A method for cloud point extraction of fluorescent whitening agent vbl in sewage

A fluorescent whitening agent and extraction technology, applied in the direction of extraction water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of residual intermediate products, incomplete treatment, complicated process, etc., and achieve Protect the environment, achieve resource recycling, and achieve high extraction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

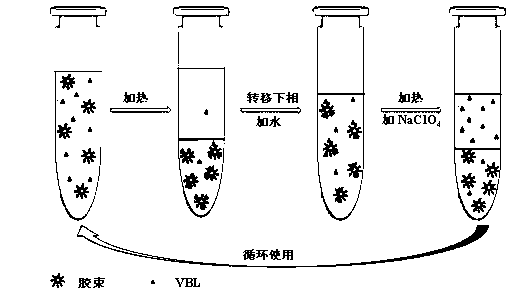

Method used

Image

Examples

Embodiment 1

[0027] (1) The aqueous solution of surfactant Triton X-114 and the wastewater containing fluorescent whitening agent VBL were mixed at a volume ratio of 1:3 to prepare a cloud point extraction system. In the extraction system, the final concentration of VBL was 7.5 mg / L, and the final concentration of Triton X-114 was 0.25%.

[0028] (2) The cloud point extraction system was oscillated and mixed, the pH of the system was adjusted to 6, and the phase separation was allowed to stand at 35 °C for 4 hours.

[0029] (3) After phase separation, the fluorescent whitening agent VBL is extracted to the lower phase, namely the surfactant phase. Dilute the lower phase with water to 1 / 3 of the total volume of the original cloud point extraction system, measure the absorbance of VBL in the diluted solution at 348 nm, and obtain an extraction rate of VBL of 81.53%; then add high chlorine to the diluted solution Sodium perchlorate was mixed evenly, so that the concentration of sodium perchl...

Embodiment 2

[0032] (1) Mix a certain concentration of surfactant Triton X-114 aqueous solution and wastewater containing fluorescent whitening agent VBL at a volume ratio of 1:3 to prepare a cloud point extraction system. In the extraction system, the final concentration of VBL was 25 mg / L, and the final concentration of Triton X-114 was 2.5%.

[0033] (2) The cloud point extraction system was oscillated and mixed, the pH of the system was adjusted to 8, and the phase separation was allowed to stand at 50 °C for 12 hours.

[0034] (3) After phase separation, the fluorescent whitening agent VBL is extracted to the lower phase, namely the surfactant phase. Dilute the lower phase with water to 1 / 3 of the total volume of the cloud point extraction system, measure the absorbance of VBL at 348 nm in the diluted solution, and obtain an extraction rate of VBL of 74.62%; then add perchloric acid to the diluted solution Sodium and mixed evenly, so that the concentration of sodium perchlorate in th...

Embodiment 3

[0037] (1) The aqueous solution of surfactant Triton X-114 and the wastewater containing fluorescent whitening agent VBL were mixed at a volume ratio of 1:3 to prepare a cloud point extraction system. In the extraction system, the final concentration of VBL was 17.5 mg / L, and the final concentration of Triton X-114 was 1%.

[0038] (2) The cloud point extraction system was oscillated and mixed, the pH of the system was adjusted to 7, and the phase separation was allowed to stand at 40 °C for 8 hours.

[0039] (3) After phase separation, the fluorescent whitening agent VBL is extracted to the lower phase, namely the surfactant phase. Dilute the lower phase with water to 1 / 3 of the total volume of the original cloud point extraction system, measure the absorbance of VBL at 348 nm in the diluted solution, and obtain the extraction rate of VBL as 92.26%; then add high chloride to the diluted solution Sodium perchlorate was mixed evenly, so that the concentration of sodium perchlora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com