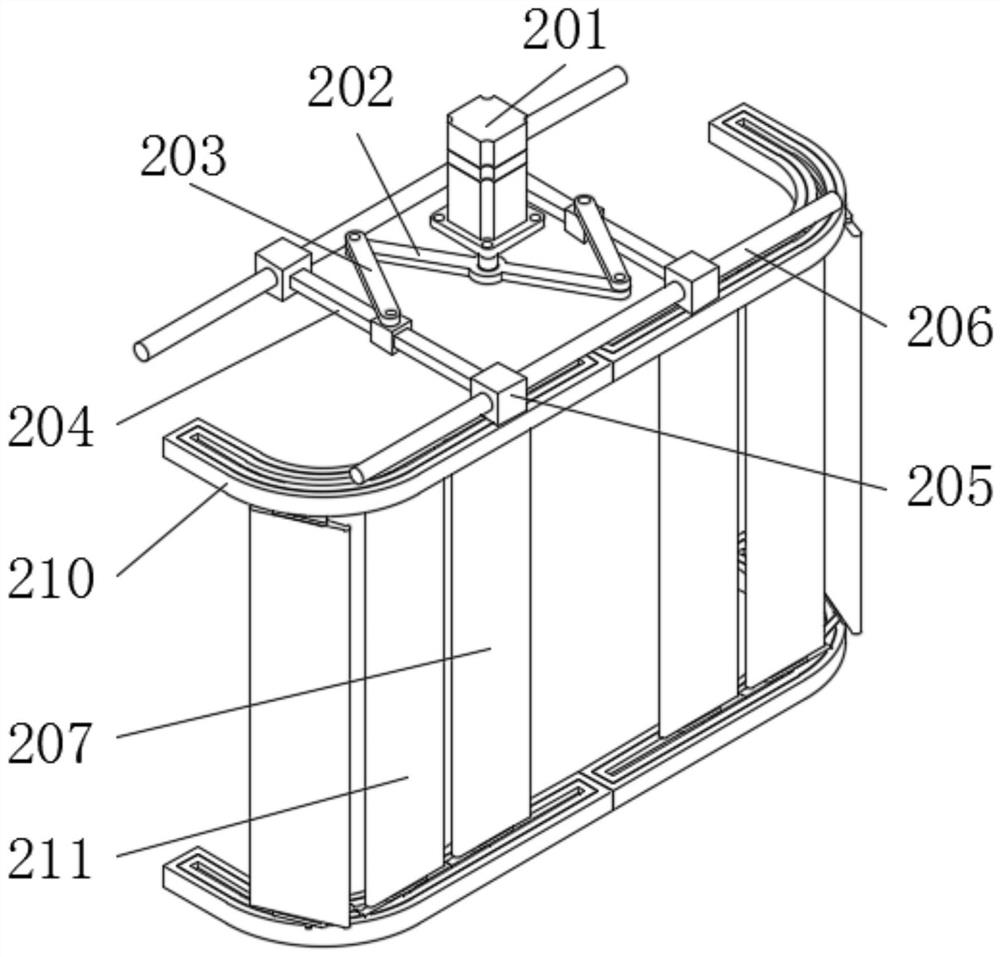

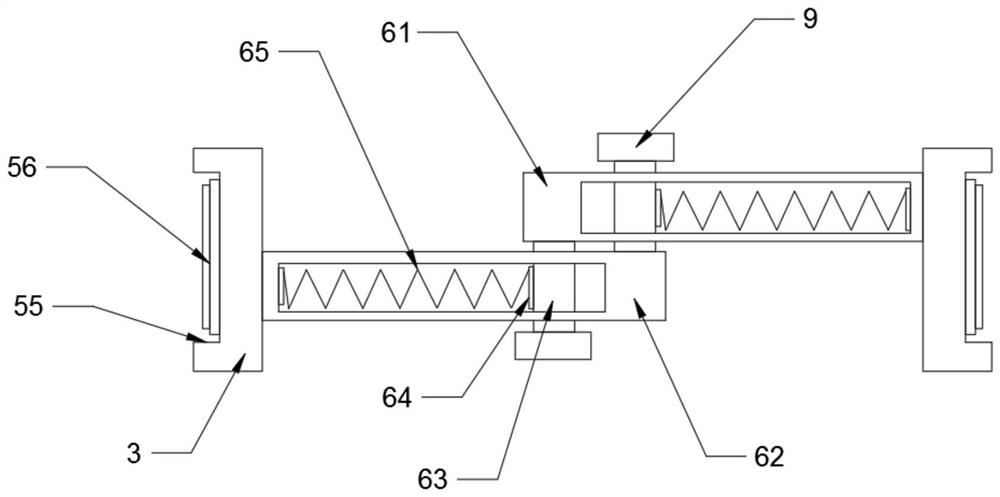

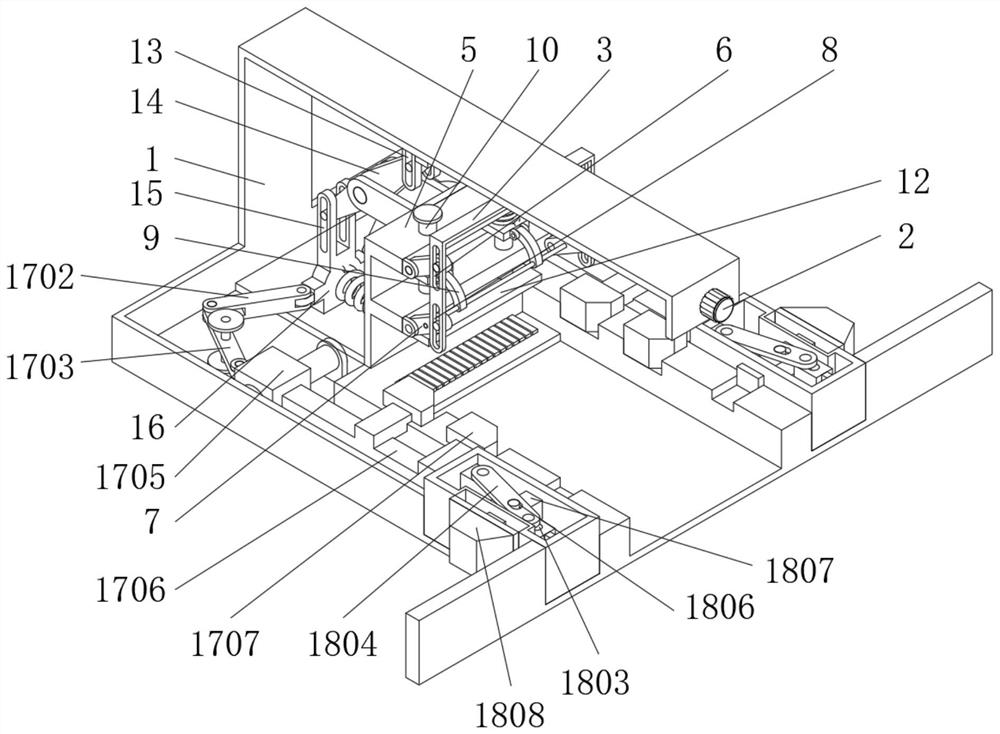

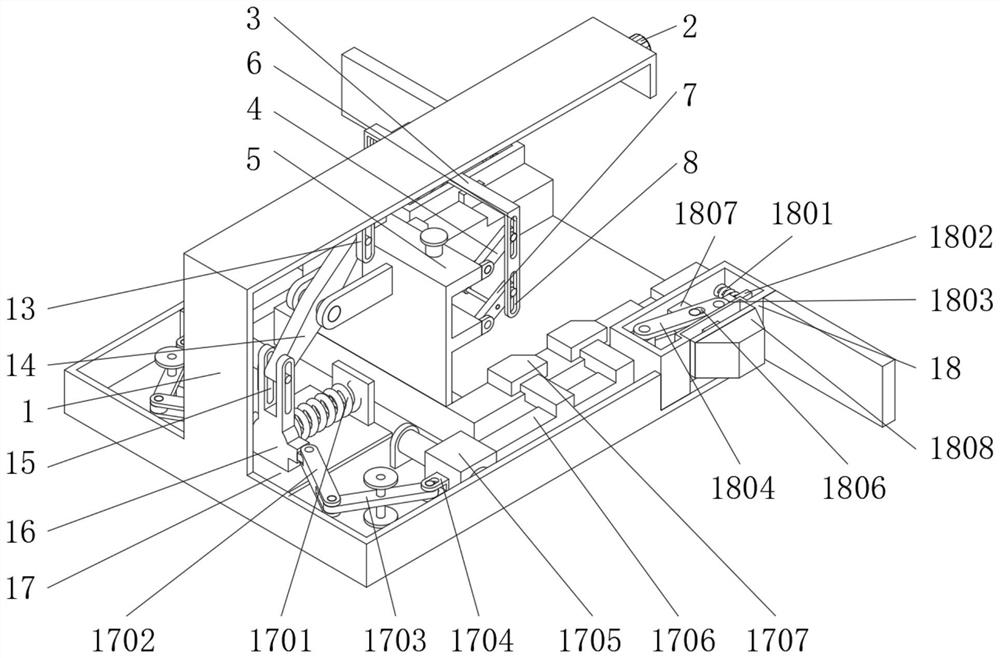

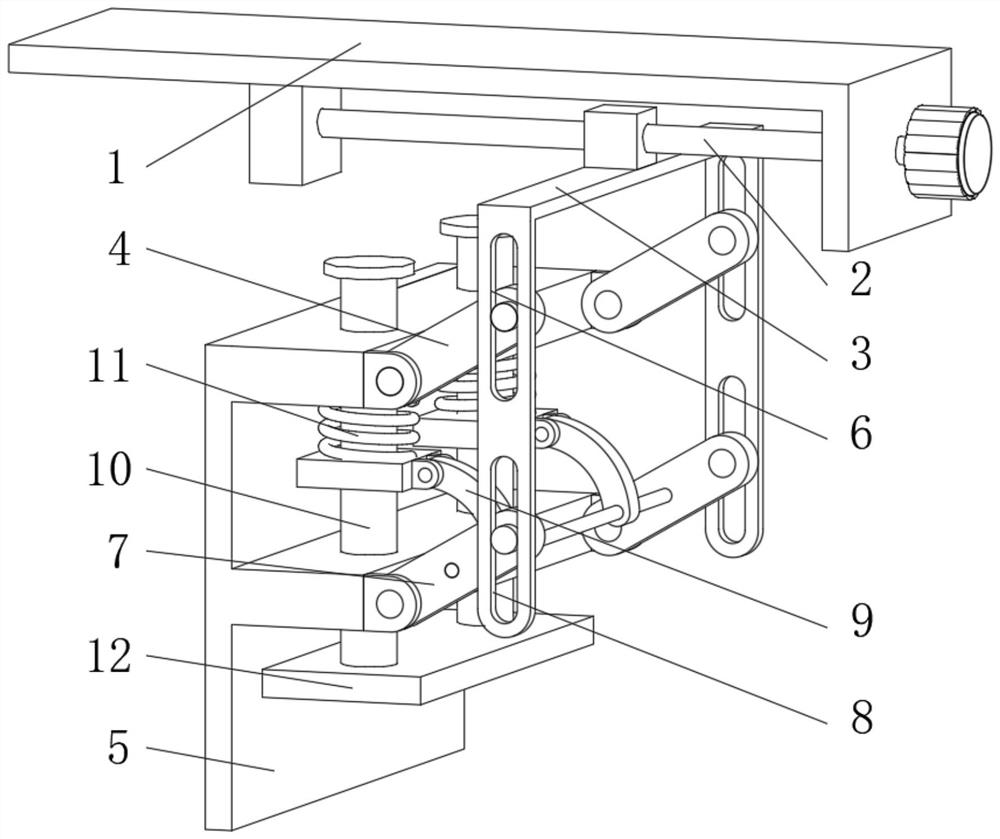

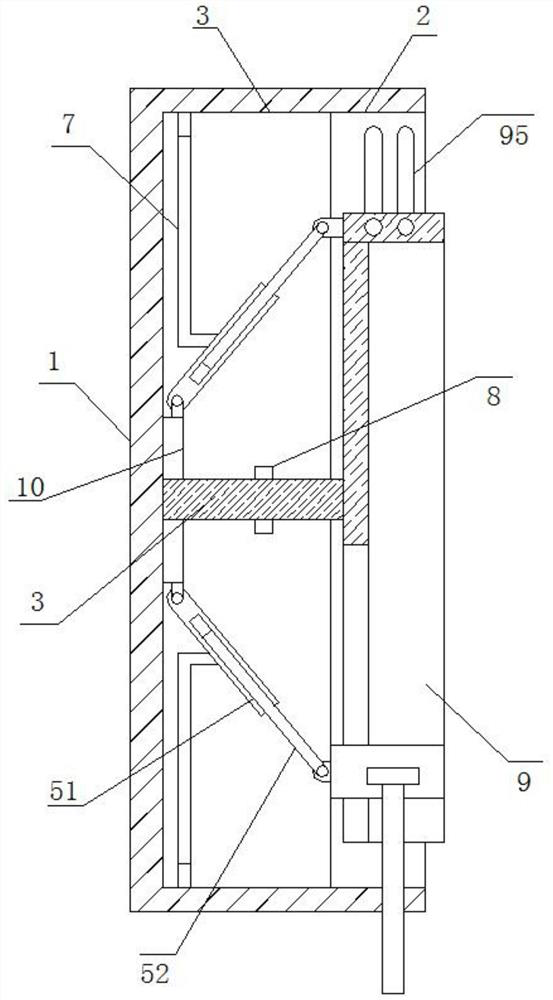

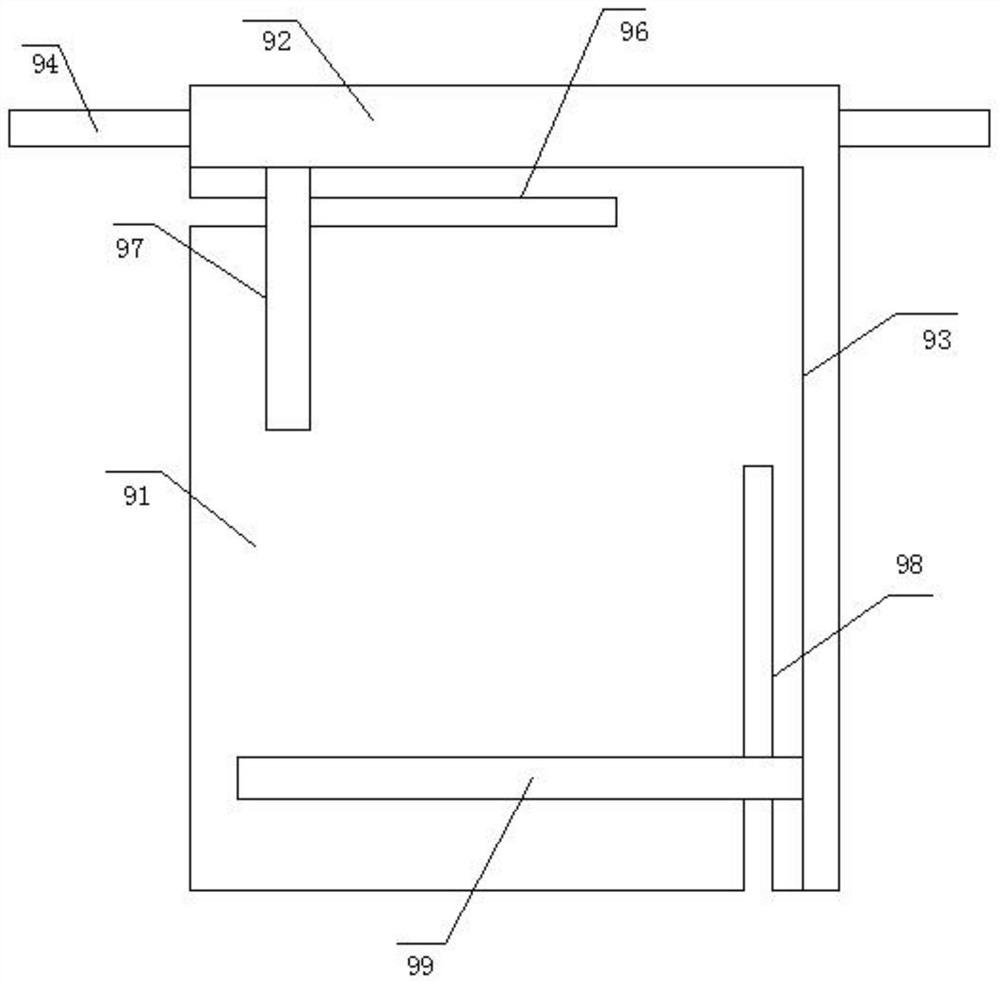

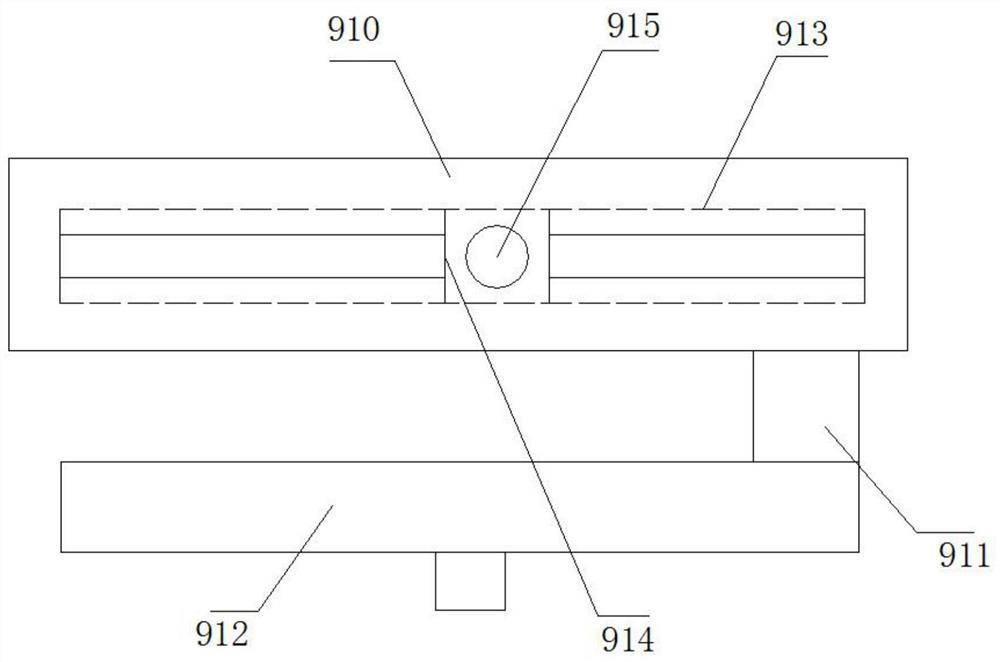

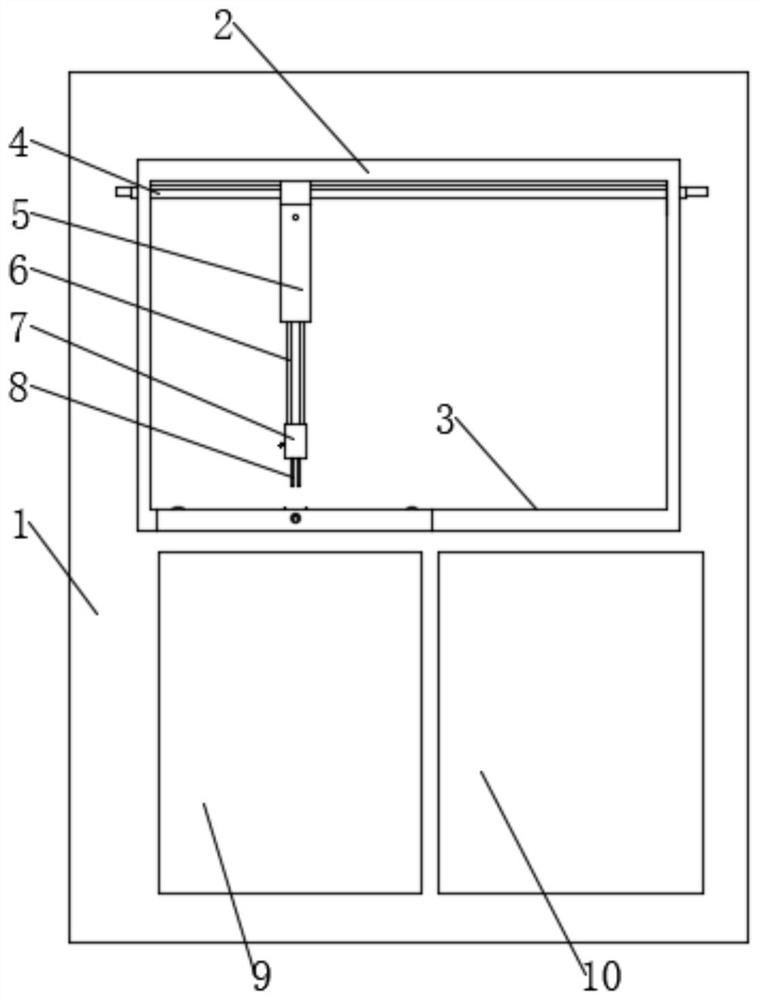

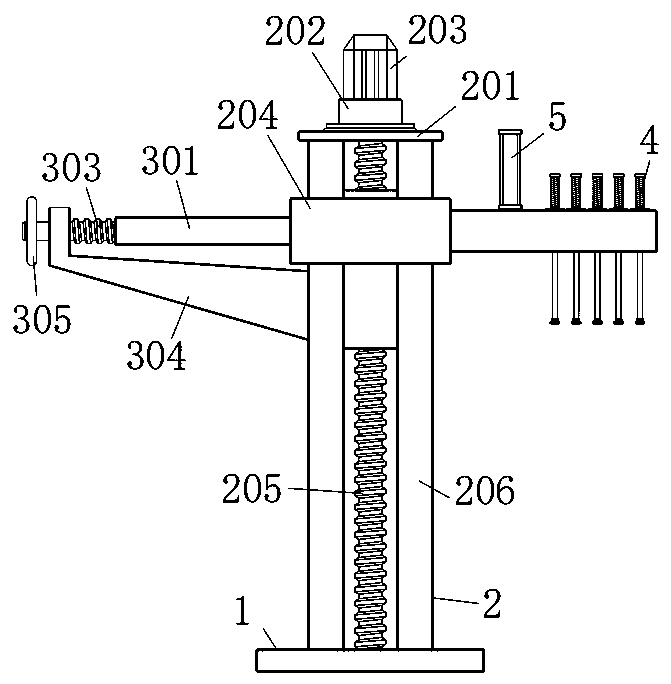

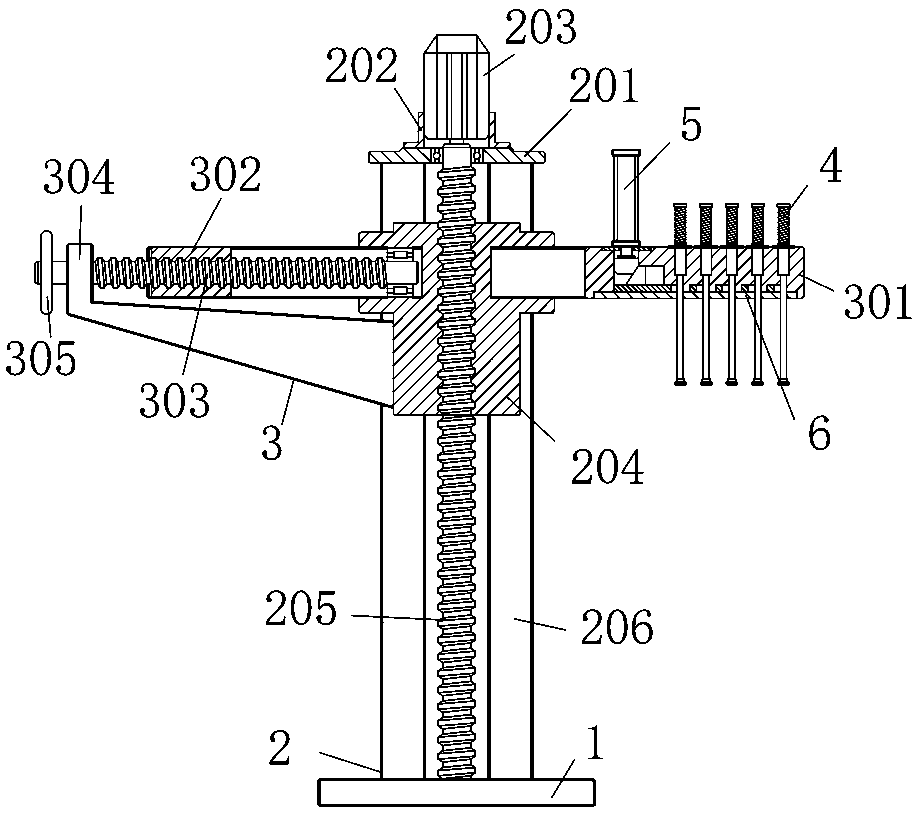

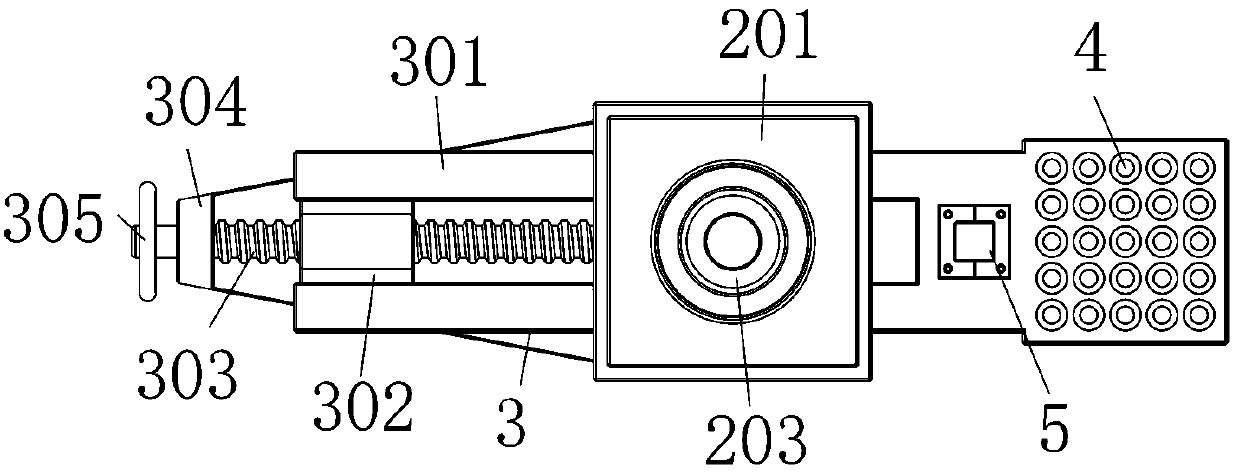

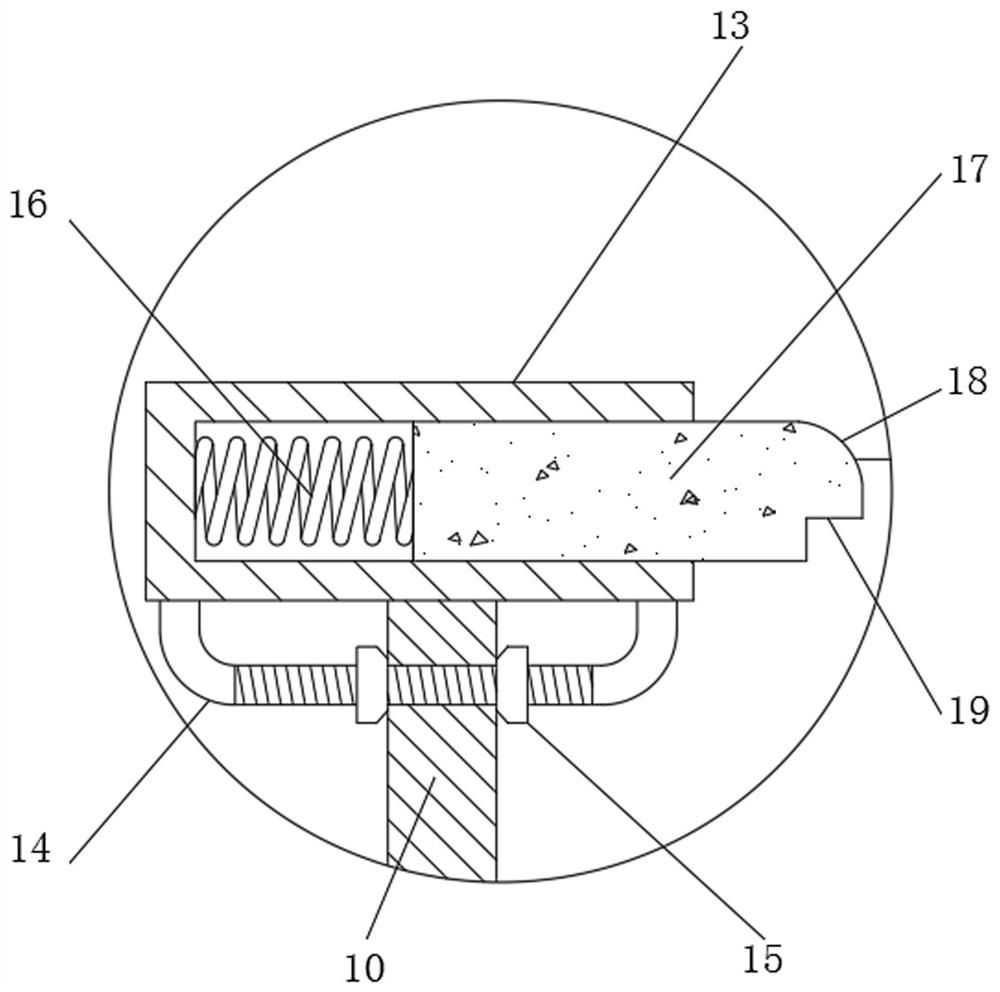

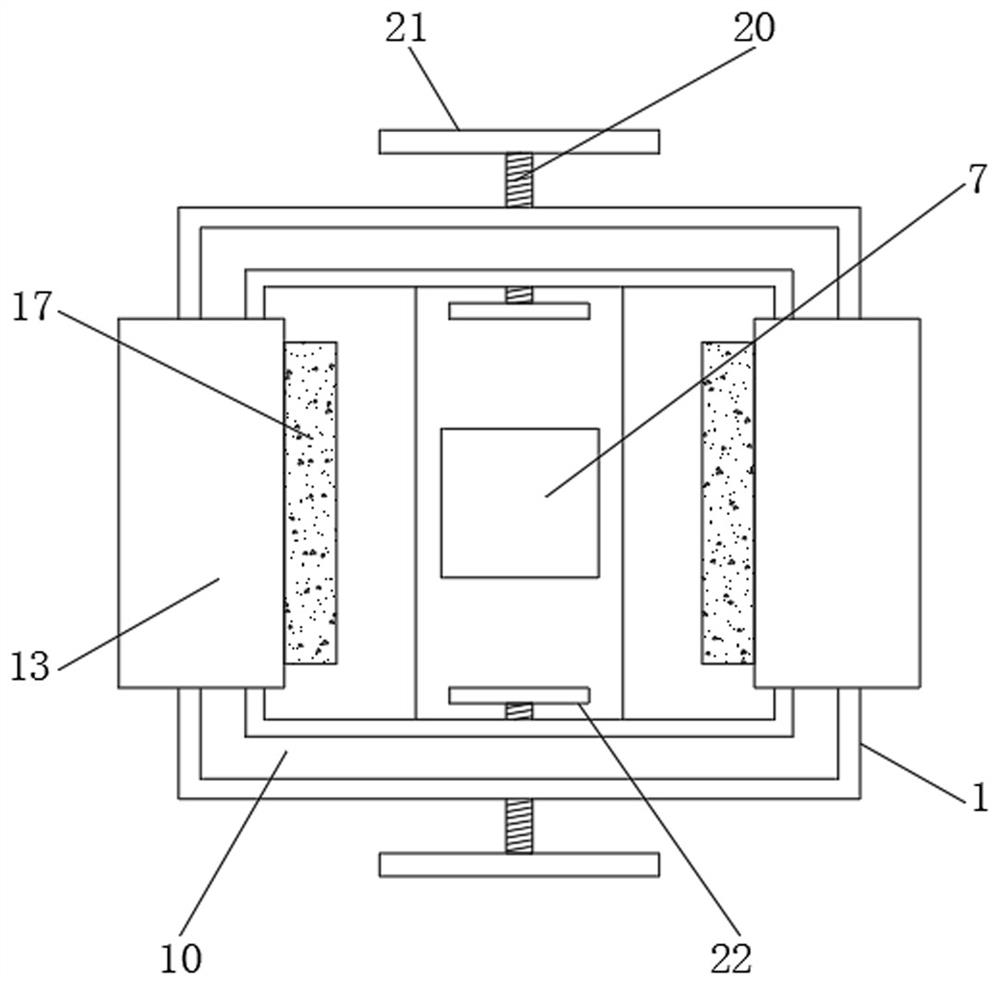

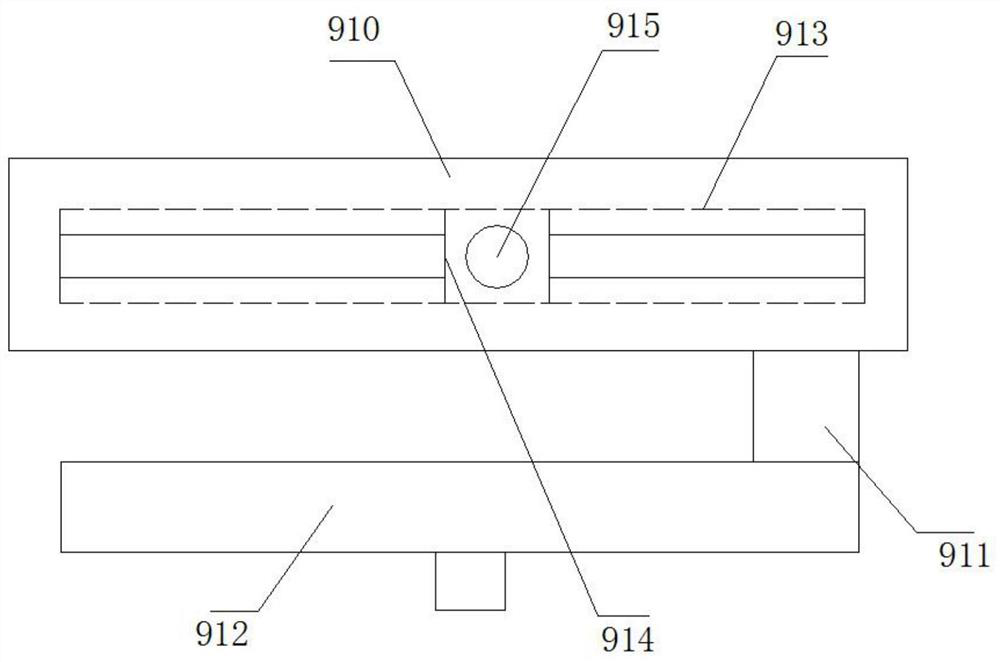

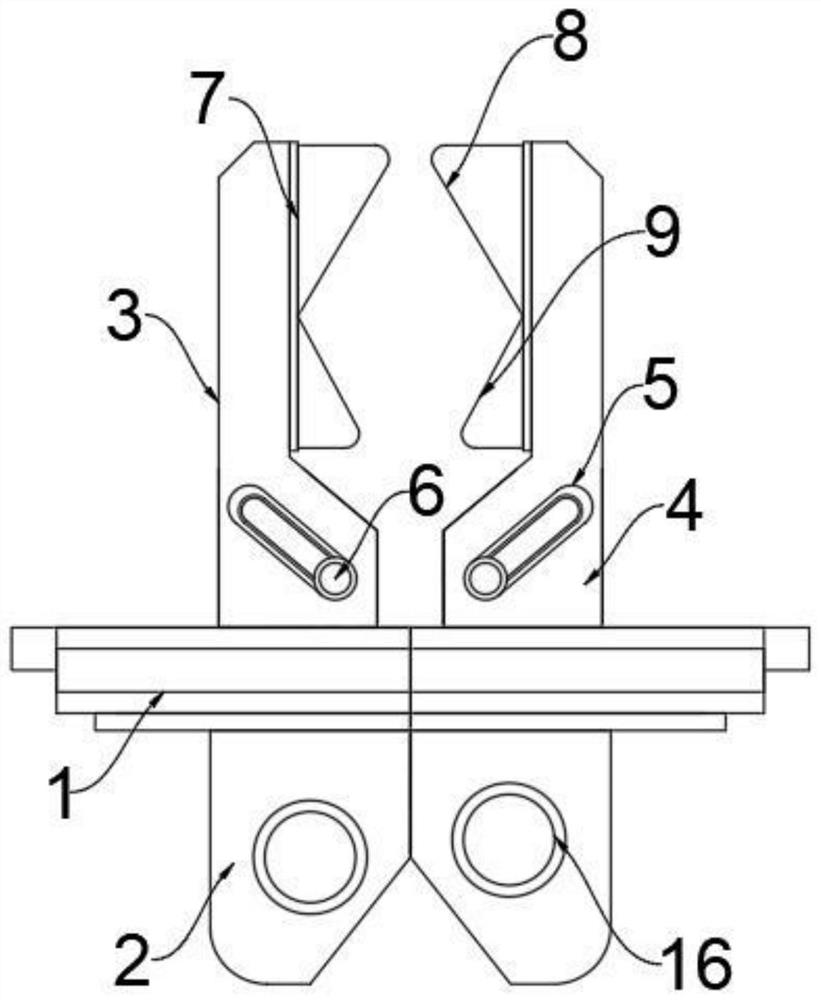

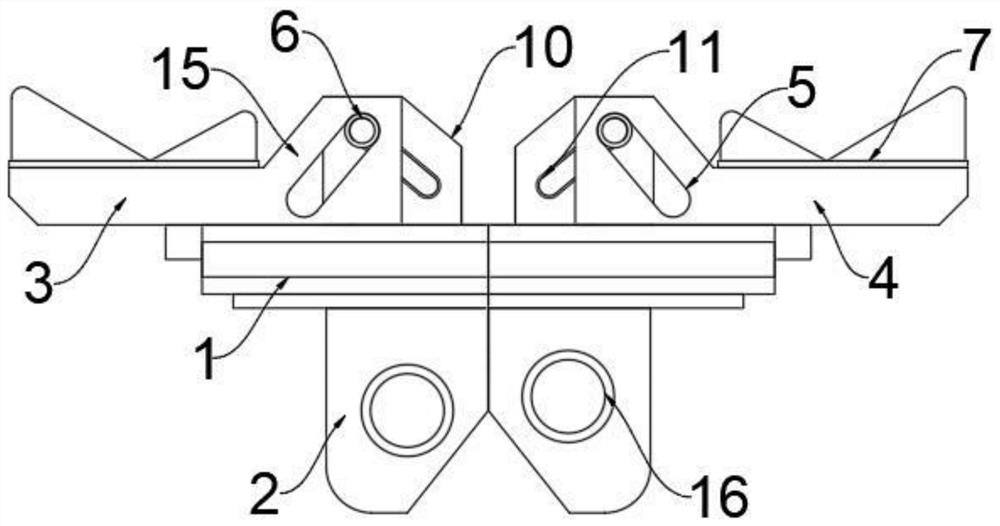

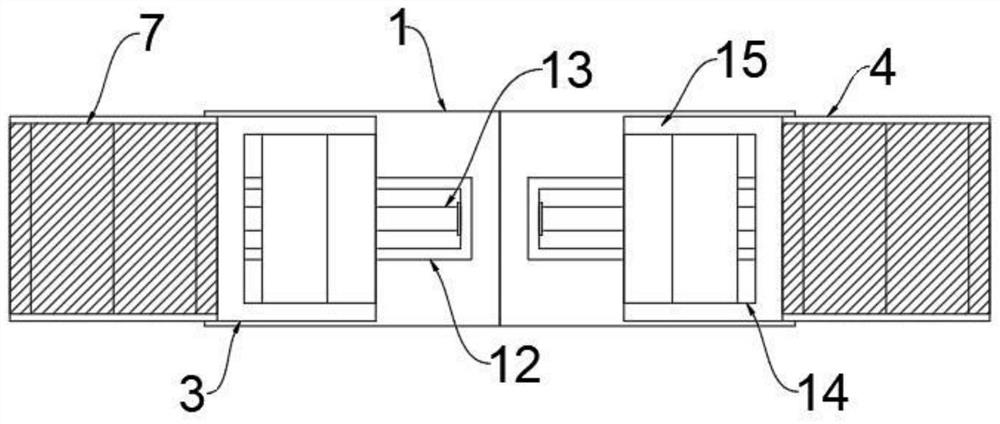

Clamping support

ActiveCN109922997ARealize clamping operationLow costVehicle componentsFriction grip releasable fasteningsEngineeringMechanical engineering

Owner:广东省齐客科技有限公司

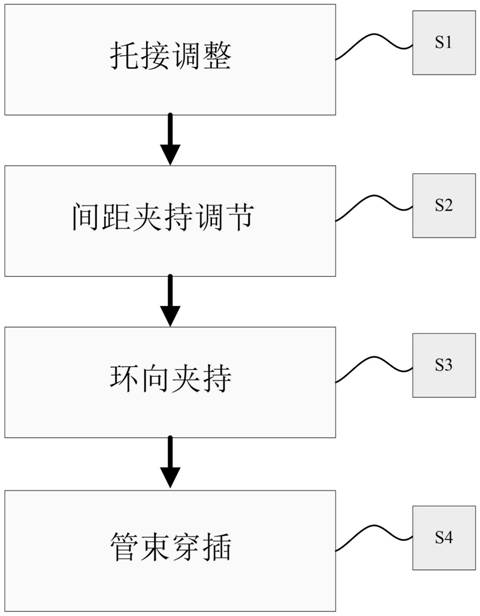

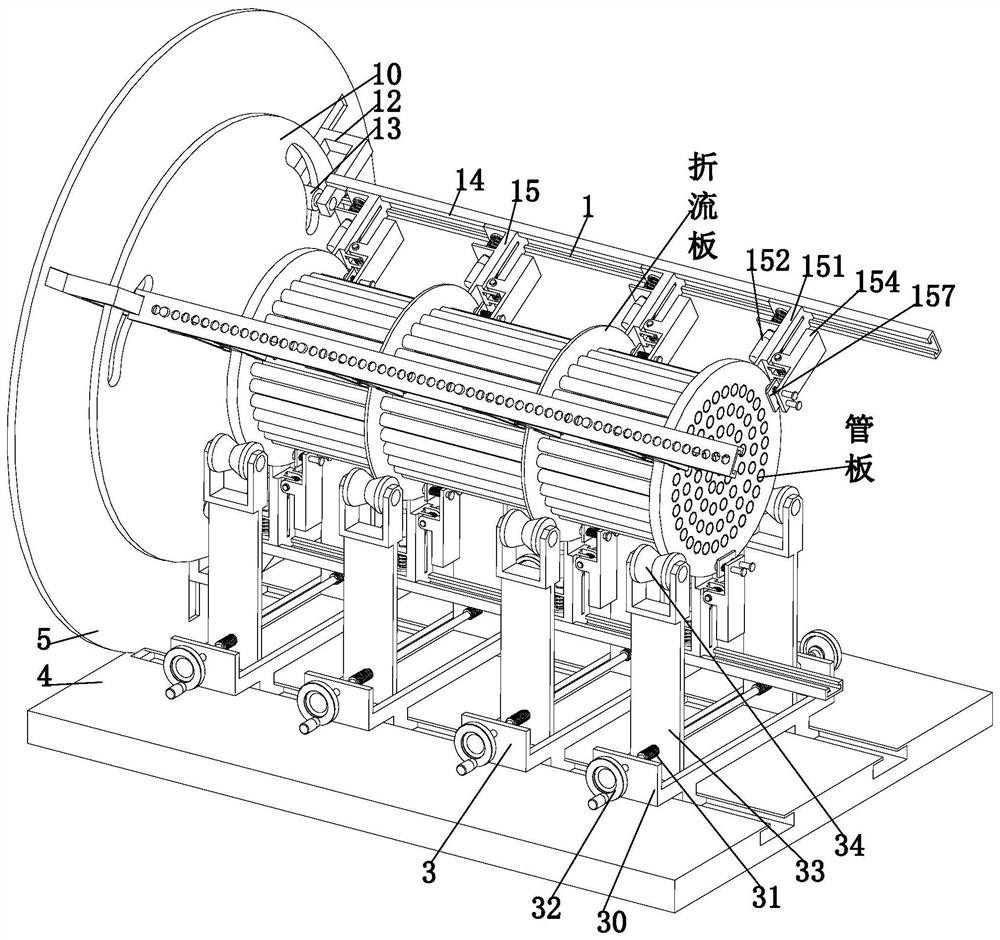

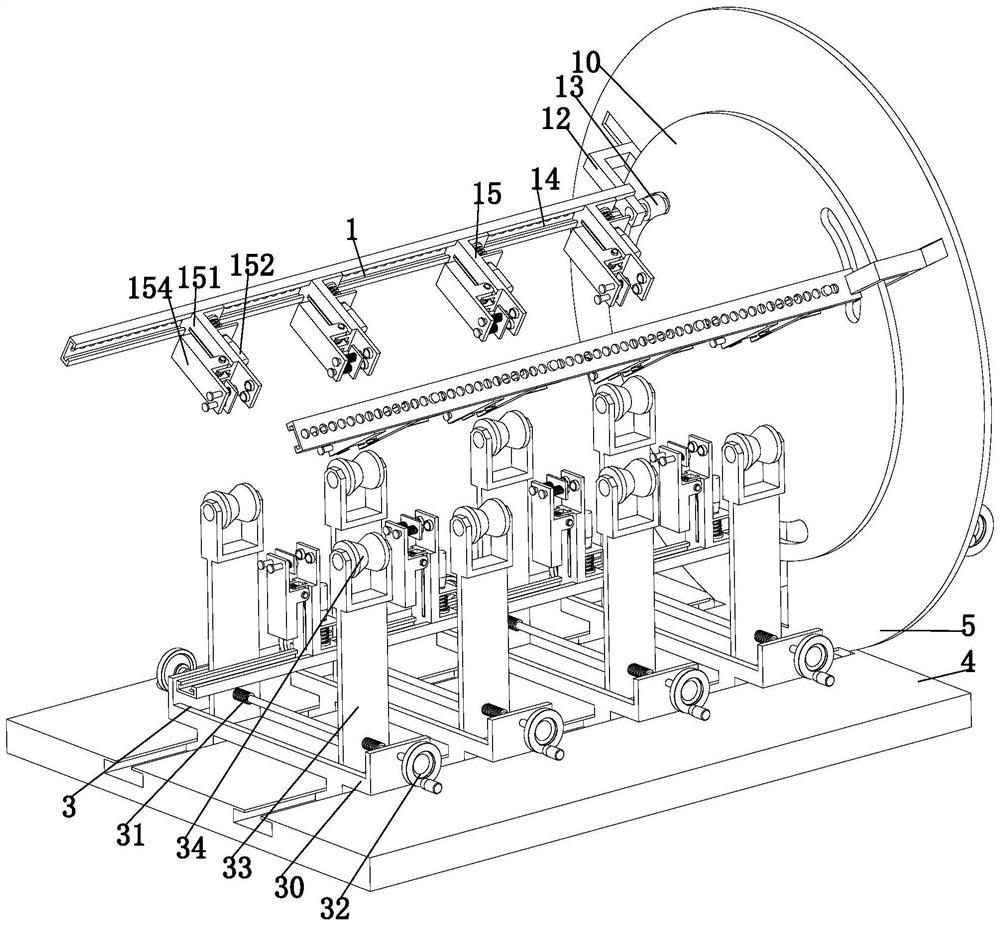

Shell-and-tube heat exchanger manufacturing and machining method

InactiveCN113146198AExpand the clamping rangeSatisfy the requirement of hoop clampingPositioning apparatusMetal working apparatusEngineeringManual handling

The invention provides a shell-and-tube heat exchanger manufacturing and machining method which involves a clamping mechanism, a regulation and control mechanism, bottom support mechanisms, a bottom plate and a ring stand vertical plate. The method solves the problems that when a heat transfer tube bundle is installed at present, tube plates at the two ends are clamped and fixed through clamps, then the spacing position of baffle plates is moved and fixed, and finally, the heat transfer tube bundle is inserted into the tube plates and the baffle plates; in the mode, manual operation is tedious, flexible and adjustable fixing clamps are not arranged to assist in the insertion process of the heat transfer tube bundle, the efficiency of the whole operation process is reduced, and large-scale production operation cannot be achieved; and the clamps can only clamp and fix the tube plates and the baffle plates with specified sizes, flexible adjustment cannot be achieved, and market requirements cannot be met.

Owner:韩洵

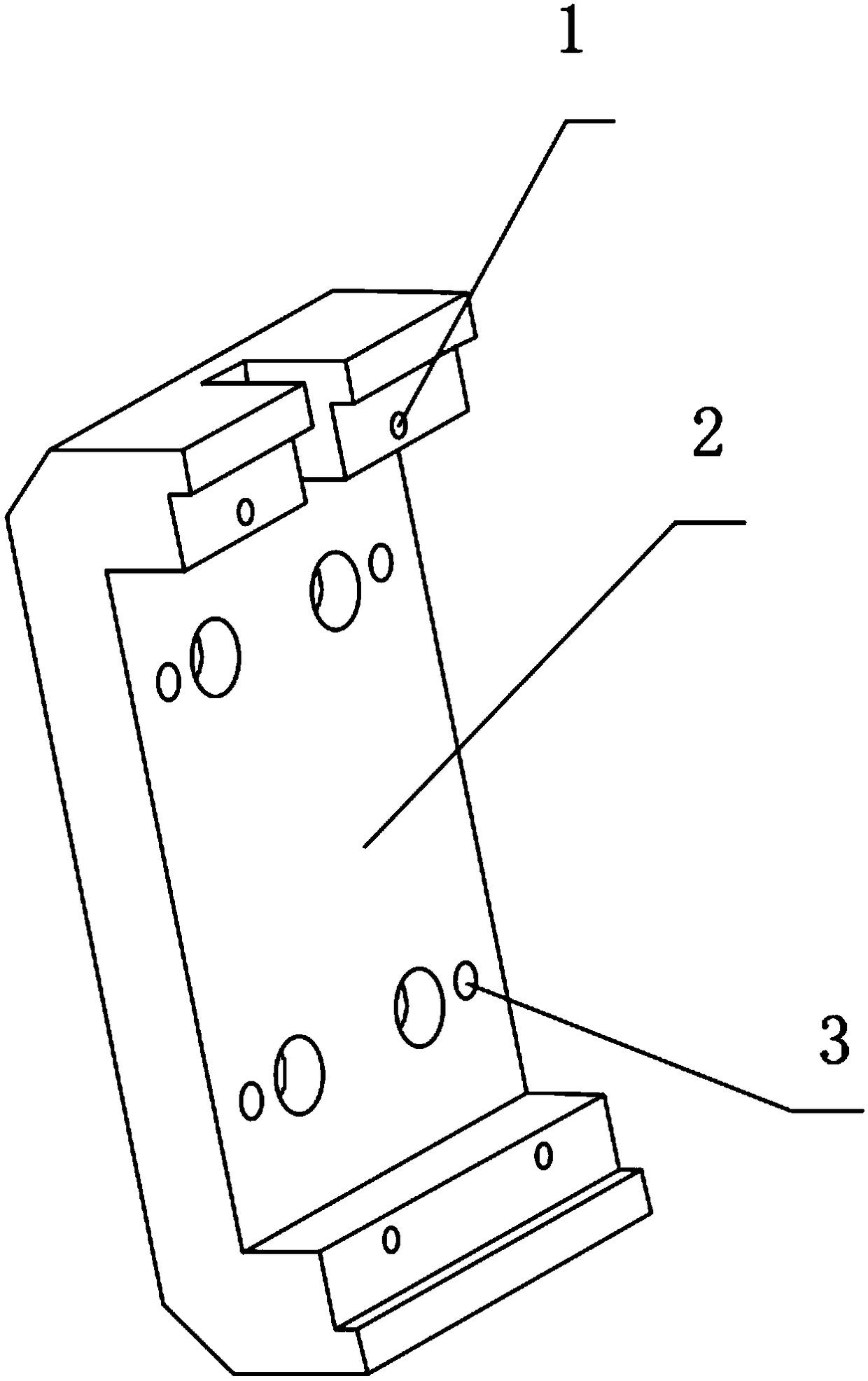

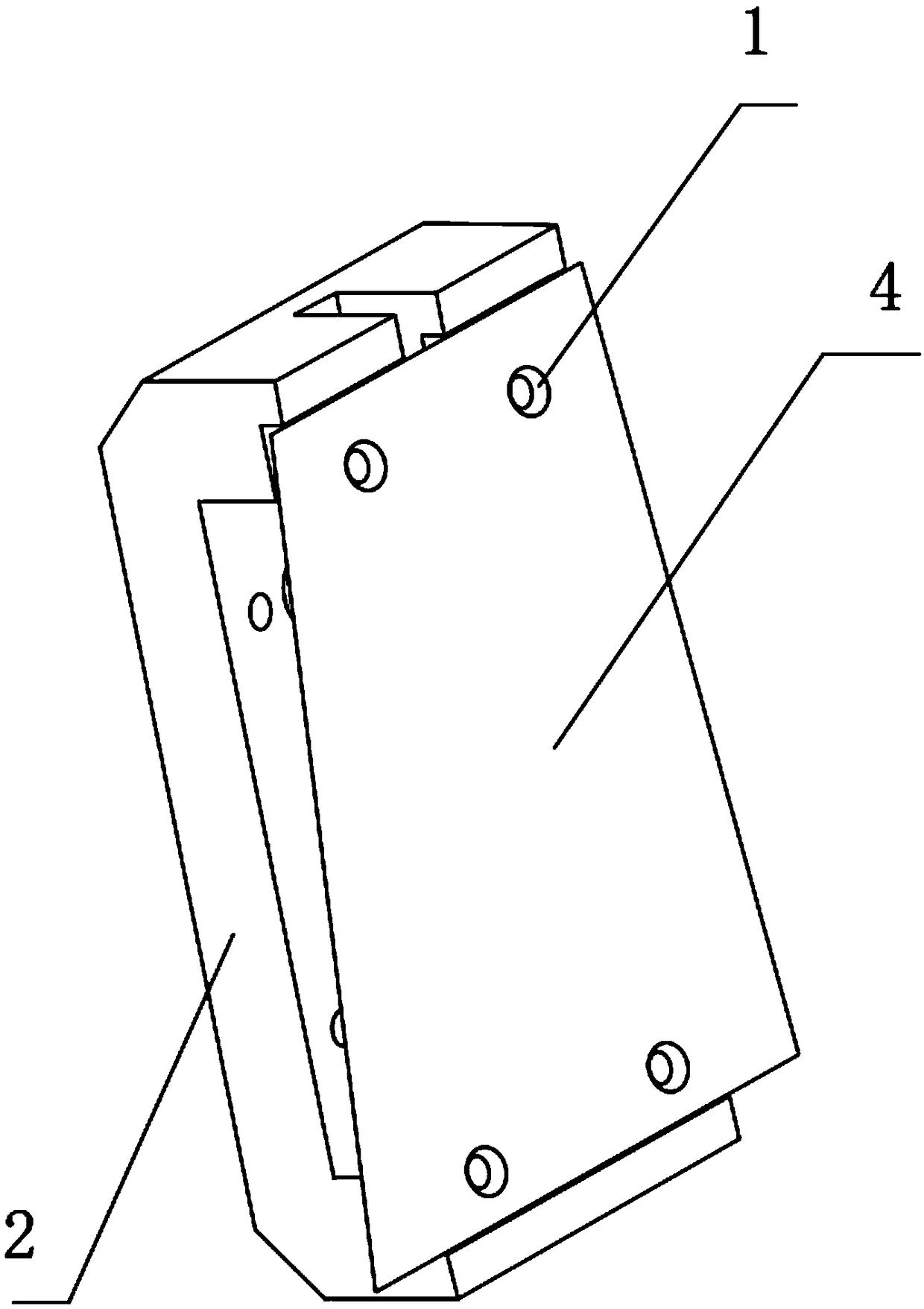

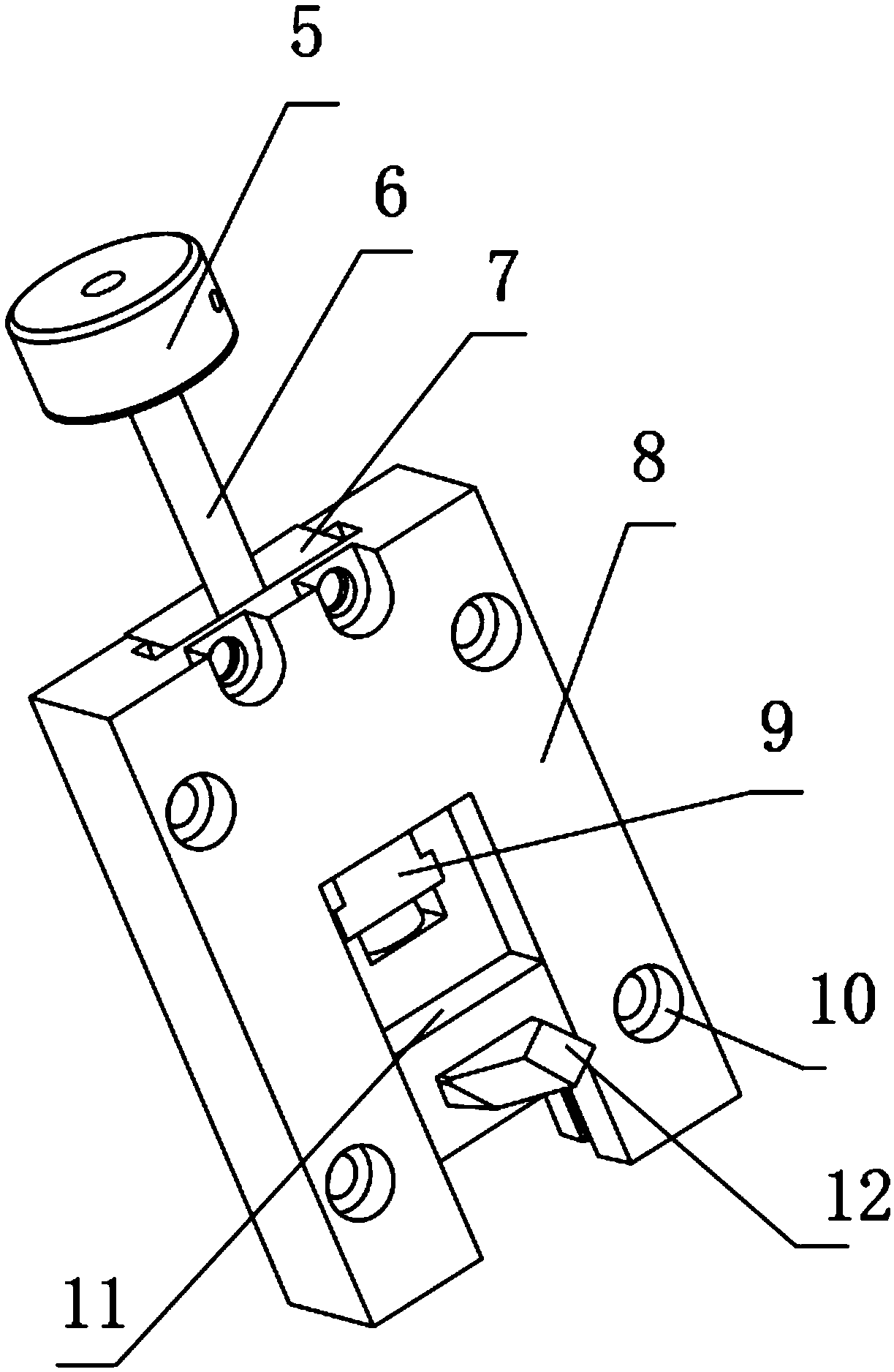

Clamping mechanism with positioning structure

InactiveCN110303516AReduce labor intensityReasonable structureGripping headsRight triangleEngineering

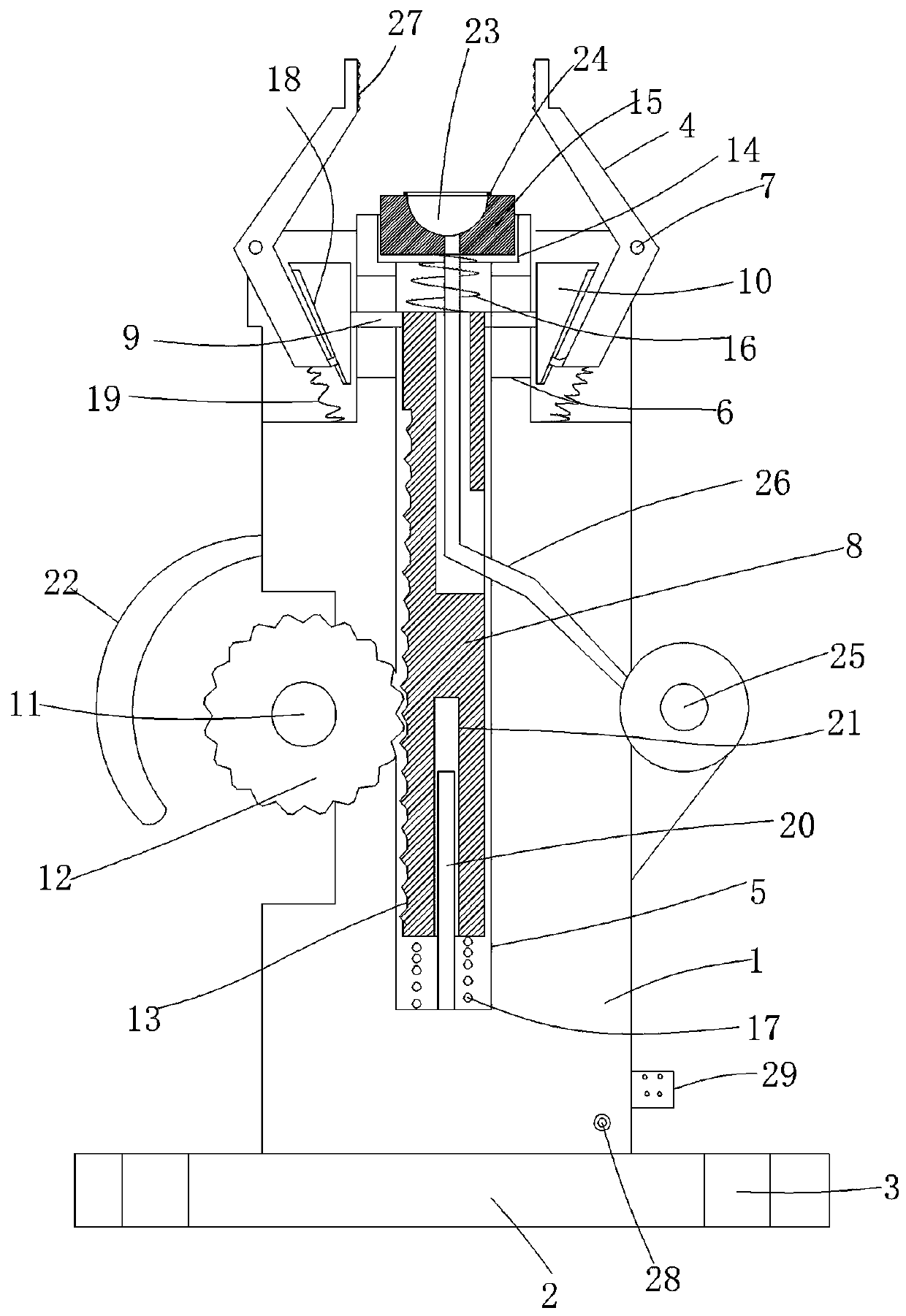

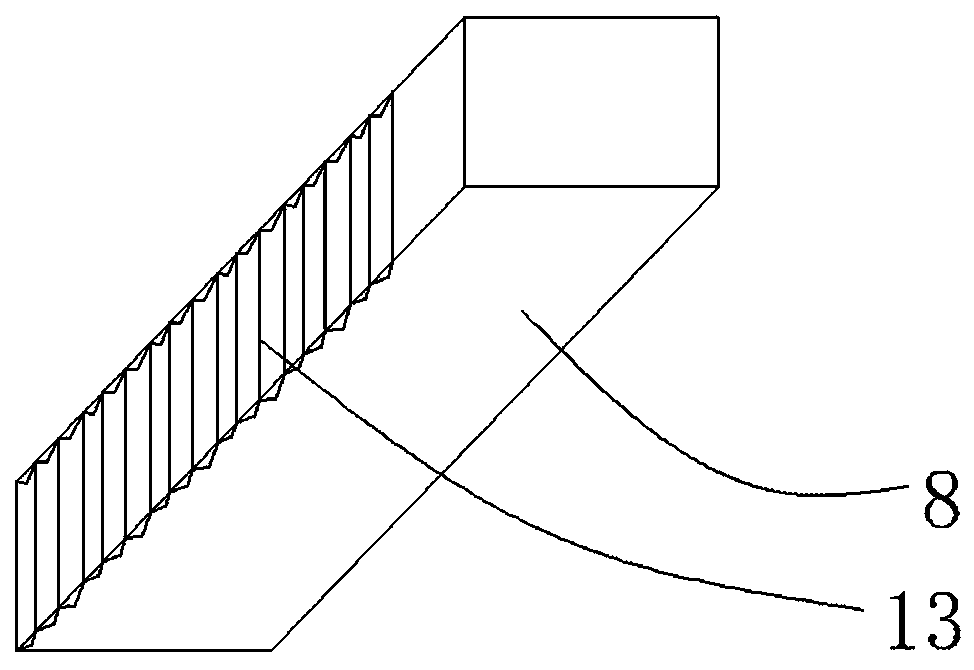

The invention discloses a clamping mechanism with a positioning structure. The clamping mechanism comprises a base, a mounting panel is integrally formed on the bottom of the base, a clamping pressingplate is arranged on the top of the base, a square vertical hole with an opening in the top face is formed in the base, vertical sliding grooves are formed in the upper parts of the symmetrical sidewalls of the base, the clamping pressing plate is an L-shaped pressing plate, corners of the clamping pressing plate are connected to the base through movable shafts, a square column rod is arranged in the square vertical hole, supporting rib rods are arranged in the vertical sliding grooves, and right-angled triangular abutting blocks are fixed to the outer side ends of the supporting rib rods; and the inner side face of a bottom rod of the L-shaped pressing plate is attached to the inclined edge of each right-angled triangular abutting block, a drive motor is fixed to the side portion of thebase, and a drive gear is fixed to a main shaft of the drive motor. The clamping mechanism is reasonable in structure arrangement, clamping operation is realized effectively and quickly, the clampingstability is ensured, the labor intensity of a worker is reduced, the clamping efficiency is improved, the applicability is strong, and the practicability is good.

Owner:刘逸

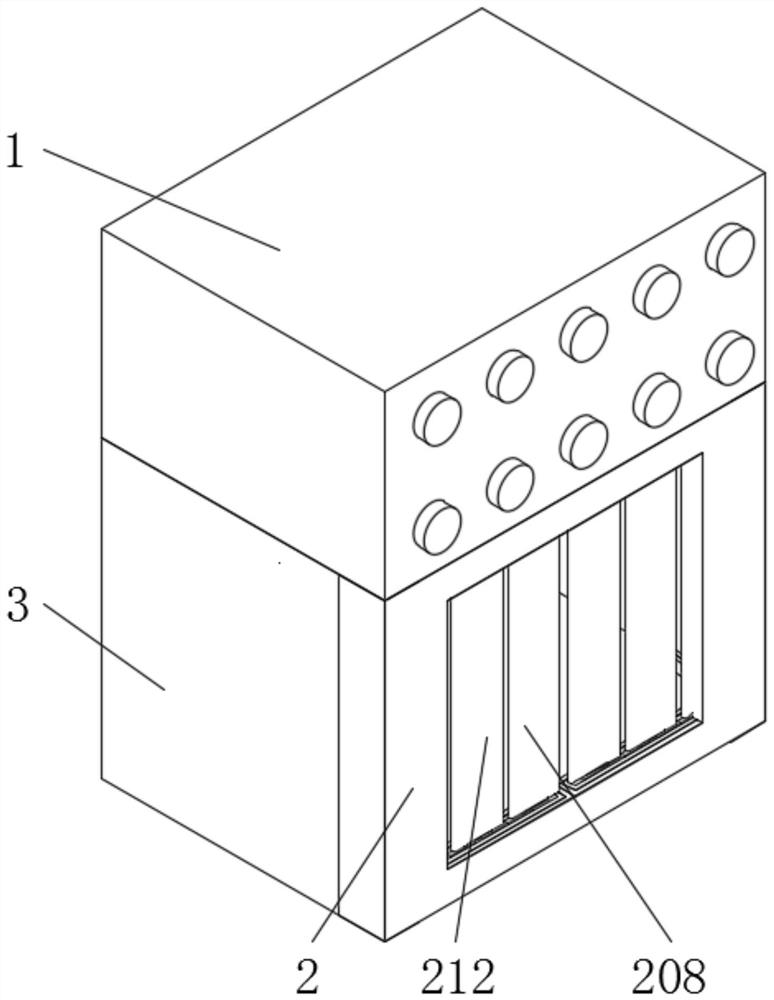

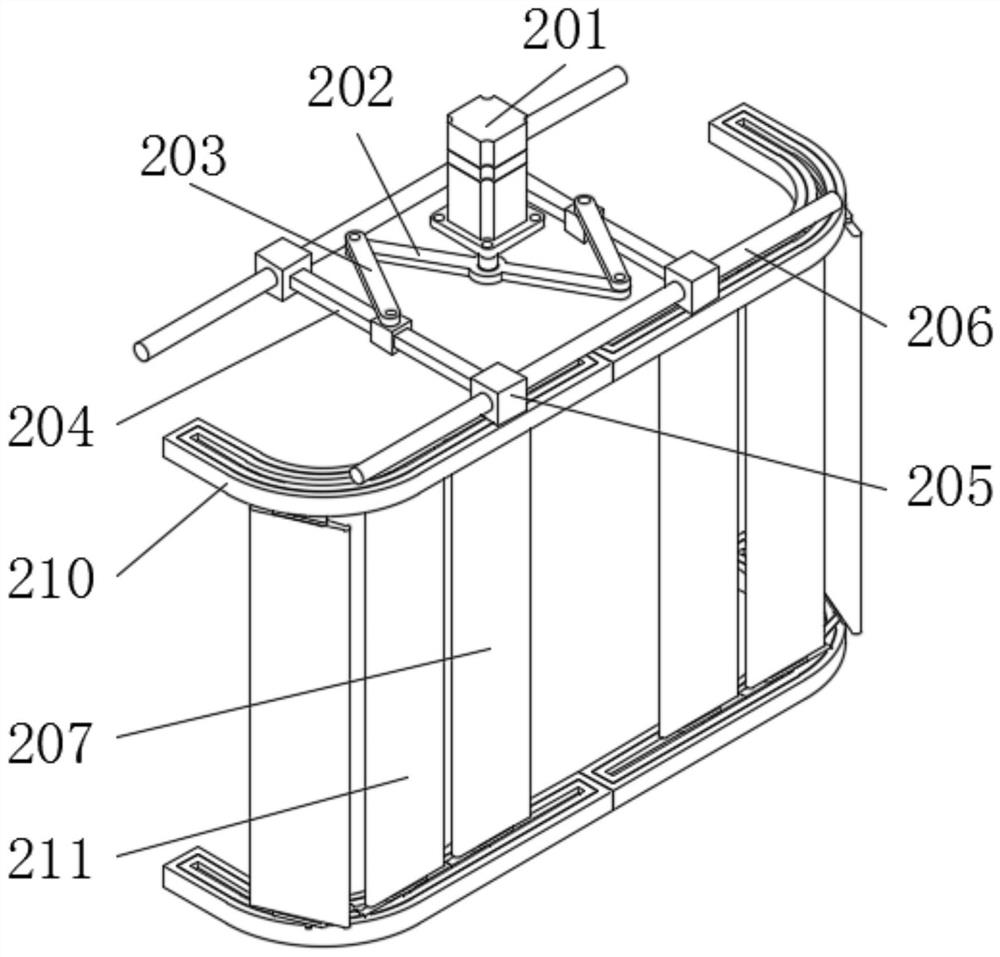

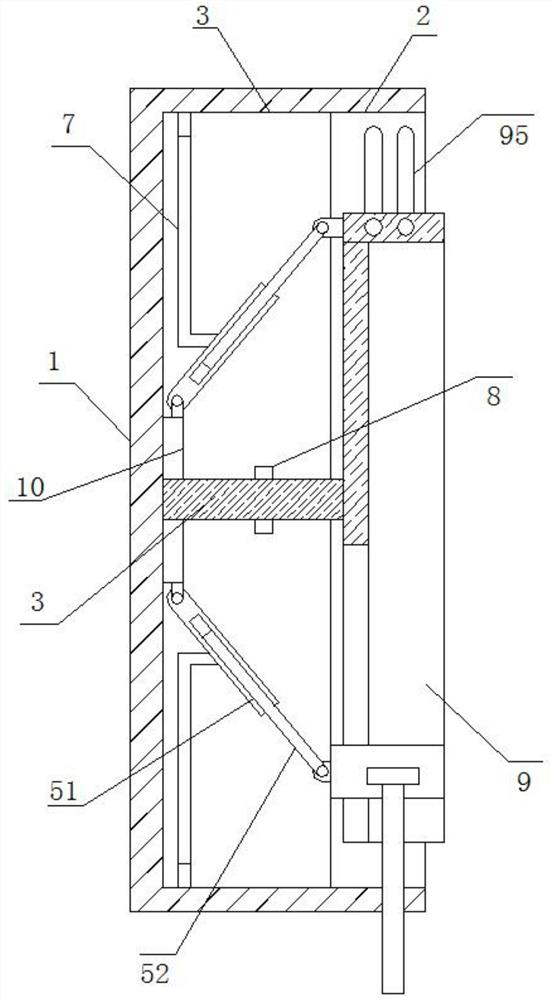

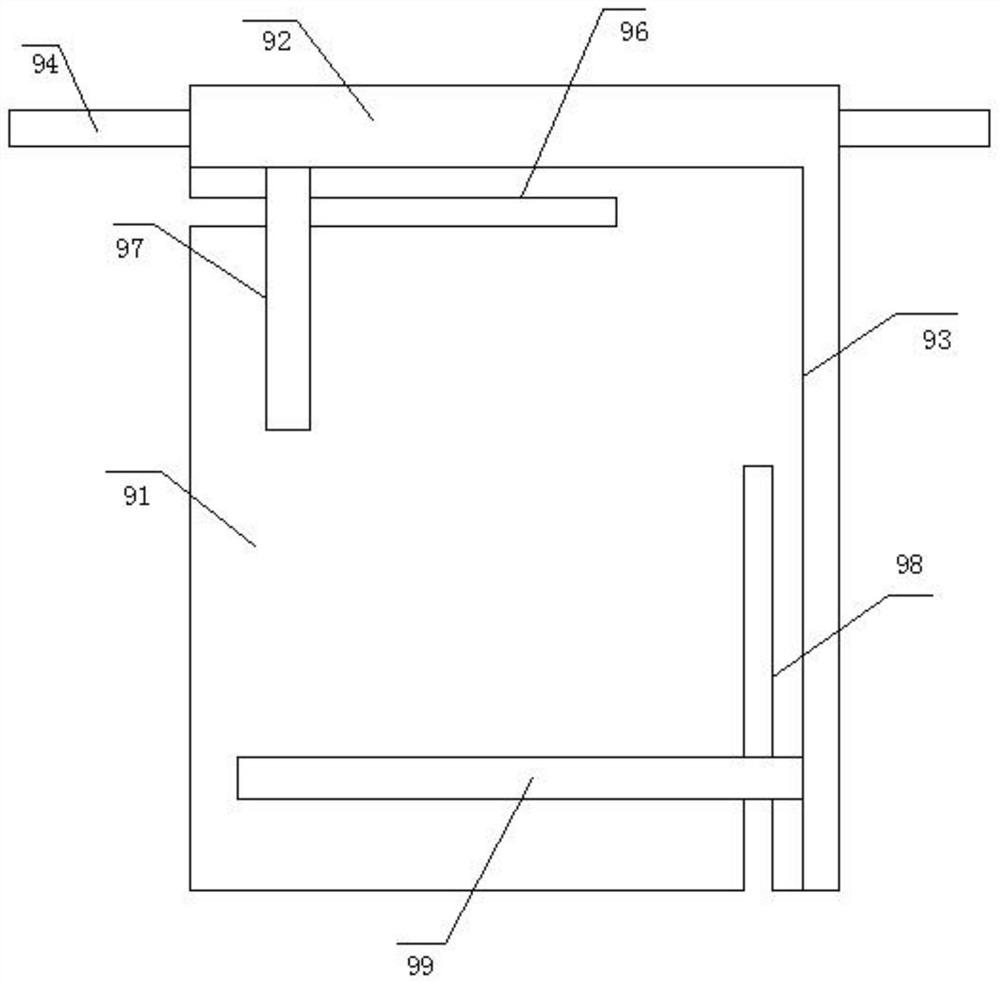

New energy automobile storage battery fixing device

ActiveCN113285164AGuaranteed stabilityRealize clamping operationElectric propulsion mountingCell component detailsNew energyBattery storage

The embodiment of the invention relates to the technical field of automobiles, in particular to a new energy automobile storage battery fixing device which is used for quickly fixing an automobile storage battery and comprises a fixing seat, a leveling and clamping mechanism, a limiting mechanism and a fixing mechanism; an accommodating groove is formed in the fixing seat, the leveling and clamping mechanism is used for clamping the storage battery in the process of horizontally placing the storage battery in the placing groove; the limiting mechanism is arranged on the fixed seat and is used for automatically limiting the storage battery after the storage battery is placed; and a fixing mechanism. According to the storage battery storage device, the storage battery can horizontally descend by the leveling and clamping mechanism so as to ensure the stability after placement, the storage battery can be clamped, after the storage battery is completely placed in the storage battery storage device, the storage battery can be automatically limited through the limiting mechanism, installation is very convenient, the other two side surfaces of the storage battery can be clamped through the fixing mechanism, so that the stability of the storage battery after installation is further ensured, and the use effect is better.

Owner:深圳市小樱桃实业有限公司

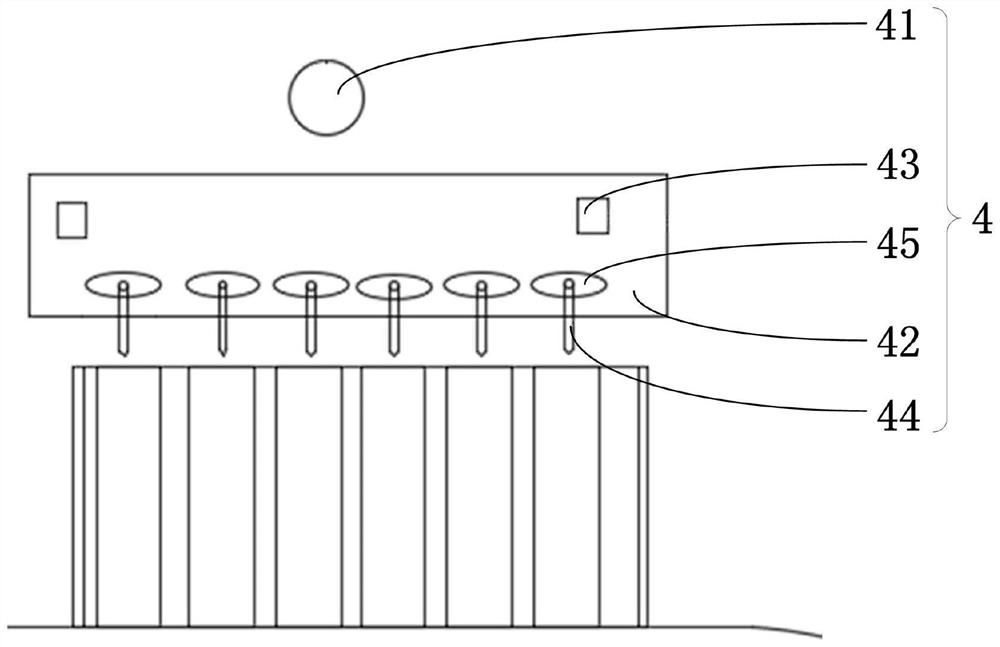

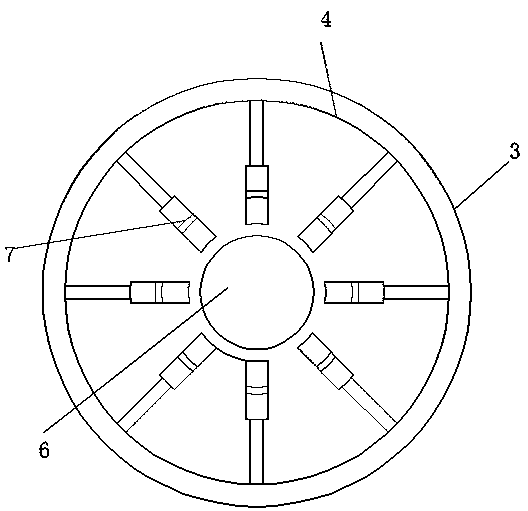

Self-adaptive multi-cable doubling fixing installation clamp

ActiveCN112202120ARealize clamping operationRealize limitElectrical apparatusGear wheelTorsion spring

The invention discloses a self-adaptive multi-cable doubling fixing installation clamp, which comprises a lower plate and an upper plate, wherein four through grooves penetrating through the upper plate and the lower plate are formed in the upper plate and the lower plate in an annular array mode, sliding blocks are embedded in four cavities between the lower plate and the upper plate in a slidingmode, limiting grooves corresponding to the through grooves are formed in the sliding blocks, a gear disc is rotationally connected to the center of the upper plate, a torsion spring is fixedly connected to the top of the gear disc, and the top end of the torsion spring is fixedly connected with the lower plate. According to the invention, a cable is placed in a key groove, under the action of atorsion spring, a gear disc drives a clamping gear rack to move so as to achieve the movement of a sliding block, the cable is pushed by a clamping groove to be clamped into the key groove so as to achieve the effect of automatically adjusting a mounting hole diameter, and an upper plate and a lower plate get close to each other by screwing a limiting piece and a connecting piece, so that the geardisc is limited by a clamping tooth ring, self-locking of the clamp is achieved, and the safety of the device is improved.

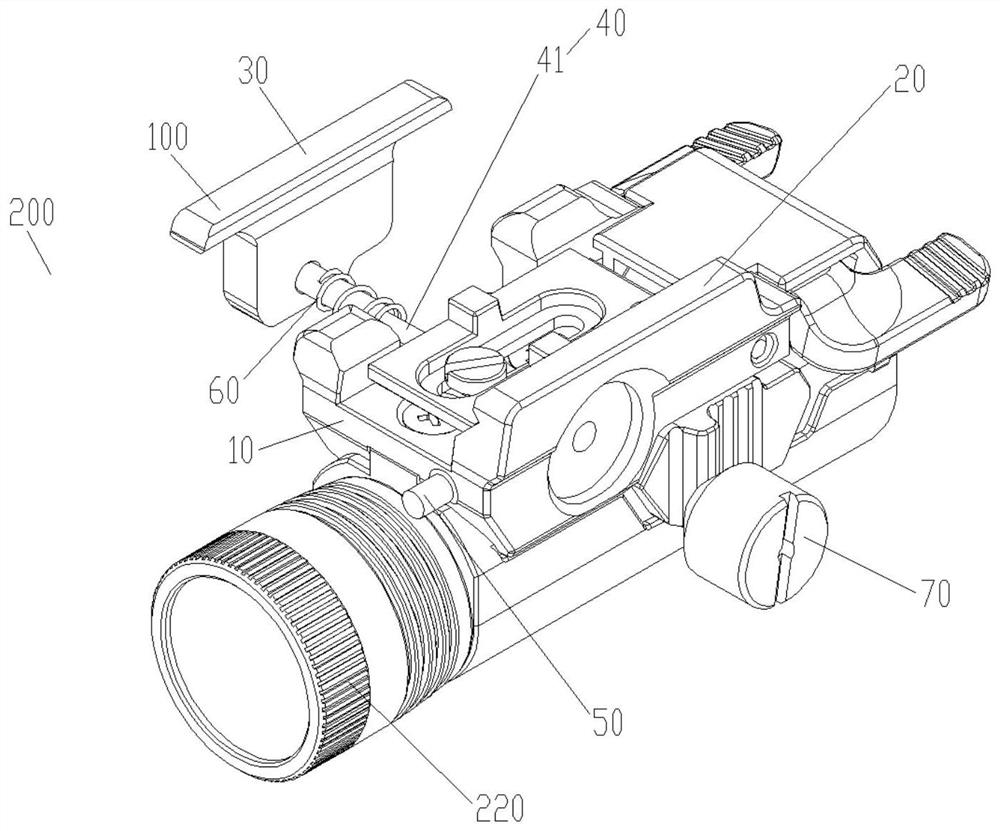

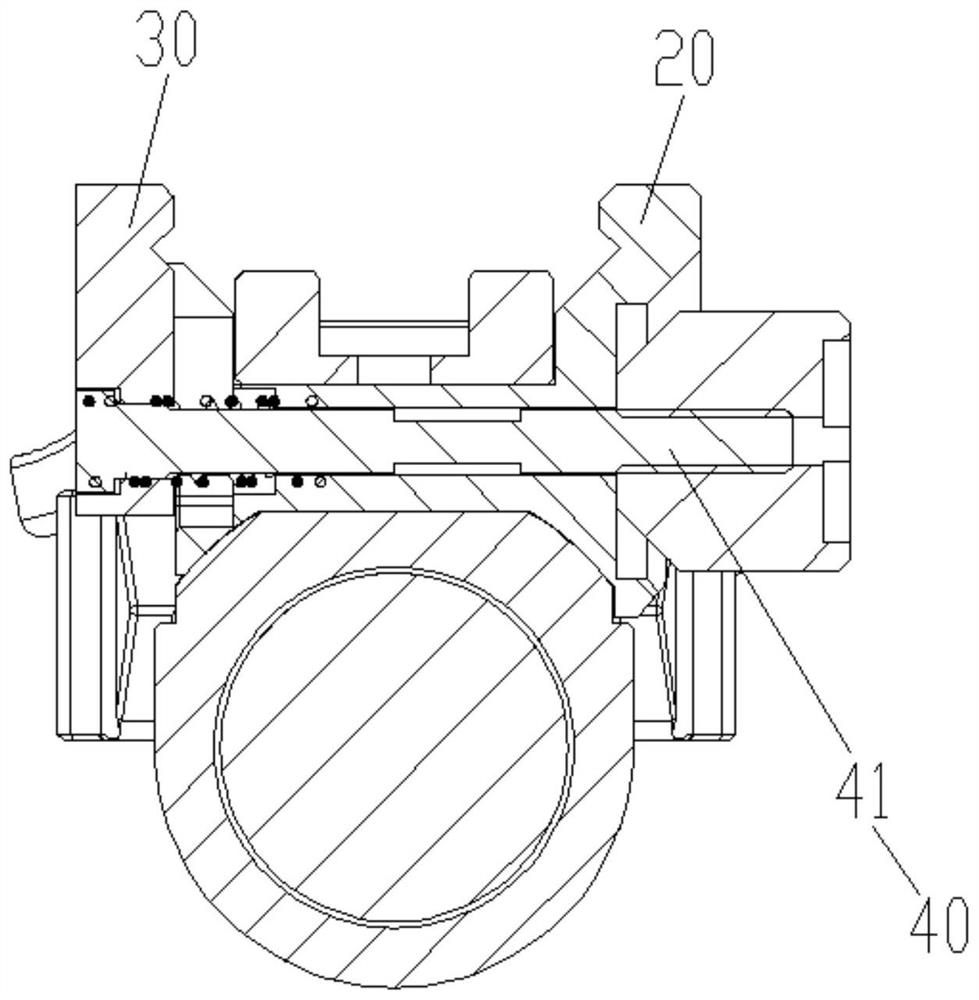

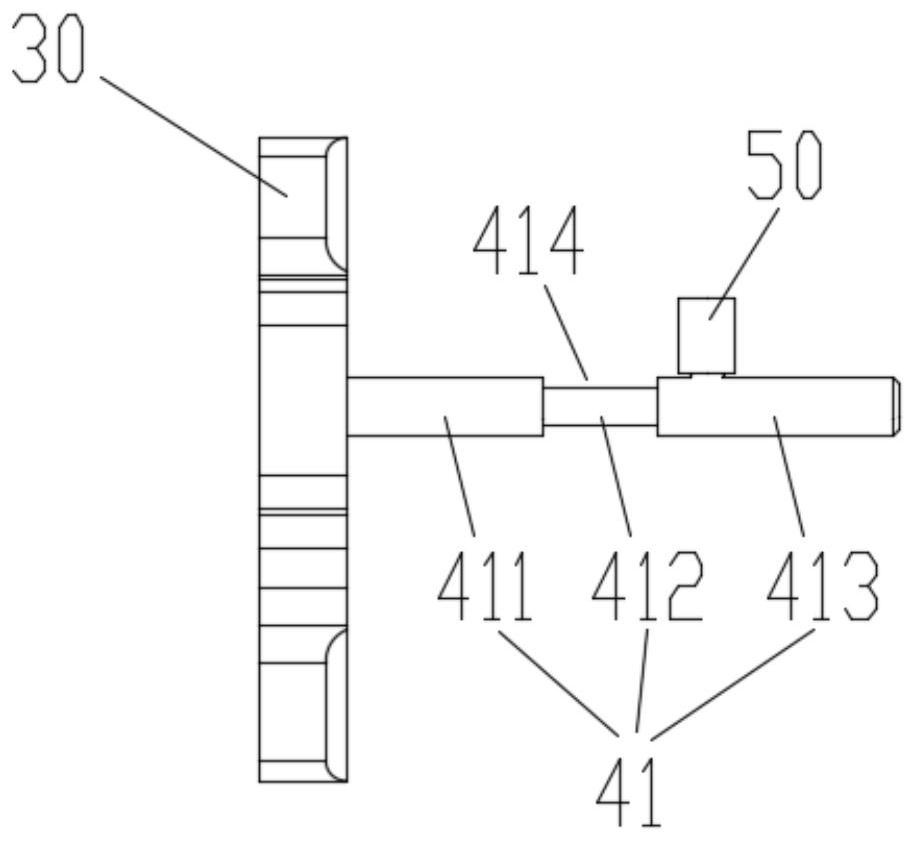

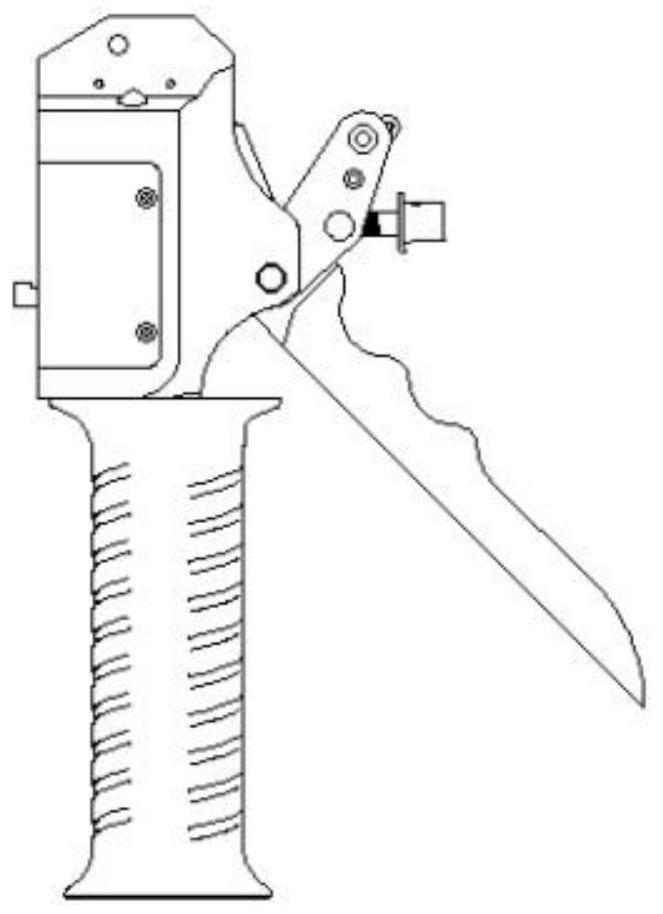

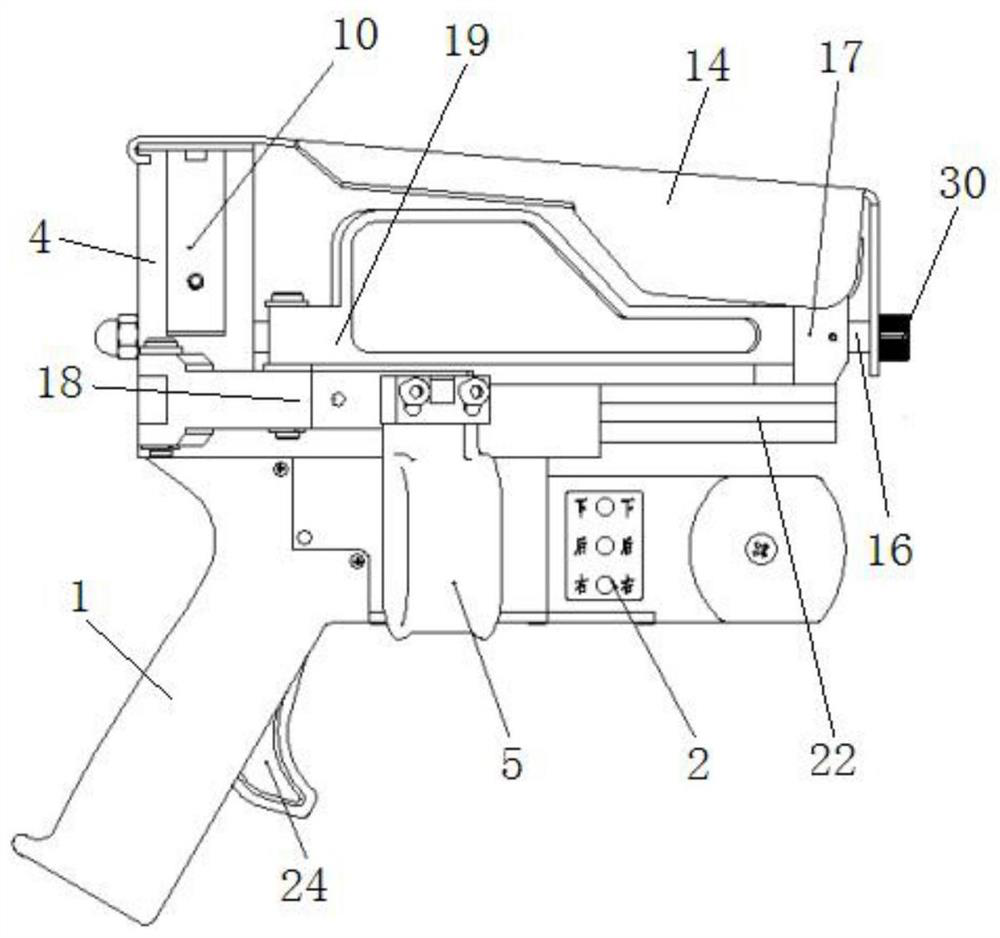

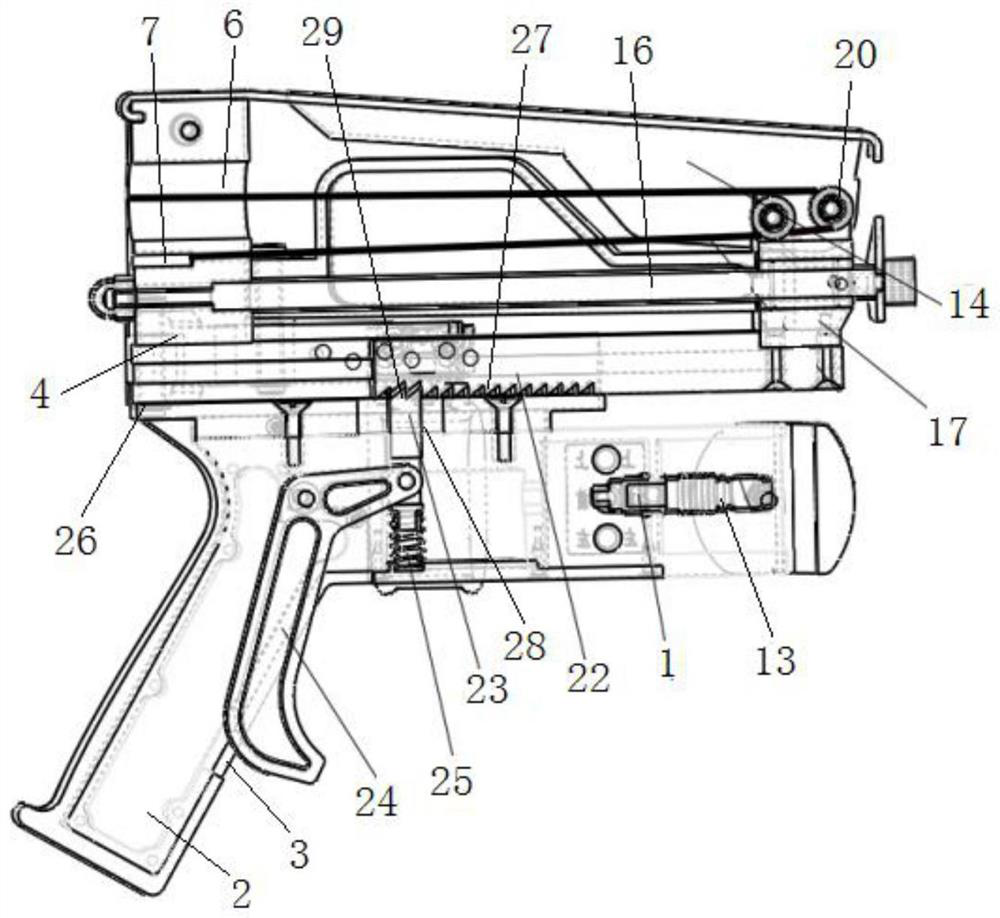

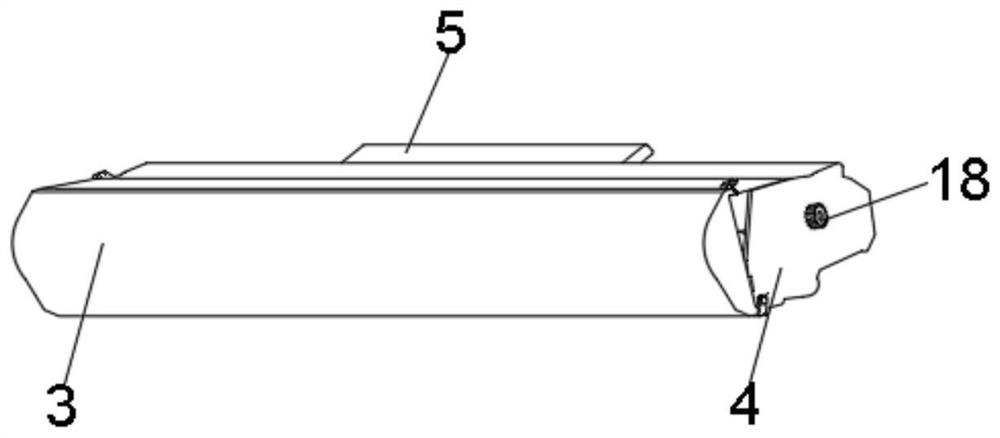

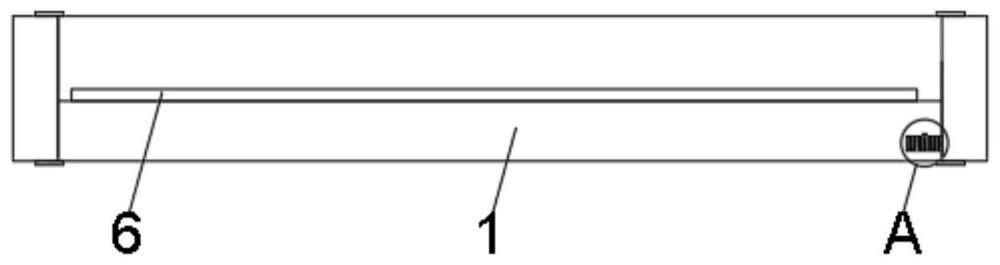

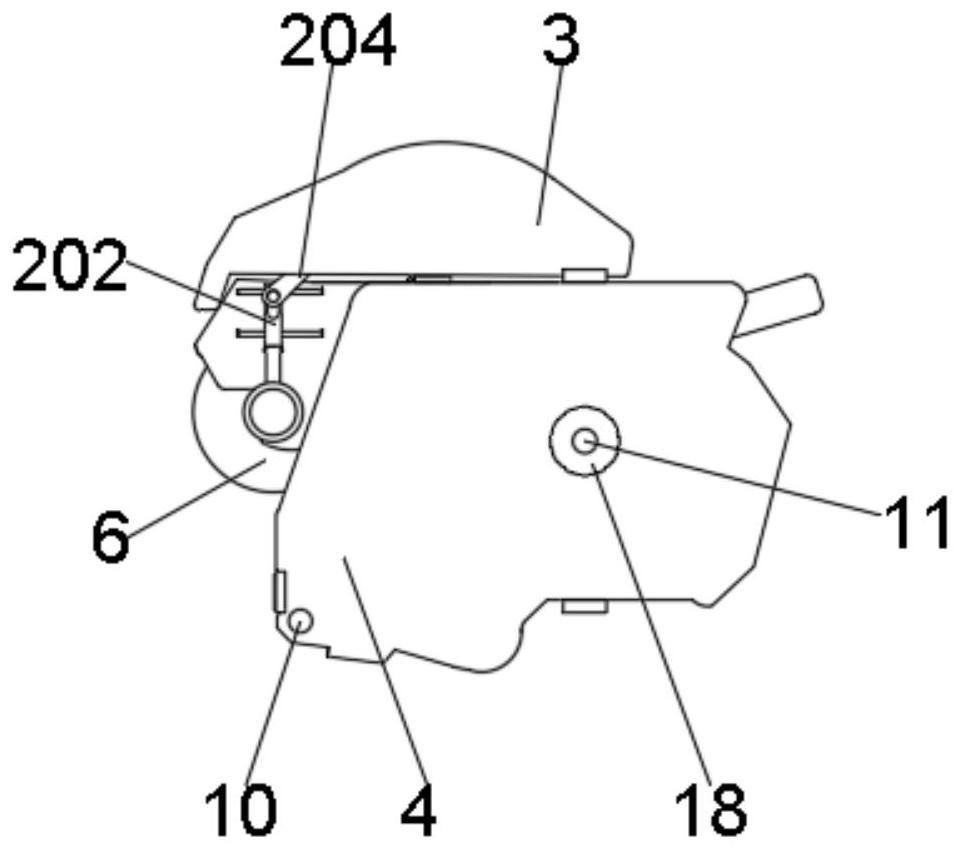

Guide rail clamp device and gun lamp equipment with same

PendingCN113446898AEasy to operateRealize clamping operationLighting elementsWeapon componentsClip deviceElectrical and Electronics engineering

Owner:NEXFLASHLIGHT INDS

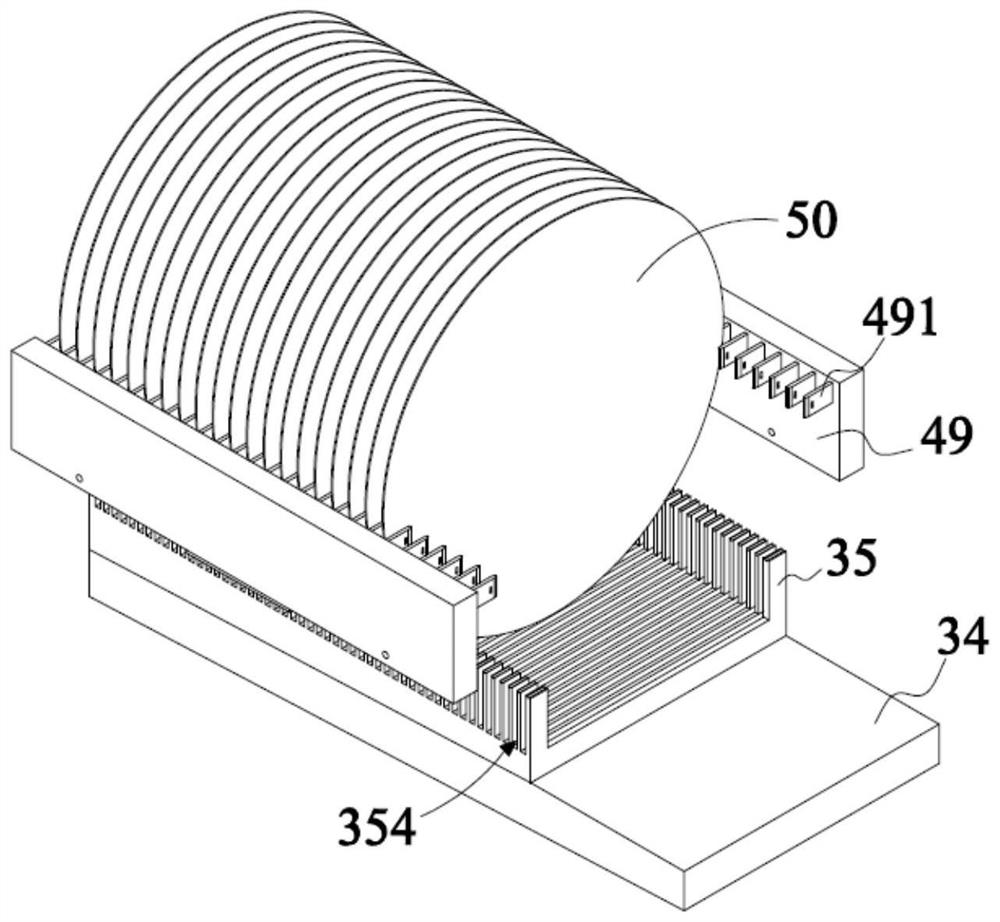

Wafer transmission system and semiconductor equipment

PendingCN114496867ARealize the execution of clamping operationsRealize clamping operationSemiconductor/solid-state device manufacturingConveyor partsPhysicsTransmission system

The invention provides a wafer transmission system and semiconductor equipment. The wafer transmission system comprises a cache table, a plurality of pressure detection units, a photoelectric detection unit and a pickup unit, wherein the pressure detection units are arranged above the cache table and used for detecting the weight of wafers; the picking unit comprises two rotary grabbing plates which are arranged in parallel, at least one side edge of each rotary grabbing plate in the extending direction forms a fixed fork tooth part which supports the edge of a wafer and is provided with a first notch, and two connecting arms which are connected with the ends of the rotary grabbing plates. The picking unit determines the axial rotation angle of the rotary grabbing plate according to detection signals sent by the photoelectric detection unit and the pressure detection unit. According to the wafer transmission system disclosed by the invention, the undesirable phenomena of wafer falling or wafer breaking and the like possibly occurring in the process of grabbing and transmitting the wafers by the wafer transmission system are avoided, the wafers with different thicknesses are clamped, and the reliability of the wafer clamping operation is improved.

Owner:上海果纳半导体技术有限公司

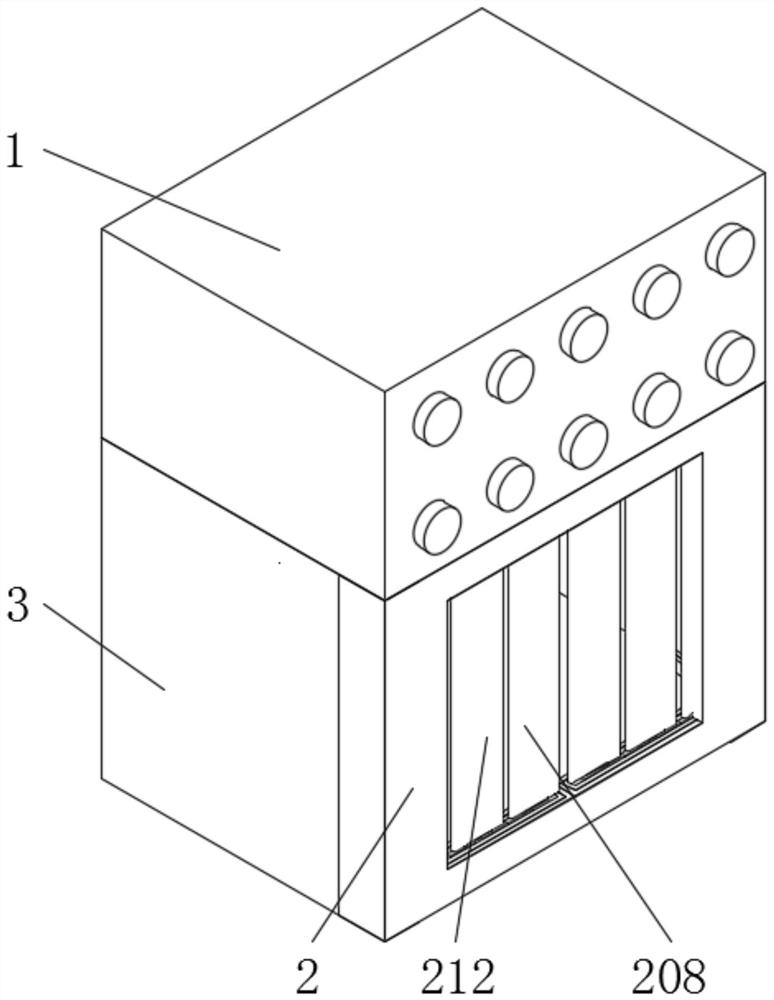

Power distribution box with cable clamping mechanism

ActiveCN113036624AStable automatic opening and closing operationStable opening and closing operationSubstation/switching arrangement detailsVertical planeEngineering

The invention discloses a power distribution box with a cable clamping mechanism. The power distribution box comprises a display box, wherein the bottom end of the display box is fixedly connected with an opening and closing mechanism which is in the same vertical plane with the side wall of the display box and is of a concentric-square-shaped structure, and the side wall of the opening and closing mechanism is located at the bottom end of the display box and is fixedly connected with a cabinet body. According to the power distribution box with the cable clamping mechanism, by arranging clamping sliding plates, in clamping plates, clamping buttons drive clamping control rods to move, the clamping control rods drive pushing blocks to slide along the inner walls of the clamping plates, the pushing blocks move to drive connecting rods to move, the connecting rods drive the clamping sliding plates to slide along the inner walls of the clamping plates through clamping springs, the sliding length of the clamping sliding plate is equal to the length of the connecting rod, the central axis of the pushing block, the middle points of the two sets of connecting rods and the central axis of the clamping groove coincide, and clamping operation on the cable is achieved through relative movement of the clamping sliding plate and the clamping groove.

Owner:山东万盛电气有限公司

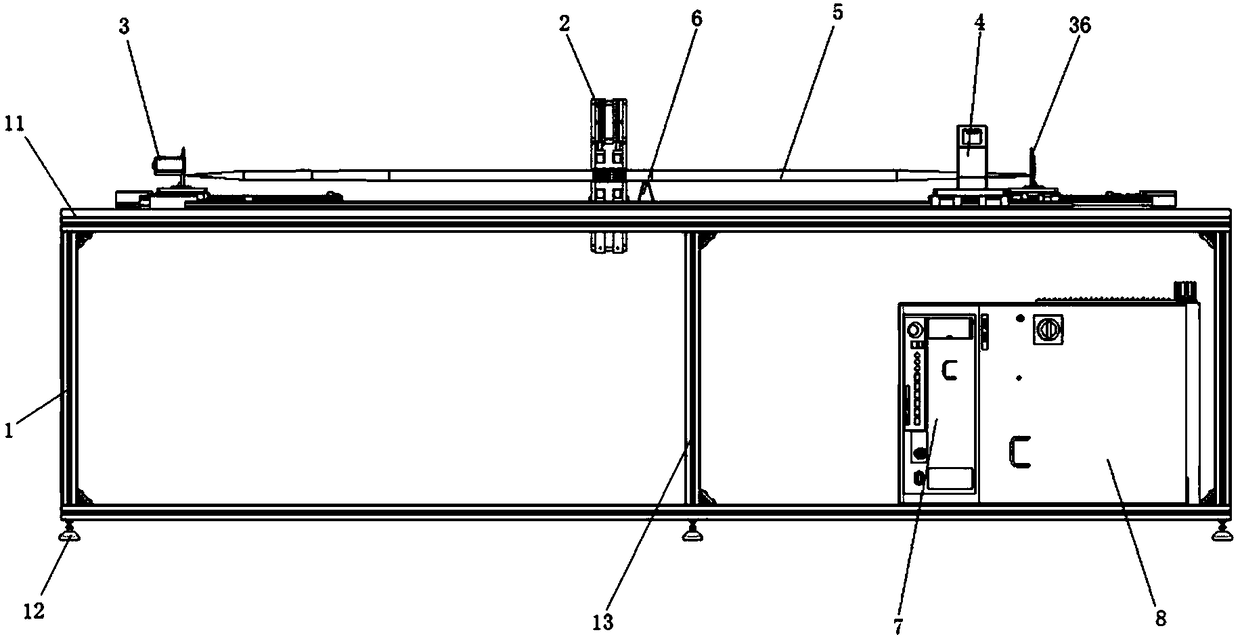

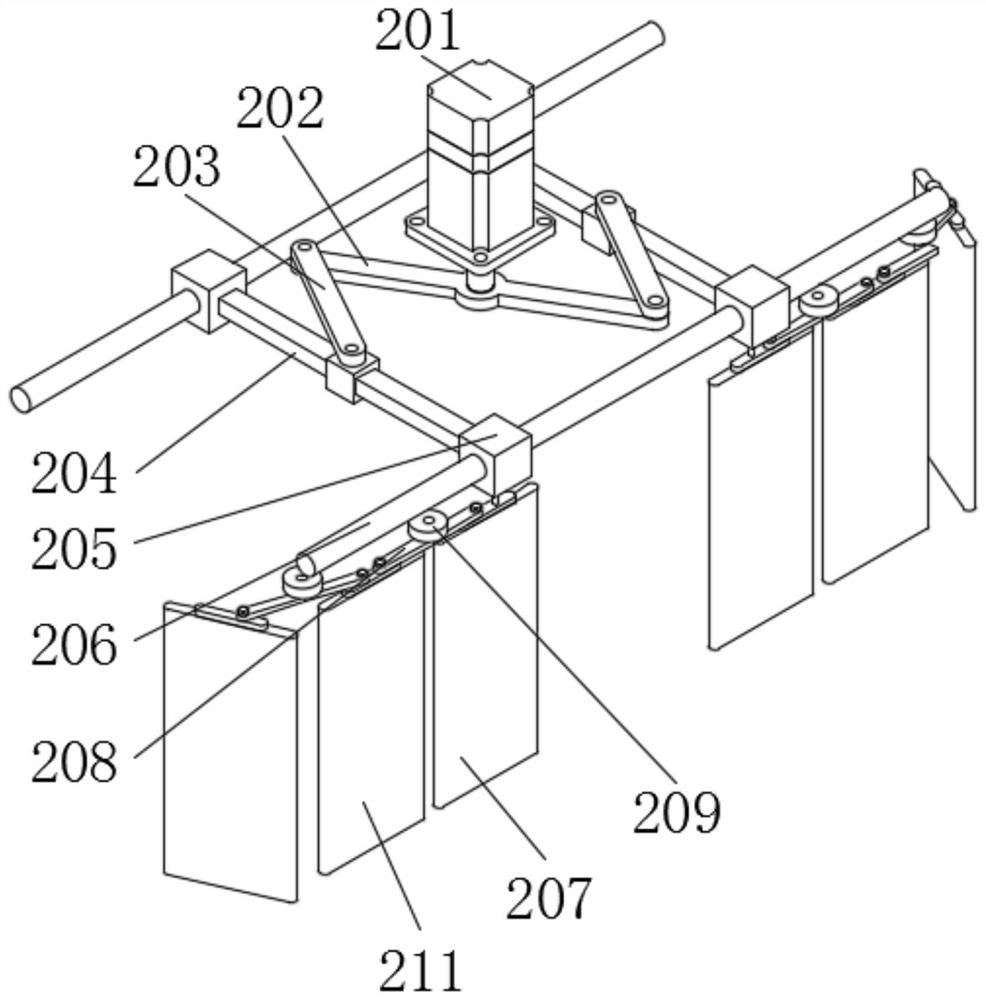

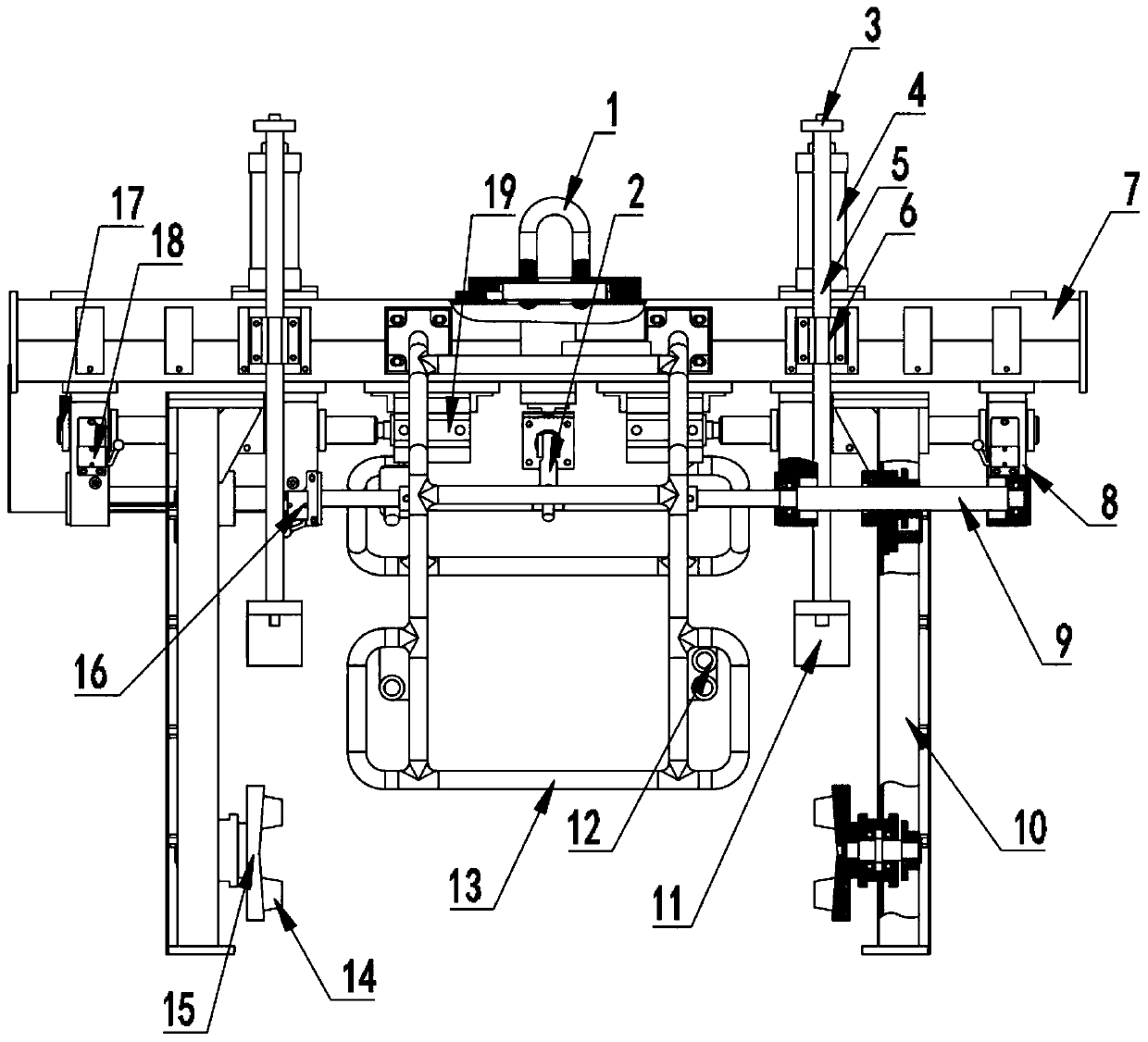

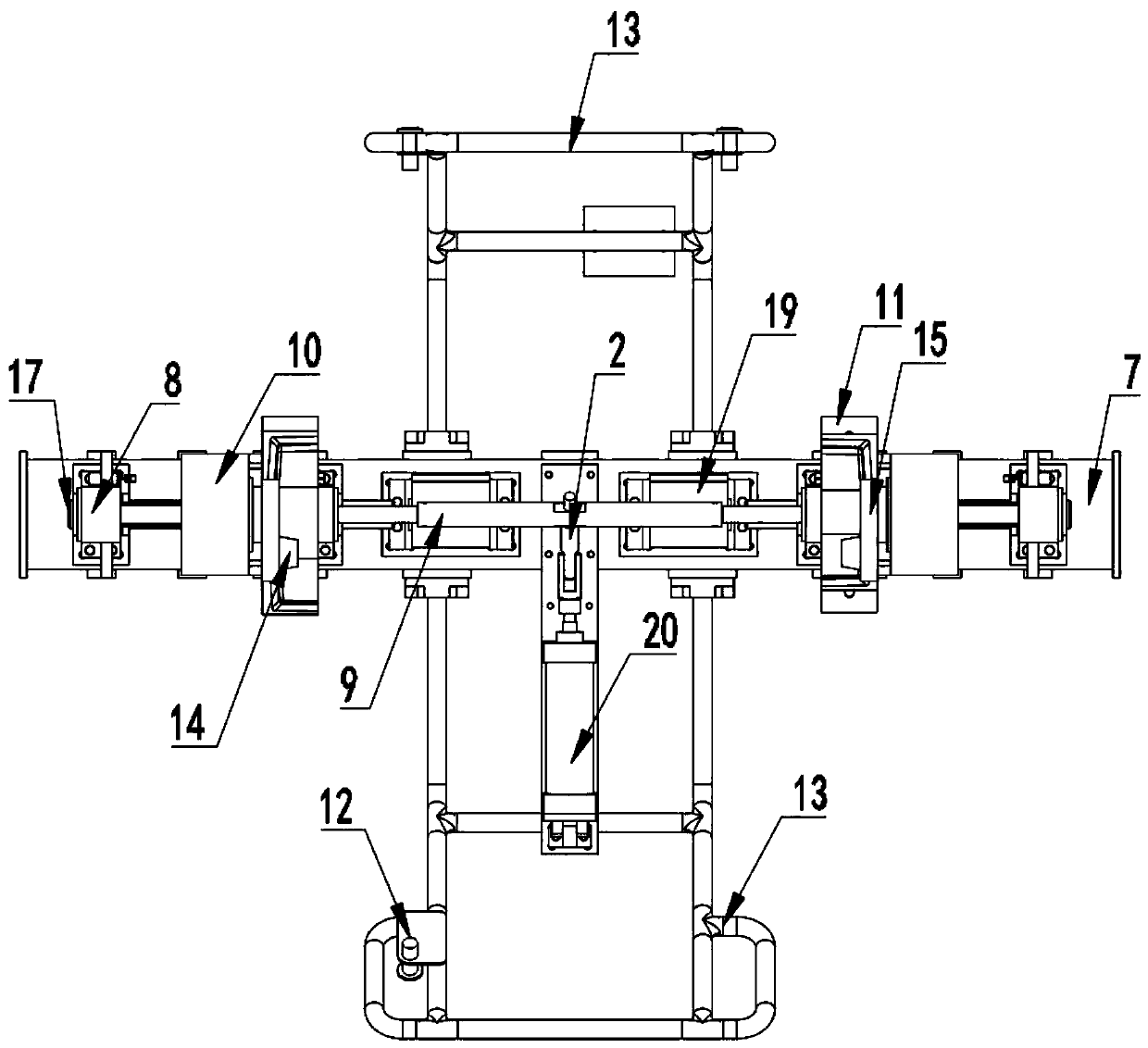

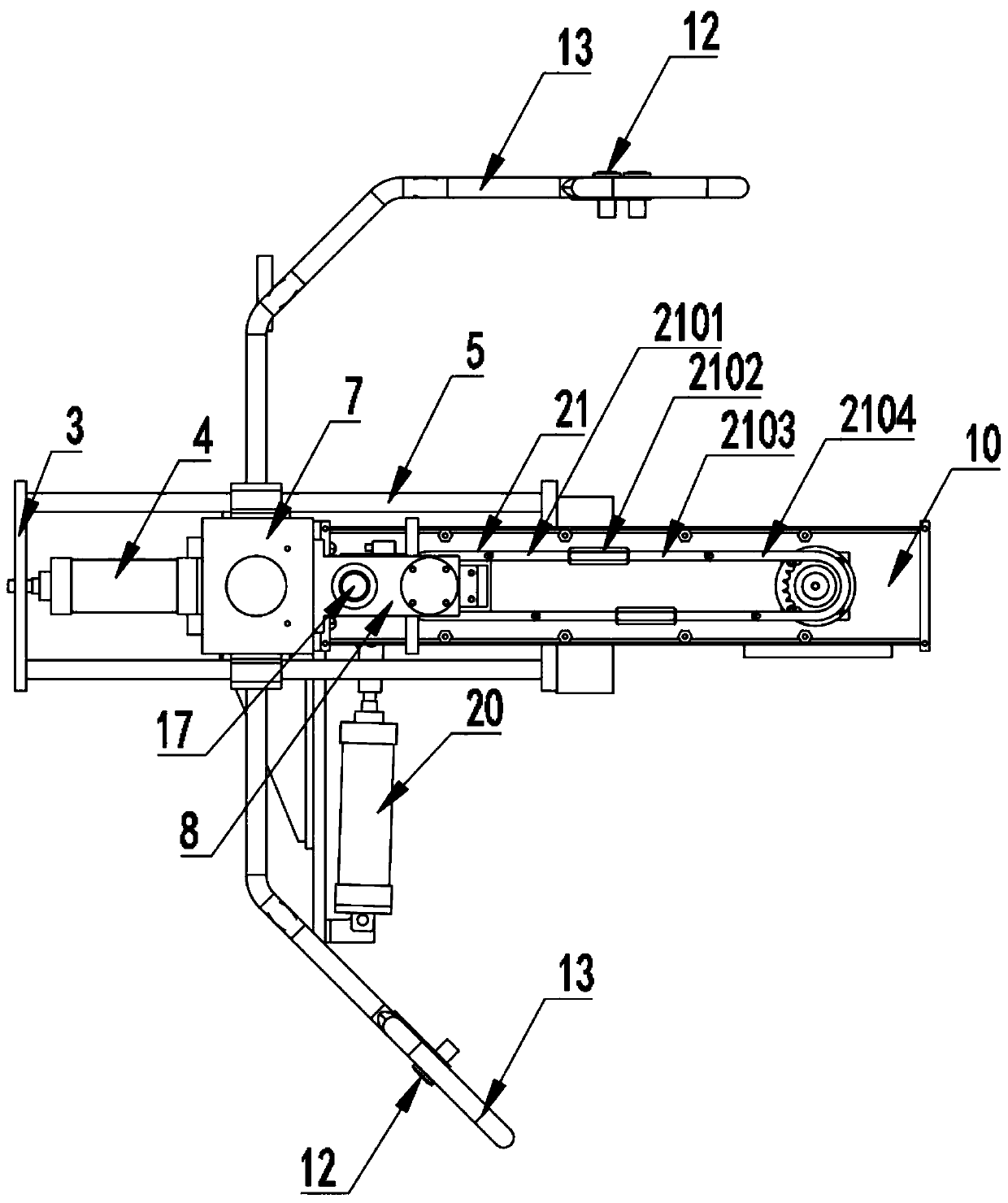

Pure pneumatic sand core full-automatic transferring sling

PendingCN110342395ARealize moving up and downAchieve positioningLoad-engaging elementsDrive shaftGraphite

The invention discloses a pure pneumatic sand core full-automatic transferring sling which comprises a hoisting ring, an overturning connecting rod and an opening-closing air cylinder, wherein the hoisting ring is fixedly arranged in the middle of the top side of a cross beam; positioning plate lifting air cylinders are arranged on the cross beam on the two sides of the hoisting ring; connecting plates are arranged at the top; sand core height positioning blocks are connected with the lower sides of the connecting plates through four guide pillars; two bearing pedestals are symmetrically arranged on the outer sides of the bottom wall of the cross beam;tips at the two ends of an overturning driving shaft and an opening-closing shaft are mounted on the inner sides of the bearing pedestals; and the overturning driving shaft is rotatably mounted; two graphite copper bush linear bearings are symmetrically arranged on the two side walls of the cross beam; and the four guide pillars are mounted in the graphite copper bush linear bearings in a sliding manner, so that the guide pillars can be effectively limited to prevent the guide pillars from deflected motion during the up-down moving process so as to avoid damage to the guide pillars.

Owner:十堰天凯模具制造有限公司

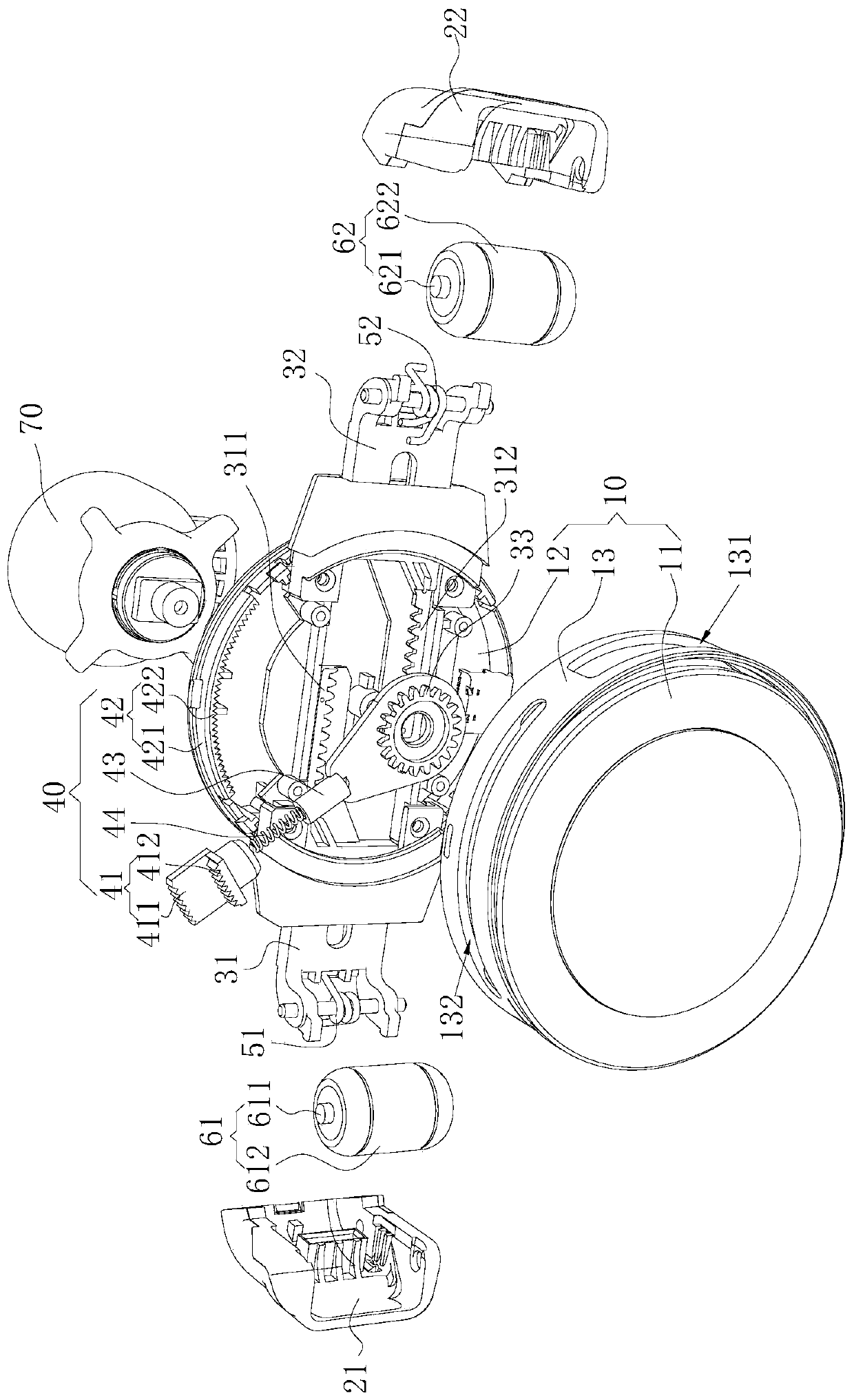

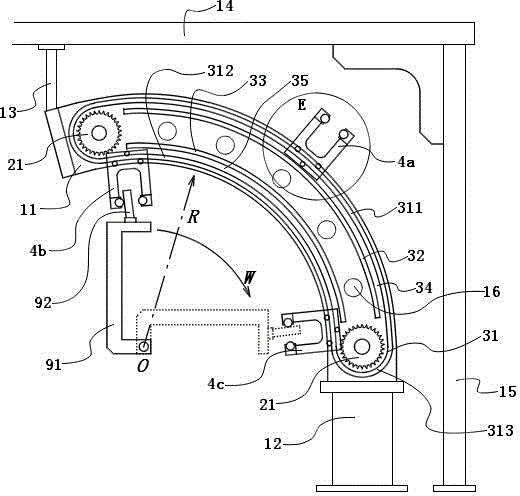

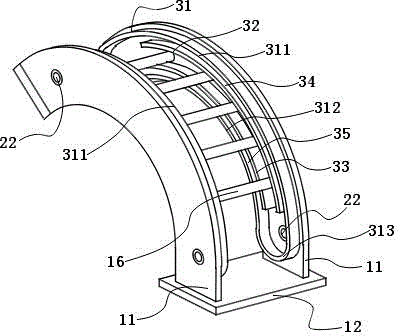

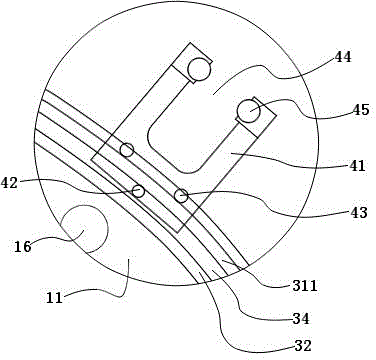

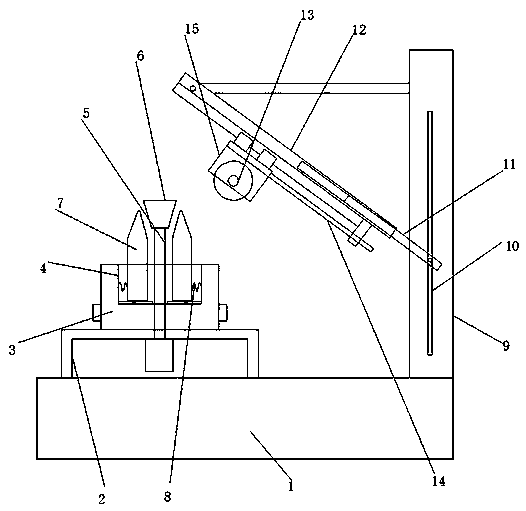

Cyclic type mold-clamping mechanism

InactiveCN104943028ARealize clamping operationCycle continuous mold clamping operationMechanical engineering

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

A distribution box with a cable clamping mechanism

ActiveCN113036624BStable automatic opening and closing operationStable opening and closing operationSubstation/switching arrangement detailsVertical planeClassical mechanics

Owner:山东万盛电气有限公司

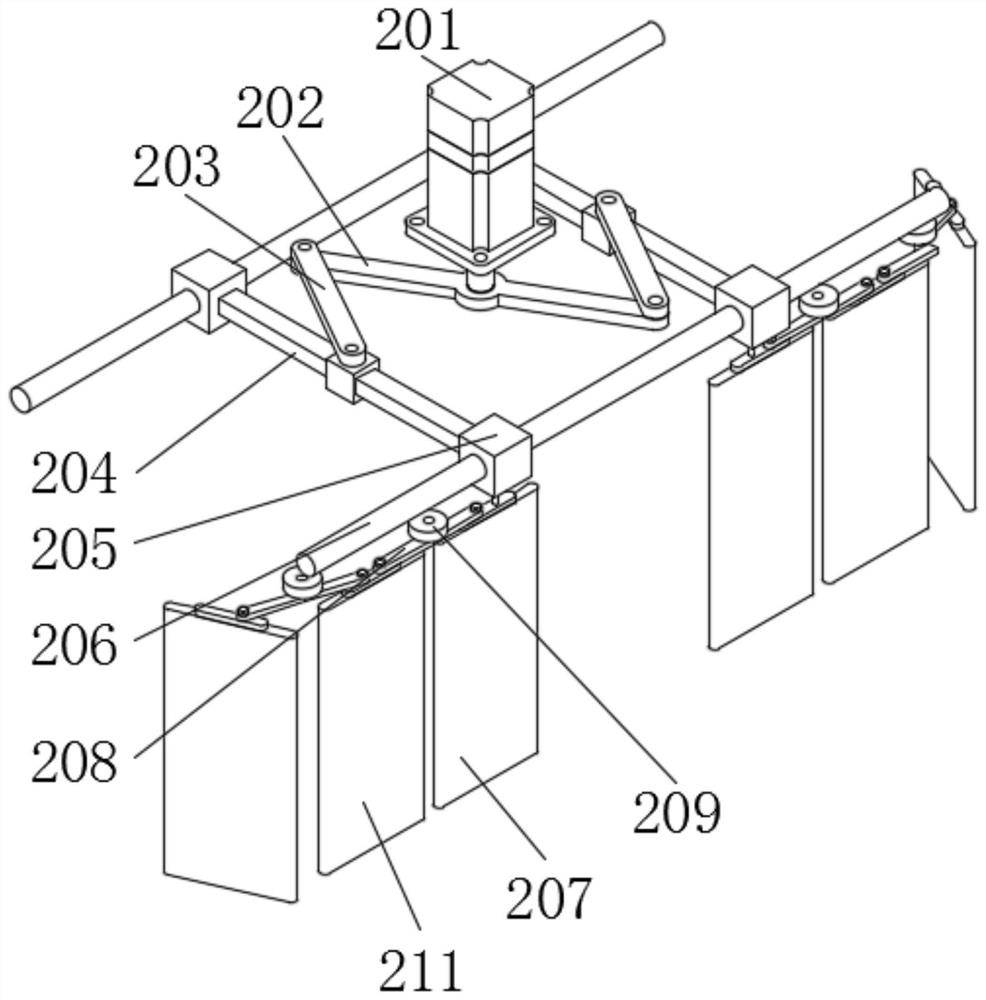

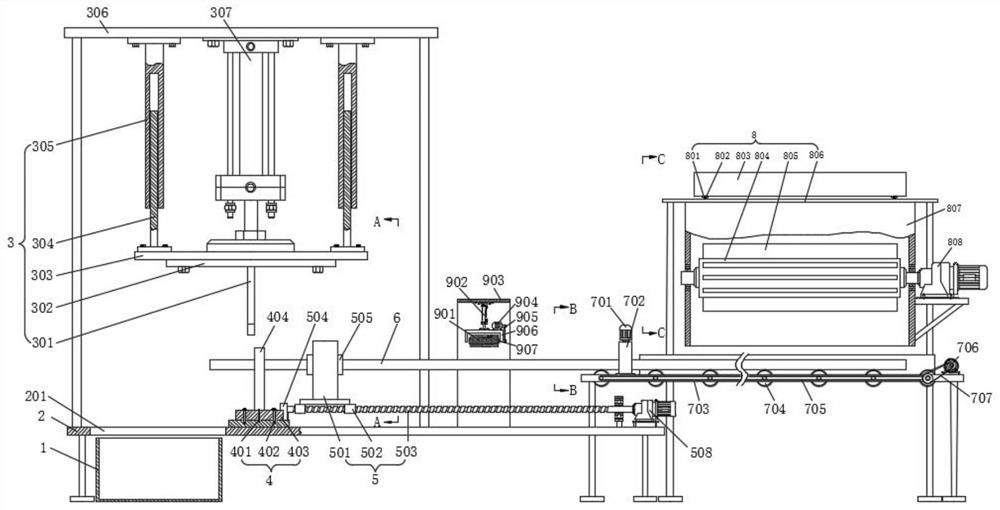

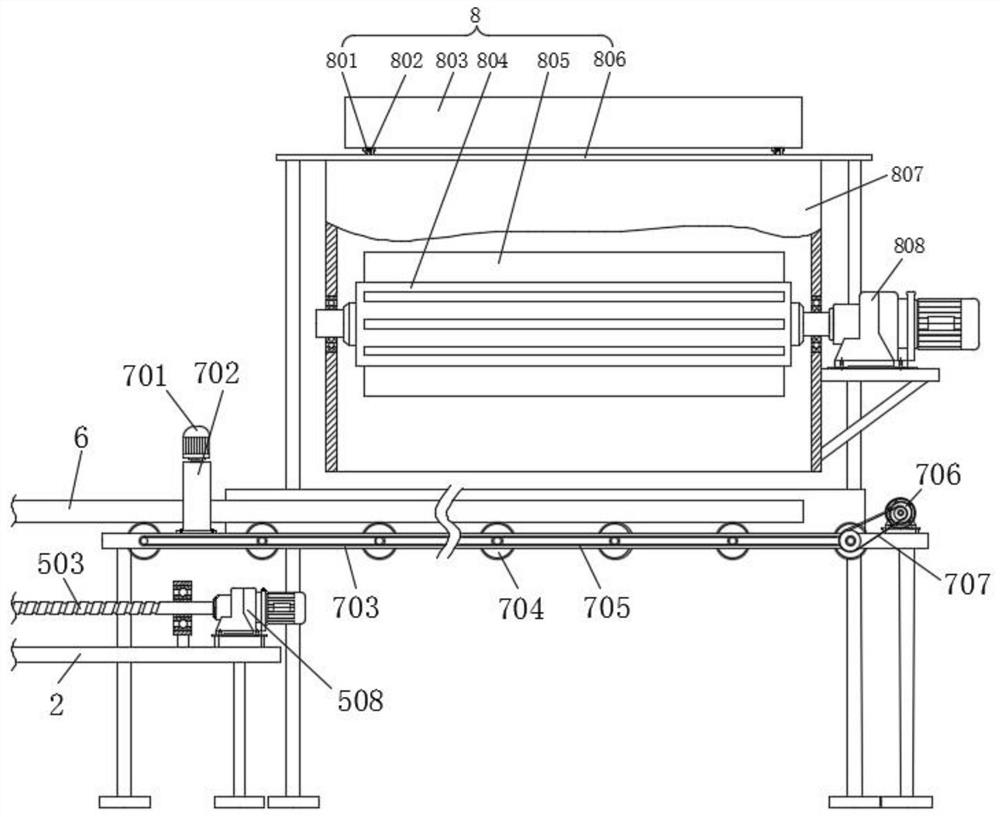

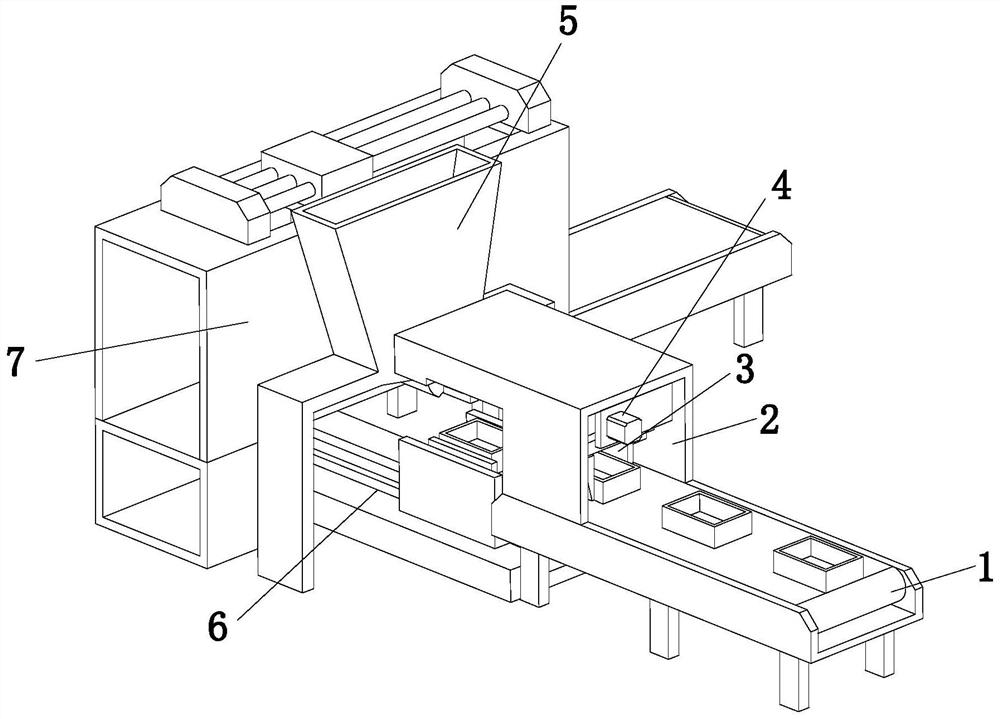

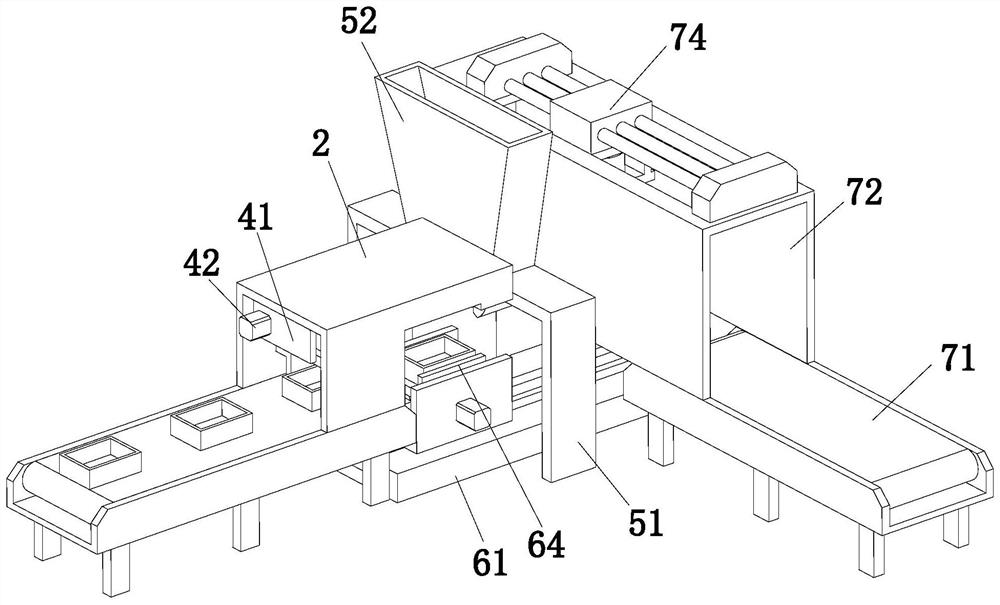

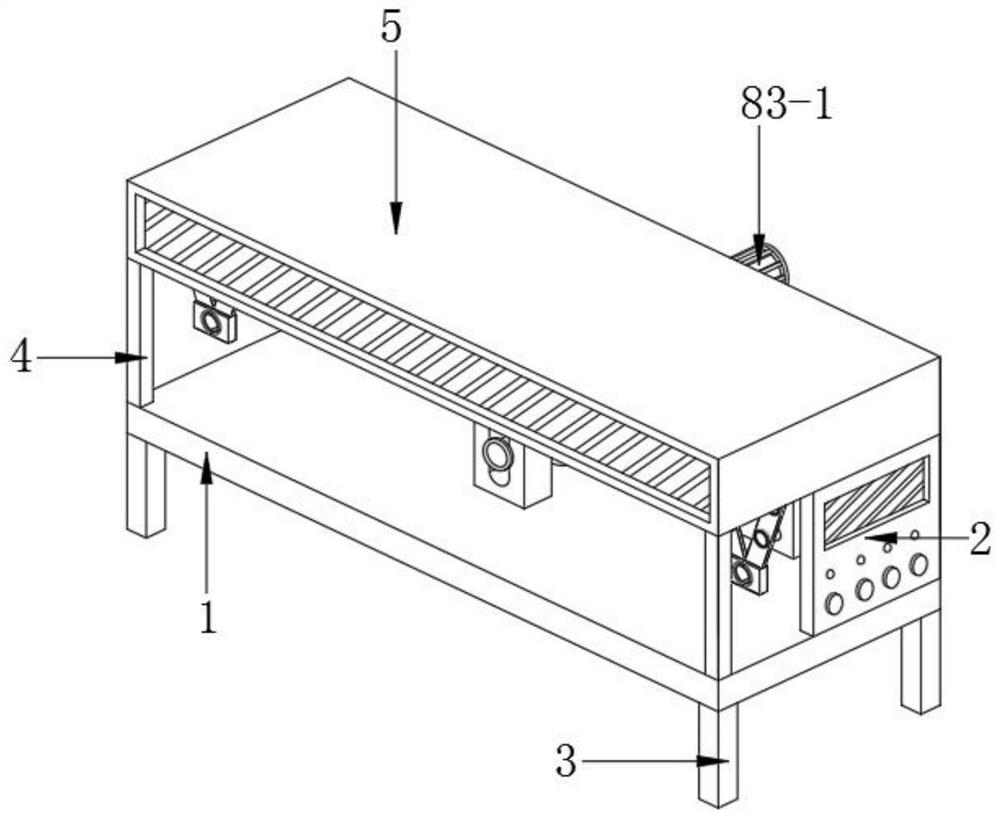

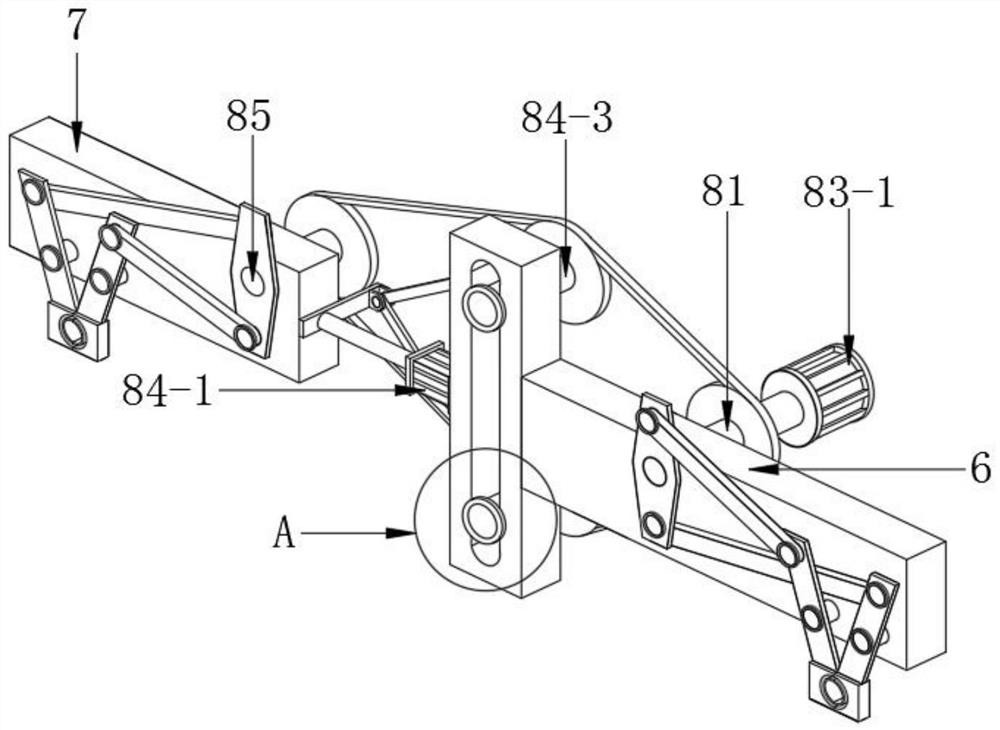

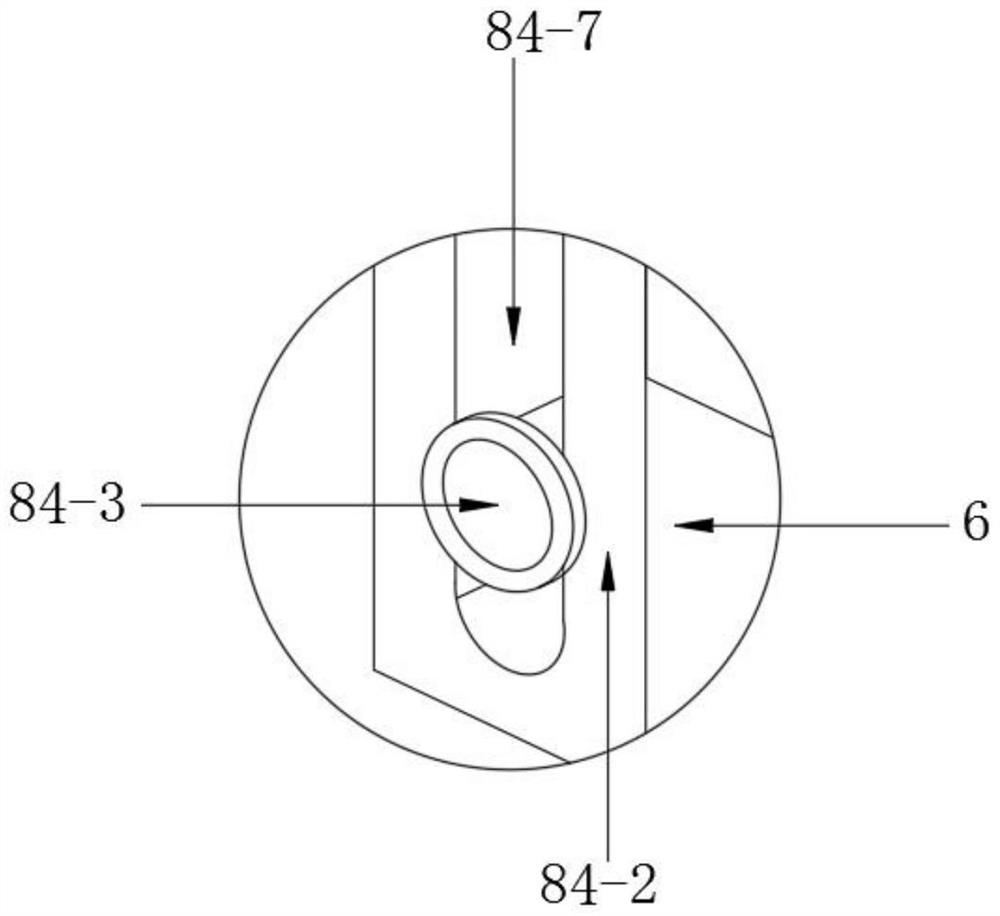

High-ductility cold-rolled straight reinforcing steel bar production system

The invention discloses a high-ductility cold-rolled straight reinforcing steel bar production system, and relates to the technical field of reinforcing steel bar production. The high-ductility cold-rolled straight reinforcing steel bar production system comprises a workbench, a lower cutting mechanism is arranged on the workbench, an upper cutting mechanism is arranged above the lower cutting mechanism, the upper cutting mechanism and the lower cutting mechanism cooperate to cut reinforcing steel bars, and a clamping mechanism used for clamping the reinforcing steel bars is arranged on the side portion of the lower cutting mechanism. A deburring mechanism and a conveying mechanism are arranged on the side portion of the clamping mechanism, and a screening mechanism used for screening the reinforcing steel bars is arranged above the conveying mechanism. The high-ductility cold-rolled straight reinforcing steel bar production system meets the requirement of enterprises for automatic feeding operation of large-batch straight reinforcing steel bars, automatic cutting operation is achieved, the conveying efficiency is high, the cutting effect is good, and clamping is stable; and the screening part is arranged, subsequent conveying and cutting operation can be conducted only when straight straight reinforcing steel bars are screened out, the whole device is easy to repair and maintain, and the production and machining requirements of screening and conveying large-batch straight reinforcing steel bars are met.

Owner:湖南复星合力新材料有限公司

Clinical fallopian tube forceps for obstetrics and gynecology department

PendingCN114305595AAchieve angle fixationEasy to adjust the lengthSurgical pincettesObstetrical instrumentsForcepsGynecology department

The invention discloses a pair of clinical fallopian tube forceps for obstetrics and gynecology, and relates to the technical field of clinical obstetrics and gynecology. A rotating shaft; the forceps body is connected with the supporting frame and can move along the inner side of the supporting frame; a clamping block; a fixing assembly; a connecting assembly; a positioning assembly; the supporting frame can rotate through the rotating shaft, the two inner bodies installed on the supporting frame can be conveniently driven to move relatively, and clamping operation is achieved. The forceps body can move along the supporting frame and can be fixed through the fixing assembly, and the length of the fallopian tube forceps can be conveniently adjusted; the two tweezers bodies are connected through the connecting assembly, so that the two tweezers bodies are conveniently kept to move synchronously, and the length of the fallopian tube tweezers is accurately adjusted; the connecting assembly is further provided with a positioning assembly, the included angle between the two forceps bodies can be fixed, and use is convenient.

Owner:史淑慧

Network terminal communication connector

PendingCN114336145AStable pressing operationRealize control operationCouplings bases/casesStructural engineeringMechanical engineering

Owner:石超

Quick mounting handle of master-slave manipulator

A quick mounting handle of a master-slave manipulator comprises an auxiliary grip, a handle body, a clamping device, a safety locking device and a quick adjusting buckle, the handle body and the auxiliary grip form a gun shape and conform to ergonomics, holding operation is facilitated, discomfort cannot be brought to an operator in the operation process, the clamping device is arranged above the auxiliary grip through a fixing block, and the safety locking device is arranged on the clamping device. The clamping device is arranged between the clamping device and the auxiliary grip and used for controlling a mechanical slave hand transmission chain so that clamping and releasing of the mechanical slave hand clamp can be achieved, the safety locking device is arranged between the clamping device and the auxiliary grip and used for locking and releasing the clamping device, the situation that the mechanical slave hand clamp is opened and closed by mistake due to misoperation of an operator is avoided, and the quick adjusting buckle is arranged on the fixing block. The mounting handle and the mechanical wrist joint can be mounted and dismounted under the condition that no auxiliary tool is used, and maintenance is convenient.

Owner:陕西通世航精密机械有限公司

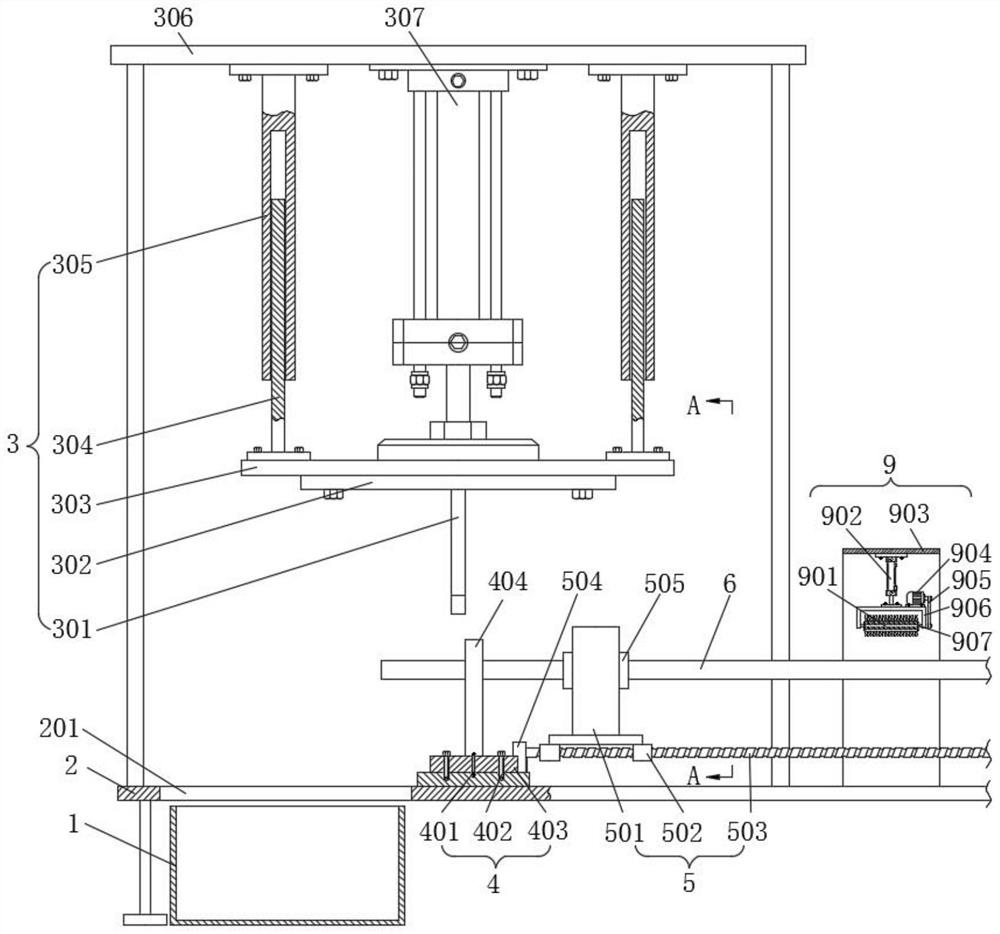

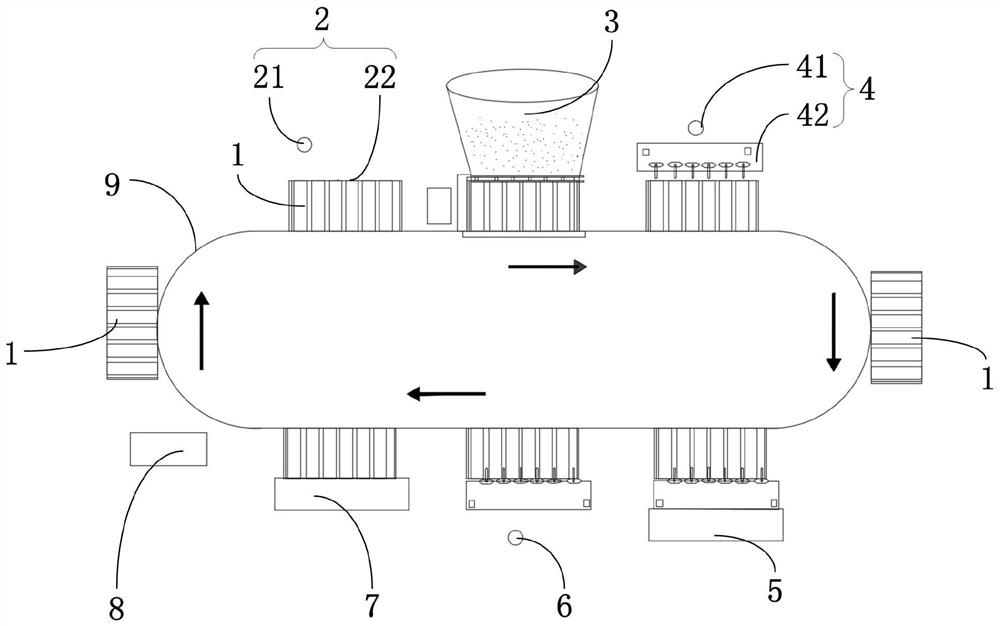

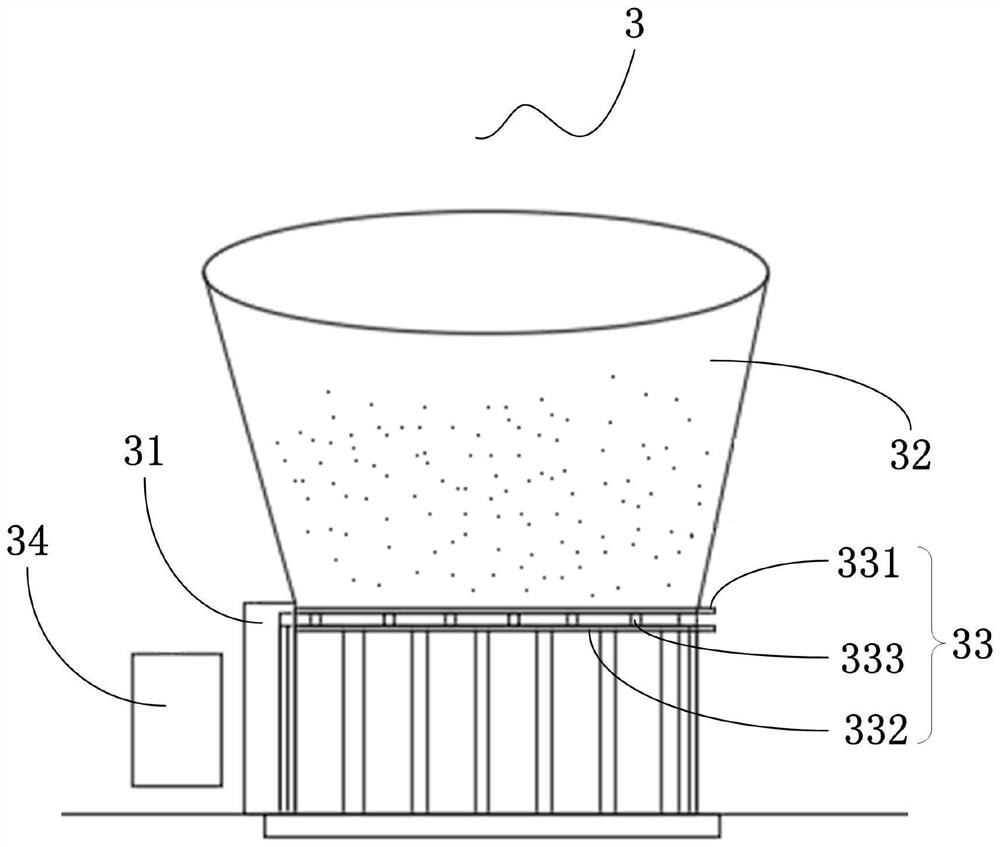

Oxygen sensor core automatic powder filling auxiliary device

PendingCN112372818ASimple structureReasonable designDischarging arrangementMouldsOxygen sensorEngineering

The invention discloses an oxygen sensor core automatic powder filling auxiliary device. The device comprises molds, a glue film feeding mechanism, a powder filling mechanism, a mold conveying and compounding mechanism, a mold vibration mechanism, a demolding mechanism, a residual powder vibration mechanism, an optical detection mechanism and a conveying mechanism. The conveying mechanism is of aclosed annular structure, and the molds are fixed on the conveying mechanism. The glue film feeding mechanism, the powder filling mechanism, the mold conveying and compounding mechanism, the mold vibration mechanism, the demolding mechanism, the residual powder vibration mechanism and the optical detection mechanism are sequentially arranged on the peripheral side of the conveying mechanism at intervals and correspond to the molds on the conveying mechanism. The device is simple in structure, reasonable in design, convenient to operate, high in automation degree and capable of effectively saving cost, reducing the labor intensity of operators, improving the production efficiency and reducing the space occupancy rate, and has good market application prospects.

Owner:东莞聚德寿科技有限公司

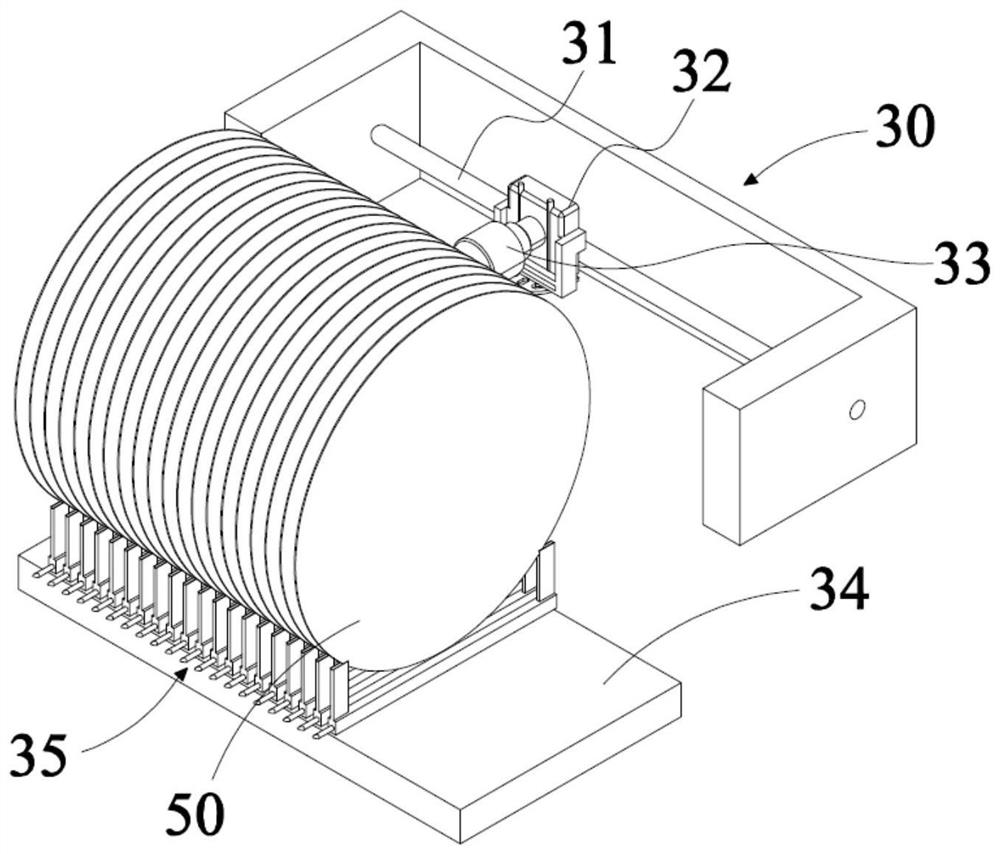

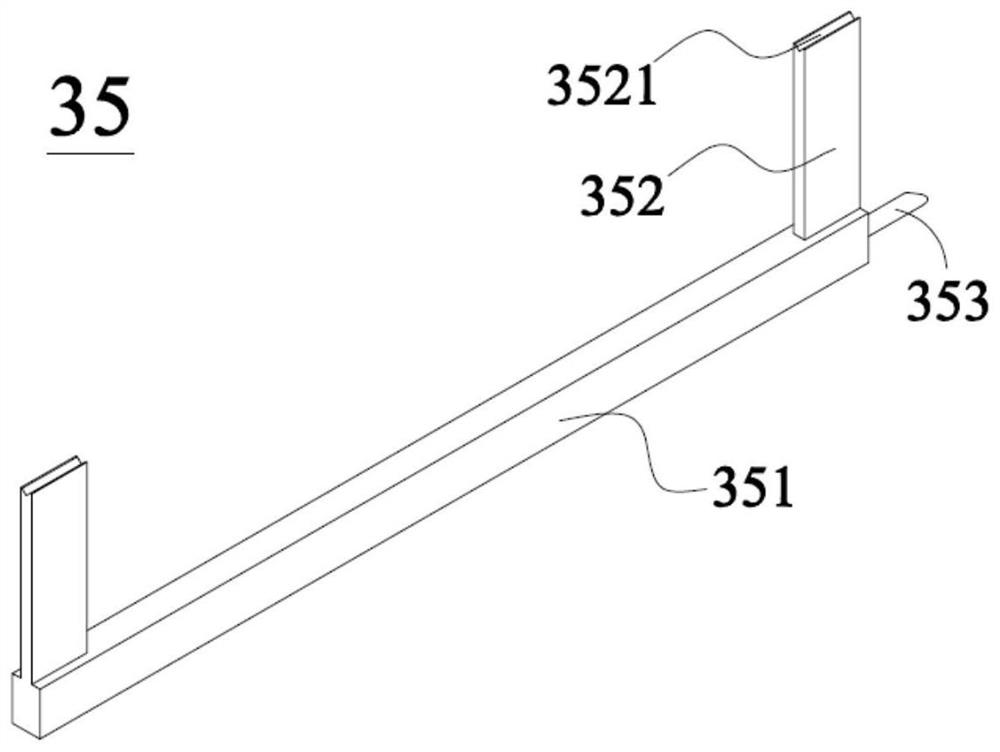

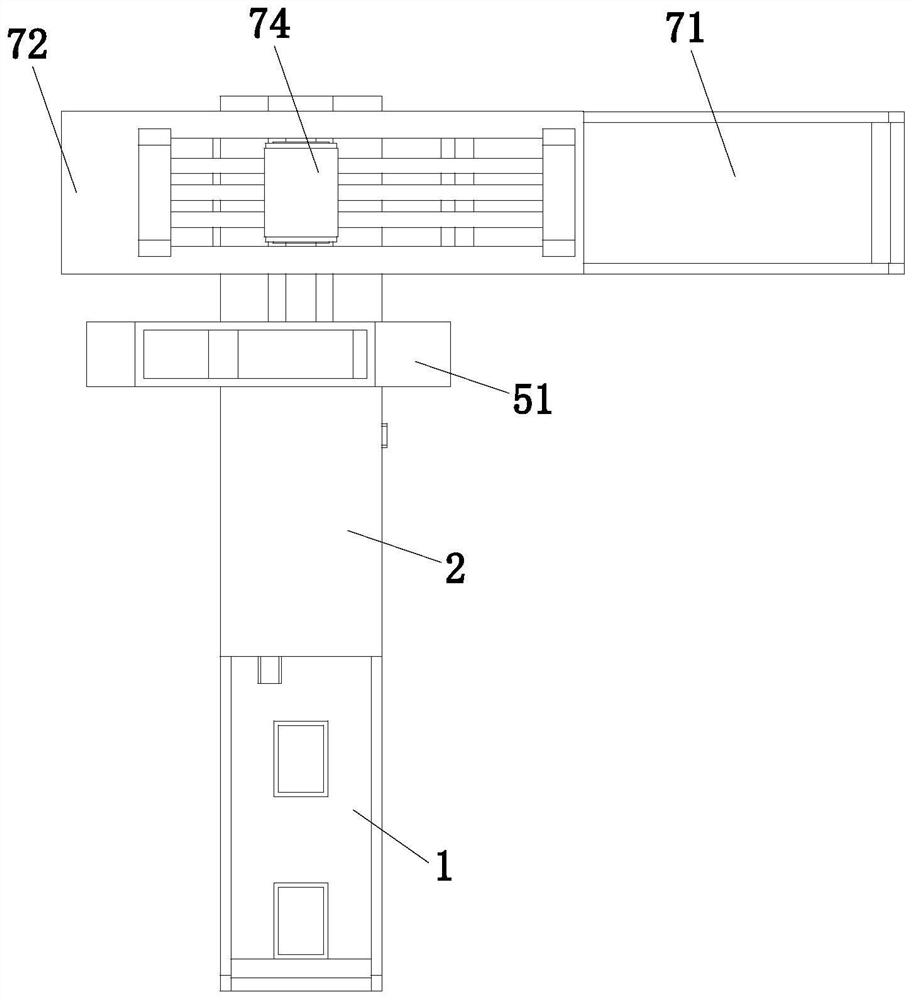

Loading device for nickel base alloy welding wire production

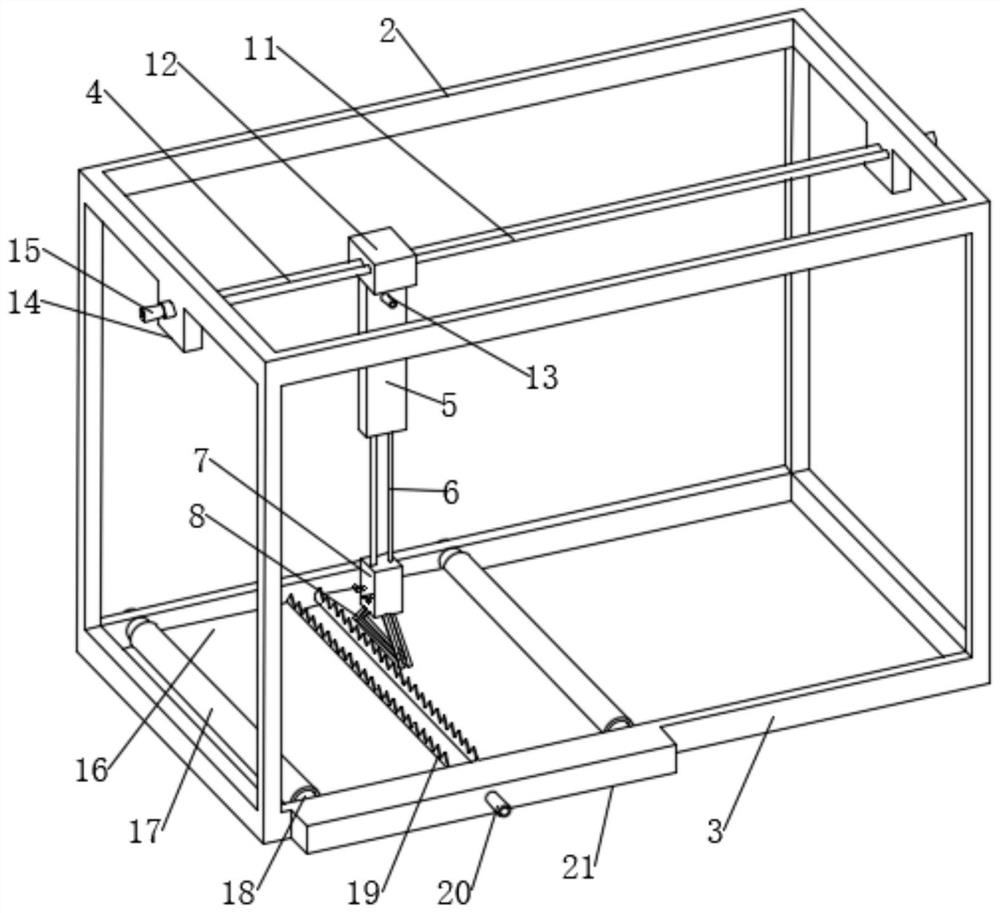

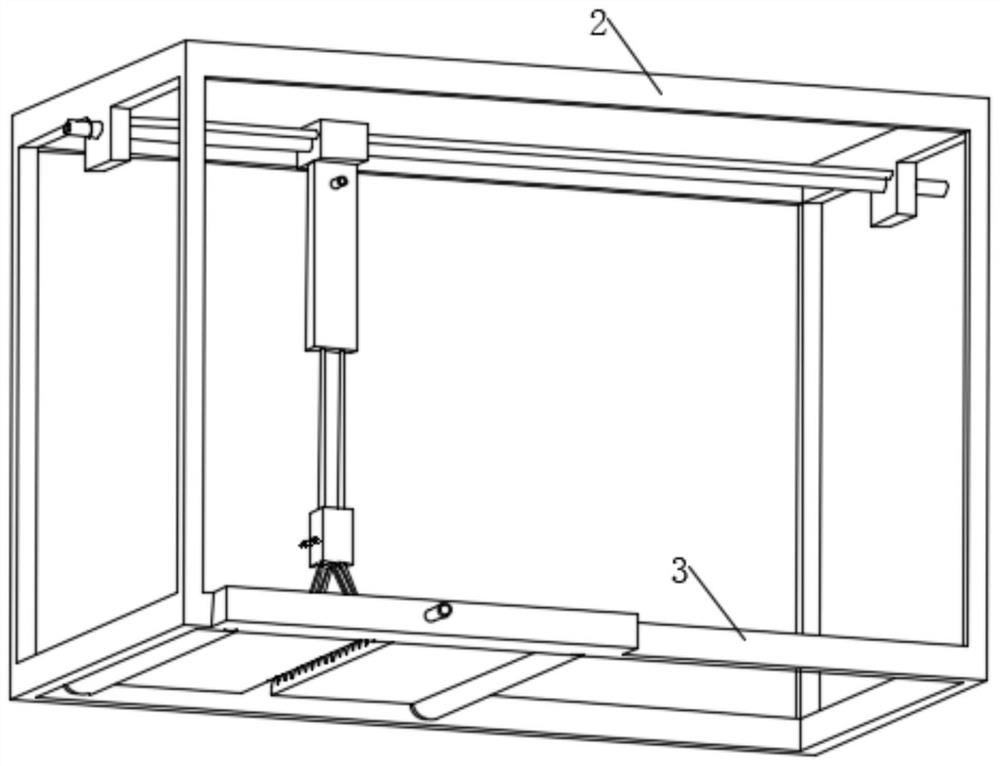

PendingCN114104418ARealize clamping operationMeet automatic transfer operationPackagingManufacturing engineeringPortal frame

The invention discloses a loading device for nickel-based alloy welding wire production, and belongs to the technical field of welding wire production equipment.The loading device comprises a packaging box feeding conveying belt, a portal frame, a limiting assembly, a moving assembly, a welding wire feeding assembly, a bearing assembly and a discharging assembly, and the portal frame is arranged between the packaging box feeding conveying belt and the welding wire feeding assembly; the two ends of the portal frame are connected with the packaging box feeding conveying belt and the welding wire supply assembly respectively, the limiting assembly is located in the portal frame and connected with the moving assembly, the moving assembly is installed on the inner top of the portal frame, and the bearing assembly is located between the packaging box feeding conveying belt and the discharging assembly. According to the welding wire loading and unloading device, the whole welding wire loading, transferring, loading and unloading integrated operation can be achieved, the automation degree is high, the practicability is high, the vibration effect of a packaging box is improved, the loading effect of the packaging box is improved, the phenomenon that the welding wire slides out of the packaging box is prevented, and the overall performance is further improved.

Owner:丹阳润泽新材料科技有限公司

Three-jaw turning tool for machining cuboid workpiece

ActiveCN112318176ARealize clamping operationImplement horizontal positioning operationsWork clamping meansPositioning apparatusPhysicsEngineering

The invention belongs to the technical field of turning tools, and particularly relates to a three-jaw turning tool for machining a cuboid workpiece. The tool comprises a main body of a cylindrical structure. A mounting groove of a rectangular structure is formed in one end of the main body, and a storage groove coaxial with the main body is formed in the end, stretching into the main body, of themounting groove. A positioning rod coaxial with the main body is fixedly connected to the inner side wall on the side, away from the mounting groove, of the storage groove, the outer ring of the end,away from the storage groove, of the positioning rod is fixedly sleeved with a fixing disc, transverse guide mechanisms symmetrically arranged along the positioning rod are hinged to the two sides ofthe outer ring of the fixing disc, and two vertical guide mechanisms which are symmetrically arranged along the positioning rod are mounted on the sides, close to each other, of two transverse guidemechanisms. With the three-jaw turning tool for machining the cuboid workpiece, eccentric rotation of a workpiece is effectively avoided, the amplitude of vibration of the workpiece due to eccentricity is reduced, the stability of the workpiece after being clamped for machining is improved, the workpiece clamping error is small, and meanwhile tool is suitable for positioning and clamping operationon workpieces of different sizes.

Owner:安徽士必达液压器材有限公司

Totally-enclosed garbage station with bag breaking robot

ActiveCN113911604ASolve the inconvenienceSolve the problem of separate classification of its internal garbageWaste collection and transferArticle unpackingComputer hardwareRefuse collection

The invention discloses a totally-enclosed garbage station with a bag breaking robot. The totally-enclosed garbage station comprises a garbage station body, a first garbage collecting box and a second garbage collecting box which are adjacently arranged are arranged in the garbage station body, clamping plates for clamping garbage bags are further arranged in the garbage station body, and a bag breaking mechanism used for breaking the bottoms of the garbage bags clamped on the clamping plates is arranged below the clamping plates. In order to solve the problem that garbage bags in a garbage station are inconvenient to separate and classify from garbage in the garbage bags, the bag breaking mechanism is arranged and can break the bags from the bottoms of the garbage bags, and the garbage falls into the first garbage collecting box below a baffle to be stored while the bags are broken; and then the clamping plates are driven by a driving mechanism to clamp the garbage bags to move to the position above the second garbage collecting box, the garbage bags are thrown into the second garbage collecting box to be stored, and the purpose of separating the garbage from the garbage bags is achieved.

Owner:安徽智湘环境科技有限公司

Multipurpose clamp device for bonded cable sample

InactiveCN109109072AReasonable designIncrease frictionPreparing sample for investigationMetal working apparatusEngineeringKnife blades

The invention discloses a multipurpose clamp device for a bonded cable sample. The multipurpose clamp device comprises a cutting knife fixing hole, a multipurpose knife rest, a dissecting knife fixinghole, a cutting knife, a screw rod knob, a screw rod, a screw rod fixing block, an opposite-dissecting knife rest, a screw rod stop block, an opposite-dissecting knife rest and multipurpose knife rest fixing holes, an opposite-dissecting knife fixing block and an opposite-dissecting knife blade. The multipurpose clamp device for the bonded cable sample has the beneficial effects that the design is reasonable, the screw rod knob and one end of the screw rod are fixed together, moreover, the screw rod knob and the screw rod are located on the same axis, the screw rod is rotated, the screw rod fixing block and the opposite-dissecting knife fixing block are fixed together, the opposite-dissecting knife fixing block is arranged in a T-shaped groove of the opposite-dissecting knife rest, the opposite-dissecting knife fixing block is in sliding fit with the T-shaped groove, the height of the opposite-dissecting knife blade is controlled, the opposite-dissecting knife blade is fixed on the opposite-dissecting knife fixing block through bolts, so that the knife blade is convenient to replace, the opposite-dissecting knife rest is connected with the multipurpose knife rest through bolts, sothat the clamp is convenient to replace.

Owner:HENAN JIANYI TECH CO LTD

A gear milling machine capable of changing height

ActiveCN108687411BRealize clamping operationImprove clamping installation efficiencyGear-cutting machinesGear teethGear wheelManufacturing engineering

Owner:CHONGQING HANYUAN MACHINERY

Tool magazine pneumatic tool-clamping device for numerically-controlled machine tool

InactiveCN108747532ARealize clamping operationConducive to manual operationPositioning apparatusMetal-working holdersNumerical controlPneumatic tool

The invention discloses a tool magazine pneumatic tool-clamping device for a numerically-controlled machine tool. The tool magazine pneumatic tool-clamping device comprises a base. The base is provided with a support pillar, a horizontal beam plate is arranged on the top of the support pillar, a moving seat is installed on the horizontal beam plate in a sliding mode, a rotating shaft is connectedto the lower end of the moving seat, and a support arm is connected to the lower end of the rotating shaft. The rotating shaft is connected to the middle end of the support arm, sleeves are separatelyarranged at the left and right ends of the support arm, cavities are formed in the sleeves, extrusion rams are installed in the cavities in a sliding mode, and extrusion sheets are arranged at the end parts of the extrusion rams. The structure is simple, operation of tool-clamping is simple and convenient, and fixing of tools is firm and stable.

Owner:安徽申德精密机械有限公司

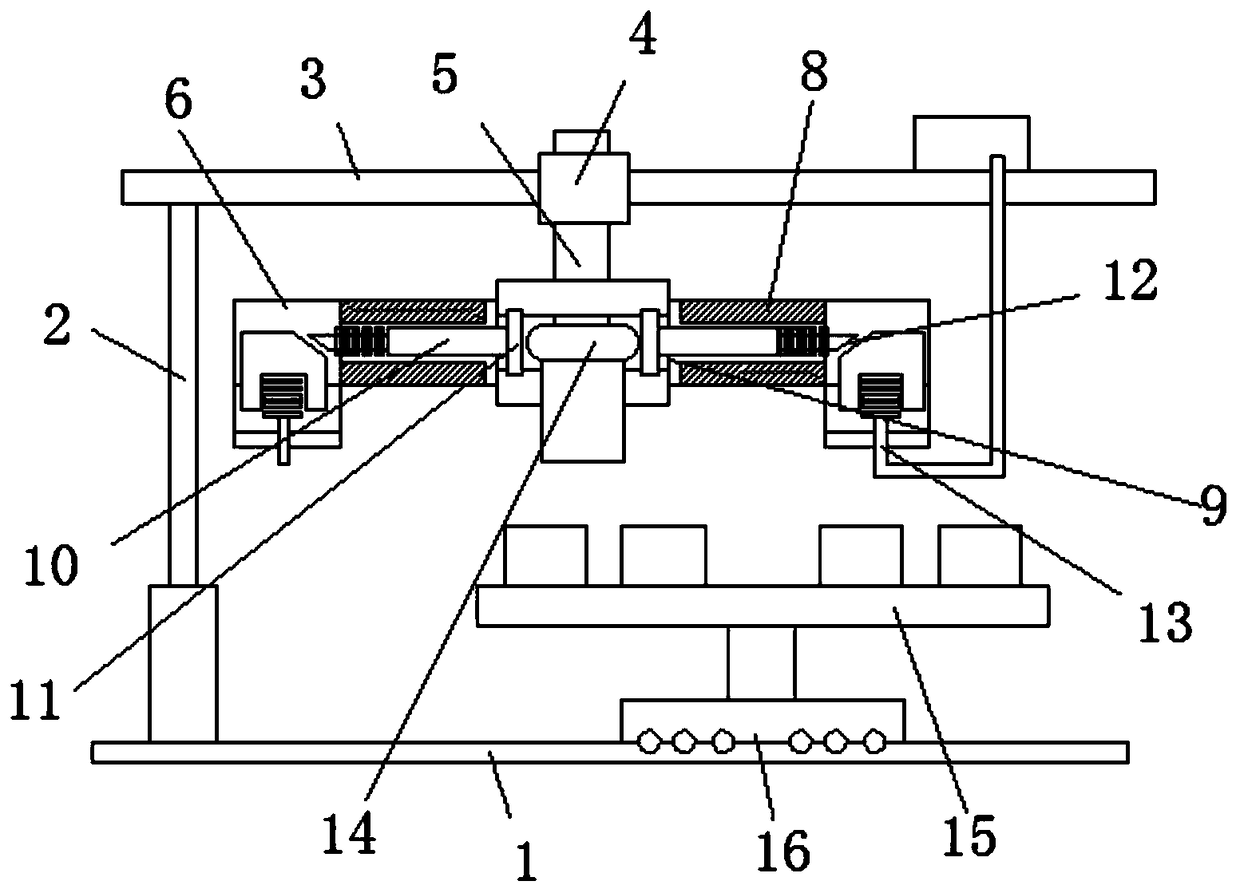

Impact resistance test equipment for single battery

InactiveCN111487127AAchieve fixationRealize different surface clampingStrength propertiesElectric machineryStructural engineering

The invention discloses impact resistance test equipment for a single battery. The test equipment comprises a bottom plate, and a lifting mechanism is mounted at the top end of the bottom plate; a motor sleeve is arranged above a top plate; a motor is arranged in the motor sleeve; the motor is fixedly connected with the top plate through the motor sleeve; the bottom end of a first threaded rod ismovably connected with the bottom plate through a bearing; the top end of the first threaded rod is movably connected with the top plate through the bearing; a plurality of vertical rods are evenly arranged on the outer side of the first threaded rod, the top ends of the multiple vertical rods are fixedly connected with the lower surface of the top plate, the bottom ends of the multiple vertical rods are fixedly connected with the upper surface of the bottom plate, the first threaded rod is in threaded connection with a lifting sleeve, and the lifting sleeve is slidably connected with the multiple vertical rods in a sleeving mode. According to the special-surface clamping device of the single battery impact resistance test equipment, the special-surface position of the storage battery canbe effectively fixed, so that special-surface clamping is realized, the time required for clamping is saved, and the working efficiency is further improved.

Owner:东莞质研工业设计服务有限公司

A new energy vehicle battery fixing device

ActiveCN113285164BGuaranteed stabilityRealize clamping operationElectric propulsion mountingCell component detailsAutomotive batteryNew energy

Owner:深圳市小樱桃实业有限公司

Tooling for machining cuboid workpiece with three-jaw turning

ActiveCN112318176BRealize clamping operationAvoid eccentric rotationWork clamping meansPositioning apparatusStructural engineeringIndustrial engineering

The invention belongs to the technical field of turning tooling, in particular a tooling for three-jaw turning of a cuboid workpiece. The following proposal is now proposed, comprising a main body with a cylindrical structure, and one end of the main body is provided with a mounting groove of a rectangular structure, and the mounting groove One end protruding into the main body is provided with a storage groove coaxial with the main body, the inner wall of the storage groove away from the installation groove is fixed with a positioning rod coaxially arranged with the main body, and the positioning rod is far away from the end of the storage groove The outer ring is fixedly sleeved with a fixed plate, and the two sides of the outer ring of the fixed plate are hinged with lateral guide mechanisms arranged symmetrically along the positioning rods. Set vertical guide mechanism. The invention effectively avoids the eccentric rotation of the workpiece, reduces the vibration amplitude of the workpiece due to eccentricity, improves the stability of the workpiece clamped after processing, reduces the clamping error of the workpiece, and is suitable for the positioning and clamping operation of workpieces of different sizes.

Owner:安徽士必达液压器材有限公司

Intelligent automatic test system based on low-frequency circuit and test method thereof

PendingCN114325313AReduce lossAvoid direct contactElectronic circuit testingHemt circuitsEngineering

The invention discloses an intelligent automatic test system based on a low-frequency circuit and a test method thereof, the system comprises a test board, the surface of the test board is provided with a control panel, the bottom of the test board is fixedly connected with a bottom frame, and the diagonal position of the top of the test board is fixedly provided with a test box through a support frame, and the invention relates to the technical field of circuit test. According to the intelligent automatic test system based on the low-frequency circuit and the test method thereof, a circuit clamping mechanism is arranged, a cylinder is utilized to drive a piston rod to move, and the piston rod drives a connecting rod and a moving plate to move, so that a rotating rod between a first rotating block and a second rotating block is driven to rotate; according to the device, the two movable rotating shafts are driven to slide in the movable grooves, so that clamping points for testing can be adjusted, transmission clamping can be synchronously realized, the energy loss is reduced, meanwhile, direct contact of personnel is avoided, and the testing safety is enhanced.

Owner:杭州仁牧科技有限公司

Multifunctional clamp for industrial robot

InactiveCN112356061ARealize clamping operationImprove applicabilityGripping headsStructural engineeringIndustrial robotics

The invention discloses a multifunctional clamp for an industrial robot, relates to the technical field of industrial robots, and aims to solve the problems that in the prior art, various kinds of clamps are used by an existing industrial robot, but each clamp has a certain limit requirement on the working range of the clamp itself, and once the working limit is exceeded, it is requested to replace the present clamp with clamps of other specifications. Groove body clamping plates are arranged on the inner sides of a first metal clamping rod and a second metal clamping rod, and are connected with the first metal clamping rod and the second metal clamping rod through screws, and side edge hinge plates are arranged at the bottoms of the first metal clamping rod and the second metal clamping rod and are fixedly connected with the first metal clamping rod and the second metal clamping rod; and inward rotating grooves are formed in the inner sides of the side edge hinge plates, flattening movable shaft blocks are arranged in the inward rotating grooves, clamping rod limiting grooves are formed in the outer surfaces of the side edge hinge plates, and shaft block limiting grooves are formed in the outer surfaces of the flattening movable shaft blocks.

Owner:苏州市渤华科技研发有限公司

Environment-friendly printer selenium drum

PendingCN114002929AEasy to fixReduce wearElectrographic process apparatusComputer printingEngineering

The invention relates to an environment-friendly printer selenium drum. The environment-friendly printer selenium drum comprises a toner bin box body and sliding assemblies; a waste toner bin box body is arranged at the top of the toner bin box body, a protective cover is arranged on the front face of the toner bin box body, mounting plates are arranged at the two ends of the toner bin box body; and the sliding assemblies are arranged at the two ends of the waste toner bin box body. According to the environment-friendly printer selenium drum, the sliding assemblies are arranged, the operation that a sleeve rod drives a photosensitive drum to move can be achieved; the photosensitive drum does not contact with a charging roller and a magnetic roller when the photosensitive drum is not used, so that abrasion of the photosensitive drum can be reduced, and therefore the service life of the photosensitive drum is prolonged; a rotating assembly is adopted, an adjusting block can be rotated, so that rotation of two rotating plates can be achieved, the rotating plates can achieve mutual clamping of the toner bin box body and the waste toner bin box body through clamping blocks, meanwhile, rapid limiting of the magnetic roller can be achieved; and a clamping assembly is arranged, clamping operation of an information board can be achieved through the clamping assembly, and the whole clamping operation process is very simple.

Owner:珠海天安华泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com