Bearing special for rowing machine

A rowing machine and bearing technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of not being able to achieve fitness effects, slipping, and poor use effects, so as to reduce the phenomenon of cooperative slipping, prolong the service life, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

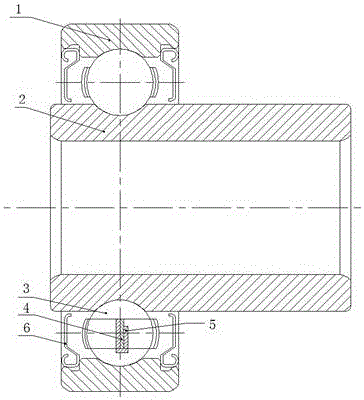

[0017] Such as figure 1 As shown, a special bearing for a rowing machine includes an outer ring 1, an inner ring 2, a rolling element 3, a first cage 4, a second cage 5 and a dust cover 6, and the rolling element 4 connects the outer ring 1 and the The inner ring 2 is positioned with the first cage 4 and the second cage 5, so that the rolling elements 3 are evenly separated to ensure the gap and coaxiality of the inner and outer rings. The width of the inner ring 2 is much larger than the width of the outer ring 1; The ring 1 is provided with a dust-proof groove, and the dust-proof cover 6 is arranged in the dust-proof groove, and grease is injected into the outer ring 1 and the inner ring 2 .

[0018] A further solution is that the dustproof groove of the outer ring 1 is a stepped groove.

[0019] A further solution is that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com