Mold surface TD treatment raw material pre-mixing stirring apparatus

A mixing device and premixing technology, which is applied in the field of mold manufacturing, can solve problems such as blockage of the connecting pipe of the surface treatment device, affecting the speed of the stirring device, and insufficient premixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

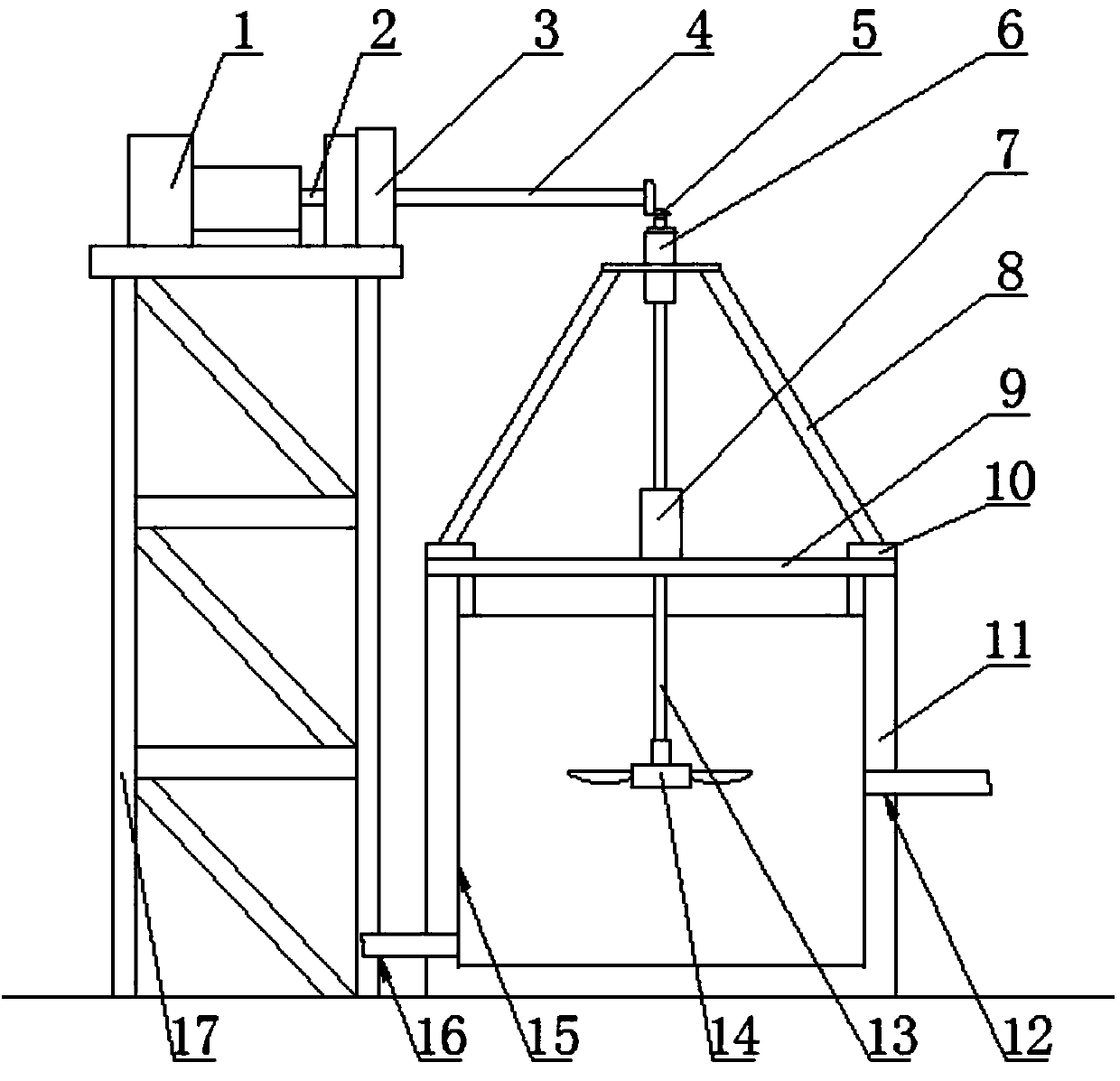

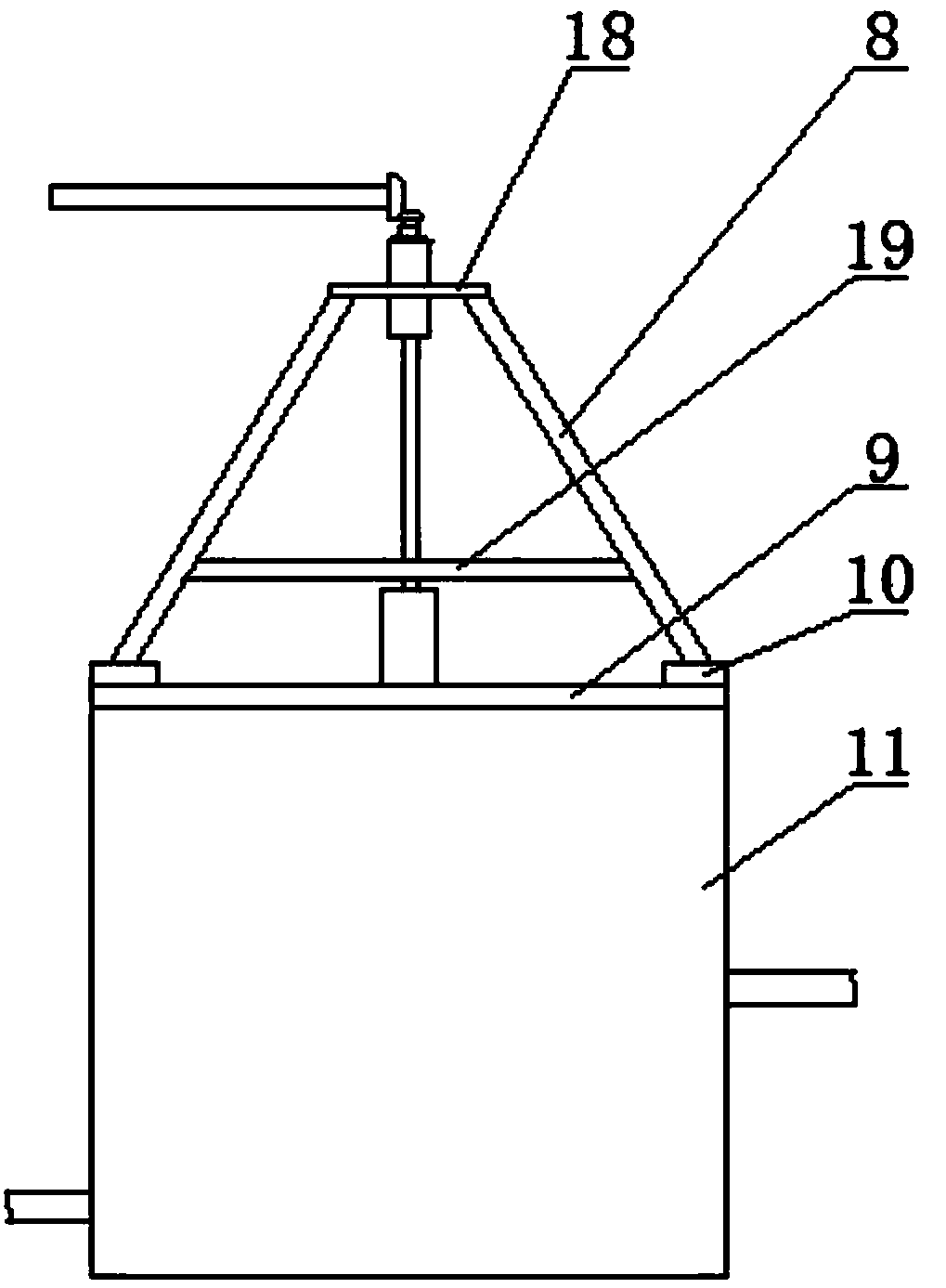

[0015] A raw material premixing device for mold surface TD treatment. The innovation of the present invention is that it includes a wide-mouthed premixing barrel 11 for accommodating raw materials. A hollow cavity 15 is formed in the wide-mouthed premixing barrel. The wide-mouthed premixing barrel In the side wall of the wide-mouthed premixing barrel, a material inlet 12 and a material outlet 16 are respectively made, and a sealing cover 9 is movably embedded in the inner edge of the wide opening made by the wide-mouthed premixing barrel, and the upper end surface of the sealing cover is installed. There is a frame of "cone type", the upper end of the frame is made a flat end surface, the upper end of a rotating shaft 13 is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com