Patents

Literature

30 results about "Fluorescent whitening agent VBL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Attapulgite interior wall emulsion varnish

The invention discloses an attapulgite interior wall emulsion varnish. The key point of the technical proposal of the invention is that the attapulgite interior wall emulsion varnish consists of paste palygorskite clay, acrylate emulsion, superfine precipitated calcium carbonate, anatase titanium dioxide, droxyethylcellulose, propanediol, tributyl phosphate, a fluorescent whitening agent VBL and deionized water. The method for producing the attapulgite interior wall emulsion varnish comprises the steps of material mixing, crashing, stirring, dispersion, dissolution, homogenization, emulsification, defoaming, grinding and canning to obtain a finished product of the attapulgite paste interior wall emulsion varnish. The attapulgite paste interior wall emulsion varnish has strong adhesive force, high durability, water resistance, scrubbing resistance and dirt resistance; the quality of the product is accordance with standards of 'GB / T 9756-2001 synthetic emulsion resin interior wall coating' and 'GB 18582-2008 hazardous substance limit quantity in interior decoration finishing material of interior wall coating'; and the attapulgite interior wall emulsion varnish is applicable to coatings for interior decoration.

Owner:LIWANG CHEM NANTONG

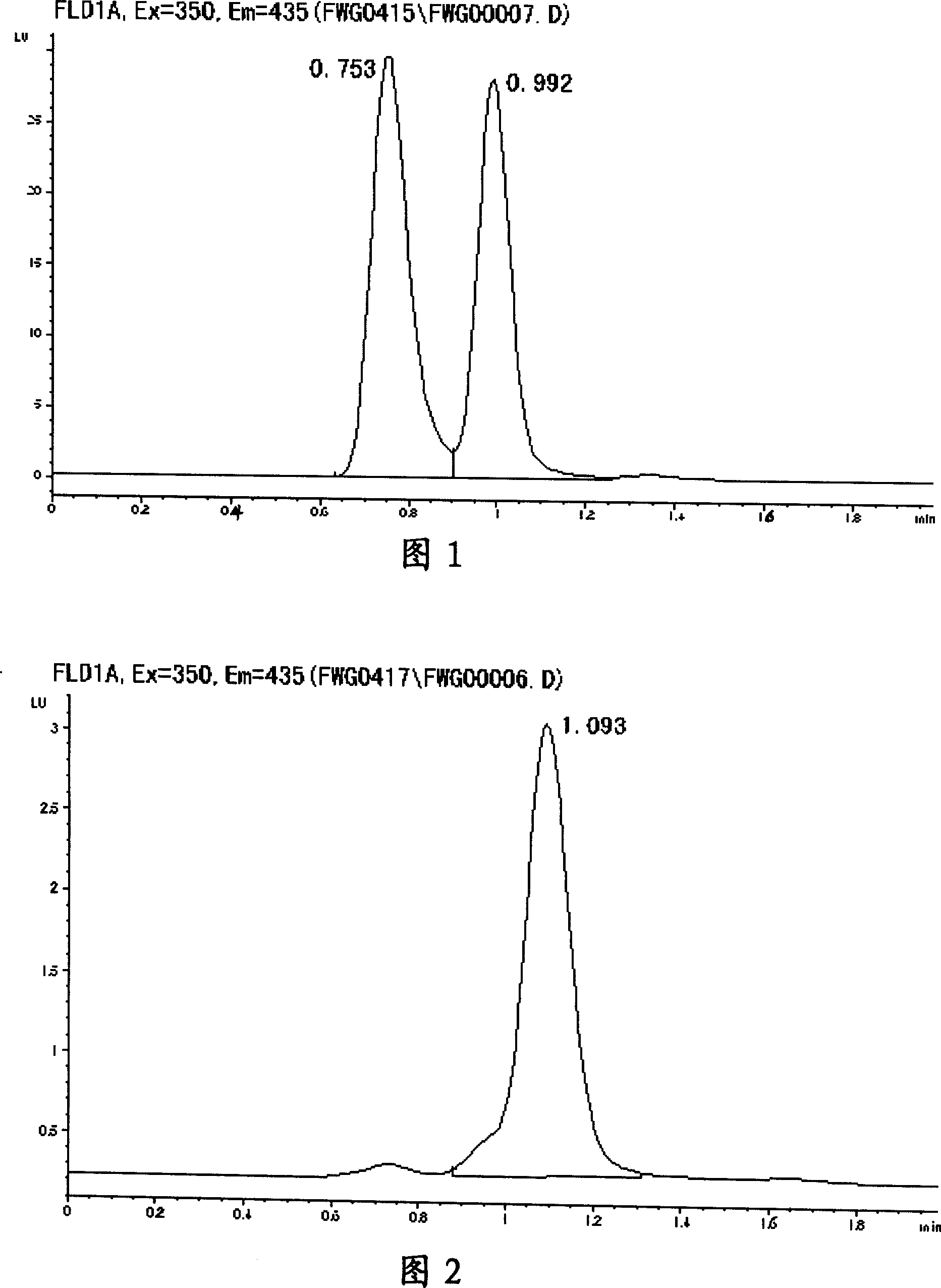

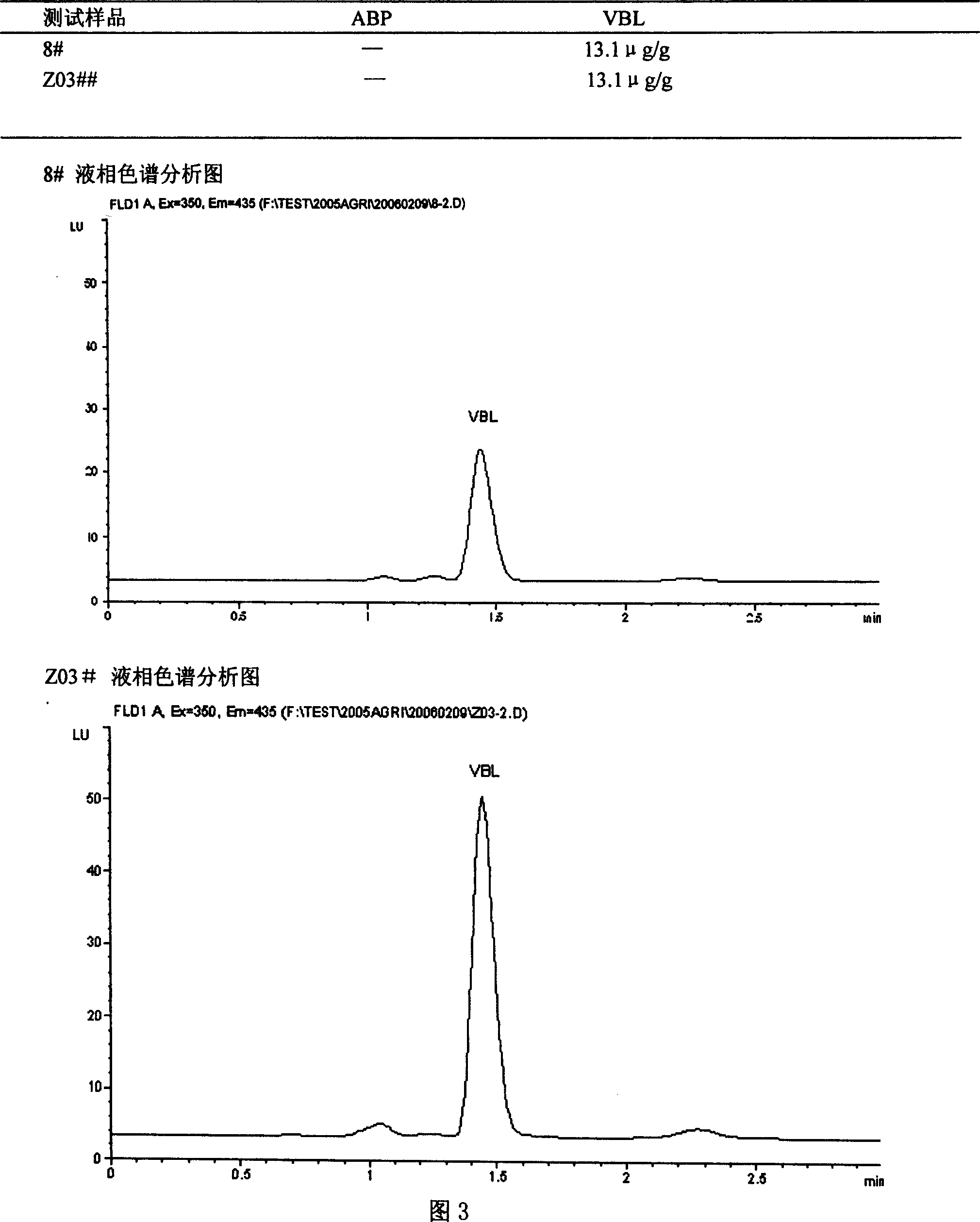

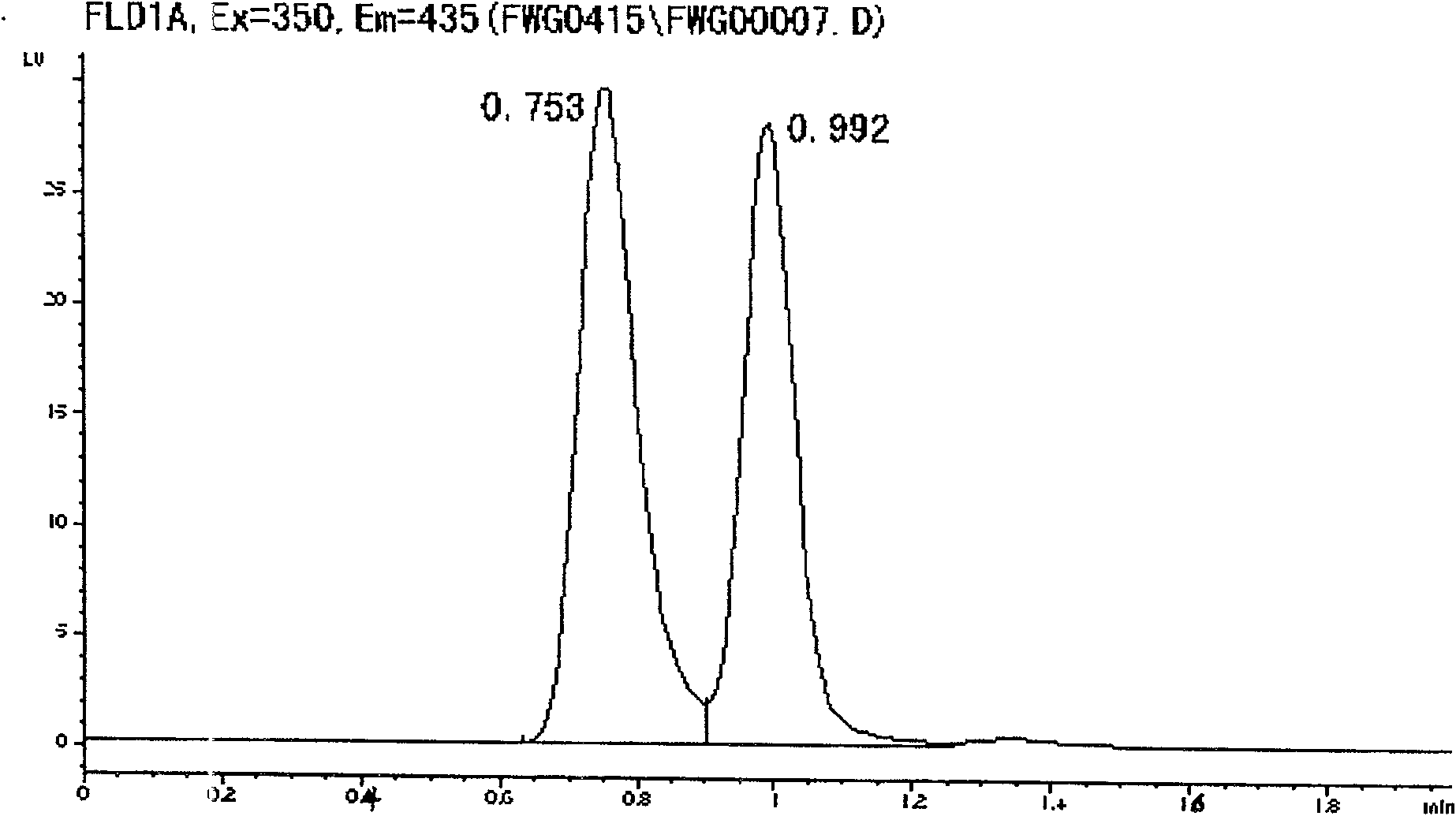

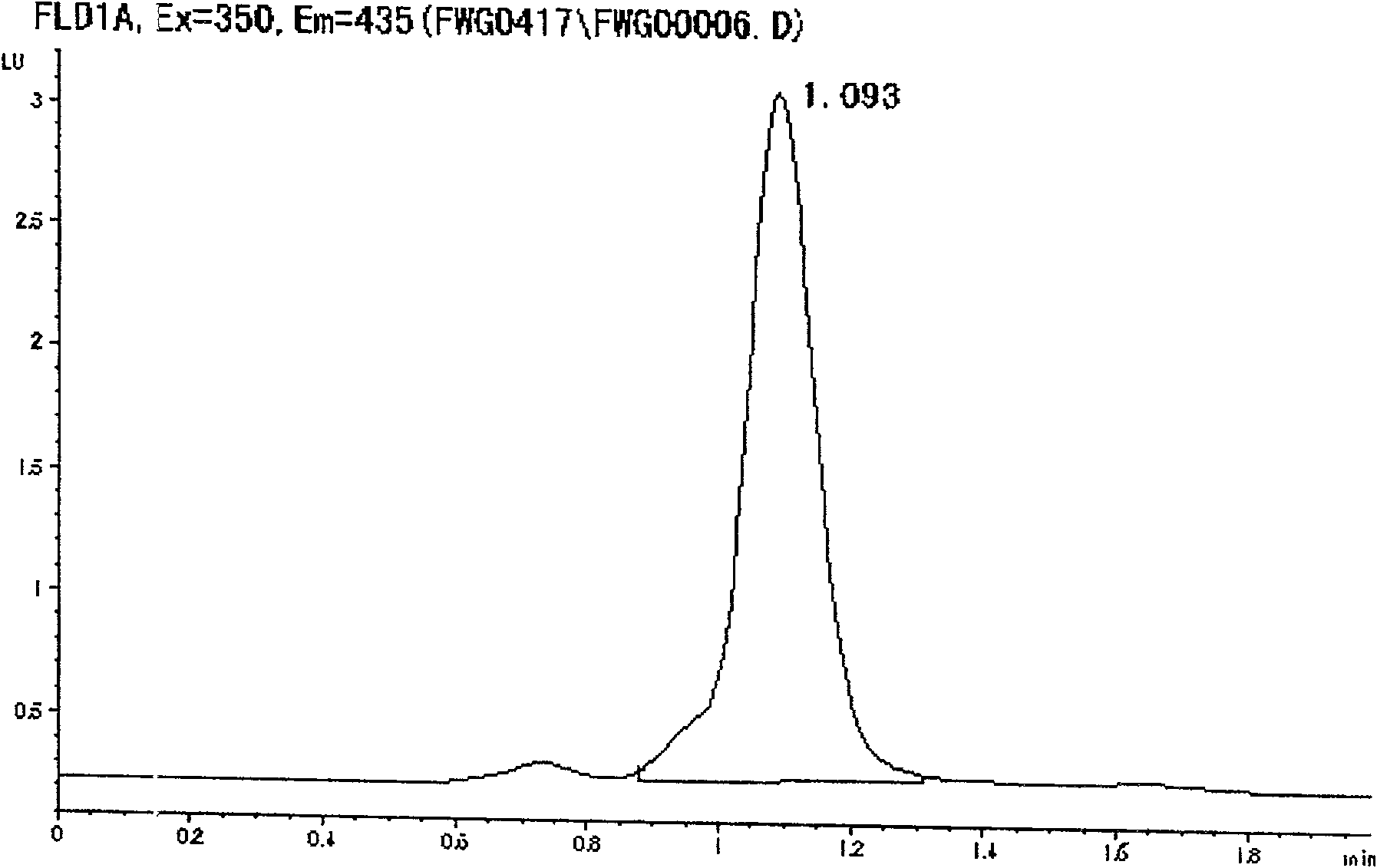

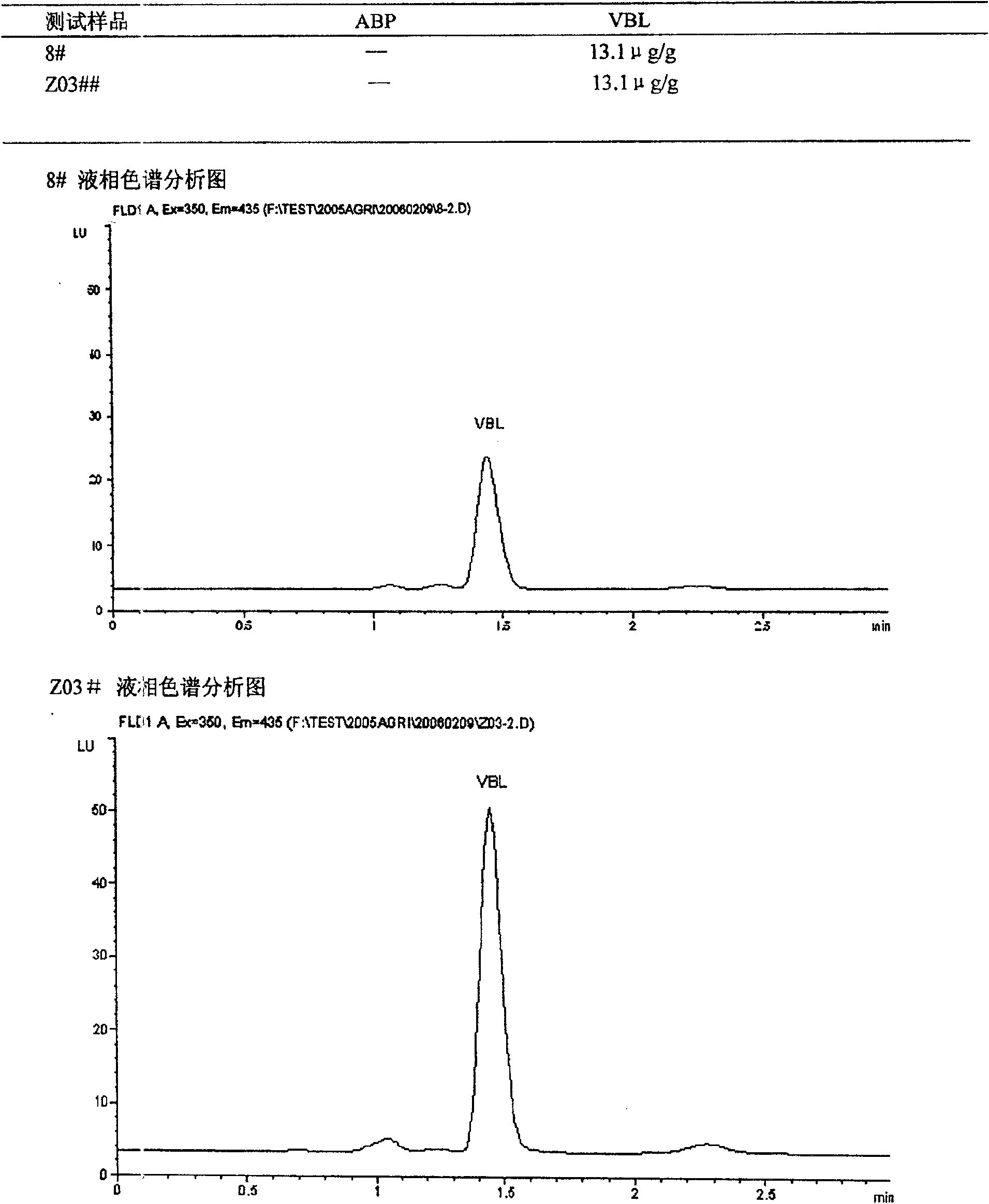

Quantitative determination method for fluorescent whitening agent VBL, ABP for tobacco

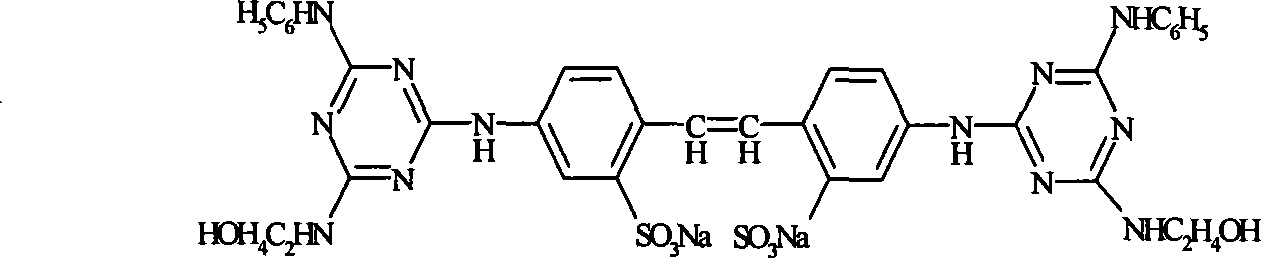

A quantitative determination method of fluorescent whitening agents VBL and ABP used in cigarette paper is characterized in that the method mainly includes steps mention below. The first step is to determine the chromatographic conditions. A chromatographic column is C18, 5Mu m column of 150mm*46mm. A mobile phase is methane or water with 45 / 55(V / V). The flow speed of the mobile phase is 1.0mL / min. The detection wavelengths include an excitation wavelength of 350mm and an emission wavelength of 425mm. The second step is the detection step, which is also a preparation step of a calibration curve. Treatment liquid for paper sample to be detected is injected in a high performance liquid chromatograph. The quality is determined according to the reserved time and the quantity is determined according to the peak area. The invention provides a quantitative determination method of fluorescent whitening agents VBL and ABP used in cigarette paper, which has the advantages of accurate detection and simple operation. The qualitative and quantitative detection of the fluorescent whitening agents VBL and ABP in cigarette paper, filter rod forming paper and cigarette tipping paper is made to be convenient for industry technicians. And potential damages on physical health of customers caused by excess whitening agent can be prevented.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

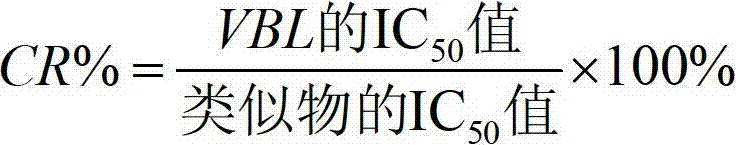

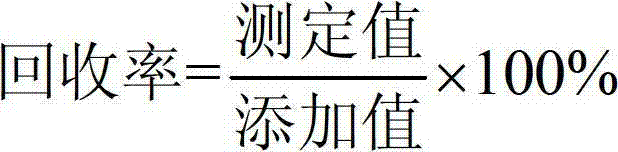

Fluorescent brightening agent VBL detection kit and preparation method thereof

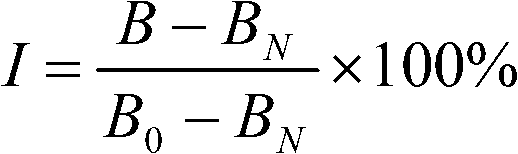

The invention discloses a fluorescent brightening agent VBL detection kit, belonging to the technical field of additive detection. The kit comprises an enzyme label plate coated by a fluorescent brightening agent VBL specific antigen and a fluorescent brightening agent VBL specific antibody solution, wherein each micropore of the enzyme label plate is coated by the fluorescent brightening agent VBL specific antigen having a concentration of 1-3 mug / mL, the concentration of the fluorescent brightening agent VBL specific antibody is 1-3 mug / mL, and the dosage ratio of the fluorescent brightening agent VBL specific antigen to the fluorescent brightening agent VBL specific antibody solution is 1:1. The invention further discloses a preparation method of the detection kit. The detection kit disclosed herein can continuously detect a plurality of samples at a time when the fluorescent brightening agent VBL is detected, has the characteristics of convenience, rapidness, sensitivity, and low cost, and is suitable for rapidly and accurately detecting fluorescent brightening agent VBL in mass samples.

Owner:GUANGZHOU QUALITY SUPERVISION & TESTING INST

Quantitative determination method for fluorescent whitening agent VBL, ABP for tobacco

A quantitative determination method of fluorescent whitening agents VBL and ABP used in cigarette paper is characterized in that the method mainly includes steps mention below. The first step is to determine the chromatographic conditions. A chromatographic column is C18, 5Mu m column of 150mm*46mm. A mobile phase is methane or water with 45 / 55(V / V). The flow speed of the mobile phase is 1.0mL / min. The detection wavelengths include an excitation wavelength of 350mm and an emission wavelength of 425mm. The second step is the detection step, which is also a preparation step of a calibration curve. Treatment liquid for paper sample to be detected is injected in a high performance liquid chromatograph. The quality is determined according to the reserved time and the quantity is determined according to the peak area. The invention provides a quantitative determination method of fluorescent whitening agents VBL and ABP used in cigarette paper, which has the advantages of accurate detection and simple operation. The qualitative and quantitative detection of the fluorescent whitening agents VBL and ABP in cigarette paper, filter rod forming paper and cigarette tipping paper is made to be convenient for industry technicians. And potential damages on physical health of customers caused by excess whitening agent can be prevented.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Whitening agent

InactiveCN103897891AShort soaking timeImprove decontamination abilitySoap detergent compositionsWhitening AgentsSodium sulfate

The invention discloses a whitening agent. The whitening agent comprises, by weight, 0.1-0.3% of a fluorescent whitening agent VBL, 0.6-1% of a softener, 0.02-0.03% of sodium sulfate, 0.01-0.02% of sulfur dioxide, 0.5-1% of soap and the balance water.

Owner:郭公甫

Attapulgite interior wall powder coating

InactiveCN101585691AGood water dispersibilityGood optical performancePolyvinyl alcoholPrecipitated calcium carbonate

The invention discloses an attapulgite interior wall powder coating. The key point of the technical proposal of the invention is that the attapulgite interior wall powder coating consists of purified attapulgite, precipitated calcium carbonate, polyvinyl alcohol ultrafines, instant sodium silicate, anatase titanium dioxide, a solid polyether defoaming agent and a fluorescent whitening agent VBL. The method for producing the attapulgite interior wall powder coating comprises the steps of material mixing, crashing, grinding into powder and packaging to obtain a finished product of the attapulgite interior wall powder coating. The attapulgite interior wall powder coating has strong adhesive force, high durability, water resistance, friction resistance and dirt resistance, and can absorb formaldehyde and volatile organic compound to purify air. The attapulgite paste interior wall powder coating is a white reference coating and can be directly adjusted in color to produce color washes of various colors; and the attapulgite interior wall powder coating is applicable to building decoration.

Owner:LIWANG CHEM NANTONG +1

Attapulgite inner wall cement paint

The invention discloses a cement paint for interior walls of attapulgite. The key point of the technical proposal is that the cement paint for interior walls of attapulgite comprises purified attapulgite, white Portland cement, polyvinyl alcohol ultrafines, anatase titanium dioxide, droxyethylcellulose, a solid silicone defoaming agent and a fluorescent brightener VBL. The manufacturing method of the cement paint for interior walls of attapulgite comprises mixing, crashing, grinding and packaging the finished product of the cement paint for interior walls of attapulgite. The cement paint for interior walls of attapulgite is characterized by super strong adhesive force, fast-drying and firm paint film, humidity resistance, wash resistance, anti-mildew and antibacterial property and high hiding power, etc. The cement paint for interior walls of attapulgite is safe without poison and pollution and the product quality accords with the standard of GB 18582-2008 Decorating and Refurbishing Materials-Limit of Harmful Substances of Interior Architectural Coatings. In addition, the cement paint for interior walls of attapulgite is applicable to the protection and decoration of interior wall surfaces and ceilings of the building structure.

Owner:LIWANG CHEM NANTONG

Method for producing attapulgite paste interior wall coating

InactiveCN101585211AAvoid production methodsClay processing apparatusPolyvinyl alcoholPrecipitated calcium carbonate

The invention discloses a method for producing an attapulgite paste interior wall coating. The key point of the technical proposal of the invention is that the method for producing the attapulgite paste interior wall coating comprises the steps of material mixing, crashing, stirring, dispersion, dissolution, homogenization, emulsification, defoaming, grinding and canning to obtain a finished product of the attapulgite paste interior wall coating. The attapulgite paste interior wall coating consists of paste palygorskite clay, superfine precipitated calcium carbonate, polyvinyl alcohol ultrafines, instant sodium silicate, anatase titanium dioxide, a solid polyether defoaming agent, a fluorescent whitening agent VBL and deionized water. The attapulgite paste interior wall coating has strong adhesive force, high durability, water resistance, friction resistance and dirt resistance, and can absorb formaldehyde and volatile organic compound to purify the air. The attapulgite paste interior wall coating is a white reference coating and can be directly adjusted in colors to produce color washes of various colors; and the method for producing the attapulgite paste interior wall coating is suitable for producing environment-friendly interior wall coatings.

Owner:许盛英

Plain cloth whitening agent

InactiveCN102021812AReasonable formulaImprove work performanceBleaching apparatusWhitening AgentsSodium thiosulfate

The invention discloses a plain cloth whitening agent prepared by mixing fluorescent bleaching agent VBL, mercerizating paste, pigment blue FFC, sodium thiosulfate and water. The invention has the advantages of reasonable formula, good work effect and low production cost.

Owner:黄跃林

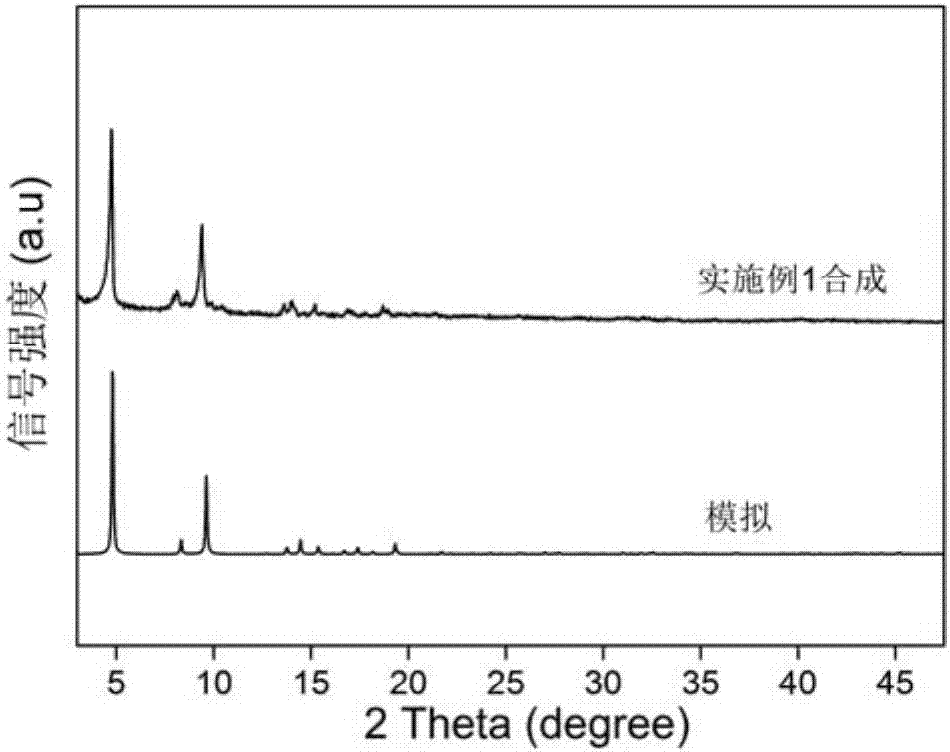

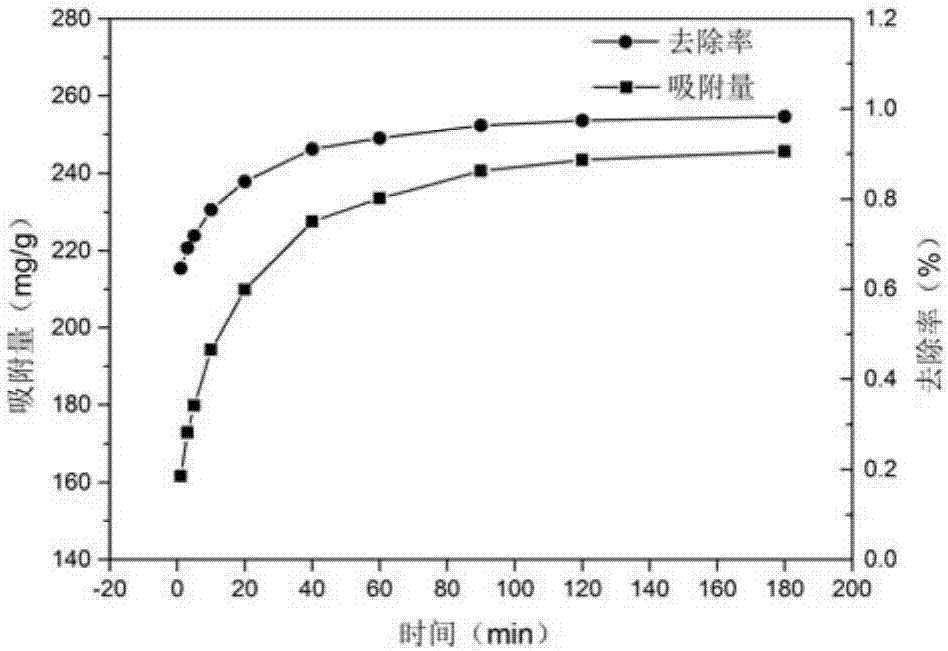

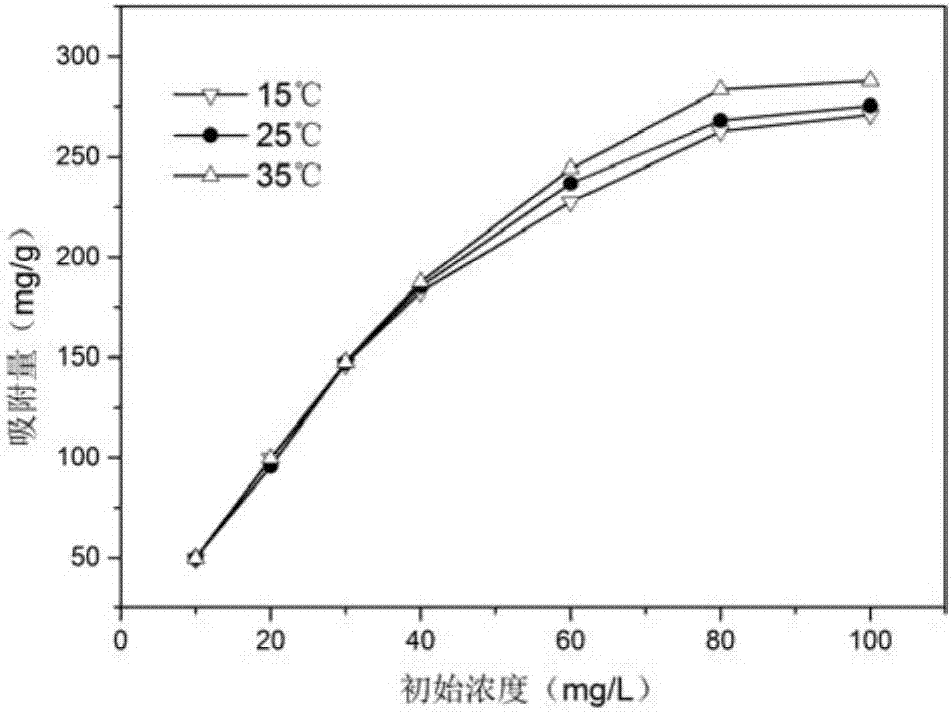

Method of removing fluorescent whitening agent VBL in water body

InactiveCN107162091ALarge specific surface areaStrong electrostatic effectOther chemical processesOrganic compound preparationMetal-organic frameworkScience and engineering

The invention belongs to the field of environmental science and engineering and discloses an application of removing fluorescent whitening agent VBL in water body. The application particularly includes the following steps: (1) preparing an aluminum based metal organic framework material MIL-68 (Al); (2) activating the MIL-68 (Al); (3) adding the MIL-68 (Al) in the step (2) to the water body containing the fluorescent whitening agent VBL according to the concentration of 0.05-0.5 g / L to obtain an adsorption initial solution; and (4) regulating the pH value of the adsorption initial solution to 2-11, and performing adsorption to obtain an adsorption purified solution. The method is simple and is easy to operate, is high in rate and efficiency on removal of the fluorescent whitening agent VBL, and has significant environmental value.

Owner:SOUTH CHINA UNIV OF TECH +1

Cleaning liquid for bleaching clothes

InactiveCN103865674ANo pollutionSimple preparation processInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEthylene diamineAcetic acid

The invention discloses cleaning liquid for bleaching clothes. The cleaning liquid comprises the following components in parts by weight: 4-8 parts of sodium lauryl sulfate, 3-5 parts of hexametaphosphate, 10-20 parts of fatty alcohol polyoxyethylene ether, 0.1-0.3 part of ethylene diamine tetraacetic acid, 3-5 parts of potassium hydrogen persulfate, 0.1-0.5 part of sodium citrate, 1-3 parts of a fluorescent brightener VBL, 0.1-0.3 part of essences and 200-400 parts of water. Compared with the prior art, the cleaning liquid disclosed by the invention has the following advantages that (1) the cleaning liquid combines washing and bleaching effects and is diversified in function; (2) the cleaning liquid is simple in preparation process, convenient to use and free of environmental pollution.

Owner:严明东

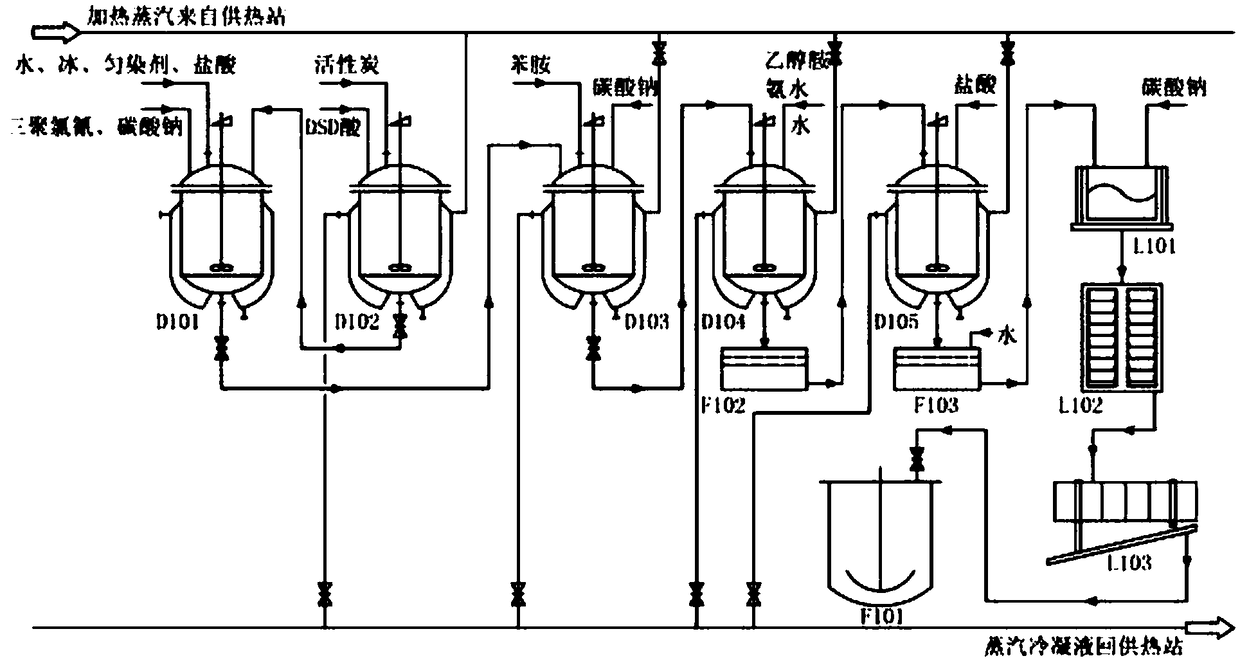

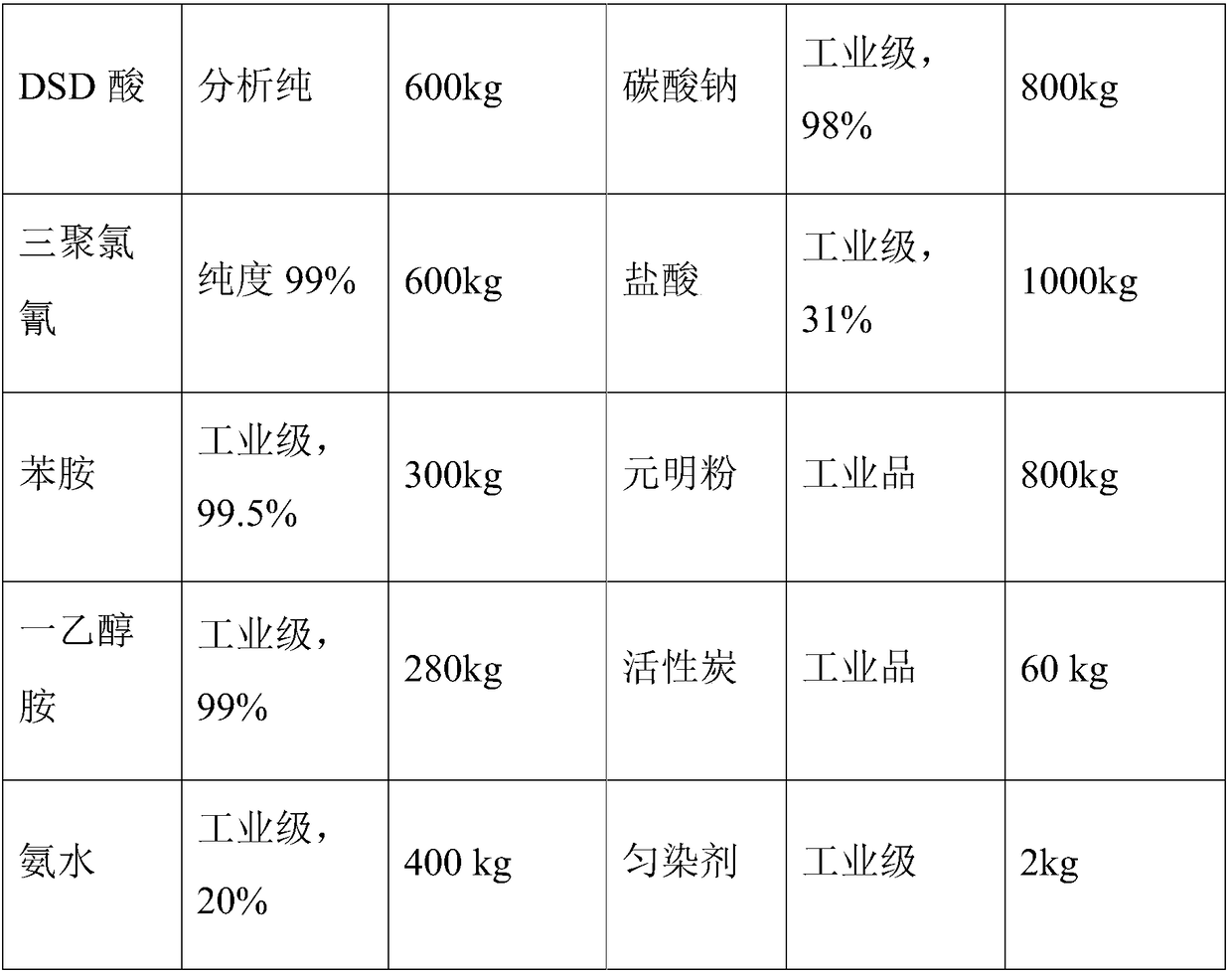

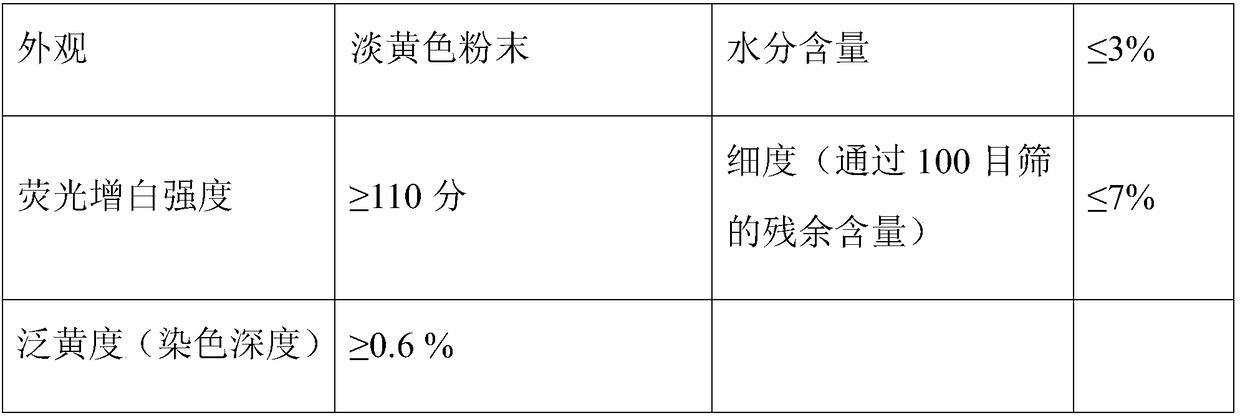

Production device of fluorescent whitening agent VBL

InactiveCN108239534AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryAzo dyesCooking & bakingDissolution

The invention discloses a production device of fluorescent whitening agent VBL. The production device mainly comprises a condensation kettle (D101), a dissolution kettle (D102), a condensation kettle(D103), a condensation kettle (D104), an acid precipitation tank (D105), a kneading machine (L101), a baking room (L102), a sand mill (L103), a blender (F101), a filter (F102) and a suction filter barrel (F103), wherein the dissolution tank (D102) is respectively connected with the condensation kettle (D101) and the condensation kettle (D103), the acid precipitation tank (D105) is respectively connected with the filter (F102) and the suction filter barrel (F103), and the condensation tank (D101) has a nominal volume of 600-660L.

Owner:CHENGDU HUI SI DUN TECH CO LTD

Attapulgite washable inner wall paint

The invention discloses attapulgite washable inner wall paint. The technical proposal comprises the following key points that: the attapulgite washable inner wall paint consists of creamy attapulgite clay, nano-alumina, polyvinyl alcohol superfine powder, instant sodium silicate, anatase type titanium pigments, tributyl phosphate, optical bleaching agent VBL and deionized water. A production method of the attapulgite washable inner wall paint comprises: compounding, crushing, stirring, dispersing, dissolving, homogenizing, emulsifying, defoaming, grinding, and canning into the finished product of the attapulgite washable inner wall paint. The attapulgite washable inner wall paint has the characteristics of no toxicity, odorlessness, hard paint film, fine and soft hand feel, water resistance, alkali resistance and good adhesion. The washable time can be more than 1,000 times, and stains cannot be left after washing for many times. The attapulgite washable inner wall paint is applicableto decorating inner walls of various civil and public buildings and the like.

Owner:LIWANG CHEM NANTONG

Attapulgite interior wall emulsion varnish

The invention discloses an attapulgite interior wall emulsion varnish. The key point of the technical proposal of the invention is that the attapulgite interior wall emulsion varnish consists of pastepalygorskite clay, acrylate emulsion, superfine precipitated calcium carbonate, anatase titanium dioxide, droxyethylcellulose, propanediol, tributyl phosphate, a fluorescent whitening agent VBL and deionized water. The method for producing the attapulgite interior wall emulsion varnish comprises the steps of material mixing, crashing, stirring, dispersion, dissolution, homogenization, emulsification, defoaming, grinding and canning to obtain a finished product of the attapulgite paste interior wall emulsion varnish. The attapulgite paste interior wall emulsion varnish has strong adhesive force, high durability, water resistance, scrubbing resistance and dirt resistance; the quality of the product is accordance with standards of 'GB / T 9756-2001 synthetic emulsion resin interior wall coating' and 'GB 18582-2008 hazardous substance limit quantity in interior decoration finishing material of interior wall coating'; and the attapulgite interior wall emulsion varnish is applicable to coatings for interior decoration.

Owner:LIWANG CHEM NANTONG

Attapulgite inner wall cement paint

The invention discloses a cement paint for interior walls of attapulgite. The key point of the technical proposal is that the cement paint for interior walls of attapulgite comprises purified attapulgite, white Portland cement, polyvinyl alcohol ultrafines, anatase titanium dioxide, droxyethylcellulose, a solid silicone defoaming agent and a fluorescent brightener VBL. The manufacturing method ofthe cement paint for interior walls of attapulgite comprises mixing, crashing, grinding and packaging the finished product of the cement paint for interior walls of attapulgite. The cement paint for interior walls of attapulgite is characterized by super strong adhesive force, fast-drying and firm paint film, humidity resistance, wash resistance, anti-mildew and antibacterial property and high hiding power, etc. The cement paint for interior walls of attapulgite is safe without poison and pollution and the product quality accords with the standard of GB 18582-2008 Decorating and Refurbishing Materials-Limit of Harmful Substances of Interior Architectural Coatings. In addition, the cement paint for interior walls of attapulgite is applicable to the protection and decoration of interior wall surfaces and ceilings of the building structure.

Owner:LIWANG CHEM NANTONG

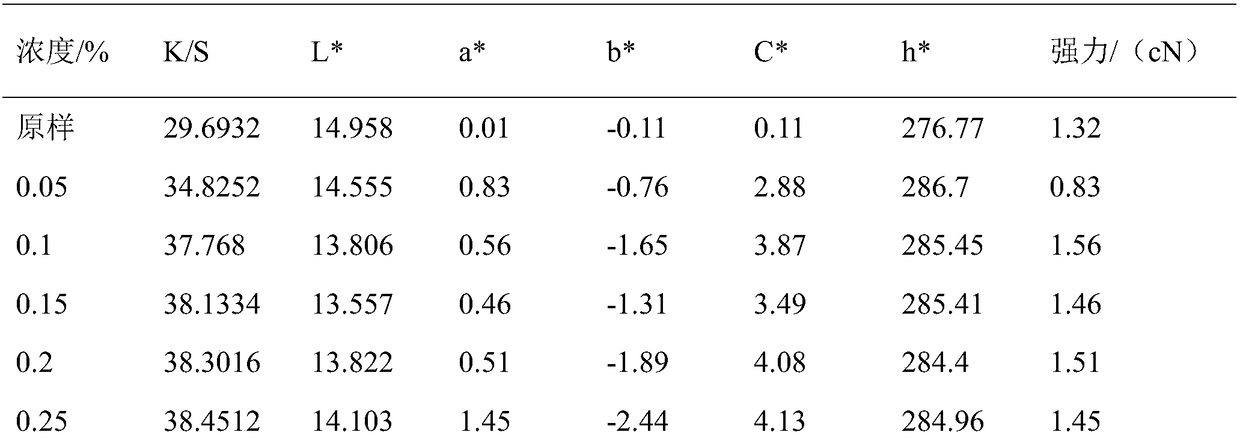

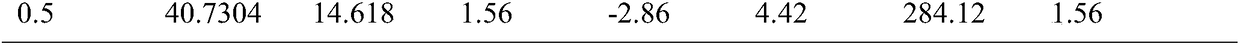

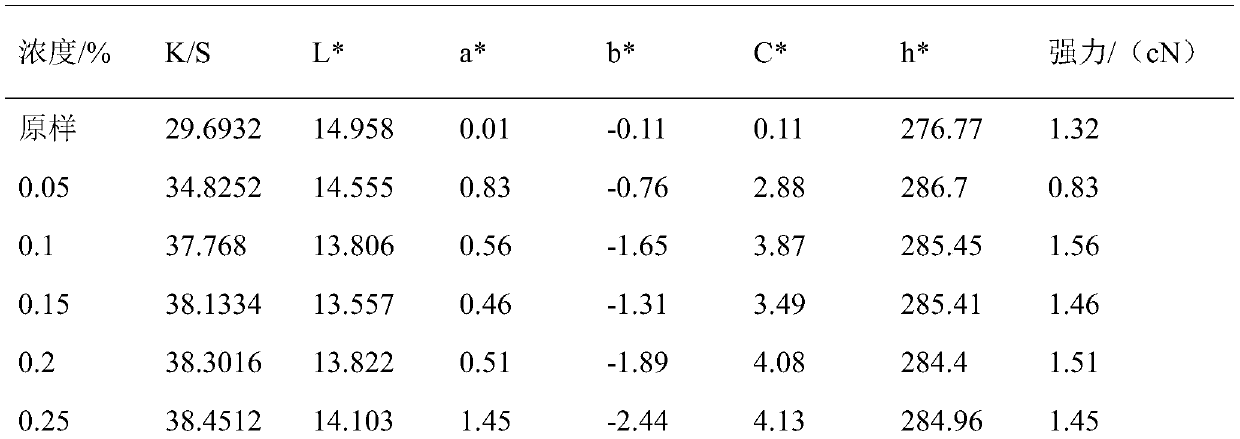

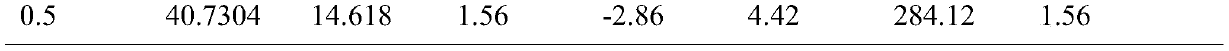

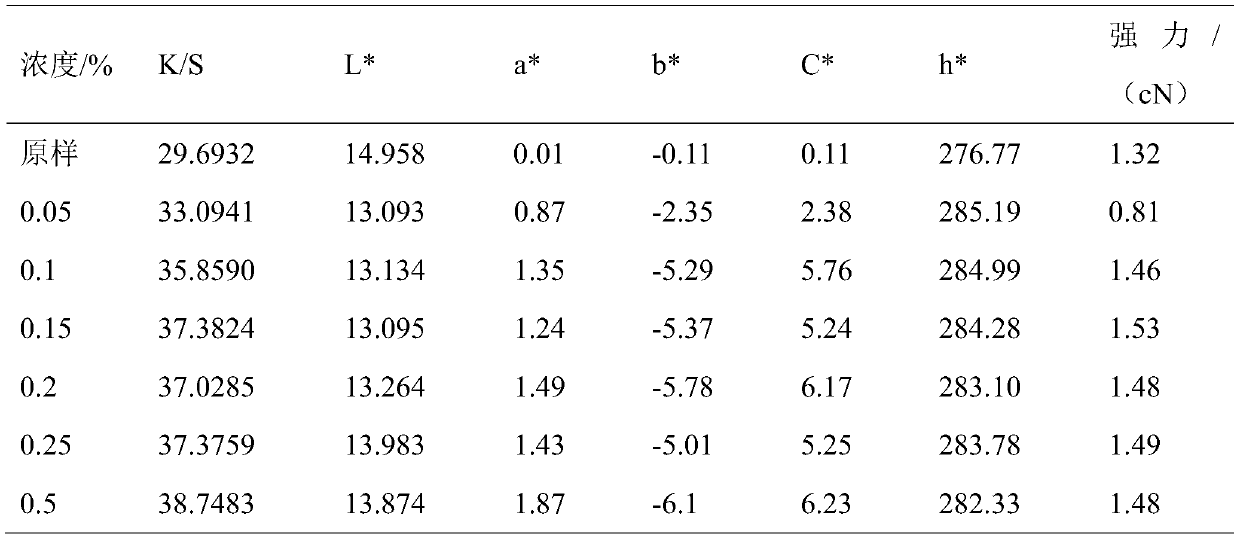

Method for improving black degree of stoste dyeing viscose

ActiveCN109137462AEliminate yellow lightPromote development and utilizationTextiles and paperWhitening AgentsViscose

The invention relates to a method for improving black degree of stoste dyeing viscose, and belongs to the technical field of textile. A fluorescent whitening agent solution is used for soaking black stoste dyeing viscose, and a fluorescent whitening agent comprises one or more of a fluorescent whitening agent 33, a fluorescent whitening agent DM-2622, a fluorescent whitening agent 367, a fluorescent whitening agent DMS, a fluorescent whitening agent WS, a fluorescent whitening agent KSN-1, a fluorescent whitening agent KSN-J, a fluorescent whitening agent VBL and a fluorescent whitening agentCBS-X. Regarding the problem that the black degree of the stoste dyeing viscose is not enough, by utilizing the fluorescent whitening agent, yellow light on the surface of the viscose can be eliminated, therefore the purpose of improving the black degree of the stoste dyeing viscose is achieved, and the development and utilization of the viscose industry in the stoste viscose aspect are promoted.

Owner:JIANGNAN UNIV

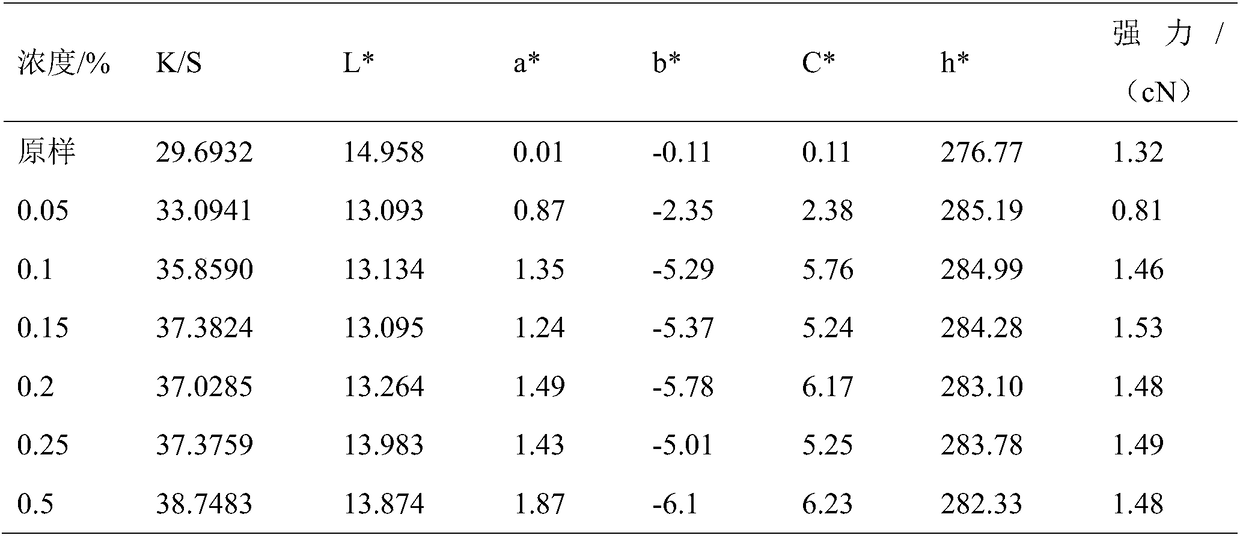

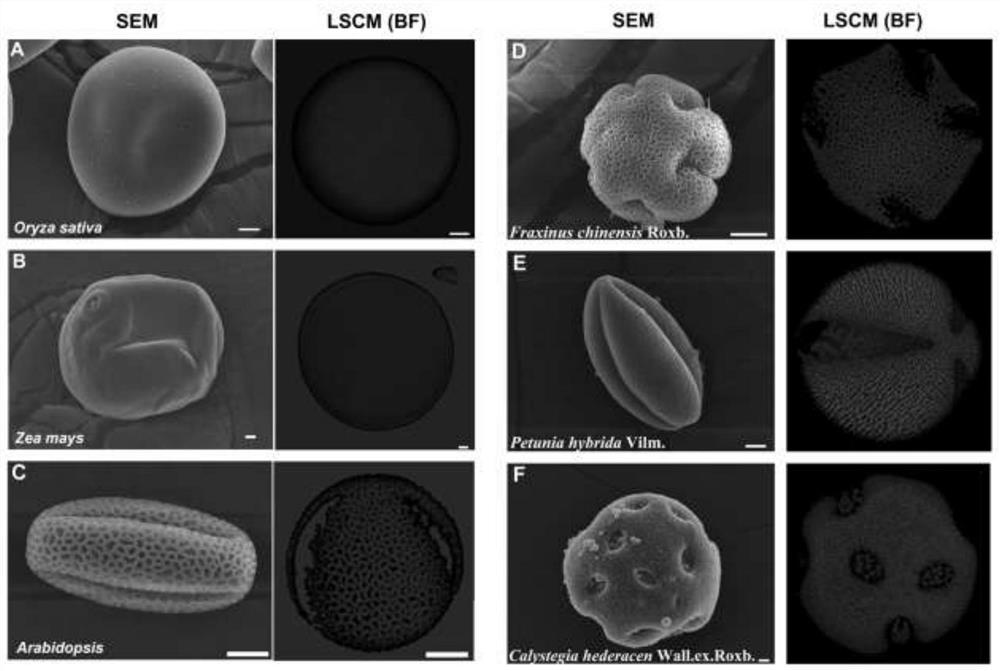

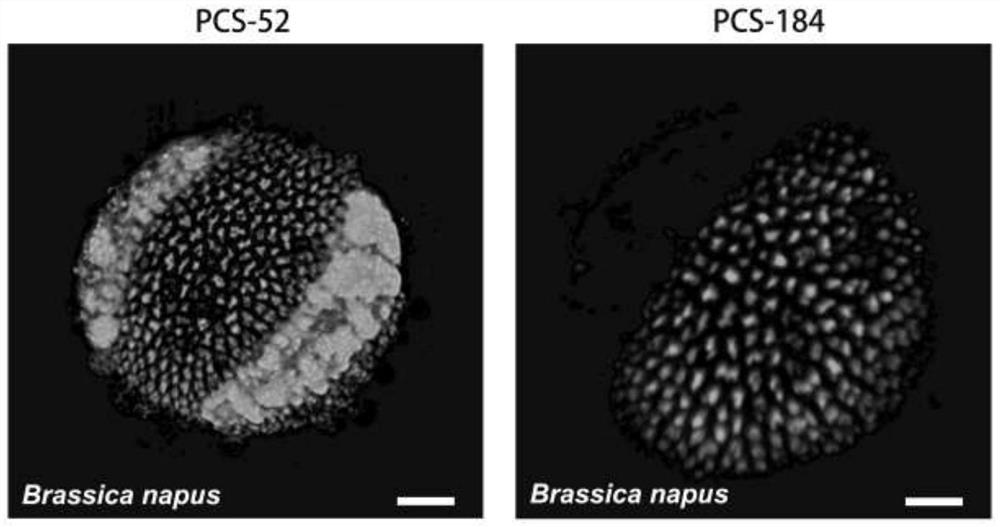

Observation method for specifically recognizing different parts of pollen, corresponding dye and application

ActiveCN112924259AFine structure profileEasy to operatePreparing sample for investigationFluorescence/phosphorescenceCelluloseStaining

The invention provides an observation method for specifically recognizing different parts of pollen, corresponding dye and application. According to the invention, a dye liquor screening method which can be shared with green fluorescent protein (GFP) / yellow fluorescent protein (YFP) is established for the first time; a dye liquor, namely basic fuchsin, capable of specifically marking pollen outer walls (sporopollen components), a dye solution capable of specifically marking the inner wall (cellulose component) of pollen, namely a fluorescent whitening agent 220 (FB-220) and a fluorescent whitening agent VBL (FB-VBL), a dye liquor capable of specifically marking pollen coating (ultra-long chain fatty acid component), namely a fluorescent whitening agent 184 (PCS-184), and a dye liquor capable of non-specifically marking pollen coating, namely a fluorescent whitening agent 52 (PCS-52), arescreened from whitening agents / coloring agents such as fluorescent whitening agents and direct dyes through large-scale screening; and a dyeing method of the dye liquor composition in plant pollen (spores) is established and optimized, and the compatibility of the dyeing method and the green fluorescent protein (GFP) is tested.

Owner:SHANGHAI NORMAL UNIVERSITY

A method for improving the blackness of stock solution dyed viscose fiber

ActiveCN109137462BEliminate yellow lightPromote development and utilizationTextiles and paperTextile technologyPolymer science

The invention relates to a method for improving black degree of stoste dyeing viscose, and belongs to the technical field of textile. A fluorescent whitening agent solution is used for soaking black stoste dyeing viscose, and a fluorescent whitening agent comprises one or more of a fluorescent whitening agent 33, a fluorescent whitening agent DM-2622, a fluorescent whitening agent 367, a fluorescent whitening agent DMS, a fluorescent whitening agent WS, a fluorescent whitening agent KSN-1, a fluorescent whitening agent KSN-J, a fluorescent whitening agent VBL and a fluorescent whitening agentCBS-X. Regarding the problem that the black degree of the stoste dyeing viscose is not enough, by utilizing the fluorescent whitening agent, yellow light on the surface of the viscose can be eliminated, therefore the purpose of improving the black degree of the stoste dyeing viscose is achieved, and the development and utilization of the viscose industry in the stoste viscose aspect are promoted.

Owner:JIANGNAN UNIV

Preparation method of fluorescent composite whitened attapulgite

InactiveCN102675929AGood dispersionAchieve whitening effectPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityFixation - action

The invention discloses a preparation method of fluorescent composite whitened attapulgite, which is characterized by comprising the following steps: (1) after pulverizing attapulgite, screening, adding water to prepare a disperse system with a certain concentration, stirring, standing for some time, taking the supernatant suspension, carrying out centrifugal dewatering on the supernatant suspension, and drying at certain temperature to obtain purified attapulgite; (2) preparing the purified attapulgite into a dispersion, dropwisely adding a silane coupling agent while stirring, heating to react for some time, filtering, washing, drying, grinding and screening to obtain modified attapulgite; and (3) carrying out composite reaction on the modified attapulgite with a melamine-formaldehyde polycondensate and a water-soluble fluorescent whitening agent VBL to obtain the fluorescent whitened attapulgite. The attapulgite surface is modified by the silane coupling agent, thereby enhancing the dispersity of the attapulgite and the coupling action with resin; and the compound obtained by reacting the melamine-formaldehyde resin with the fluorescent whitening agent is compounded onto the attapulgite surface under the coupling action, thereby effectively enhancing the fixation action of the fluorescent whitening agent on the attapulgite surface and achieving the effect of whitening the attapulgite.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Attapulgite interior wall powder coating

The invention discloses an attapulgite interior wall powder coating. The key point of the technical proposal of the invention is that the attapulgite interior wall powder coating consists of purified attapulgite, precipitated calcium carbonate, polyvinyl alcohol ultrafines, instant sodium silicate, anatase titanium dioxide, a solid polyether defoaming agent and a fluorescent whitening agent VBL. The method for producing the attapulgite interior wall powder coating comprises the steps of material mixing, crashing, grinding into powder and packaging to obtain a finished product of the attapulgite interior wall powder coating. The attapulgite interior wall powder coating has strong adhesive force, high durability, water resistance, friction resistance and dirt resistance, and can absorb formaldehyde and volatile organic compound to purify air. The attapulgite paste interior wall powder coating is a white reference coating and can be directly adjusted in color to produce color washes of various colors; and the attapulgite interior wall powder coating is applicable to building decoration.

Owner:LIWANG CHEM NANTONG +1

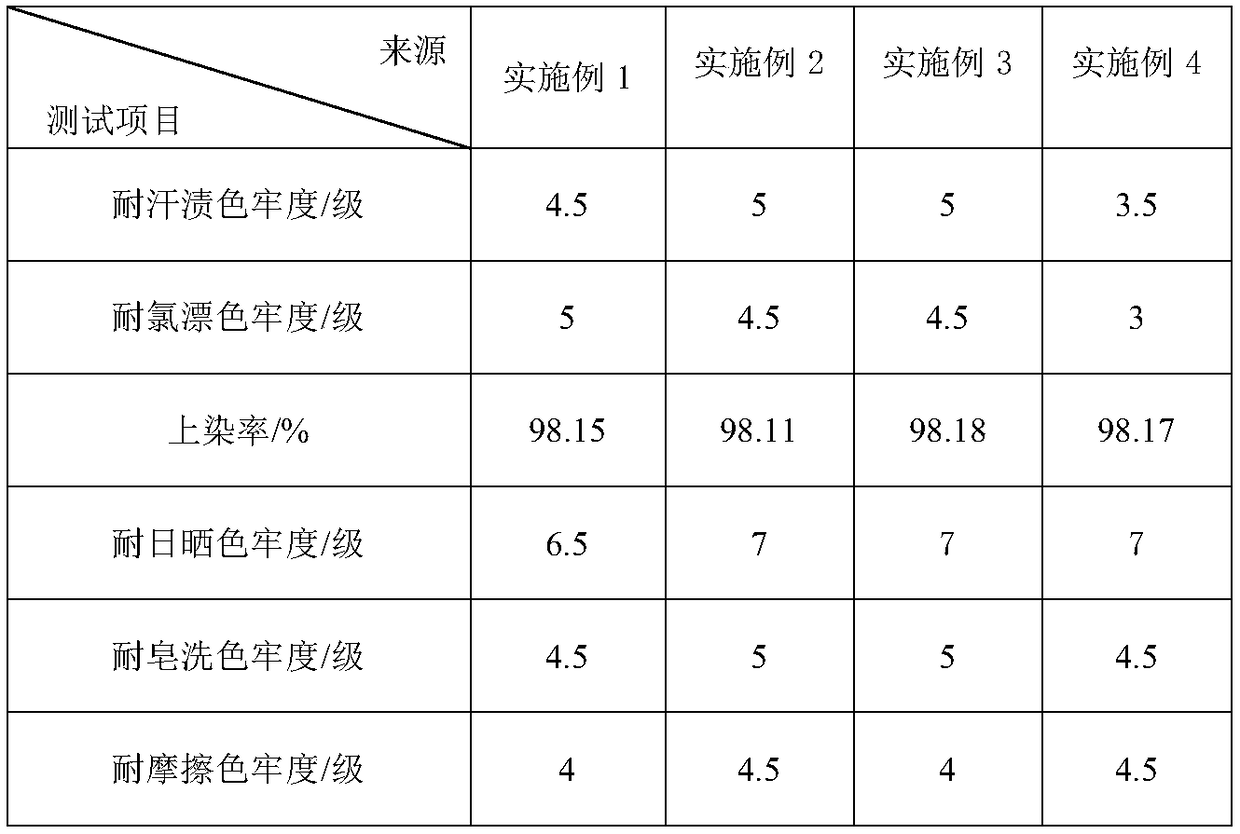

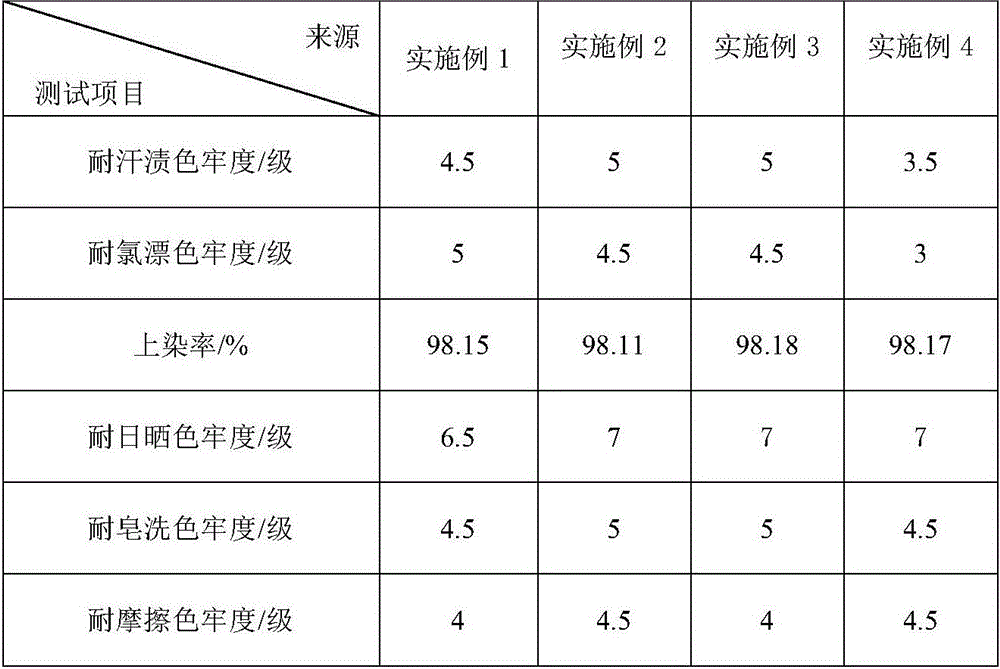

Method for preparing perspiration-resistant and chlorine bleach-resistant indigo dyeing water with indigo paste

ActiveCN106675090BHigh fastnessHigh color fastness to sunlightOrganic dyesHydrogen SulfateSodium bisulfate

The invention belongs to the field of dyes, and specifically relates to a method for preparing perspiration-resistant and chlorine-resistant indigo dye water by utilizing an indigo paste. The method comprises the following specific steps: S1, adding water into the indigo paste to obtain a water solution of the indigo paste; S2, adding fatty alcohol-polyoxyethylene ether, polyoxyethylene benzene alkyl phenolic ether, nekal and a flourescent brightener VBL into water in sequence, and stirring uniformly; S3, adding the water solution of the indigo paste into the solution obtained in the step S2, then adding sodium hydrogen sulfate, sodium chloride and vinasse, and stirring uniformly; and S4, putting the solution obtained in the step S3 into a dyeing pool, sealing, standing for fermentation until the solution is light yellow, using a whiteware container for sampling vibration observation, and stopping fermentation when a light blue flowing cloud appears in the solution. The indigo dye water prepared in the invention is high in perspiration-resistant color fastness and chlorine-resistant color fastness; and meanwhile, the indigo dye water prepared with the method is high in sunshine-resistant color fastness, washing-resistant color fastness and rub-resistant color fastness, and is also high in dye-uptake.

Owner:GUIZHOU DANZHAI NINGHANG BATIK

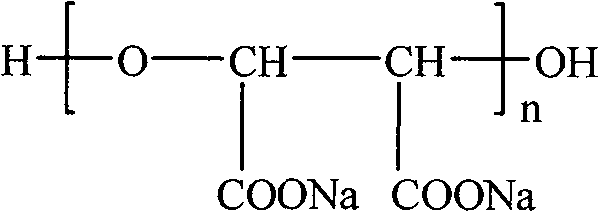

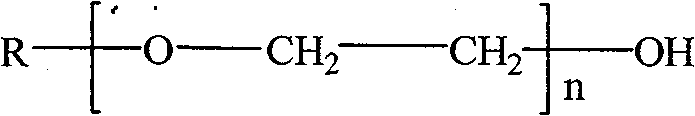

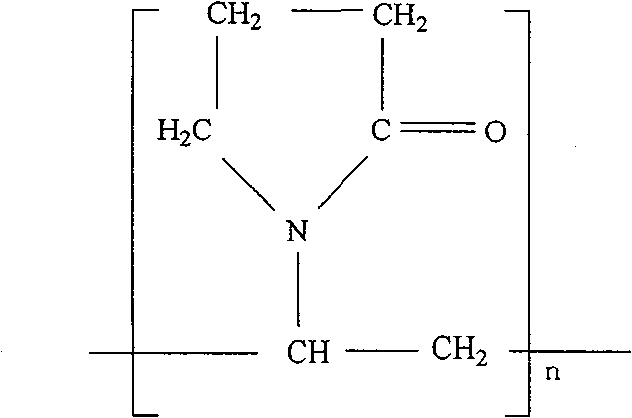

Environmental friendly synthetic detergent taking poly epoxy succinic acid as washing assistant

InactiveCN101514308BStrong ability to prevent redepositionWide range of water qualityOrganic detergent compounding agentsSurface-active detergent compositionsSodium bicarbonateEpoxy

The invention belongs to the daily chemical industry technical field, in particular to an environmental friendly synthetic detergent taking poly epoxy succinic acid as a washing assistant. The synthetic detergent comprises the following components according to the percentage by weight: 8%-15% of linear alkylbenzene sulphonic acid, 10-30% of poly epoxy succinic acid, 1%-5% of fatty alcohol polyoxyethylene ether (polyoxyethylene fatty alcohol sodium sulfate), 4%-6% of sodium bicarbonate, 4%-6% of borax, 0.5%-1.5% of polyvinyl-pyrrolidone, 5%-12% of sodium silicate, and 0.03%-0.2% of optical brightness VBL, and the rest of bulking agent sodium sulfate, which meets the gross weight of 100%. The poly epoxy succinic acid used by the synthetic detergent as the washing detergent plays a part in anti redeposition and dispersion, not only can chelate with metal ions such as calcium, magnesium and the like but also has dispersive action on calcium and magnetism precipitation, thus achieving the effect of anti redeposition and dispersion and increasing the washing effect. All components in the synthetic detergent have good synergistic action and obvious decontamination and anti redeposition effects. The environmental friendly synthetic detergent does not contain nitrogen and phosphorus, and the poly epoxy succinic acid can be biodegraded; therefore, after being used, the synthetic detergent does not cause the severe harm to the environment.

Owner:TONGJI UNIV

Method for preparing perspiration-resistant and chlorine-resistant indigo dye water by utilizing indigo paste

ActiveCN106675090AHigh fastnessHigh color fastness to sunlightOrganic dyesHydrogen SulfateSodium bisulfate

The invention belongs to the field of dyes, and specifically relates to a method for preparing perspiration-resistant and chlorine-resistant indigo dye water by utilizing an indigo paste. The method comprises the following specific steps: S1, adding water into the indigo paste to obtain a water solution of the indigo paste; S2, adding fatty alcohol-polyoxyethylene ether, polyoxyethylene benzene alkyl phenolic ether, nekal and a flourescent brightener VBL into water in sequence, and stirring uniformly; S3, adding the water solution of the indigo paste into the solution obtained in the step S2, then adding sodium hydrogen sulfate, sodium chloride and vinasse, and stirring uniformly; and S4, putting the solution obtained in the step S3 into a dyeing pool, sealing, standing for fermentation until the solution is light yellow, using a whiteware container for sampling vibration observation, and stopping fermentation when a light blue flowing cloud appears in the solution. The indigo dye water prepared in the invention is high in perspiration-resistant color fastness and chlorine-resistant color fastness; and meanwhile, the indigo dye water prepared with the method is high in sunshine-resistant color fastness, washing-resistant color fastness and rub-resistant color fastness, and is also high in dye-uptake.

Owner:GUIZHOU DANZHAI NINGHANG BATIK

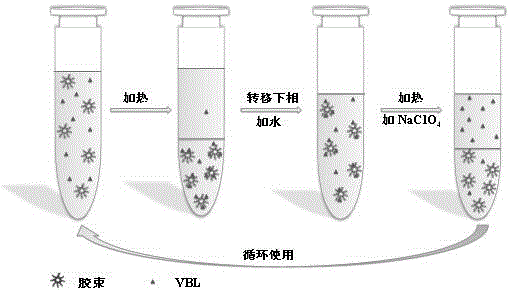

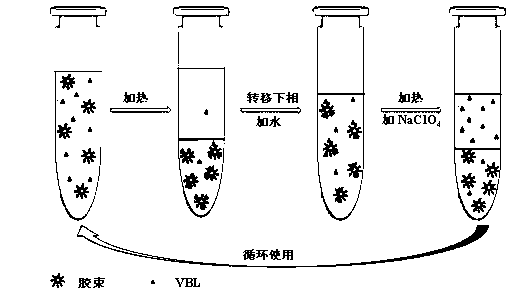

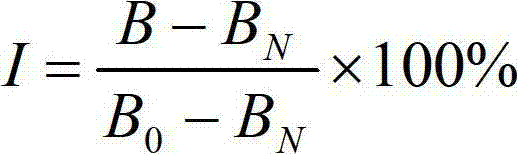

Method of cloud point extraction for fluorescent whitening agent VBL in sewage

ActiveCN105923681AHigh extraction rateRemove completelyWater treatment compoundsWater contaminantsActive phaseSewage

The invention relates to a method of cloud point extraction for a fluorescent whitening agent VBL in sewage and belongs to the technical field of industrial dye wastewater treatment. The method comprises the following steps: firstly, proportionally mixing an aqueous solution of a surfactant triton X-114 with fluorescent whitening agent VBL-containing wastewater to prepare a cloud point extraction system; adjusting pH and then standing for phase separation; after phase separation, i.e., extraction of the VBL to a lower phase, diluting the lower phase and then adding sodium perchlorate thereto for mixing evenly to undergo secondary phase separation with the VBL shifting to an upper phase; and removing the upper phase containing the VBL with the triton X-114 left in the lower phase that may be used to repeatedly treating the VBL in wastewater. The method allows the cloud point extraction of the VBL in wastewater to a surface active phase by means of the thermosensitivity of the surfactant triton X-114 with a VBL extraction yield reaching up to 99.79% and the recovery of the surfactant triton X-114 above 90%.

Owner:JIANGSU UNIV

A method for cloud point extraction of fluorescent whitening agent vbl in sewage

ActiveCN105923681BHigh extraction rateRemove completelyWater treatment compoundsWater contaminantsActive phaseSewage

The invention relates to a method of cloud point extraction for a fluorescent whitening agent VBL in sewage and belongs to the technical field of industrial dye wastewater treatment. The method comprises the following steps: firstly, proportionally mixing an aqueous solution of a surfactant triton X-114 with fluorescent whitening agent VBL-containing wastewater to prepare a cloud point extraction system; adjusting pH and then standing for phase separation; after phase separation, i.e., extraction of the VBL to a lower phase, diluting the lower phase and then adding sodium perchlorate thereto for mixing evenly to undergo secondary phase separation with the VBL shifting to an upper phase; and removing the upper phase containing the VBL with the triton X-114 left in the lower phase that may be used to repeatedly treating the VBL in wastewater. The method allows the cloud point extraction of the VBL in wastewater to a surface active phase by means of the thermosensitivity of the surfactant triton X-114 with a VBL extraction yield reaching up to 99.79% and the recovery of the surfactant triton X-114 above 90%.

Owner:JIANGSU UNIV

Preparation method of fluorescent composite whitened attapulgite

InactiveCN102675929BGood dispersionAchieve whitening effectPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsFixation - actionDispersity

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Emulsion paint for interior wall

InactiveCN106905730AImprove adhesionIncreased durabilityAntifouling/underwater paintsPaints with biocidesMicrospherePliability

The invention relates to the field of emulsion paint, in particular to an emulsion paint for interior walls. It is composed of the following parts by weight: 45-55 parts of water-based resin, 25-45 parts of paste-like attapulgite clay, 15-25 parts of pure acrylic emulsion, 5-15 parts of superfine light calcium carbonate, bamboo carbon powder 15-20 parts, 5-10 parts of anatase titanium dioxide, 5-10 parts of hydroxyethyl cellulose, 3-10 parts of sodium hexametaphosphate, 15-25 parts of nano-polymer hollow microspheres, 25- 35 parts, 3-5 parts of propylene glycol, 0.05-0.08 parts of tributyl phosphate, 0.02-0.05 parts of fluorescent whitening agent VBL, 5-8 parts of vinyl acetate, 15-25 parts of butyl acrylate, 25-45 parts of deionized water share. The latex paint for interior walls provided by the invention does not contain formaldehyde, contains bamboo vinegar, can absorb harmful substances in the air, has good adhesion, has good durability, water resistance, scrub resistance and stain resistance, and has good Excellent elasticity and flexibility, with good film-forming properties.

Owner:彭志成

Fluorescent brightening agent VBL detection kit and preparation method thereof

The invention discloses a fluorescent brightening agent VBL detection kit, belonging to the technical field of additive detection. The kit comprises an enzyme label plate coated by a fluorescent brightening agent VBL specific antigen and a fluorescent brightening agent VBL specific antibody solution, wherein each micropore of the enzyme label plate is coated by the fluorescent brightening agent VBL specific antigen having a concentration of 1-3 mug / mL, the concentration of the fluorescent brightening agent VBL specific antibody is 1-3 mug / mL, and the dosage ratio of the fluorescent brightening agent VBL specific antigen to the fluorescent brightening agent VBL specific antibody solution is 1:1. The invention further discloses a preparation method of the detection kit. The detection kit disclosed herein can continuously detect a plurality of samples at a time when the fluorescent brightening agent VBL is detected, has the characteristics of convenience, rapidness, sensitivity, and low cost, and is suitable for rapidly and accurately detecting fluorescent brightening agent VBL in mass samples.

Owner:GUANGZHOU QUALITY SUPERVISION & TESTING INST

Towel whitening and brightening agent

InactiveCN102021811AReasonable formulaImprove work performanceBleaching apparatusOrganic chemistryFluorescent whitening agent VBL

The invention discloses a towel whitening and brightening agent which is formed by mixing a fluorescent brightening agent VBL, soap and water. The invention has the advantages of reasonable prescription, good working effect and low production cost.

Owner:金海洋

Method for producing attapulgite paste interior wall coating

InactiveCN101585211BAvoid production methodsClay processing apparatusPolyvinyl alcoholPrecipitated calcium carbonate

The invention discloses a method for producing an attapulgite paste interior wall coating. The key point of the technical proposal of the invention is that the method for producing the attapulgite paste interior wall coating comprises the steps of material mixing, crashing, stirring, dispersion, dissolution, homogenization, emulsification, defoaming, grinding and canning to obtain a finished product of the attapulgite paste interior wall coating. The attapulgite paste interior wall coating consists of paste palygorskite clay, superfine precipitated calcium carbonate, polyvinyl alcohol ultrafines, instant sodium silicate, anatase titanium dioxide, a solid polyether defoaming agent, a fluorescent whitening agent VBL and deionized water. The attapulgite paste interior wall coating has strongadhesive force, high durability, water resistance, friction resistance and dirt resistance, and can absorb formaldehyde and volatile organic compound to purify the air. The attapulgite paste interiorwall coating is a white reference coating and can be directly adjusted in colors to produce color washes of various colors; and the method for producing the attapulgite paste interior wall coating issuitable for producing environment-friendly interior wall coatings.

Owner:许盛英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com