Gas turbine

a technology of gas turbine and turbine blade, which is applied in the direction of reaction engines, hot gas positive displacement engine plants, non-positive displacement engines, etc., can solve the problems of inability to convert the greater part of high-temperature high-pressure gas spurting from the combustion chamber into a rotational force, the efficiency of the turbine rotational energy conversion is very low, and the gas flow resistance can be reduced. , the effect of improving the efficiency of the turbine rotational energy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Problem

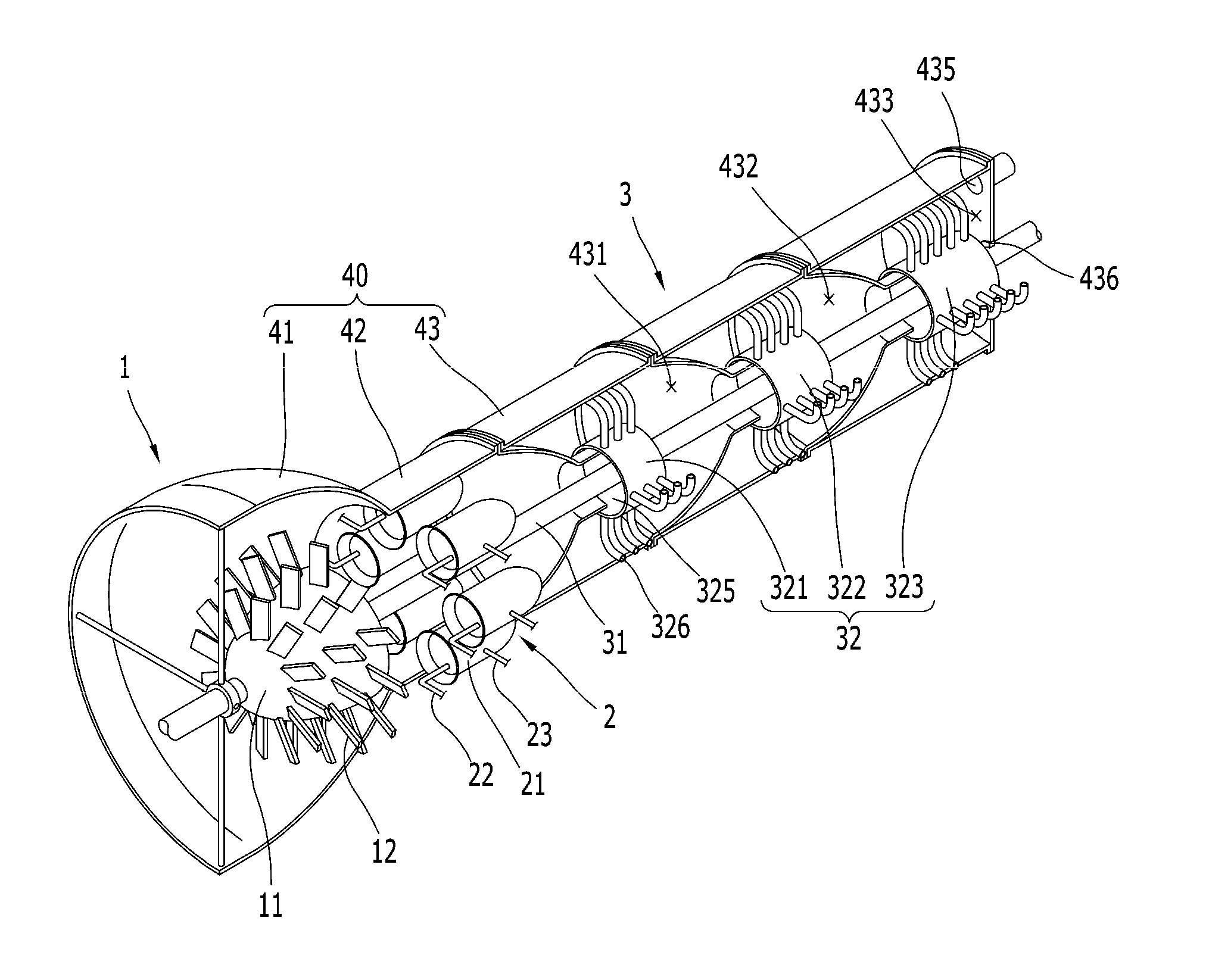

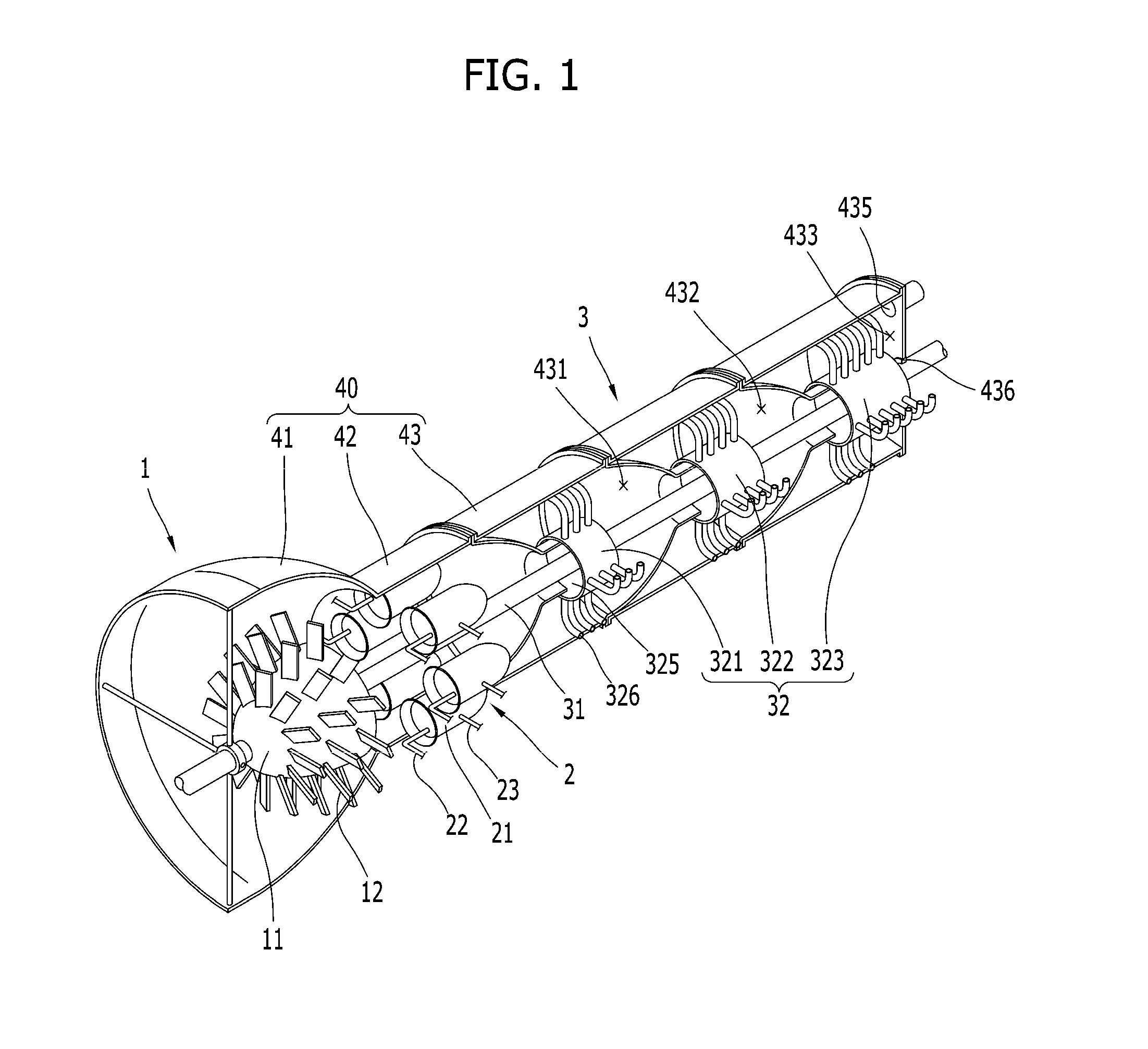

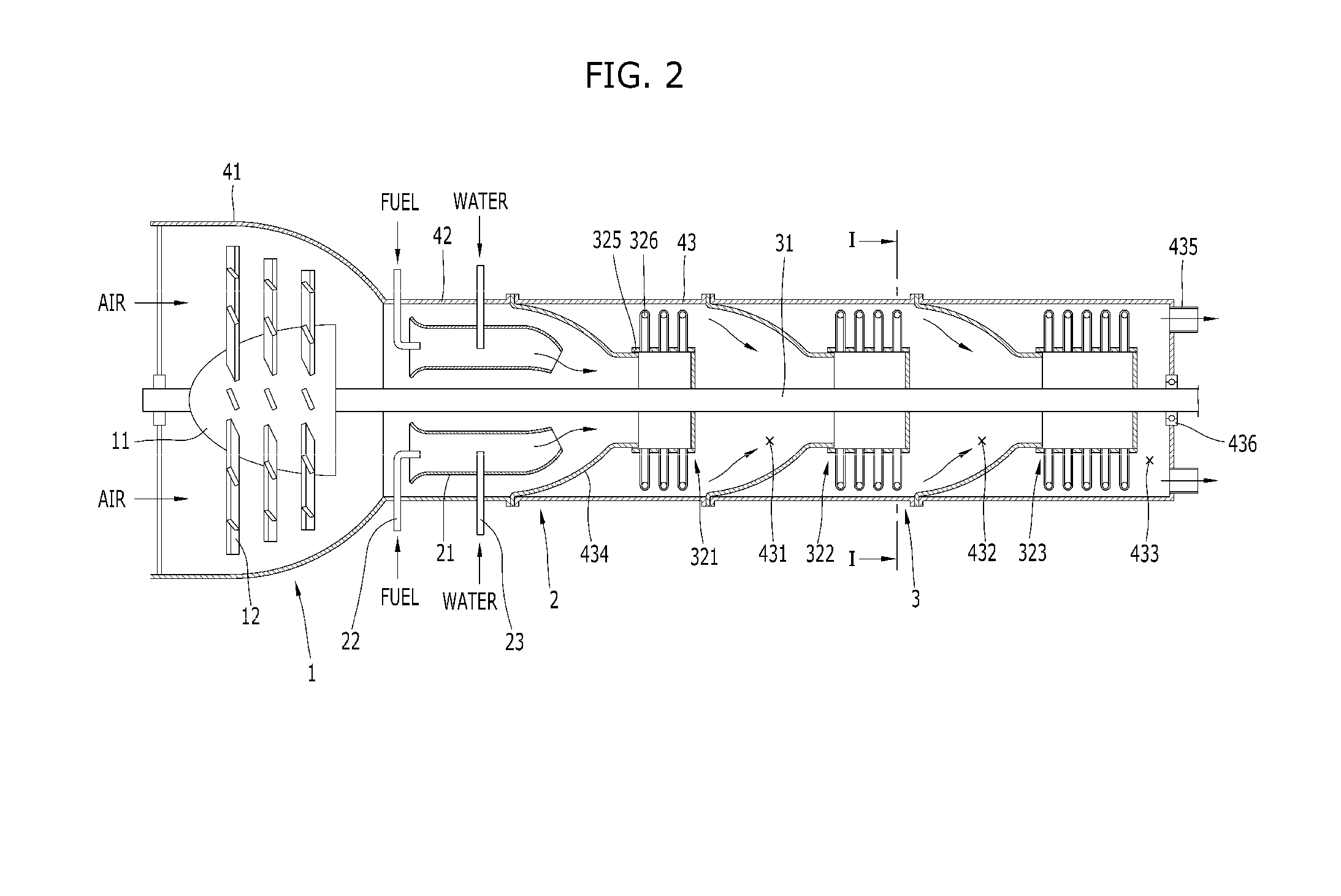

[0009]The present invention provides a gas turbine that is capable of improving thermal efficiency of a turbine for power generation by converting energy of an exhaust gas into rotational energy at a high rate if possible.

[0010]The present invention also provides a gas turbine that is capable of easily manufacturing a turbine having high efficiency by simplifying factors for determining the momentum caused by a gas.

[0011]The present invention also provides an innovative gas turbine that is capable of forming a turbine in multiple stages and reducing the temperature of a combustion gas so as to convert energy of an exhaust gas into a rotational force and that is capable of improving thermal efficiency of the gas turbine even though the temperature of the exhaust gas is remarkably reduced.

Technical Solution

[0012]According to an aspect of the present invention, there is provided a gas turbine including: a gas expansion part that expands gas; a power generation part tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com