Hub motor

A wheel hub motor and wheel frame technology, applied in the field of motors, can solve the problems of extra motor cover cost, axial displacement, and affecting the sensing effect of Hall sensing components, etc., to save costs, improve the setting position, and avoid eccentricity The effect of rotation and axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

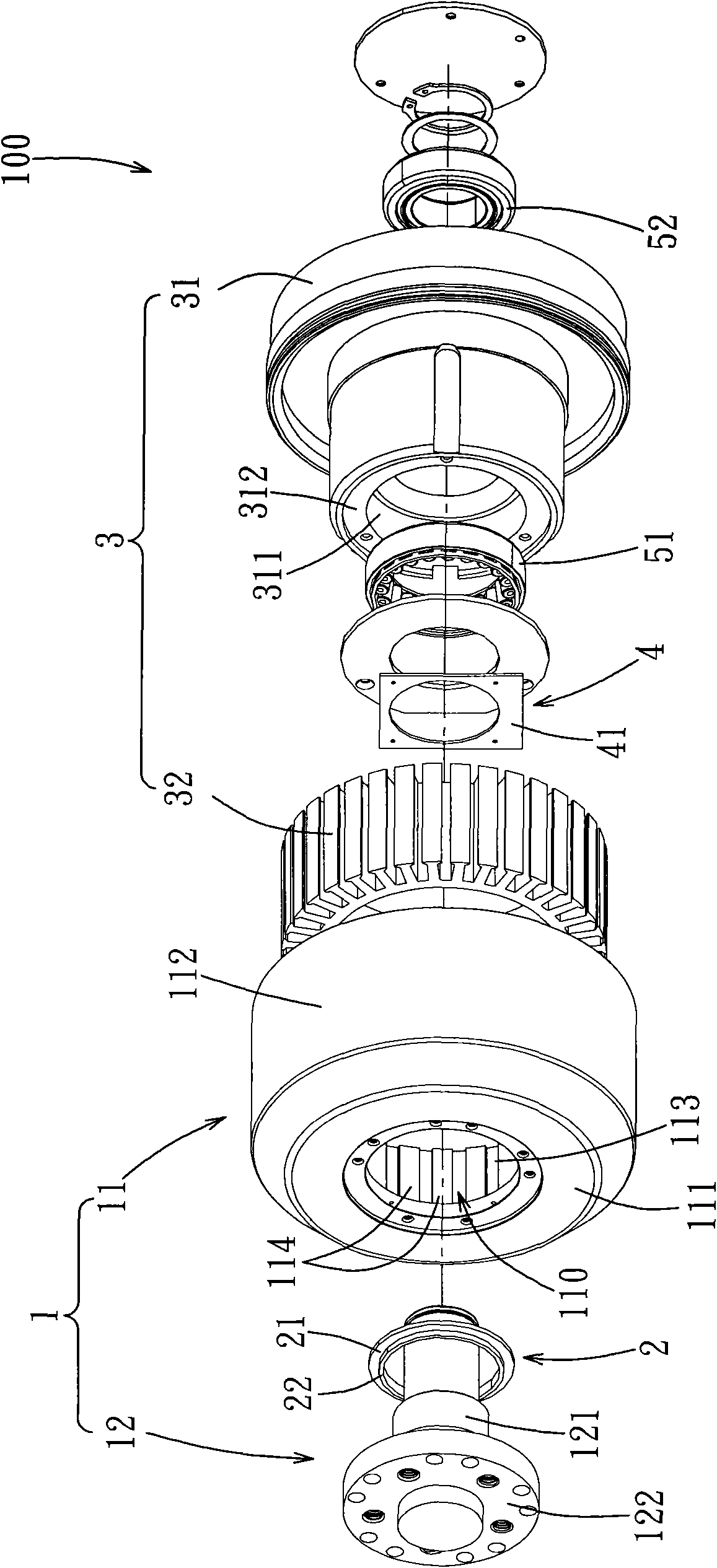

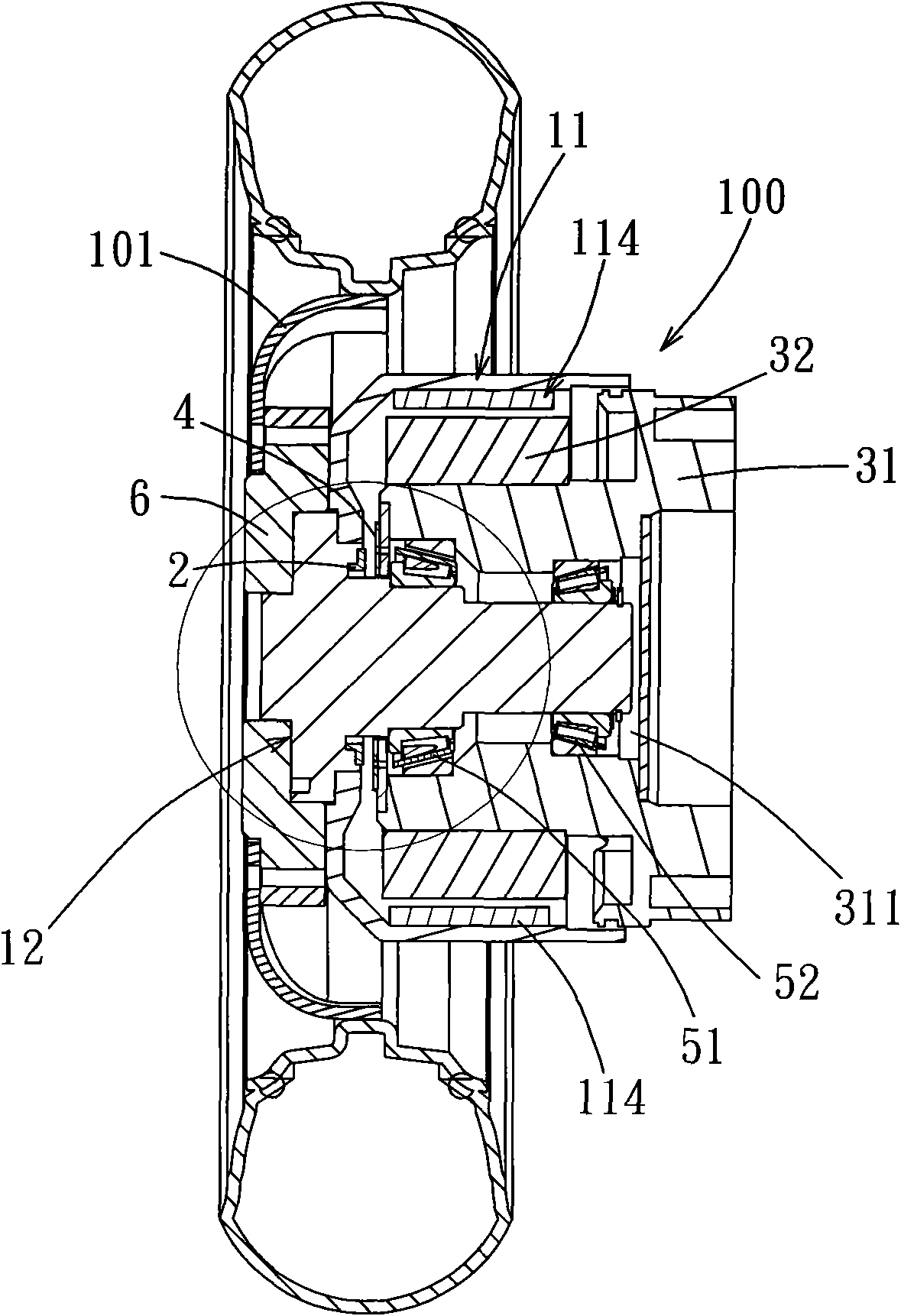

[0018] see figure 1 , figure 2 , a preferred embodiment of the in-wheel motor 100 of the present invention can be arranged on a wheel frame 101 of an electric scooter. The in-wheel motor 100 includes a rotor unit 1, a magnetic ring 2 arranged on the rotor unit 1, a stator unit 3, A sensing circuit unit 4 , a plurality of bearings 51 , 52 and a rotor unit fixing seat 6 arranged on the stator unit 3 .

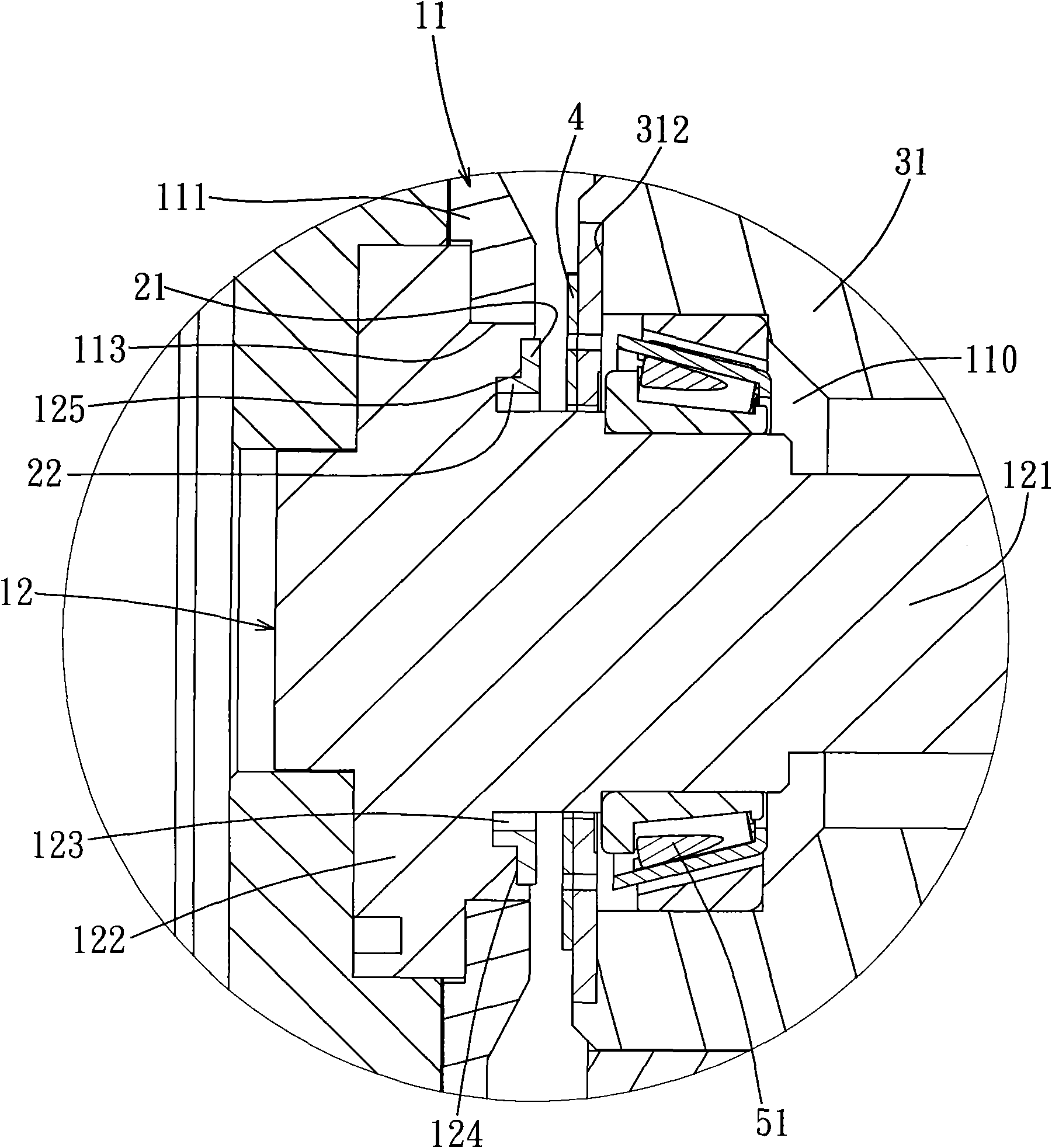

[0019] see Figure 1 to Figure 3 , the rotor unit 1 is formed with a shaft portion, and the shaft portion is relatively rotatable through the stator unit 3, in more detail, the rotor unit 1 includes a rotor housing 11, a rotor output shaft 12 and a plurality of magnets 114, the rotor The housing 11 includes a base wall 111 and a surrounding wall 112 extending from the base wall 111 . The base wall 111 cooperates with the surrounding wall 112 to define ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com