Draught fan dewaterer and boiler room

A technology of induced draft fan and dehydrator, which is applied in the field of boilers and can solve problems such as short service life, violent vibration of induced draft fan, and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

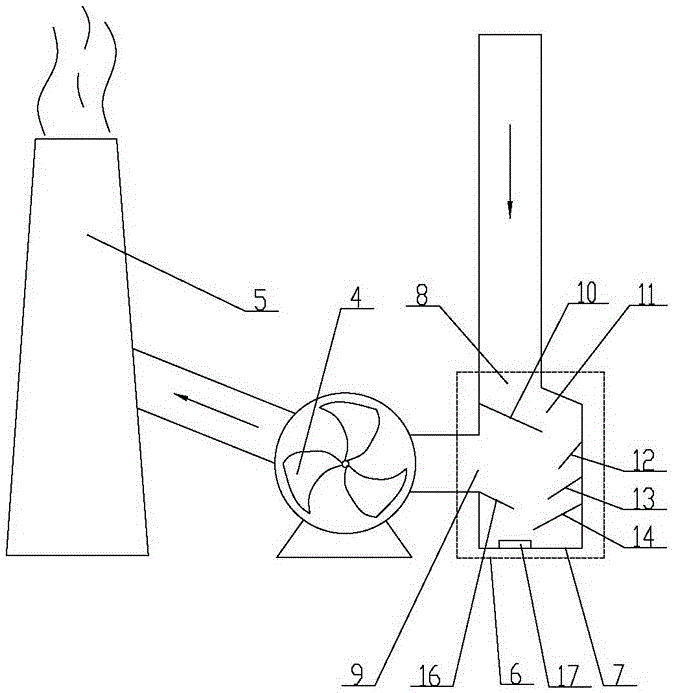

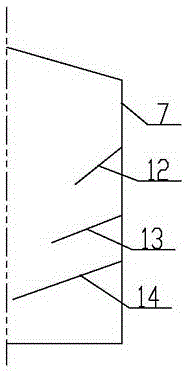

[0023] Embodiment one: as attached figure 2 , 3 , 4, the induced draft fan dehydrator 6 includes a tank body 7, the upper end of the tank body 7 is provided with a flue gas inlet 8, the left side of the tank body 7 is provided with a flue gas outlet 9, and the tank body above the flue gas outlet 9 The left inner wall of 7 is provided with a deflector 10 with a high left and a low right, and a flue gas passage 11 is formed between the upper end surface of the deflector 10 and the right inner wall of the tank body 7 . In the present invention, a tank body 7 is added on the pipeline before the entrance of the induced draft fan 4, the flue gas inlet 8 of the tank body 7 communicates with the pipeline, and the flue gas outlet 9 of the tank body 7 communicates with the inlet of the induced draft fan 4. An inclined deflector 10 is installed on the inner wall of the tank body 7 below the inlet 8 and above the flue gas outlet 9, thereby changing the direction of the flue gas flow, so...

Embodiment 2

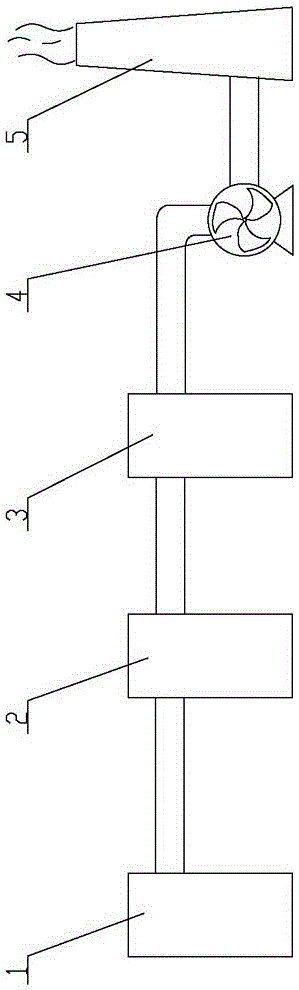

[0031] Embodiment two: as attached Figure 5 As shown, a boiler room includes boiler 1, dust remover 2, desulfurization equipment 3, induced draft fan 4, chimney 5, and induced draft fan dehydrator 6 in the above technical solution. The smoke inlet of the device 2 is connected, the smoke outlet of the dust collector 2 is connected with the smoke inlet of the desulfurization equipment 3 through the pipeline, and the smoke outlet of the desulfurization equipment 3 is connected with the flue gas inlet 8 of the tank body 7 through the pipeline, and the tank body 7 The flue gas outlet 9 is communicated with the inlet of the induced draft fan 4 through a pipeline, and the outlet of the induced draft fan 4 is communicated with the inlet of the chimney 5 through a pipeline. The tank body 7 of the induced draft fan dehydrator 6 is welded and installed with the pipeline, and the tank body 7 is customized according to the size of the induced draft fan 4 specification and the pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com