Pure pneumatic sand core full-automatic transferring sling

A fully automatic, sand core technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of cumbersome operation, hoisting shaking, low intelligent operation, etc., achieve accurate transmission, high stability and strength, and improve convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

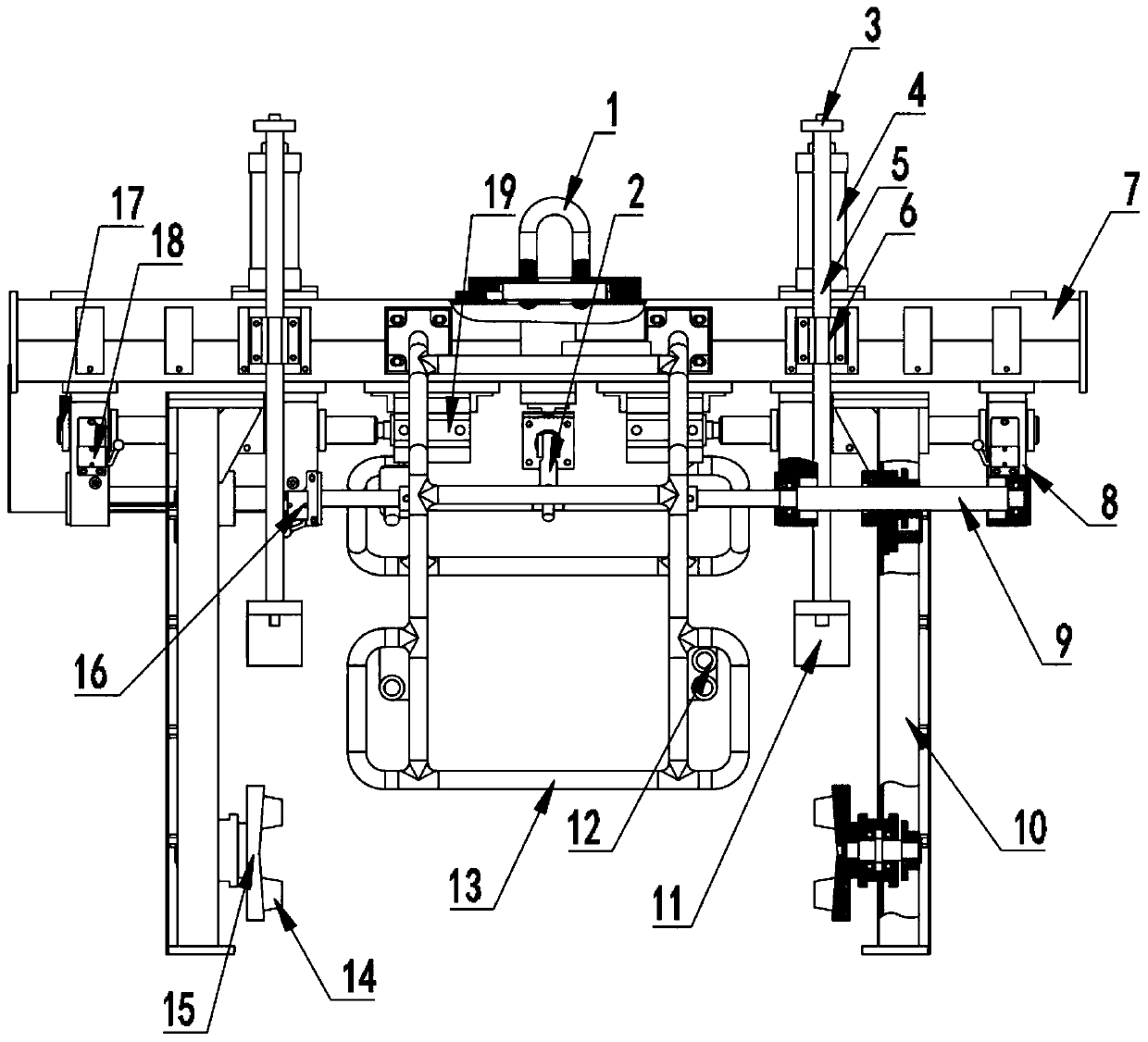

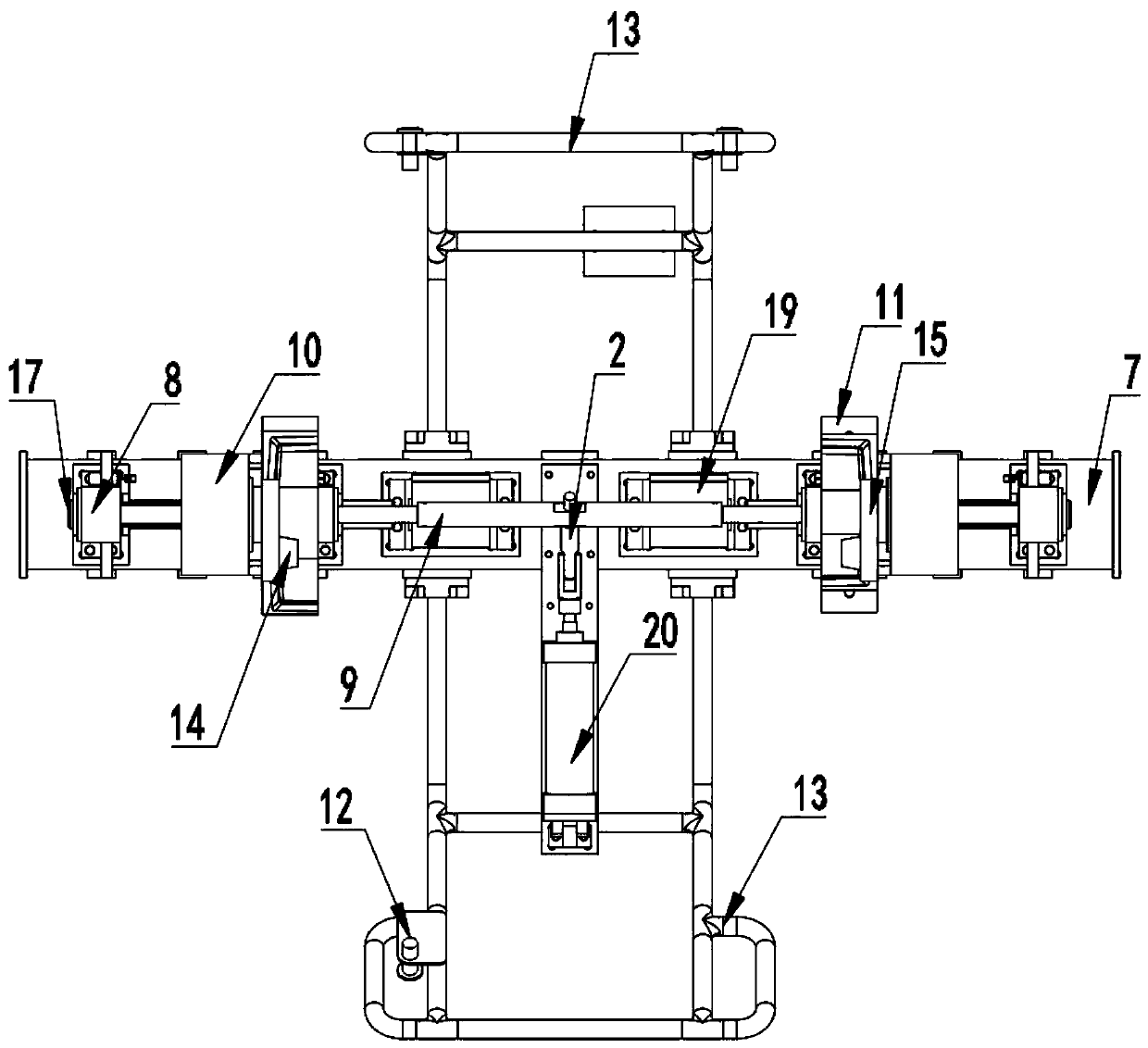

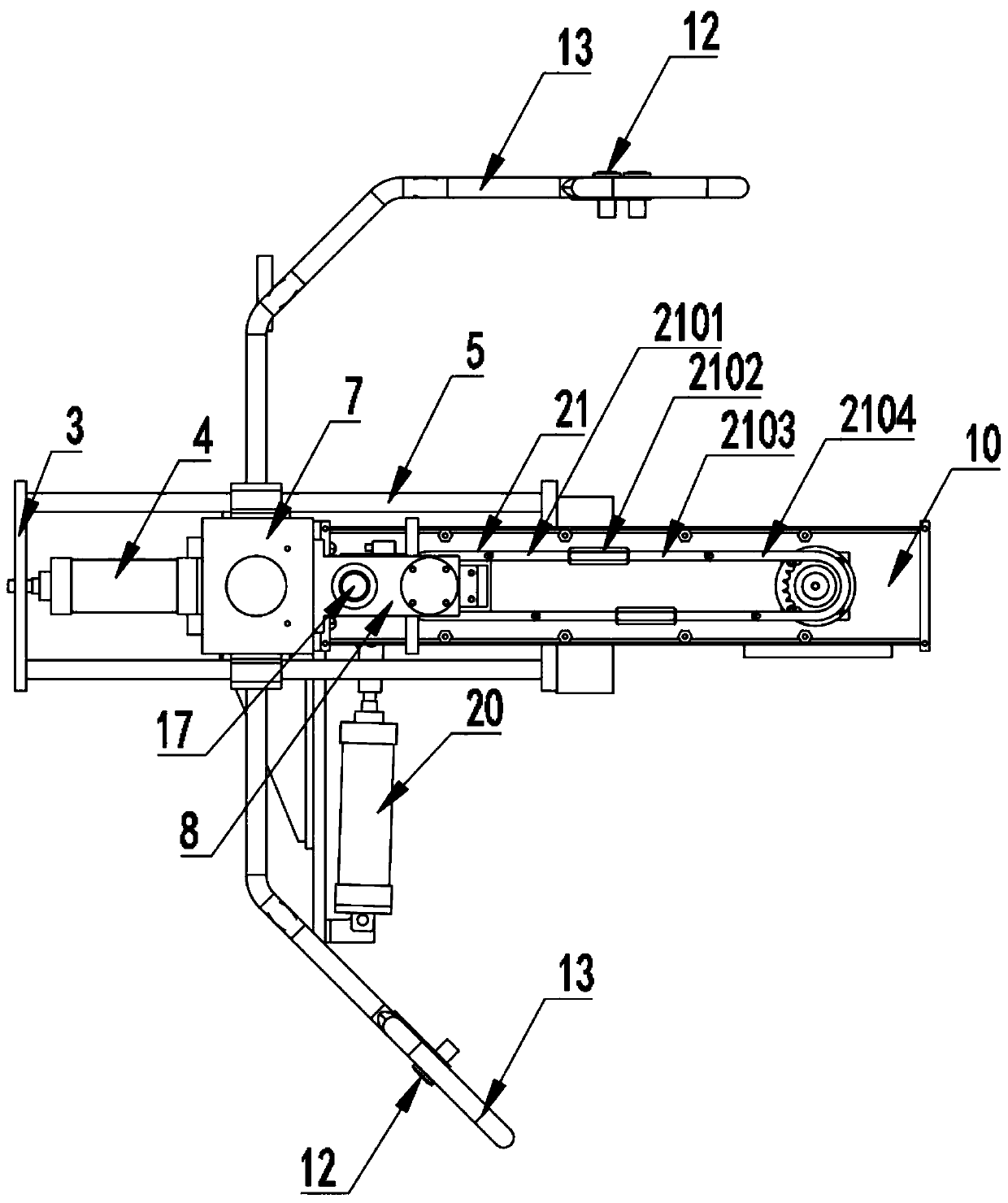

[0034] as attached figure 1 to attach image 3 Shown:

[0035] The invention provides a purely pneumatic sand core automatic transfer hoist, including: a lifting ring 1, a flip connecting rod 2, a connecting plate 3, a positioning plate lifting cylinder 4, a guide column 5, a graphite copper sleeve linear bearing 6, and a girder 7. Bearing seat 8, turning drive shaft 9, moving arm 10, sand core height positioning block 11, control button 12, armrest frame 13, sand core positioning block 14, sand core clamping plate 15, positioning plate lifting sensor 16, The opening and closing shaft 17, the clamping plate opening sensor 18, the opening and closing cylinder 19, the turning cylinder 20, the drive chain 21, the normal wire connecting screw 2101, the positive and negative wire connecting nut 2102, the reverse wire connecting screw 2103 and the chain 2104; the girder 7 is fixedly provided with a hoisting ring 1 at the middle position of the top side; the girder 7 on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com