High-low pressure combined method for extracting black liquor

A combined extraction, high and low pressure technology, applied in the regeneration of pulping liquid, textile and papermaking, fiber raw material treatment, etc., to achieve the effect of overcoming silicon interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

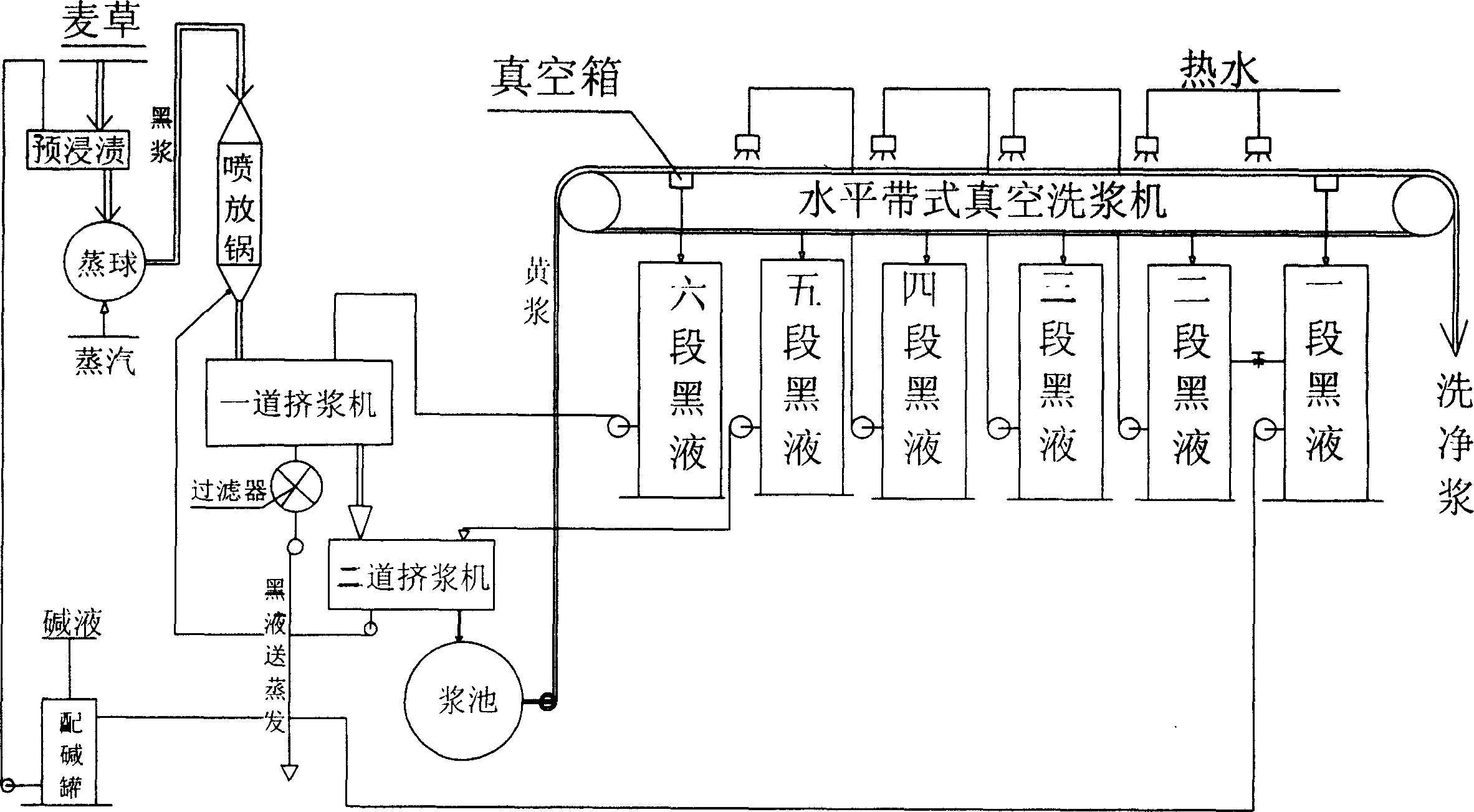

[0009] As shown in the figure, the hot water spraying on the horizontal vacuum pulp washer of the present invention is divided into six sections, and the black liquor produced by one section of hot water spray washing pulp enters the alkali distribution tank through the pipeline and mixes with the alkali liquor for cooking and alkali distribution , the mixed lye is mixed with wheat straw and pre-soaked, and then sent to the steaming ball and steamed together to form black pulp. The excess black liquor from alkali blending in the first stage can also be merged into the second stage for countercurrent washing, diffusion and thickening.

[0010] The second-stage black liquor produced by the second-stage hot water spray washing pulp enters the three-stage, four-stage, and five-stage hot water spray process through the pipeline and the nozzle in series, and is used for countercurrent washing, diffusion replacement, and step-by-step thickening of the entire stage. Generate five segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com