Method for improving black degree of stoste dyeing viscose

A technology of dope dyeing and viscose fiber, applied in textiles and papermaking, etc., can solve the problems of insufficient blackness of colored viscose fibers and no solution, and achieve the effect of improving the blackness and promoting development and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment selects black dope dyed viscose fiber for use, and the technology that adopts is as follows:

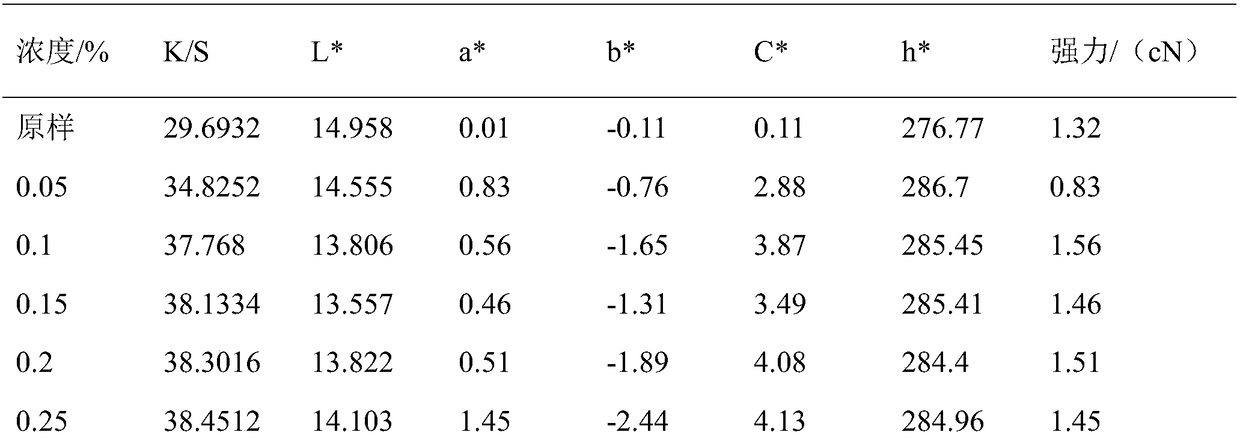

[0022] Process steps: Weigh 2g of black stock solution dyed viscose fiber, wet it with water, prepare a series of corresponding fluorescent whitening agents with concentrated gradients of 0.05%, 0.1%, 0.15%, 0.2%, 0.25%, and 0.5% After the DM-2622 solution is poured into the dyeing cups respectively, the bath ratio is 1:50, and then the black stock solution dyed viscose fiber is treated at 60°C for 60 minutes. After the reaction, the sample is taken out, marked, and water Washing, drying, and the effect of the amount of fluorescent whitening agent on the color properties of black dope-dyed viscose fiber are shown in Table 1.

[0023] The impact of the amount of fluorescent whitening agent in table 1 on the color performance of black dope dyed viscose fiber

[0024]

[0025]

[0026] From Table 1, it can be found that with the increase of the amoun...

Embodiment 2

[0028] The present embodiment selects black dope dyed viscose fiber for use, and the technology that adopts is as follows:

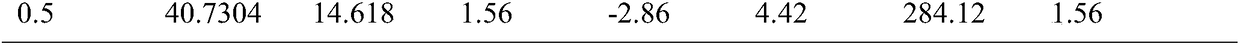

[0029] Process steps: Weigh 2g of black stock solution dyed viscose fiber, wet it with water, prepare a series of corresponding fluorescent whitening agents with concentrated gradients of 0.05%, 0.1%, 0.15%, 0.2%, 0.25%, and 0.5% After the 367 solution, pour them into the dyeing cups respectively, the bath ratio is 1:50, and then treat the black stock solution dyed viscose fiber at 50°C for 60 minutes. After the reaction, take out the sample, mark it, and wash it with water , drying, and the effect of the amount of fluorescent whitening agent on the color properties of black dope-dyed viscose fiber are shown in Table 2.

[0030] The influence of the dosage of table 2 fluorescent whitening agent on the color performance of black dope dyed viscose fiber

[0031]

[0032] From Table 2, it can be found that with the increase of the amount of fluorescent ...

Embodiment 3

[0034] The present embodiment selects black dope dyed viscose fiber for use, and the technology that adopts is as follows:

[0035] Process steps: Weigh 2g of black stock solution dyed viscose fiber, wet it with water, prepare a series of corresponding fluorescent whitening agents with concentrated gradients of 0.05%, 0.1%, 0.15%, 0.2%, 0.25%, and 0.5% After the KSN-J solution is poured into the dyeing cups respectively, the bath ratio is 1:50, and then the black stock solution dyed viscose fiber is treated at 50°C for 40 minutes. After the reaction, the sample is taken out, marked, and water Washing, drying, and the effect of the amount of fluorescent whitening agent on the color properties of black dope-dyed viscose fiber are shown in Table 3.

[0036] The influence of the dosage of table 3 fluorescent whitening agent on the color performance of black dope dyed viscose fiber

[0037]

[0038] It can be found from Table 3 that with the increase of the amount of fluorescen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com