Impeller assembly and washing machine

A technology of washing machine and pulsator, which is applied in the field of washing machine to achieve the effect of preventing splashing, enhancing washing strength and preventing water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

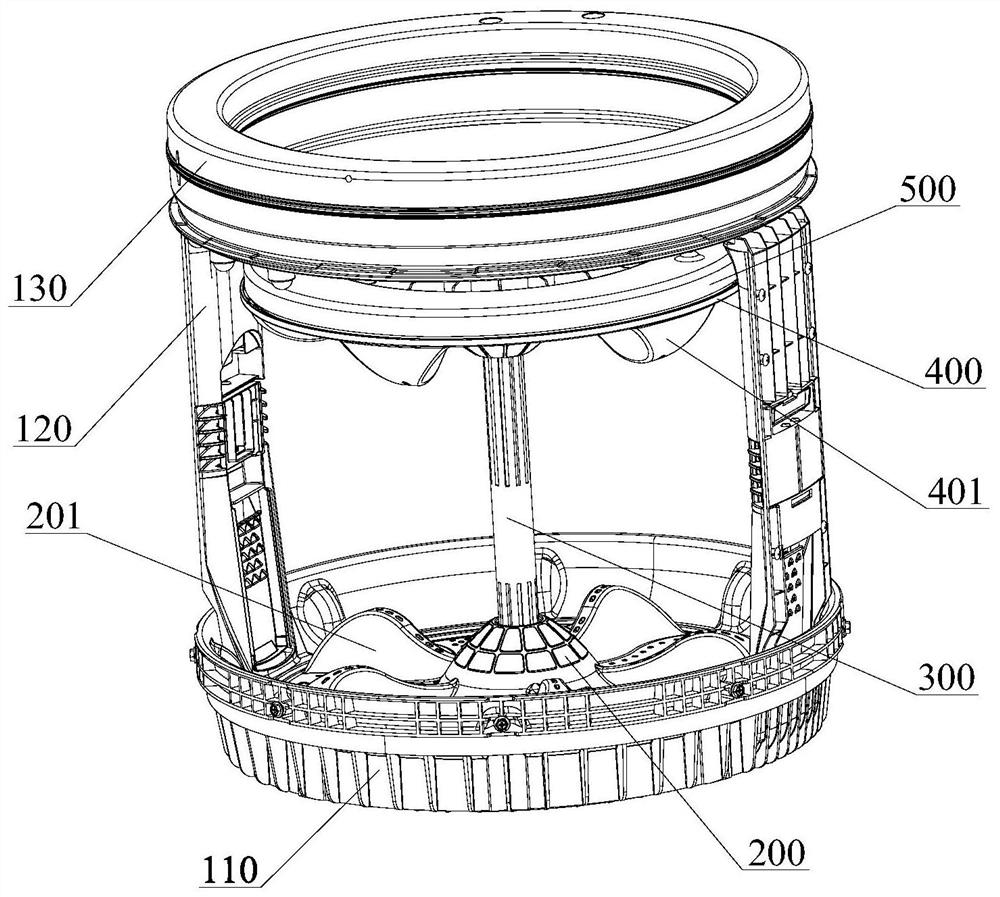

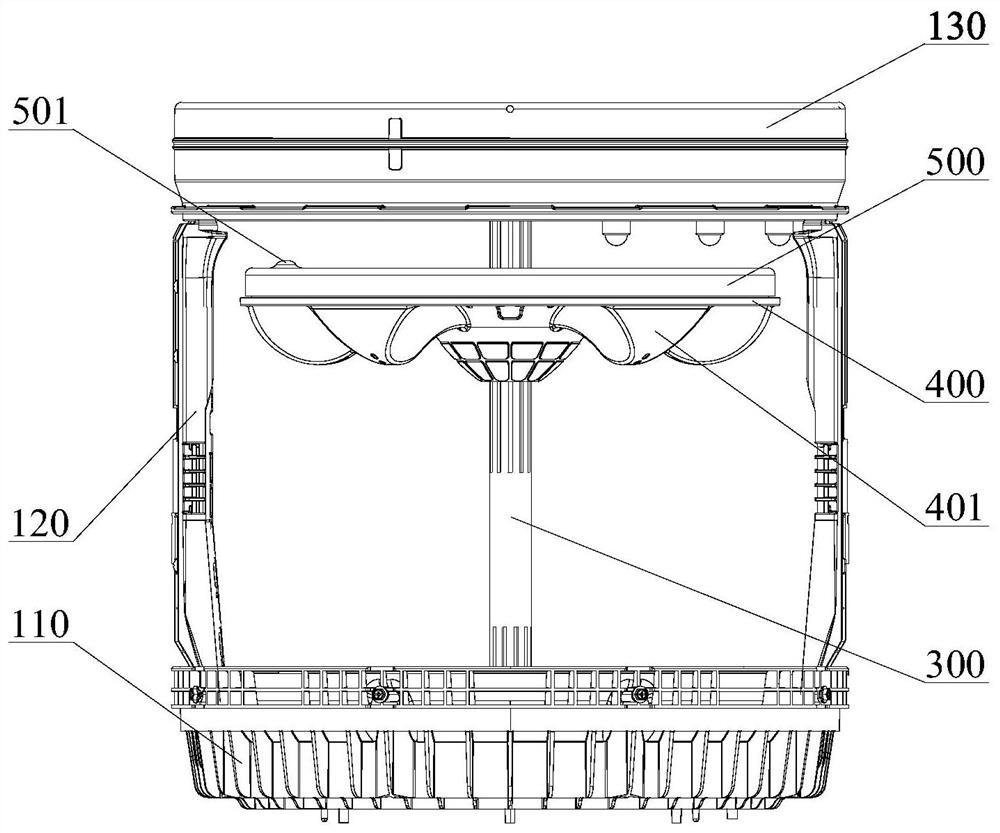

[0058] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a pulsator assembly and a washing machine including the pulsator assembly.

[0059] Specifically, the pulsator assembly includes:

[0060] The first wave wheel 200;

[0061] The second pulsator 400 is arranged above the first pulsator 200;

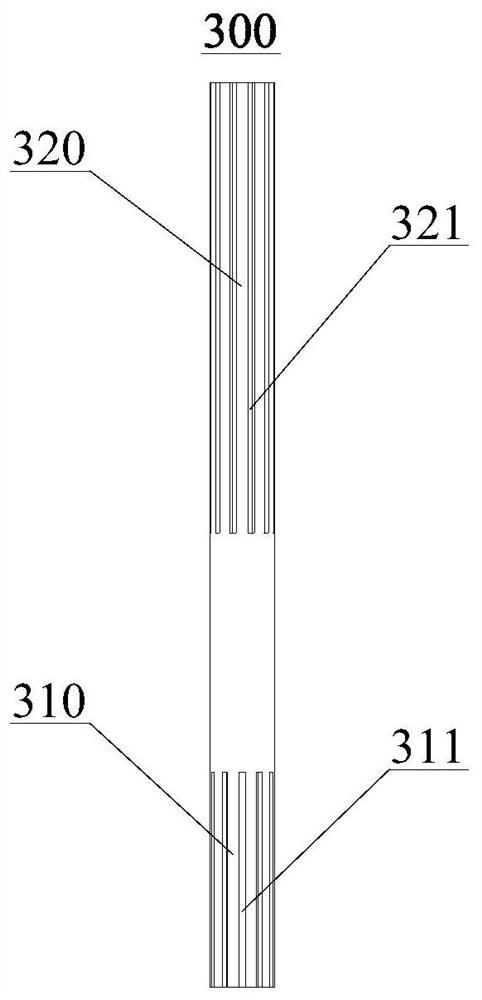

[0062] The connecting piece 300 is used for connecting the first pulsator 200 and the second pulsator 400 .

[0063] The second pulsator 400 is mounted on the connecting member 300 so as to be relatively movable, and the second pulsator 400 moves closer to or away from the first pulsator 200 relative to the connecting member 300 .

[0064] The washing machine in this embodiment specifically includes an inner tub, and the above-mentioned pulsator assembly disposed inside the inner tub. Wherein, the first pulsator 200 is rotatably arranged at the bottom of the inner tub.

[0065] In this embodiment, a first stirring rib 201 is provided on the upper surface of...

Embodiment 2

[0089] This embodiment is a further limitation of the first embodiment above. A limiting device is provided on the connecting portion, and the limiting device is installed above the second pulsator to limit the highest sliding position of the second pulsator.

[0090] During the laundry process, especially when the washing speed is high and the weight of the second pulsator is relatively light, the second pulsator may slide up a large distance along the connecting part during the rotation process, causing the second stirring rib to sink into the water surface. Partially reduced, or even completely separated from the washing water, resulting in weakened agitation of the washing water, and unable to produce effective friction with the clothes to achieve the ideal washing effect.

[0091] In this embodiment, by providing a limiting device on the connecting part that can limit the second pulsator, the highest position that the second pulsator can reach when sliding on the connectin...

Embodiment 3

[0100] Such as Figure 1 to Figure 5 As shown, this embodiment is a further limitation of the first embodiment above, and the second pulsator 400 is provided with a weight adjusting device that can adjust the weight. The user can adjust the weight of the weight adjusting device to realize the adjustment of the overall weight of the second pulsator 400, especially when the wetness of the laundry is poor, the second pulsator 400 can have enough weight to fully wash the clothes. Press into the water to ensure the garment is fully soaked.

[0101] At the same time, adjusting the overall weight of the second pulsator 400 to an appropriate level for different washing speeds and washing water conditions can also ensure that the second pulsator 400 floats stably at the height of the water surface during the entire washing process, avoiding the second wave The wheel 400 falls off the water surface too lightly, or sinks into the bottom of the water too heavily, so as to ensure the effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com