Method for preparing perspiration-resistant and chlorine-resistant indigo dye water by utilizing indigo paste

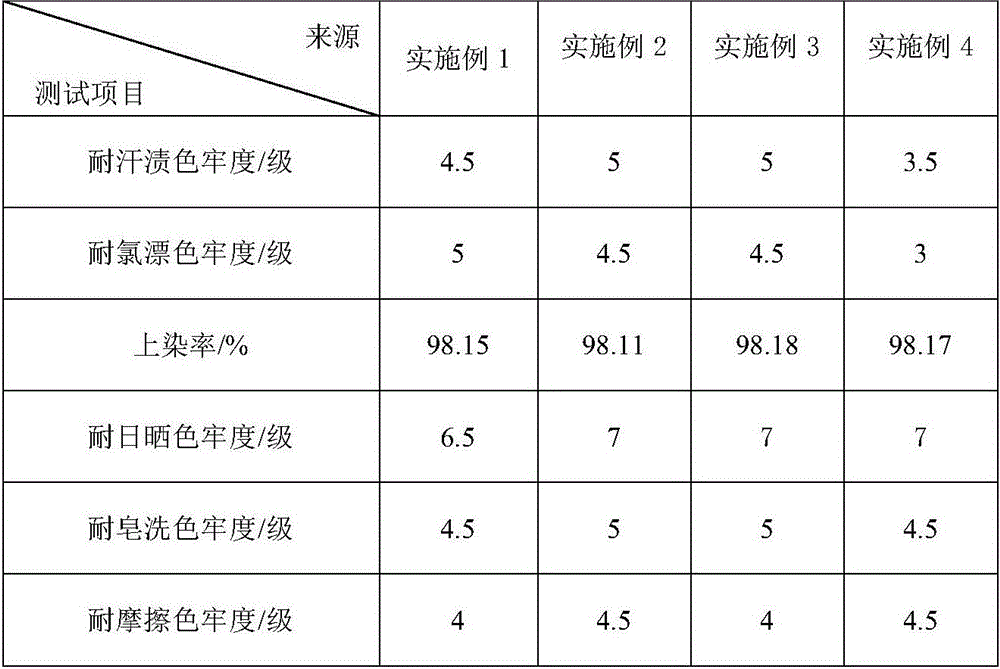

A technology of perspiration resistance and chlorine bleaching resistance, applied in the field of dyes, can solve the problems of low color fastness, decolorization, and troublesome dye processing and production, and achieve high color fastness to perspiration and chlorine bleaching, and high dyeing fastness. The effect of high rate, color fastness to soaping and color fastness to rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for preparing perspiration-resistant and chlorine bleaching-resistant indigo dyeing water with indigo paste, the specific steps are:

[0024] S1: add the water of its quality 10 times in the blue indigo paste, obtain the aqueous solution of the blue indigo paste;

[0025] S2: Add carbon tetradecanoyl alcohol polyoxyethylene ether, polyoxyethylene phenylalkylphenol ether, sodium dibutylnaphthalene sulfonate and fluorescent whitening agent VBL (carbon tetradecanoyl alcohol polyoxyethylene ether, poly The mass ratio of oxyethylene phenylalkylphenol ether, sodium dibutylnaphthalene sulfonate and fluorescent whitening agent VBL is: 6:2:2:1, and the quality of the added carbon tetradecyl fatty alcohol polyoxyethylene ether is water 5% of ), and stir evenly;

[0026] S3: in step S2 gained solution, add the aqueous solution of its quality 1.56% indigo paste, then add sodium bisulfate, sodium chloride and distiller's grains (the ratio of the mass of sodium bisulfate,...

Embodiment 2

[0029] The method for preparing perspiration-resistant and chlorine bleaching-resistant indigo dyeing water with indigo paste, the specific steps are:

[0030] S1: add the water of its quality 8 times in the blue indigo paste, obtain the aqueous solution of the blue indigo paste;

[0031] S2: Add Cetyl Alcohol Polyoxyethylene Ether, Polyoxyethylene Phenylphenol Ether, Sodium Dibutyl Naphthalene Sulfonate and Fluorescent Whitening Agent VBL (Added Cetyl Alcohol Polyoxyethylene Ether) to the water successively , polyoxyethylene phenylalkylphenol ether, sodium dibutylnaphthalene sulfonate and fluorescent whitening agent VBL are in a mass ratio of 6:2:2:1, and the mass of hexadecanoyl alcohol polyoxyethylene ether added 3% of water,), and stir well;

[0032] S3: in step S2 gained solution, add the aqueous solution of its quality 1.78% indigo paste, then add sodium bisulfate, sodium chloride and distiller's grains (the ratio of the mass of sodium bisulfate, sodium chloride and dis...

Embodiment 3

[0035] The method for preparing perspiration-resistant and chlorine bleaching-resistant indigo dyeing water with indigo paste, the specific steps are:

[0036] S1: add the water of its quality 9 times in the blue indigo paste, obtain the aqueous solution of the blue indigo paste;

[0037] S2: add carbon fourteen fatty alcohol polyoxyethylene ether, carbon sixteen fatty alcohol polyoxyethylene ether, polyoxyethylene phenylalkylphenol ether, sodium dibutyl naphthalene sulfonate and fluorescent whitening agent VBL to water successively (adding The mass ratio of carbon fourteen fatty alcohol polyoxyethylene ether, carbon sixteen fatty alcohol polyoxyethylene ether, polyoxyethylene phenylalkylphenol ether, sodium dibutyl naphthalene sulfonate and fluorescent whitening agent VBL is: 2.4 :3.6:2:2:1, the quality of the carbon tetradetradecyl alcohol polyoxyethylene ether added is 0.8% of water,), and stir evenly;

[0038] S3: in step S2 gained solution, add the aqueous solution of it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com