Washing mode of washing machine of wheel type screw full-automatic washing machine and the washing machine

A fully automatic washing machine and washing method technology, which is applied in the field of washing machines to achieve the effects of reducing consumption, saving electric energy, and strengthening washing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

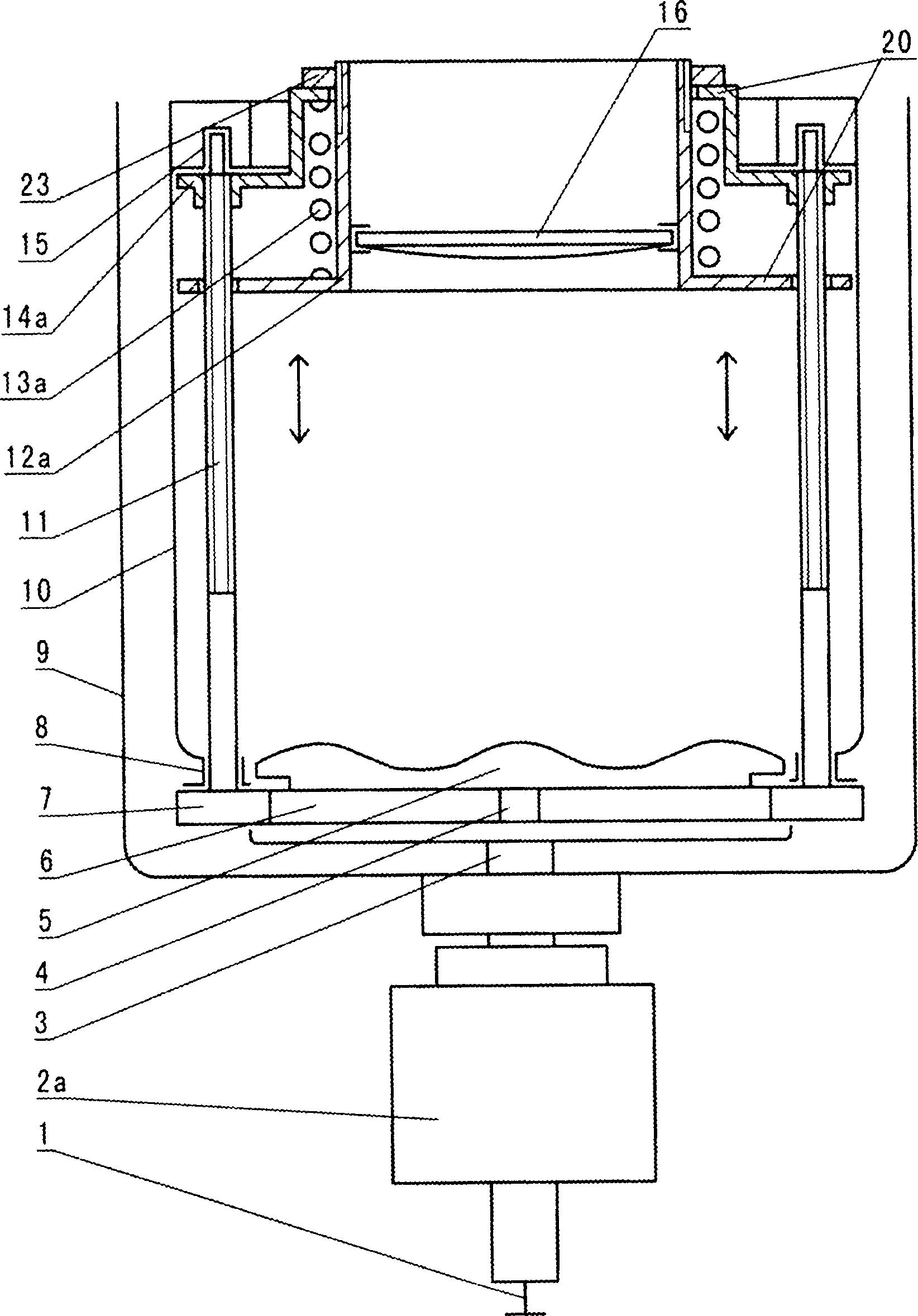

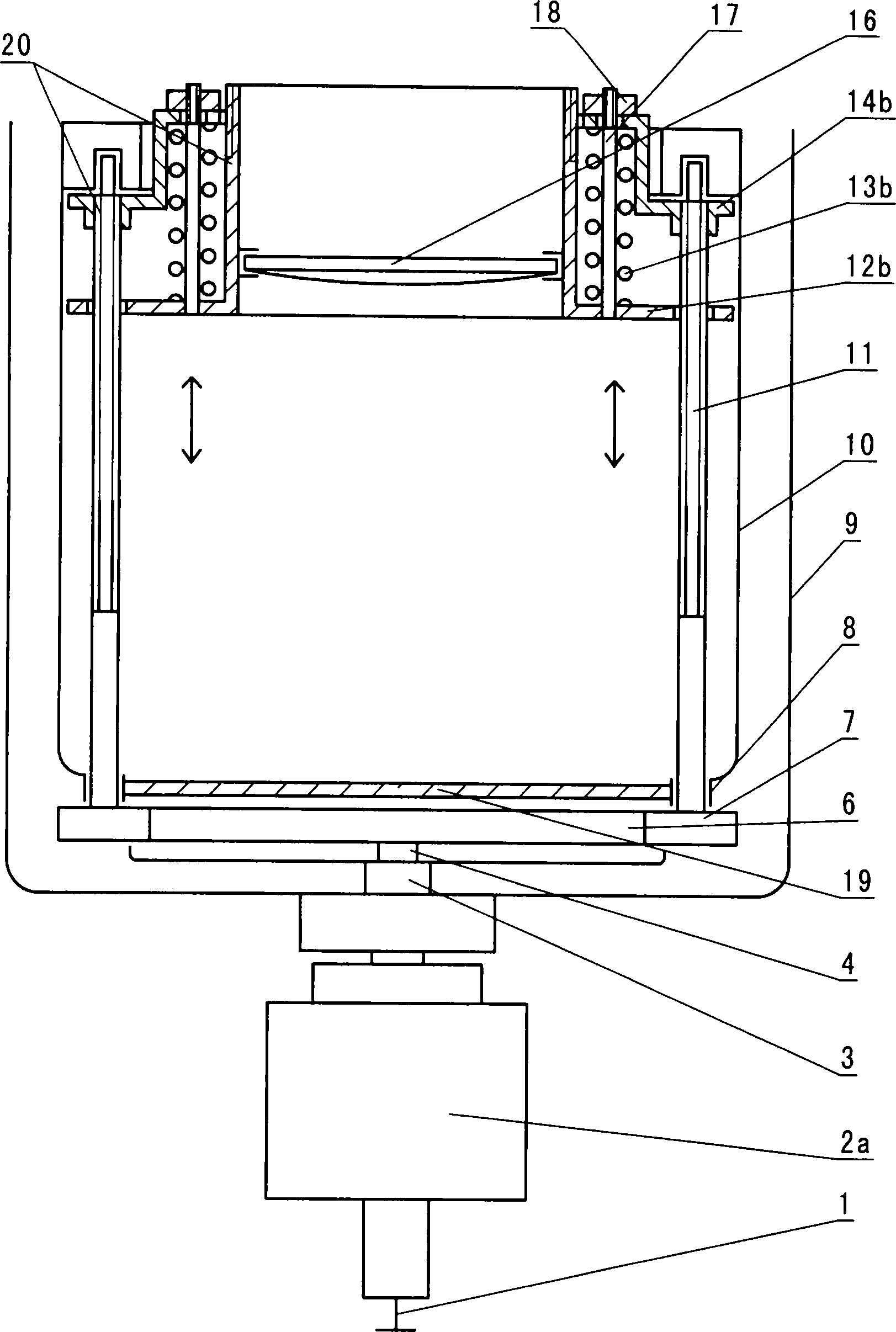

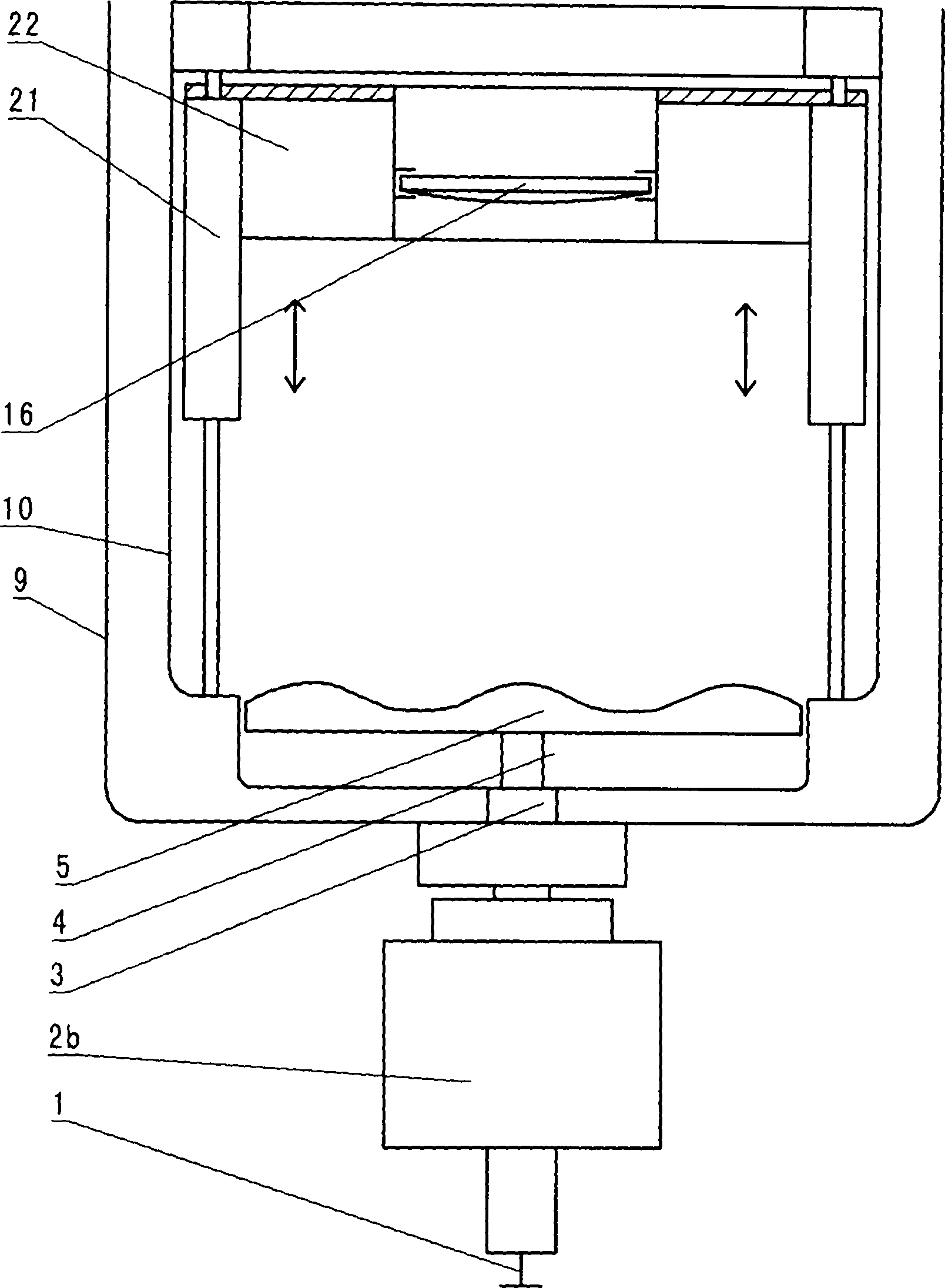

[0029] The structure and features of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] figure 1 It is a structural schematic diagram of the first embodiment of the automatic washing machine of the present invention, which is a mechanical spinning type automatic washing machine, which includes: an input shaft 1, a speed reducer 2a placed on the input shaft 1, and a speed reducer 2a placed on the speed reducer 2a. The outer tub 9, the inner tub 10 placed in the outer tub 9, the output shaft sleeve 3 placed on the speed reducer 2a, the output shaft 4 inserted into the inner tub 10 in the output shaft sleeve 3, the output shaft 4 placed on the output shaft 4 The pulsator 5 is a pressure plate device 20 that reciprocates axially along the output shaft 4 and is placed in the inner tub 10 .

[0031] Described platen device 20 is as figure 1 As shown, it includes: a bull gear 6 placed below the pulsator 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com