Quantitative determination method for fluorescent whitening agent VBL, ABP for tobacco

A fluorescent whitening agent, quantitative determination technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unable to eliminate interference, unable to determine the type of fluorescent whitening agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

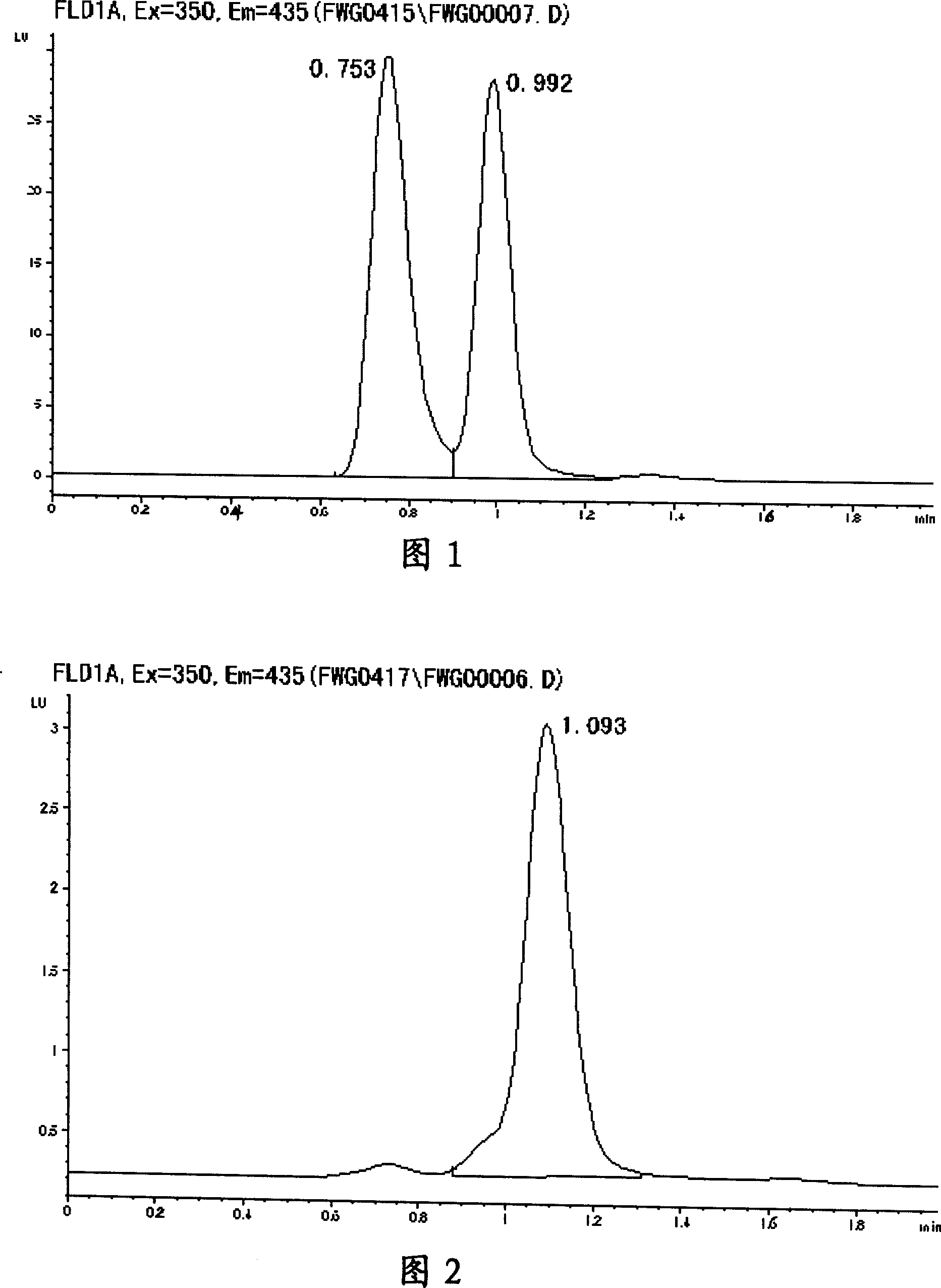

[0066] Column: Alltima C 18 Column, 150 mm x 4.6 mm, 5 μm.

[0067] Mobile phase: methanol / water: 45 / 55 (V / V), before HPLC analysis, filter through a 0.45 μm filter membrane and vacuum degassing.

[0068] Mobile phase flow rate: 1.0 mL / min.

[0069] Detection wavelength: excitation wavelength 350nm, emission wavelength 435nm.

[0070] Extraction solution: N,N-dimethylformamide.

[0071] Extraction time: 30min.

[0072] Extraction temperature: 40°C.

[0073] Use stainless steel scissors to cut the sample of tipping paper for cigarettes to 1mm×1mm, weigh 0.5g of the paper sample into a 50mL stoppered test tube, add 25.0mL of N,N-dimethylformamide to completely infiltrate the paper sample, and place 1 hour, ultrasonic oscillation at 40°C for 30 minutes. The oscillating solution was filtered through a 0.45 μn membrane filter, and the filtrate was used for later use. The above operations should be carried out in the dark as much as possible.

[0074] Use a microsampler or a...

Embodiment 2

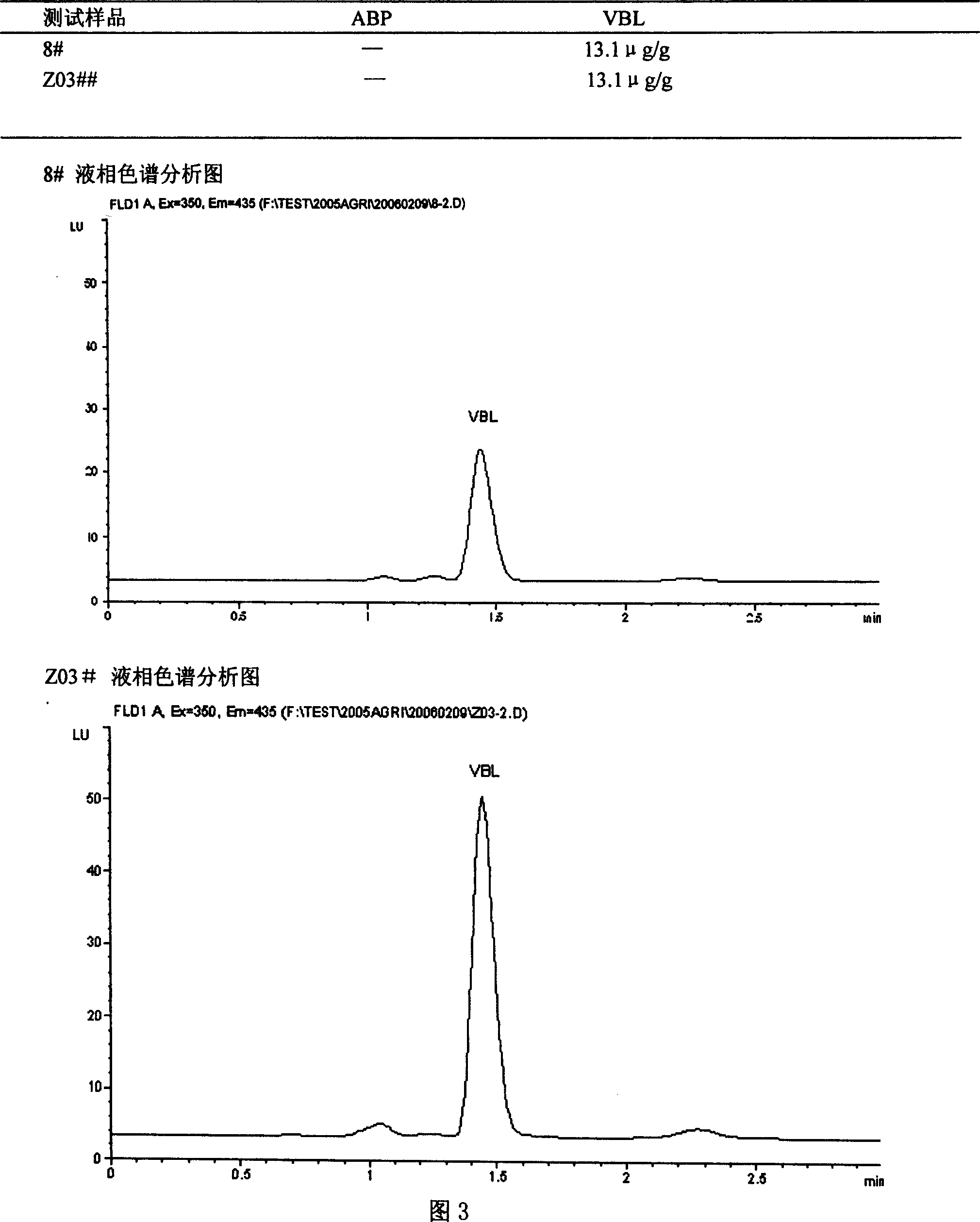

[0080] Column: Alltima C 18 Column, 150 mm x 4.6 mm, 5 μm.

[0081] Mobile phase: methanol / water: 45 / 55 (V / V), before HPLC analysis, filter through a 0.45 μm filter membrane and vacuum degassing.

[0082] Mobile phase flow rate: 1.0 mL / min.

[0083] Detection wavelength: excitation wavelength 350nm, emission wavelength 435nm.

[0084] Extraction solution: N,N-dimethylformamide.

[0085] Extraction time: 30min.

[0086] Extraction temperature: 40°C.

[0087] Use stainless steel scissors to cut the filter rod forming paper sample to 1mm×1mm, weigh 0.5g of the paper sample into a 50mL stoppered test tube, add 25.0mL of N,N-dimethylformamide, soak overnight, and make the paper sample fully Infiltration, ultrasonic vibration at 40°C for 30min. The oscillating liquid was filtered through a 0.45 μm filter membrane, and the filtrate was used for later use.

[0088] Use a microsampler or autosampler to measure 10 μL of the sample treatment solution and inject it into the high pe...

Embodiment 3

[0093] Column: Alltima C 18 Column, 150 mm x 4.6 mm, 5 μm.

[0094] Mobile phase: methanol / water: 45 / 55 (V / V), before HPLC analysis, filter through a 0.45 μm filter membrane and vacuum degassing.

[0095] Mobile phase flow rate: 1.0 mL / min.

[0096] Detection wavelength: excitation wavelength 350nm, emission wavelength 435nm.

[0097] Extraction solution: N,N-dimethylformamide.

[0098] Extraction time: 30min.

[0099] Extraction temperature: 40°C.

[0100] Use stainless steel scissors to cut the samples of cigarette paper and filter rod forming paper to 1mm×1mm respectively, weigh 0.5g of the paper sample into a 50mL stoppered test tube, add 25.0mL of N,N-di-methylformamide, soak overnight , to fully infiltrate the paper sample, and vibrate ultrasonically at 40°C for 30min. The oscillating liquid was filtered through a 0.45 μm filter membrane, and the filtrate was used for later use.

[0101] Use a microsampler or autosampler to measure 10 μL of the sample treatment so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com