Method of removing fluorescent whitening agent VBL in water body

A fluorescent whitening agent, -VBL technology, applied in the field of environmental science and engineering, can solve the problems of limited adsorption capacity, poor adsorption effect of fluorescent whitening agent wastewater, etc., and achieves a simple preparation process, low cost, and high adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

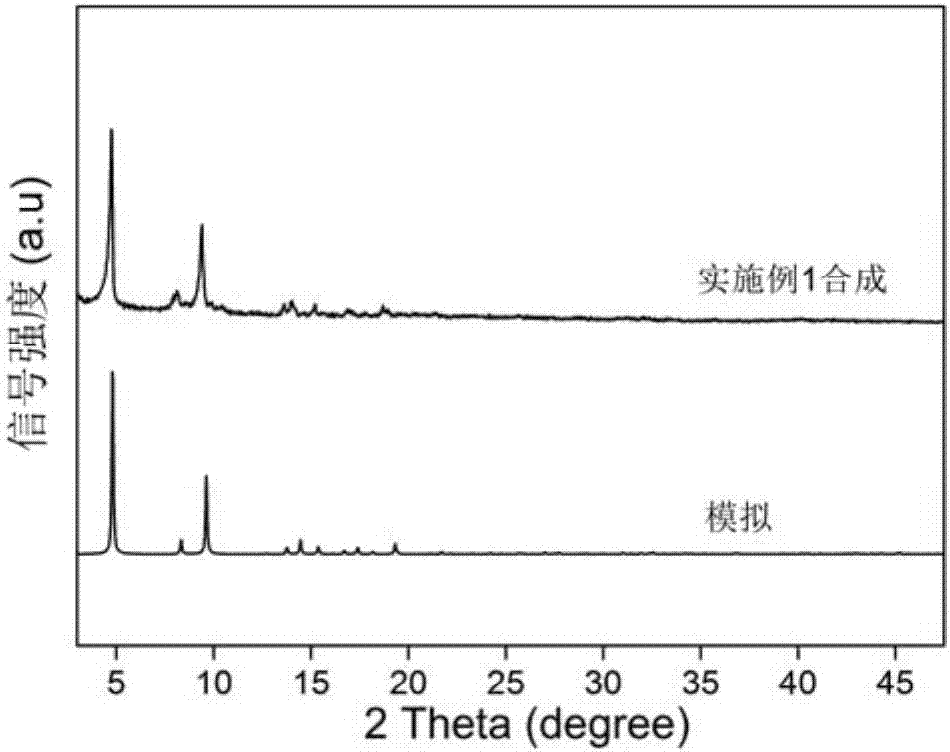

[0028] Embodiment 1: prepare MIL-68 (Al) material

[0029] Dissolve 4.40g of aluminum chloride hexahydrate and 0.61g of terephthalic acid in 21mL of propanol, place in a reaction kettle and stir evenly, and the resulting reaction solution rises from 60°C to 140°C at a rate of 20°C / h. Keep the temperature at 140°C for 5h, then cool down to room temperature naturally. The filtered product was washed 3 times with deionized water for 2 hours each time, and calcined at 300° C. for 8 hours in a tube furnace to obtain a sample and mark it as MIL-68(Al).

Embodiment 2

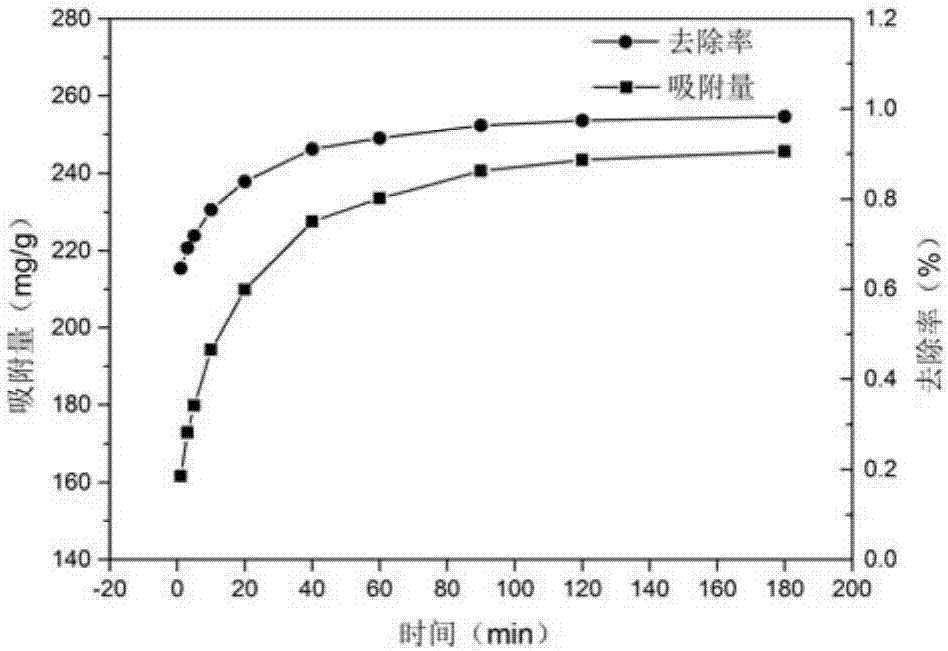

[0030] Embodiment 2: MIL-68 (Al) is to the adsorption of fluorescent whitening agent-VBL in water

[0031] Take ten 250mL conical flasks, and add 100mL of 50mg / L fluorescent whitening agent-VBL solution to each conical flask. The aluminum-based metal-organic framework MIL-68(Al) material prepared in Example 1 was added to each set of Erlenmeyer flasks, and the amount of the material added to each Erlenmeyer flask was 20 mg. The adsorption was carried out in a constant temperature shaker at a temperature of 298K for different times, and the results are shown in figure 2 .

Embodiment 3

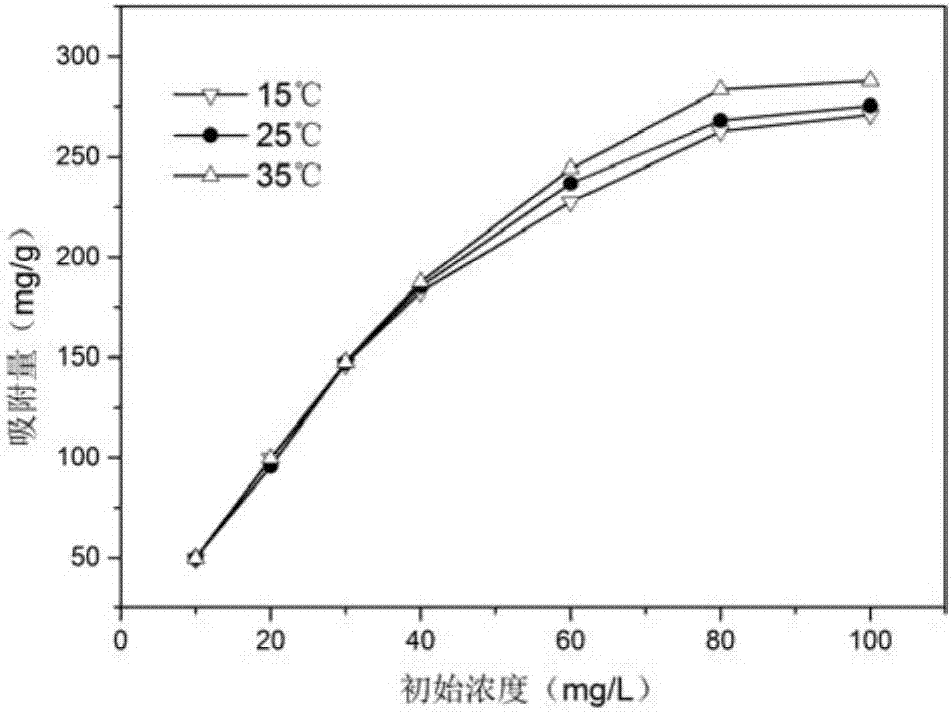

[0032] Embodiment 3: MIL-68 (Al) is to the adsorption of fluorescent whitening agent-VBL in water

[0033] Take 21 250mL Erlenmeyer flasks and divide them into three groups. The concentration gradient of fluorescent whitening agent-VBL solution in each group is 10, 20, 30, 40, 60, 80, 100mg / L, and the volume is 100mL. The aluminum-based metal-organic framework MIL-68(Al) material prepared in Example 1 was added to each Erlenmeyer flask in an amount of 20 mg. At 288K, 298K and 308K, the adsorption of different initial concentrations was carried out in a constant temperature shaker, and the results are shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com