Chip breaking structure of reducing position cutting edge of stepped drill

A cutting edge and stepped drilling technology, which is applied in the direction of stepped drilling, boring machine/drilling machine parts, drilling repair, etc., can solve the problems of scratching the hole wall chips, entanglement, and continuous chips, so as to improve the degree of brittleness and reduce the hardness. Toughness and plasticity, the effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and technical solutions.

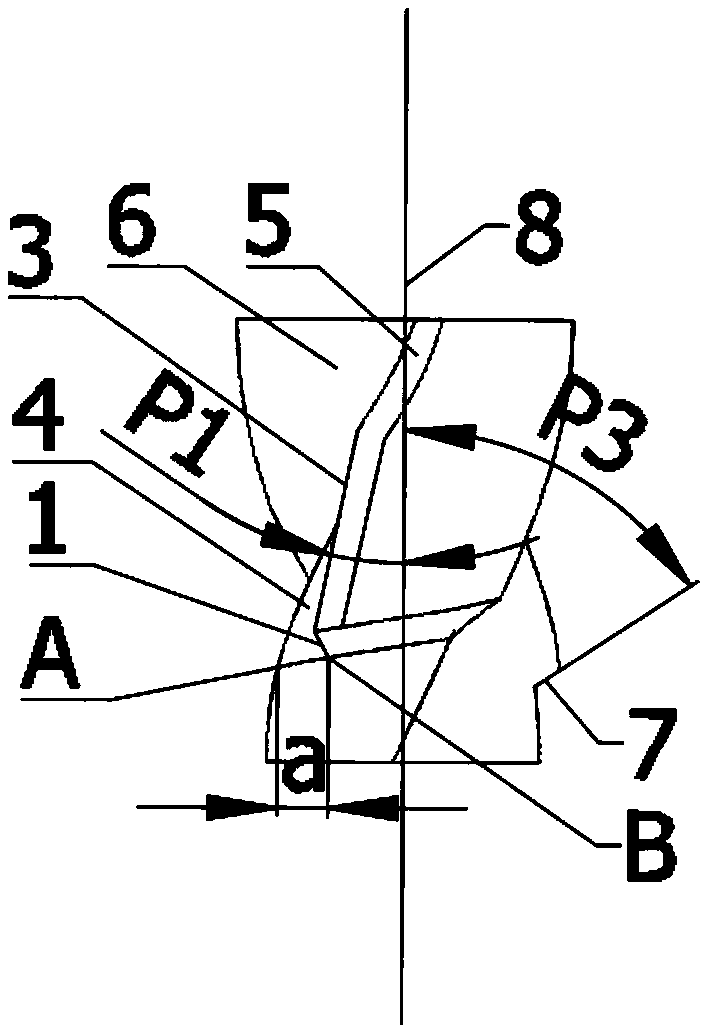

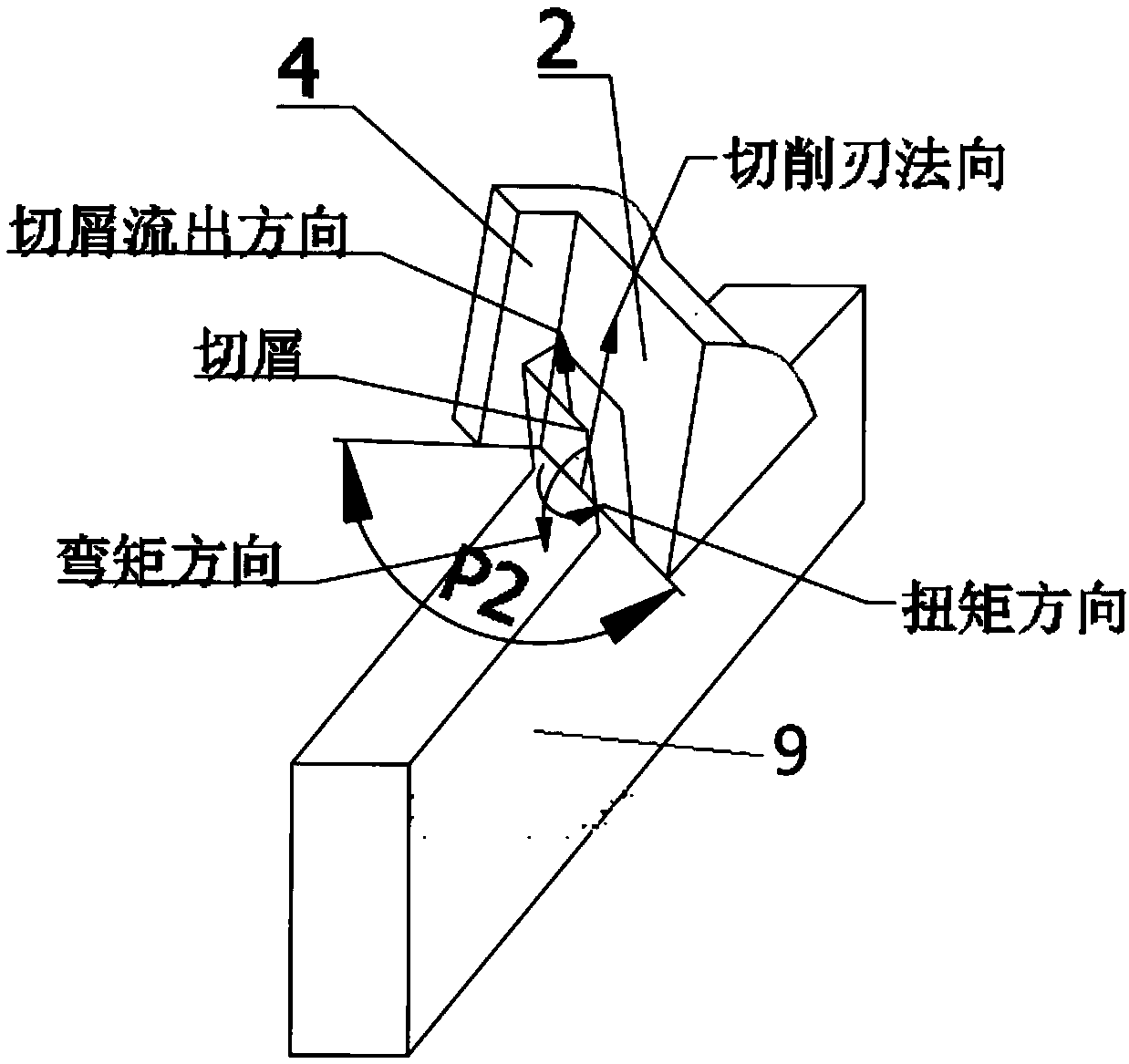

[0013] like figure 1 , figure 2 As shown, the present invention is a chip breaking structure of the cutting edge at the variable diameter position of the stepped drill. The chip flute 6 is formed by the end face 7 of the stepped rear section. This chip breaking structure changes the traditional continuous spiral edge cutting into step edge co-cutting, and the rake face also changes from an arc shape to an angled straight face to form a chip breaking space, and the angled rake faces make the chip break Bending and torsional deformation increase the chip stress, and it is easier to reach the breaking strength of the chip, effectively realizing metal chip breaking and debris.

[0014] Since CFRP is a complex mixture composed of fiber-reinforced phase and resin matrix phase, it has very different properties from homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com