Washing powder containing nano carbon crystal grains

A nano-carbon crystal and carbon crystal technology, applied in the field of daily necessities, can solve the problems of weak ability to remove stubborn stains, slow dissolution rate of washing powder, inconvenient washing of clothes, etc., achieves significant economic and social benefits, and promotes washing. The development of the agent industry and the effect of saving washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

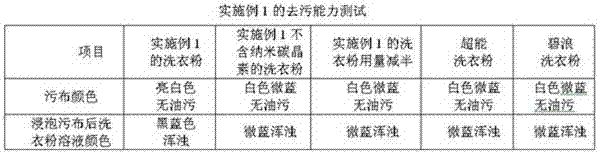

Embodiment 1

[0020] A washing powder containing nano-carbon crystal, which is composed of the following raw materials in weight percentage: 15% anionic surfactant (10% sodium fatty alcohol methyl ester sulfonate, 5% sodium lauryl sulfate), nonionic surfactant 5% detergent (fatty alcohol polyoxyethylene ether), 1% polymer builder (maleic anhydride-acrylic acid copolymer), 2% sodium carboxymethyl cellulose, 20% soda ash, water glass (42% concentration) 15%, liquid caustic soda (concentration is 40%) 2.8%, Yuanming powder 30%, whitening agent 0.05% (fluorescent whitening agent VBL), biological enzyme 0.1% (alkaline protease), essence 0.1%, 4A zeolite 5 %, modified nano carbon crystal 3.95%.

[0021] The modified nano-carbon crystal is prepared by the following method: at room temperature, the nano-carbon crystal is dispersed in absolute ethanol, and the surface modifier (titanate coupling The dosage ratio of agent NDZ-311 and NDZ-201 is 3︰7), at 80°C, heat and reflux for 5h, cool and centrif...

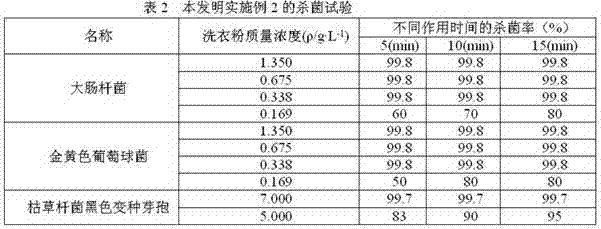

Embodiment 2

[0023] A washing powder containing nano-carbon crystal, which is composed of the following raw materials in weight percentage: 1% anionic surfactant (sodium fatty alcohol methyl sulfonate), 1% nonionic surfactant (fatty alcohol polyoxyethylene ether) 10% polymer builder (maleic anhydride-acrylic acid copolymer), 0.1% sodium carboxymethyl cellulose, 5% soda ash, 8% water glass (41% concentration), 8% liquid alkali (41% concentration) 1.3%, Yuanming powder 55.7%, whitening agent 0.5% (fluorescent whitening agent VBL), biological enzyme 1% (alkaline lipase 0.5%, amylase 0.5%), essence 0.4%, 4A zeolite 15%, modified Sexual nano carbon crystal element 1%.

[0024] The modified nano-carbon crystal is prepared by the following method: at room temperature, the nano-carbon crystal is dispersed in absolute ethanol, and the surface modifier (titanate coupling The dosage ratio of agent NDZ-101 and NDZ-102 is 2︰3), heated to reflux at 75°C for 4h, cooled and centrifuged, washed the precip...

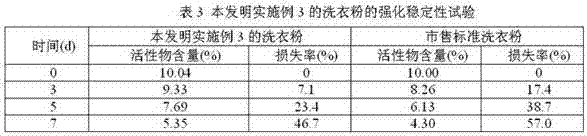

Embodiment 3

[0026] A kind of washing powder containing nano-carbon crystal element, is made up of the raw material of following percentage by weight: anionic surfactant 14% (fatty alcohol methyl ester sodium sulfonate 4%, sodium lauryl sulfate 6%, alpha-sodium sulfonate 4%), non-ionic surfactant 4% (fatty alcohol polyoxyethylene ether), polymer builder 9% (maleic anhydride-acrylic acid copolymer), carboxymethyl cellulose sodium 1%, soda ash 18%, Water glass (concentration of 42%) 13%, liquid alkali (concentration of 40%) 2.0%, Yuanming powder 20%, whitening agent 0.1% (fluorescent whitening agent VBL), biological enzyme 0.8% (alkaline protease 0.3 %, alkaline cellulase 0.5%), essence 0.2%, 4A zeolite 7.9%, modified nano carbon crystal 10%.

[0027] Refer to Example 1 for the preparation method of modified nano-carbon crystal elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com